Lecture 3

Types of metals alloys

1

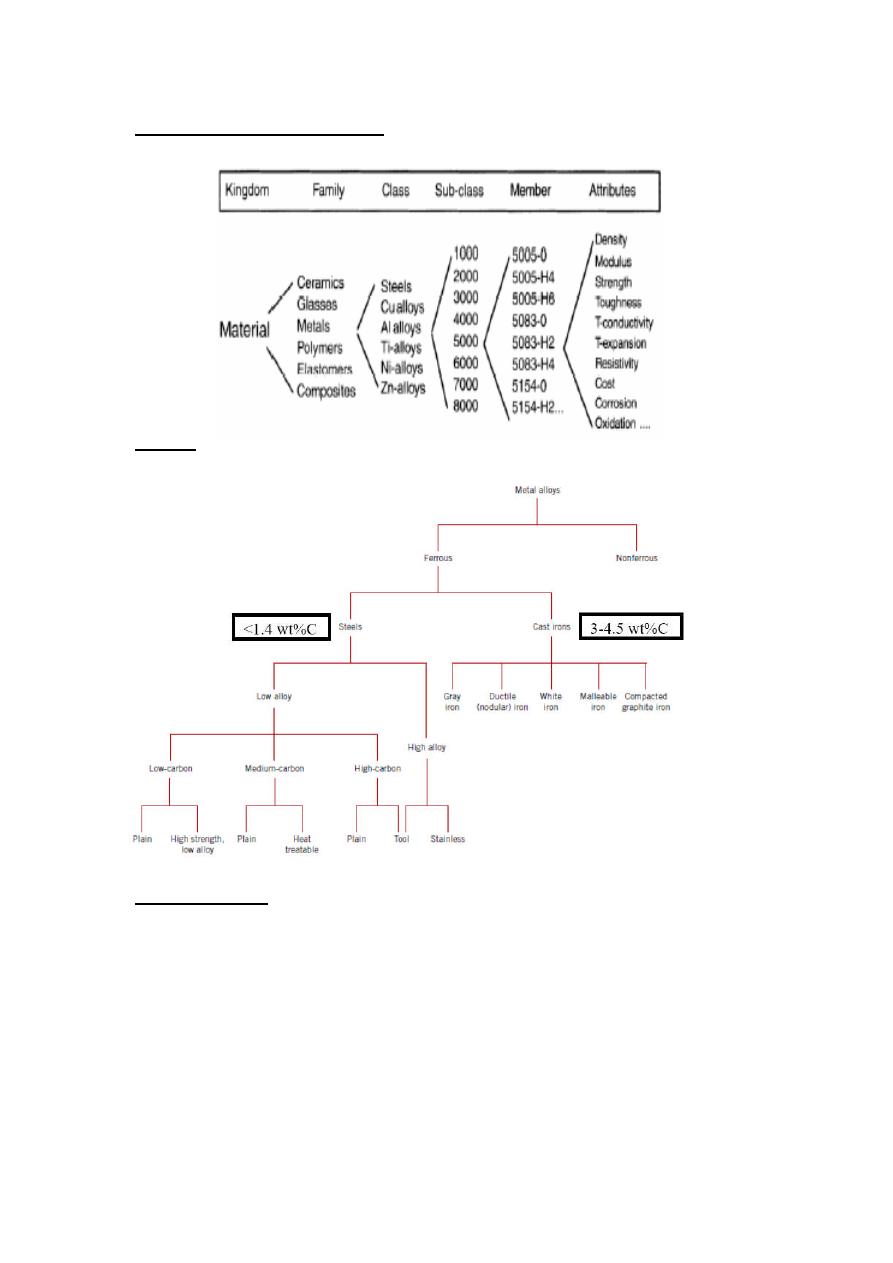

General Material Classifications

Metals

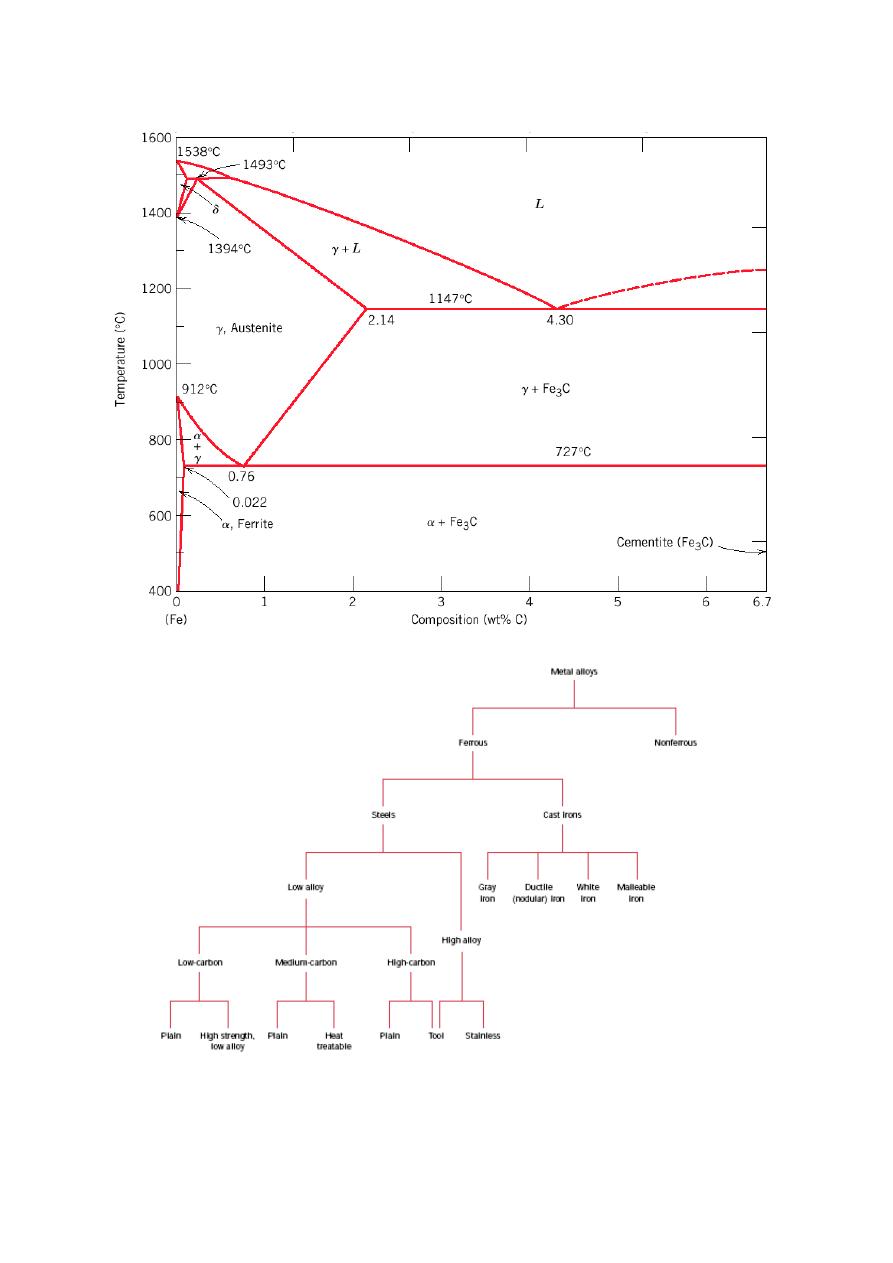

Ferrous Alloys

Those with iron as prime constituent (except for high alloy steel)

Important as engineering construction material (especially steel Fe-C) is

because:

They important – Abundant within the earth-crust – low cost

Easier to be produced

Good strength toughness and ductility

Versatile – wide range of mechanical and physical properties

Lecture 3

Types of metals alloys

2

.

