Industrial Engineering (IE)

Dr. Khallel Ibrahim Mahmoud

University of Technology

Electro-mechanical Engineering Dept.

Introduction

Production and

Productivity

Break Even Analysis(B.E)

Lec.N

o(1)

2011

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

Introduction:

1.1 Concept of Industrial Engineering (IE)

Industrial Engineering is concerned with the design,

Improvement, and installation of integrated system of men,

material, and machines for the benefit of mankind .It draws

upon specialized knowledge and skills in the mathematical

and physical sciences together with the principles and

methods of engineering analysis and design to specify,

predict and evaluate the results to be obtained from such

systems.

1.2 IE Objectives

The basic objectives of Industrial Engineering are:

1- Improving operating methods and controlling costs.

2- Reducing these costs through cost reduction programs.

The aim of IE department is to provide specialized services

to production departments, such as methods improvement,

time study, Job evaluation and merit rating and to head new

projects if required.

1.3 IE Activities

Basic activities of industrial engineering as stated to

American Institute of industrial engineering as follows:

1- Processes (and methods) selection.

2- Selection and design of tools and equipment.

2

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

3- Facilitates planning, plant location, materials handling and

storage facilities.

4- System design for planning and control of production

inventory, quality, and plant maintenance and distribution.

5- Cost analysis and control.

6- Develop time standards and performance standards.

7- Value engineering and analysis system design and install.

8- Mathematical tools and statistical analysis technia.

9- Performance evaluation.

10- Project feasibility studies.

1.4 IE Approach

Industrial engineering department uses scientific

approaching identifying and solving the problems .It collects

factual information regarding the problem analysis the

problem, prepares alternative solutions taken into account all

the internal and external constraints, selects the best

solution for implementation.

This stage is called problem identification .It consists of the

following steps:

1) Collect all details about the job, using standard recording

techniques like charts, diagrams, models and templates.

2) Recorded facts are subjected to critical examination using

a series of questions.

3) Find alternative solutions for the problem.

3

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

4) Evaluate the alternatives and find the best solution.

Next the industrial engineering department makes

recommendation for the implementation of the best

alternatives so that the

1.5 Techniques of Industrial Engineering

The main aim of tools and techniques of industrial

engineering is to improve the productivity of the organization

by optimum utilization of organizations resources: men,

materials, and machines. The major tools and techniques

used in industrial engineering are:

1) Production planning and control.

2) Inventory control.

3) Job evaluation.

4) Facilitates planning and material handling.

5) System analysis.

6) Linear programming.

7) Simulation.

8) Network analysis (PERT, CPM).

9) Queuing models.

10) Assignment.

11) Sequencing and transportation models.

12) Games theory and dynamic programming.

13) Group technology.

4

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

14) Statistical techniques.

15) Quality control.

16)

17) Decision making theory.

18) Replacement models.

19) Assembly line balancing.

20) MRP-JIT-ISO-TQM.etc.

1.6 The six standards phases of IE:-

1- Formulating the problem.

2- Constructing a mathematical model to represent the

system under study.

3- Deriving a solution from the model.

4- Testing the model and the solution derived from it.

5- Establishing controls over the solution.

6- Putting the solution to work: Implementation.