Can be alloyed and heat treated to get desired mechanical properties

Alloying is combining or mixing other material like carbon or other

metals to iron

Heat treatment is a process of heating and cooling a metal to achieve

specific microstructure which in turns display specific mechanical

properties (e.g. Quenching austenite gives martensite witch be treated

to martensite which is can heat (tempered) produced tempered more

ductile

Nomenclature of Ferrous Alloys

Nomenclature AISI (American Iron and Steel Institute) & SAE (Society of

Automotive Engineers)

10xx Plain Carbon Steels

11xx Plain Carbon Steels (resulfurized for machinability)

15xx Mn (10 ~ 20%)

40xx Mo (0.20 ~ 0.30%)

43xx Ni (1.65 - 2.00%), Cr (0.4 - 0.90%), Mo (0.2 - 0.3%)

44xx Mo (0.5%)

where xx is wt% C x 100

example: 1060 steel – plain carbon steel with 0.60 wt% C

Stainless Steel -- >11% Cr – AISI number e.g. 409

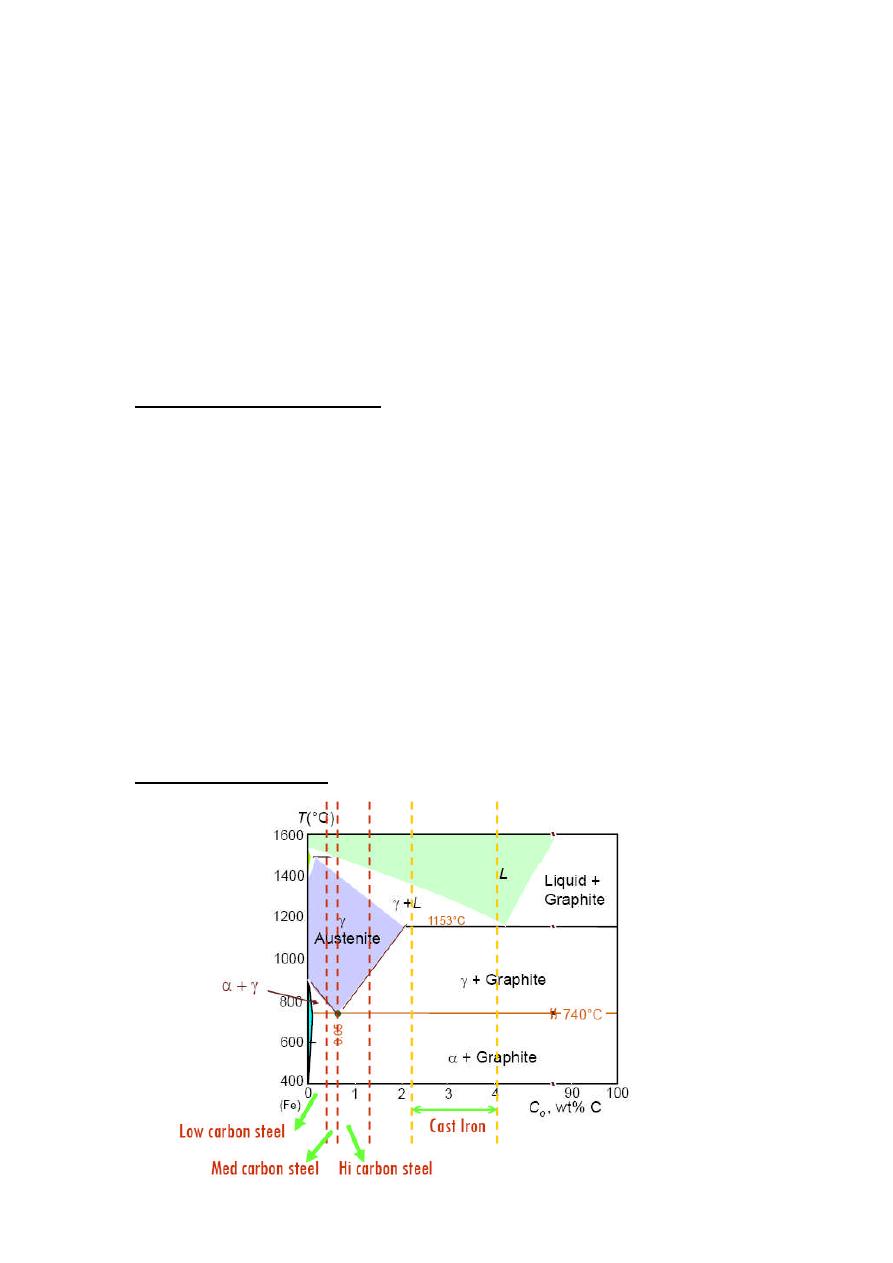

Iron-C phase Digram

Lecture 3

Types of metals alloys

3

Low Carbon steel

Alloys of low carbon steel being produced in the greatest quantity

<0.25wt %C

Consists of ferrites and pearlites and weak but can be treated to achieve high

strength

Machineable, weldable and cheaper to be produced

Types:

Plain low carbon steel

no alloying, variable tensile strength (TS) (415-550)MPa and Yield Strength

(YS) = 275MPa

Applications –– crankshafts, bolts, hammers, hand tools, gears, knives

High strength low allow (HSLA)

with alloying, higher TS and YS

Applications –– automobiles opines, nails, wire, pipe structural and sheet,

steel, railway cars

Medium Carbon Steel

0.25 –– 0.6 wt %C

Heat treated to achieve good mechanical properties

Used tampered condition (tampered martinsitic)

Strength - ductility combination can be tailored by heat treatment and alloying

(with Ni, Cr and Mo)

Applications: high strength structural components –– railway wheels, tracks,

crankshafts

High Carbon Steel

0.6 –– 1.4 %C wt

Hardest, strongest and least ductile carbon steel

Used in harden and tempered conditions

Can be alloyed with carbon and other metals to form vary hard and wear

resistance material (e.g C, Cr, Ni, W, Mo and V)

Applications: cutting tools, drills, embossing dies, saws, cutlery, paper cutters,

concrete drill, blacksmith tools.

Lecture 3

Types of metals alloys

4

Stainless--Steels

Highly resistance alloy to corrosion (rusting) in a variety of environment.