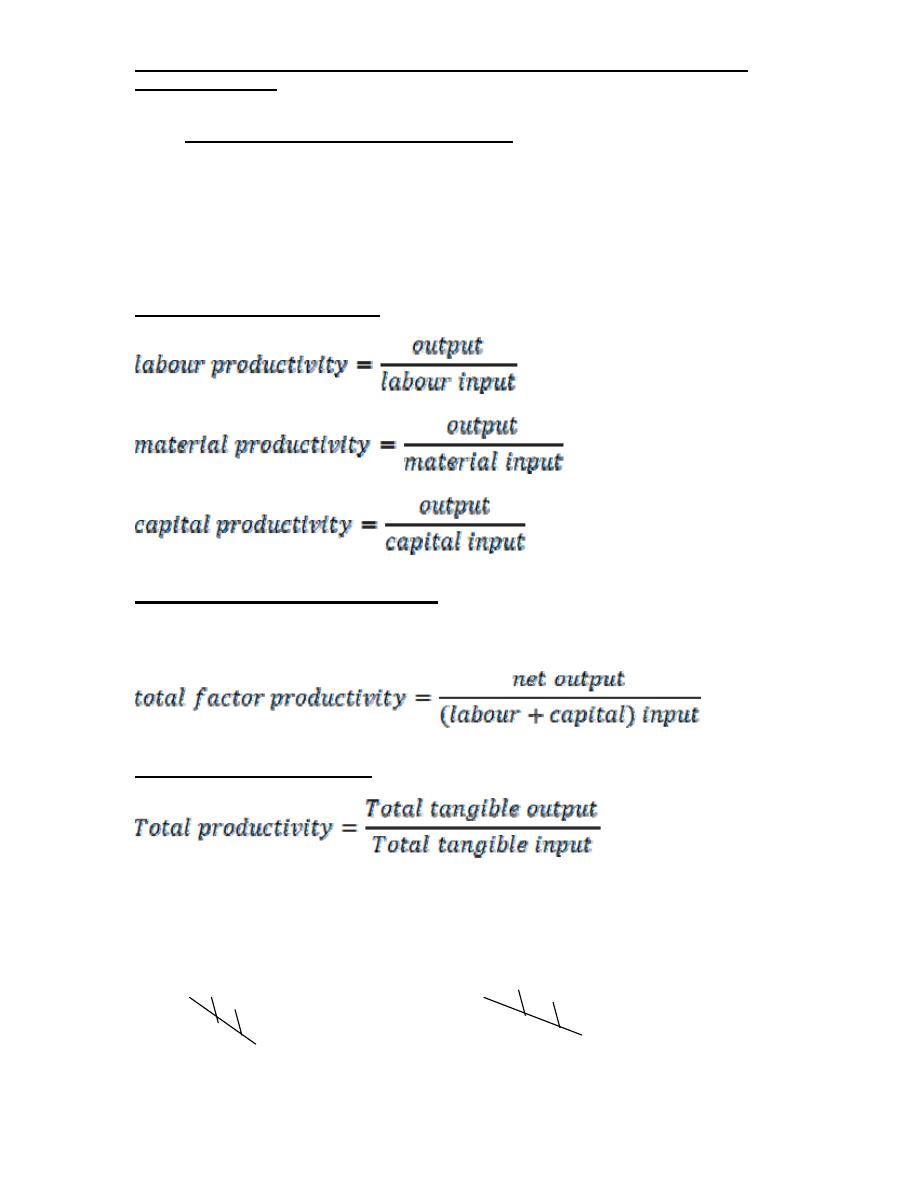

2- Productivity

The standard of living of industrialized nations depends upon

the economic efficiency of all its industrial enterprise great or

small.

2.1 Introduction/Definition of productivity

5

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

Productivity can be defined as the ratio of output in a period

of time to the input in the same period time. Productivity can

thus be measured as:

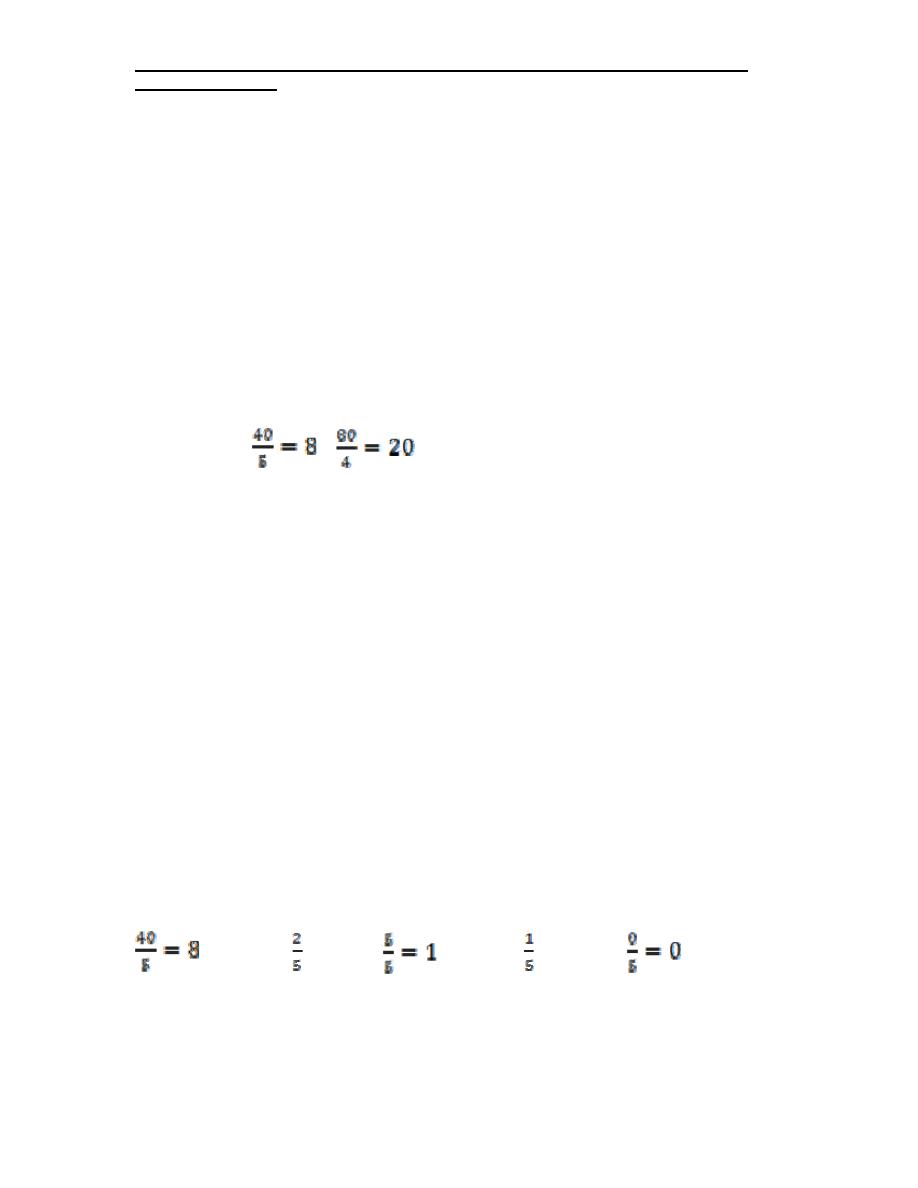

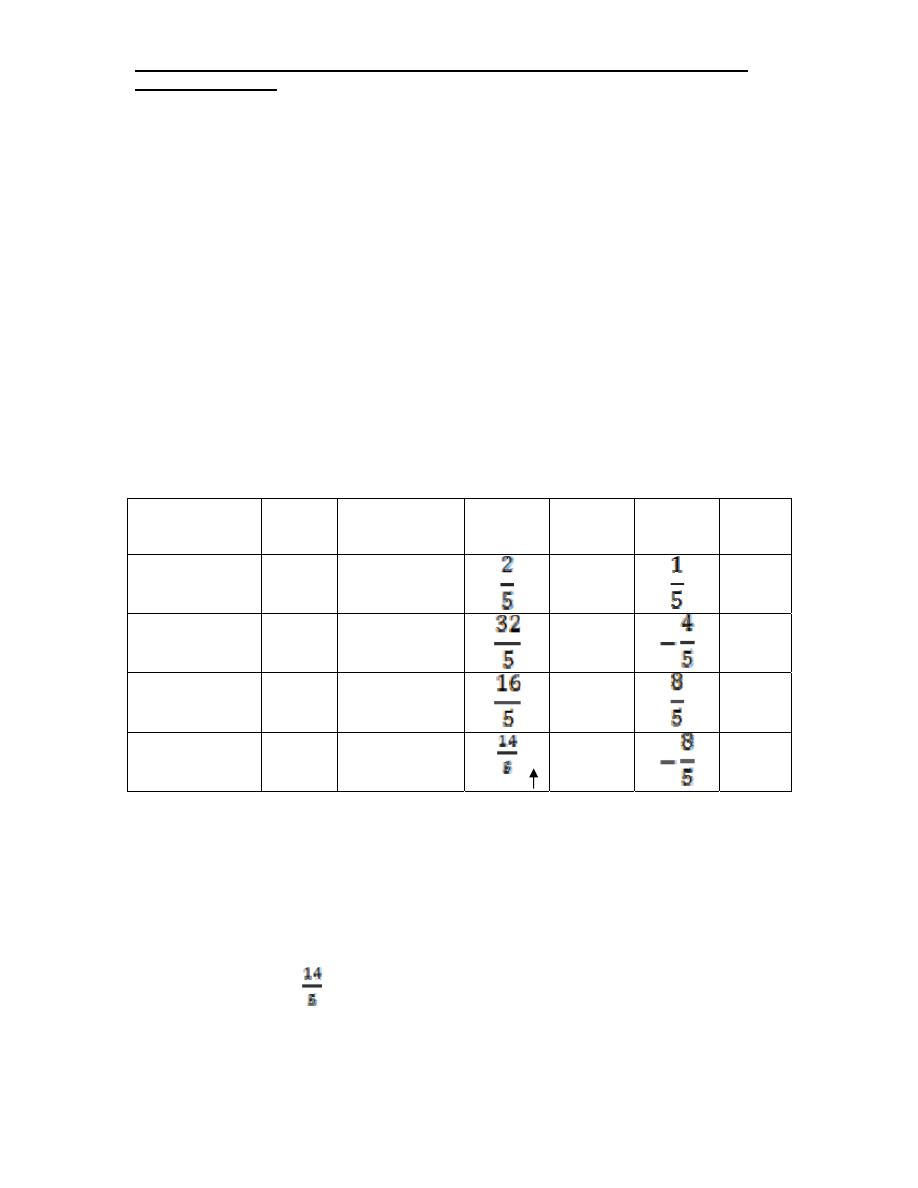

Productivity =

In simple terms productivity is the quantitative relationship

between what we produce (output) and the resources

(inputs) which we used.