Mechanical integrity maintains

Consisting of iron-- carbon and > 11 wt% Cr. Ni, Mn may also be present

Example 0.08 C, 11.0 Cr, 1. Mn, 0.50 Ni, 0.75 Ti : S40900

Cast Irons

3.0-4.5 wt% C

Liquid at 1150-1300

o

C

Easily melted and amenable to casting

Gray Iron

graphite flakes

weak& brittle under tension

stronger under compression

excellent vibrational dampening

wear resistant

used e.g. as base structure for machines and heavy equipment

Ductile Iron

add Mg or Ce

graphite in nodules not flakes

matrix often pearlite- better ductility

Applications: valves, pump bodies, gears, crankshafts

White Iron

< 1wt% Si so harder but brittle

more cementite

Typical applications: connecting rods, transmission gears, pipe fittings,

flanges

Malleable Iron

- heat treat at 800-900

o

C

- graphite in rosettes

- more ductile

Lecture 3

Types of metals alloys

5

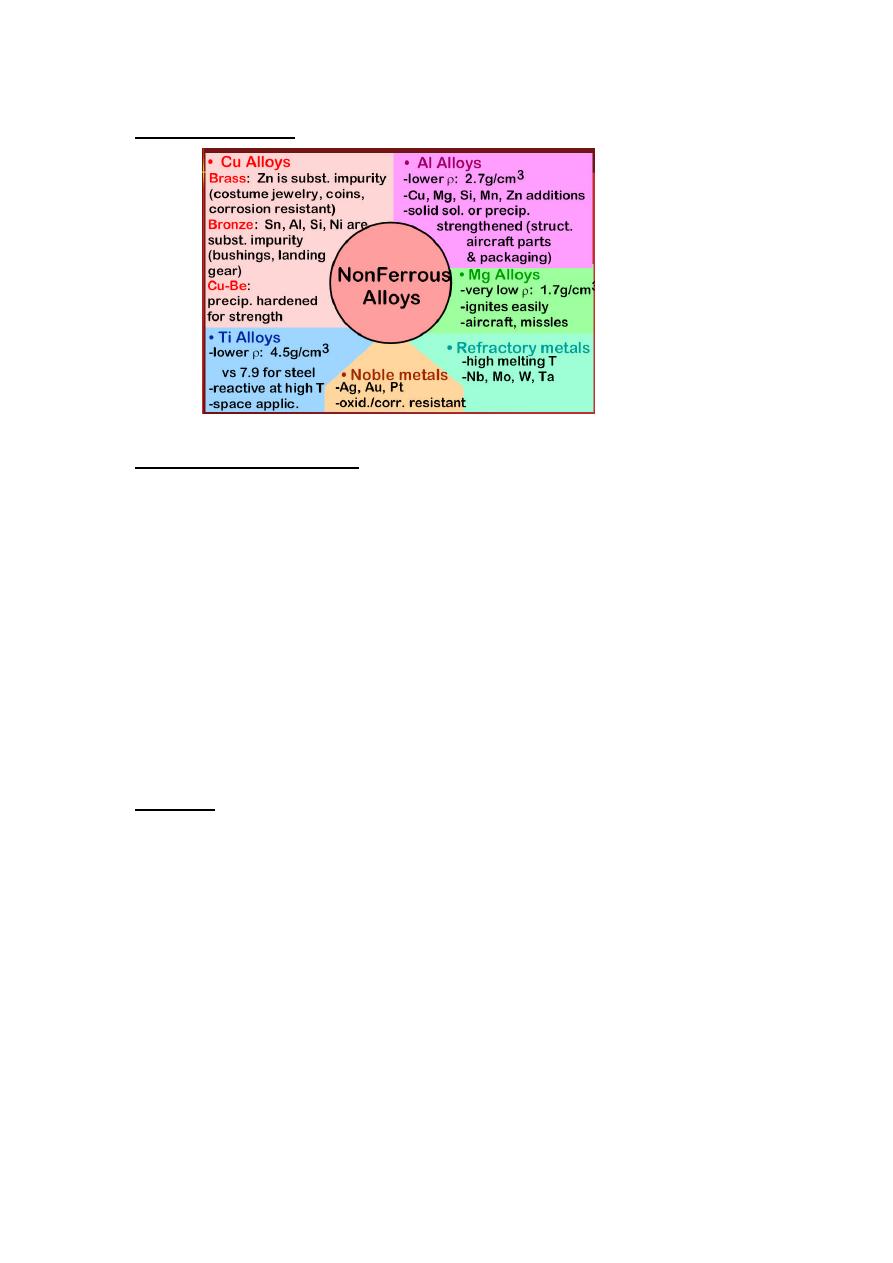

Nonferrous alloys

Aluminum and its Alloys

Pure aluminum is a silvery-white metal with many desirable characteristics. It is light,

nontoxic (as the metal), nonmagnetic and nonsparking. It is easily formed, machined,

and cast. Pure aluminum is soft and lacks strength, but alloys with small amounts of

copper, magnesium, silicon, manganese, and other elements have very useful

properties. Aluminum is an abundant element in the earth's crust, but it is not found

free in nature. The Bayer process is used to refine aluminum from bauxite, an

aluminum ore. Because of aluminum's mechanical and physical properties, it is an

extremely convenient and widely used metal. Aluminium alloys can be classified as;

cast or wrought alloys, examples are; Al--Li, Al-Cu-Si etc

Properties

Very lightweight (about 1/3 the mass of an equivalent volume of steel or

copper) but with alloying can become very strong.

excellent thermal conductor

excellent electrical conductor (on a weight-for-mass basis, aluminium will

conduct more than twice as much electricity as copper)

highly reflective to radiant energy in the electromagnetic spectrum

highly corrosion resistant in air and water (including sea water)

highly workable and can be formed into almost any structural shape

non-magnetic

non-toxic

Lecture 3

Types of metals alloys

6

Applications

door and window frames

high tension power lines, wires, cables, bus bars, components for television,

radios, refrigerators and air-conditioners

beverage cans, bottle tops

propellers, airplane and vehicle body sheet, gear boxes, motor parts

Al-Cu food/ chemicals handing and storage equipments.

Al-Cu-Mn-Zn- Cooking utensils.

Al-Zn-Mg-Cu-Cr

Aircraft structural parts

Copper and its Alloys

Properties

Good thermal and electrical conductivity

Ease of forming, ease of joining, and color.

However, copper and its alloys have relatively low strength-to-weight ratios

Low strengths at elevated temperatures.

Copper is resistant to corrosion in most atmospheres including marine and

industrial environments. It is corroded by oxidizing acids, halogens, sulphides

and ammonia based solutions

Copper and its alloys -- the brasses and bronzes -- are available in rod, plate,

strip, sheet, tube shapes, forgings, wire, and castings.

Applications

Pure Cu

Electrical and thermal conductors (cast Cu), transistor components,

coaxial cables rectifiers, lead in wires (cold--worked Cu)

Cu- Be- Co

moulds for plastic parts, bearings, valves, gears(cast Cu)

Cu--30Zn & Cu --40Zn (cold --work brass)

fasteners, locks, heal exchange

components, large nuts and bolts, plumbing accessories, pints and rivets.

Cu--4Si

bearing, belts, marine fittings

Lecture 3

Types of metals alloys

7

Magnesium and its Alloys

Properties

Low density metal (1.7g/cm

3

)

limited cold working

Relatively soft low elastic modulus

Easily oxidized

Magnesium is expensive compared to Al

Mg is difficult to cast and it burn in air (handling must be with care and cannot

be used temperature at high)

Mg- Al- Zn alloys –– improve strength

Applications

Mg--alloys replace engineering plastics that have similar densities

Handheld devices (chain saw, power told etc)

Automobiles (steering wheels, tyre ream, seat, frames)

Laptop computers, cam coders, TV etc

Titanium and its Alloys

Properties

Low density metal (4.5 g/cm cm

3

)

High melting point = 1668

o

C

elastic modulus = 107MPa

Chemical reactivity with other material at elevated temperatures

Corrosion resistance

Ti—alloys ,very high elastic modulus ~1400MPa, easily forged and machined,

high ductility

Applications

•

Pure Ti - Jet engine cases and airframe skins, corrosion--resistance equipment

for marine's applications chemical processing, industries.

•

Ti--5Al--2.55Sn – Gas turbine engine casing

•

Ti--6Al-4V – High strength prosthetic implants, orthopedics, airframe

structured components

Lecture 3

Types of metals alloys

8

Nickel and nickel alloys

•

Nickel (Ni) has strength, toughness, and corrosion resistance to metals.

•

Used in stainless steels and nickel-base alloys.

•

Alloys are used for high temperature applications, such as jet-engine

components and rockets.

Superalloys

•

Superalloys are high-temperature alloys use in jet engines, gas turbines and

reciprocating engines.

Refractory metals

•

Refractory metals have a high melting point and retain their strength at

elevated temperatures.

•

Applications are electronics, nuclear power and chemical industries.

•

Molybdenum, columbium, tungsten, and tantalum are referred to as refractory

metal

Other nonferrous metals

1. Beryllium

2. Zirconium

3. Low-melting-point metals:

- Lead

- Zinc

- Tin

4. Precious metals:

- Gold

- Silver

- Platinum

Lecture 3

Types of metals alloys

9