2.2 Productivity and production:

Production is the process of converting the raw materials

into finished products by performing a set of manufacturing

operations in a predetermined sequence. Production refers

to absolute output. Thus, if the input increases the output will

normally increase in the same proportion. The productivity

remains unchanged if however the output increases with the

input of the resources, the productivity increases production

means the output in terms of money without any regard to

the input of resources , which productivity is a human

attitude to produce more and more with less input of

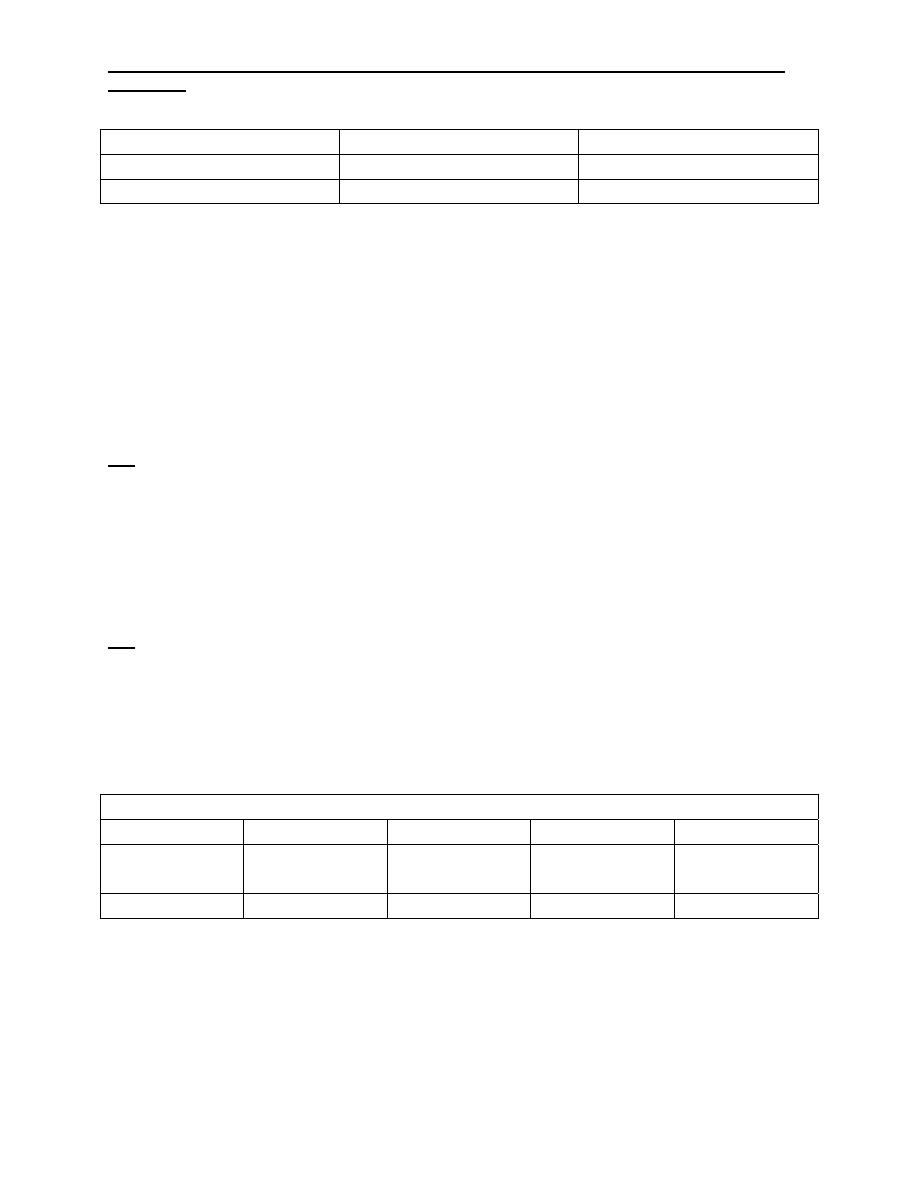

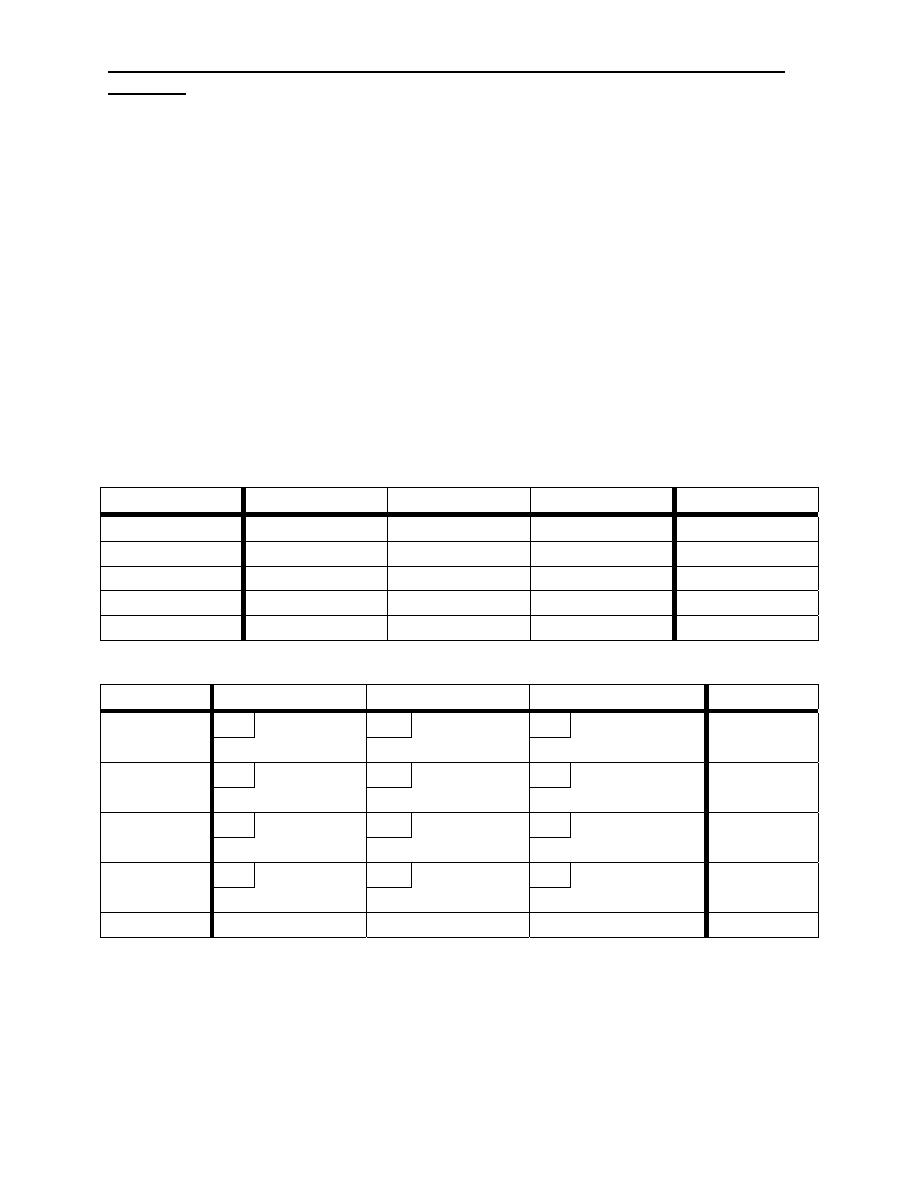

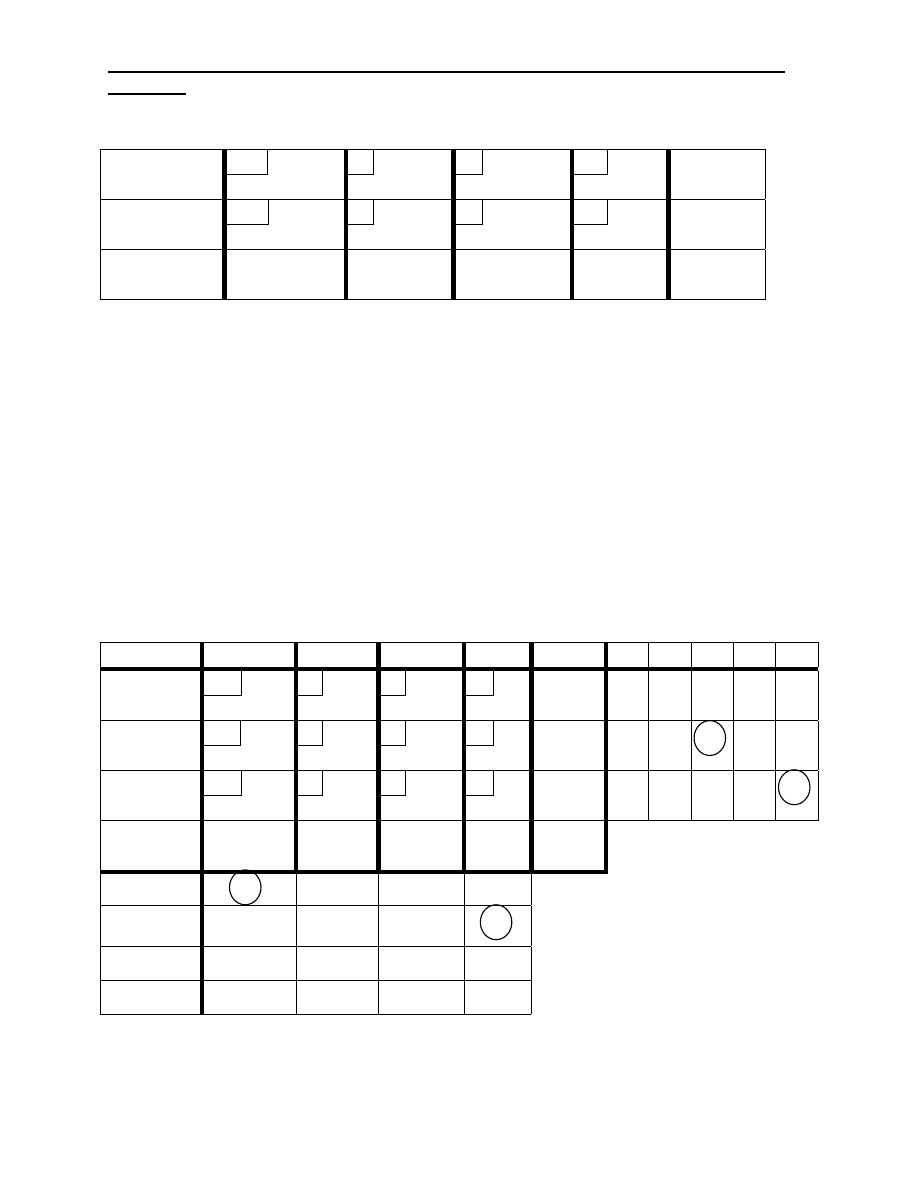

resources. There are six cases to increase the productivity

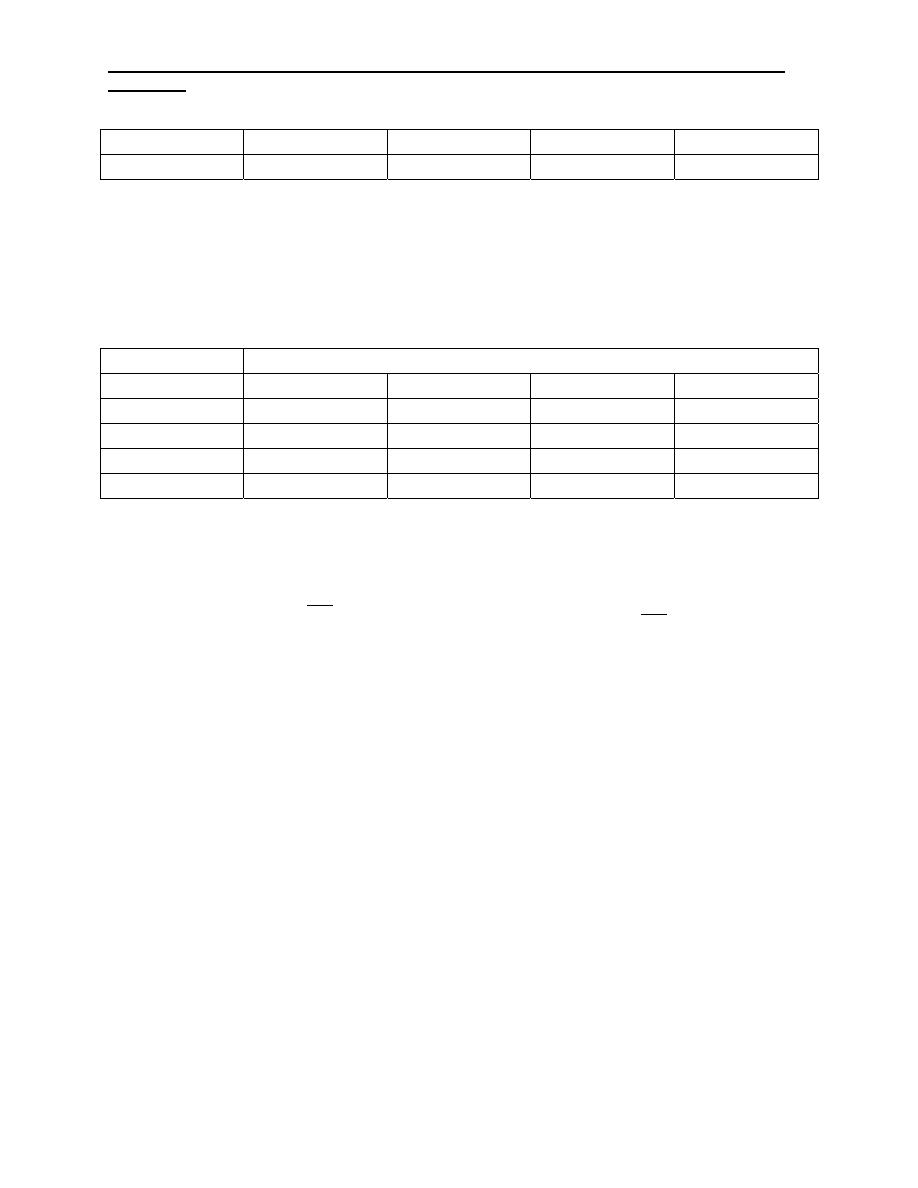

as shown

output +

+

c ++% -%

input - c - +% --%

2.3 Types of production systems:

6

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

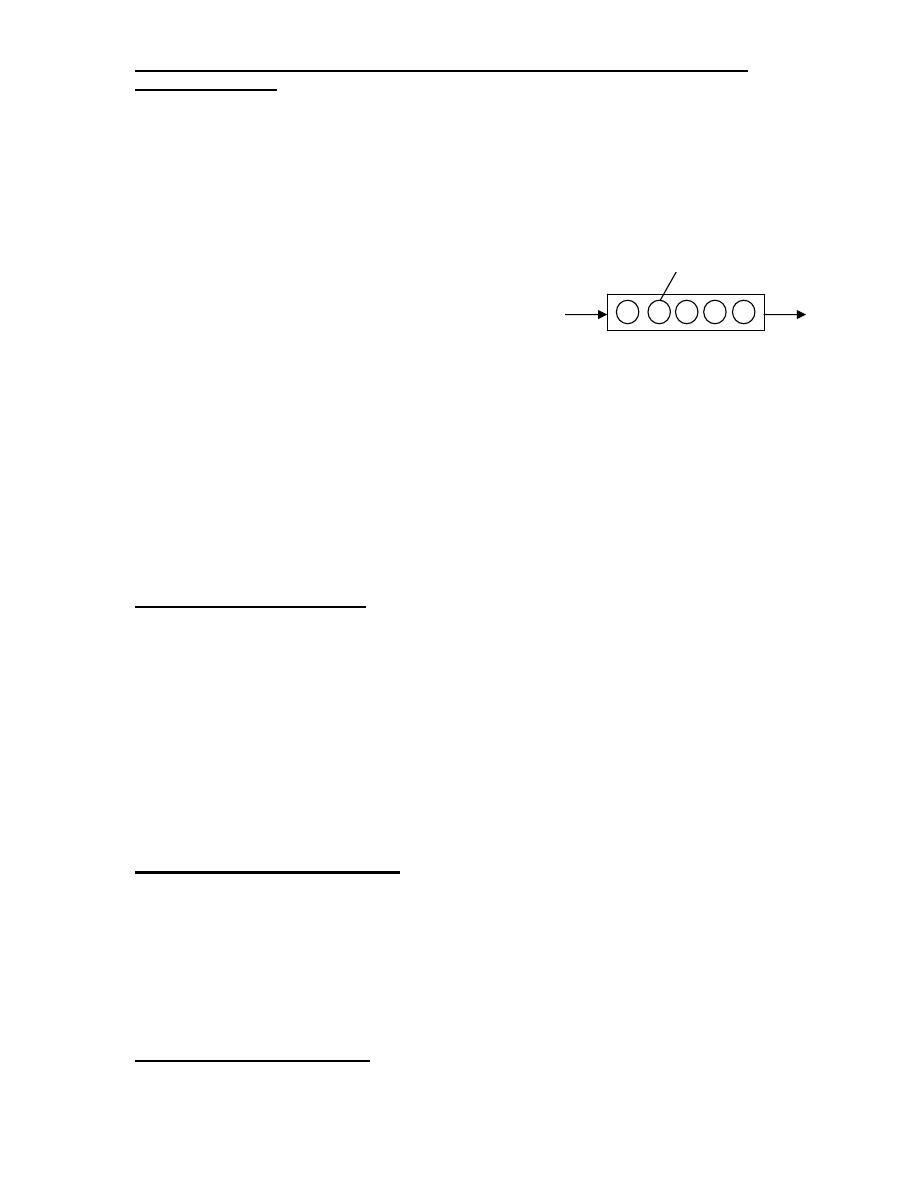

A production system consists of plant facilitates, equipment

and operating methods arranged in a systematic order. This

arrangement depends upon the type of product and the

strategy that a company employs to serve its customers.

There are two major types of production systems:

i) Make to stock production.

ii) Make to order production.

In make to stock production the products are manufactured

kept as ready stock and supplies to customers as orders are

operatio

input

output

system

Examples of such items are nuts, bolts, bearings, screws,

etc.

In make to order production the products are made only

Types of production

The production or manufacturing systems are classified as

follows:

a) Job type production.

b) Batch production.

c) Continuous or mass production.

a) Job type production.

It is characterized by high variety, low volume production,

producing one or a few products specially designed and

produced according to customer specifications like aircraft,

ships, special train.

b) Batch production.

7

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

Here the product similar in design but different in size and

capacities are produced in batches of one size and capacity

at one time, at regular interval and stocked at warehouses a

waiting sales. Examples as pumps, motor etc, of different

capacities and types manufactured in batches.

c) Mass (Repetitive) production.

This production is characterized by high volume low variety

in this system several standard products are produced in

large quantity and stocked in warehouse awaiting dispatch

examples of such production, nuts bearings, t-shirts, etc.

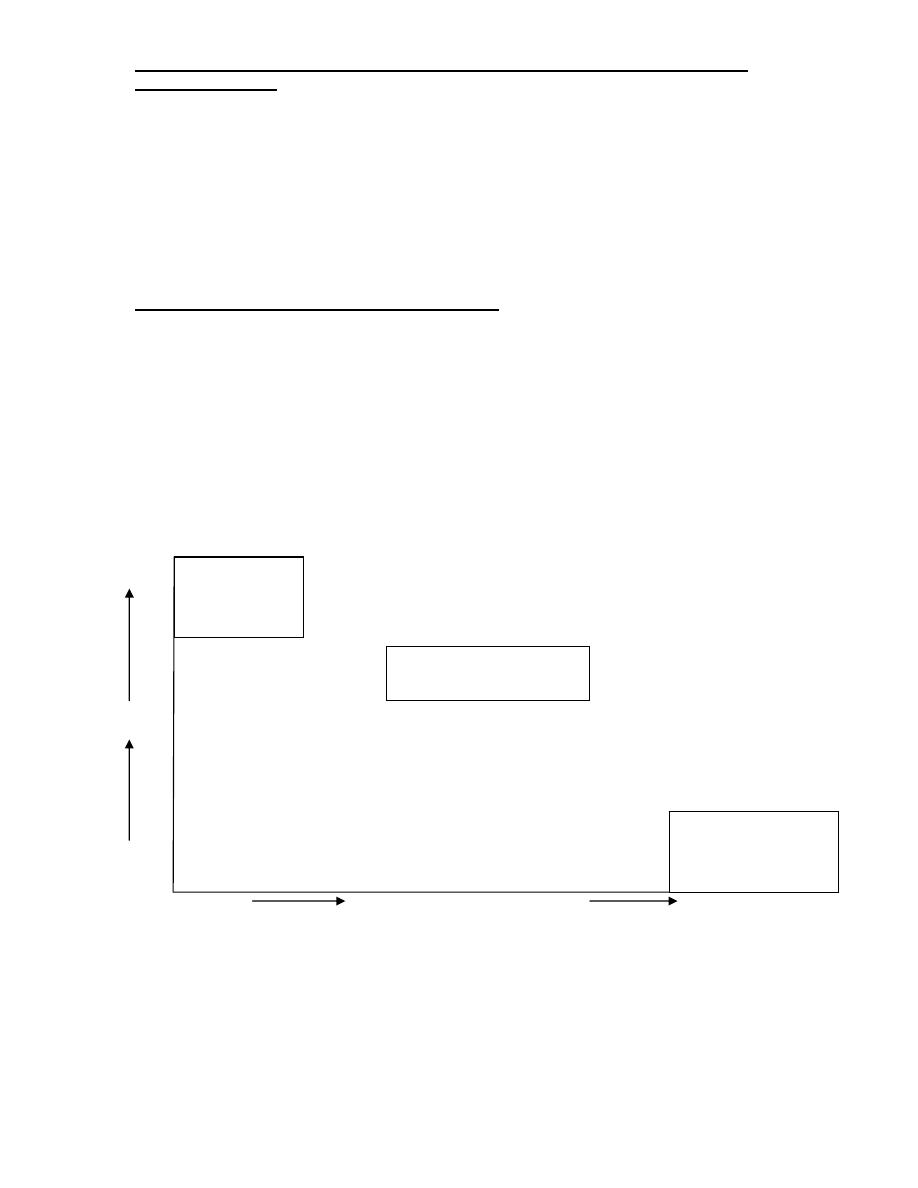

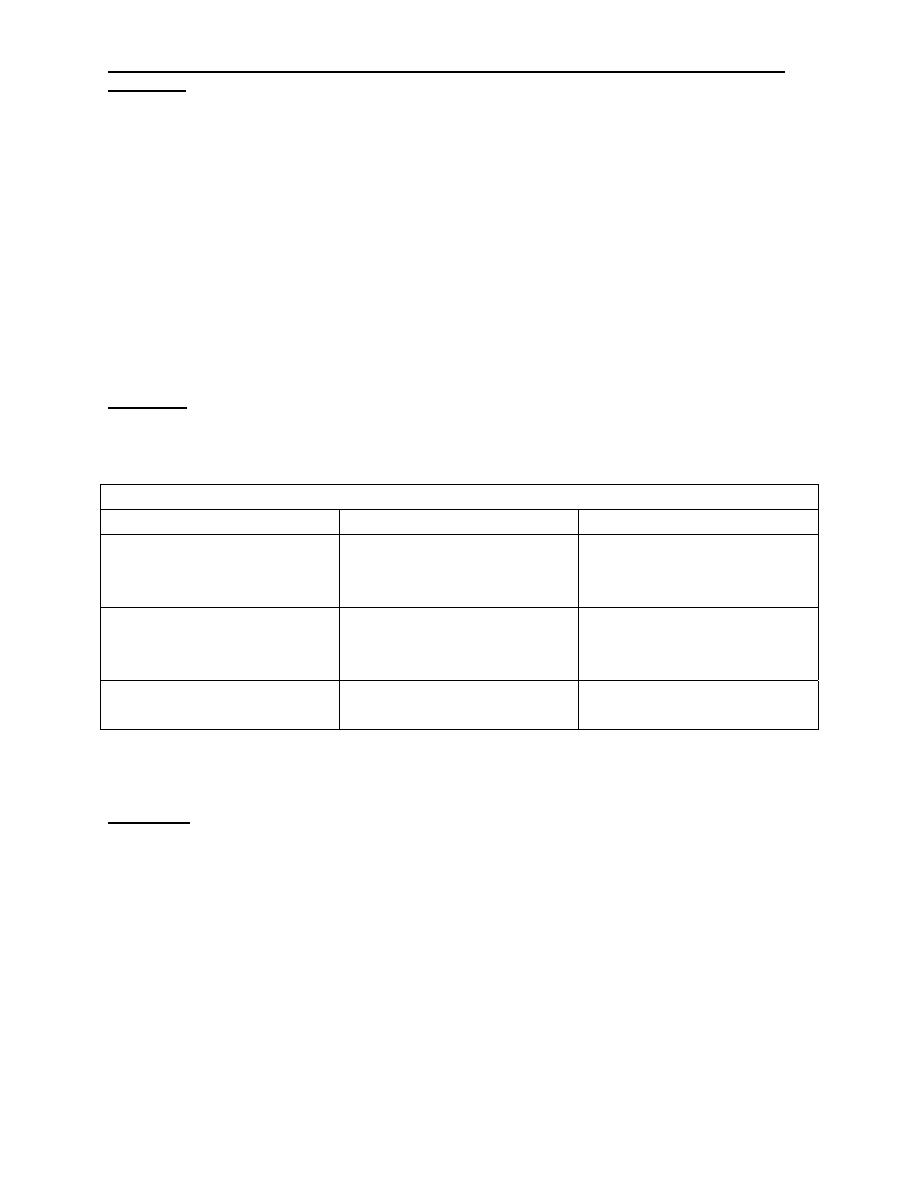

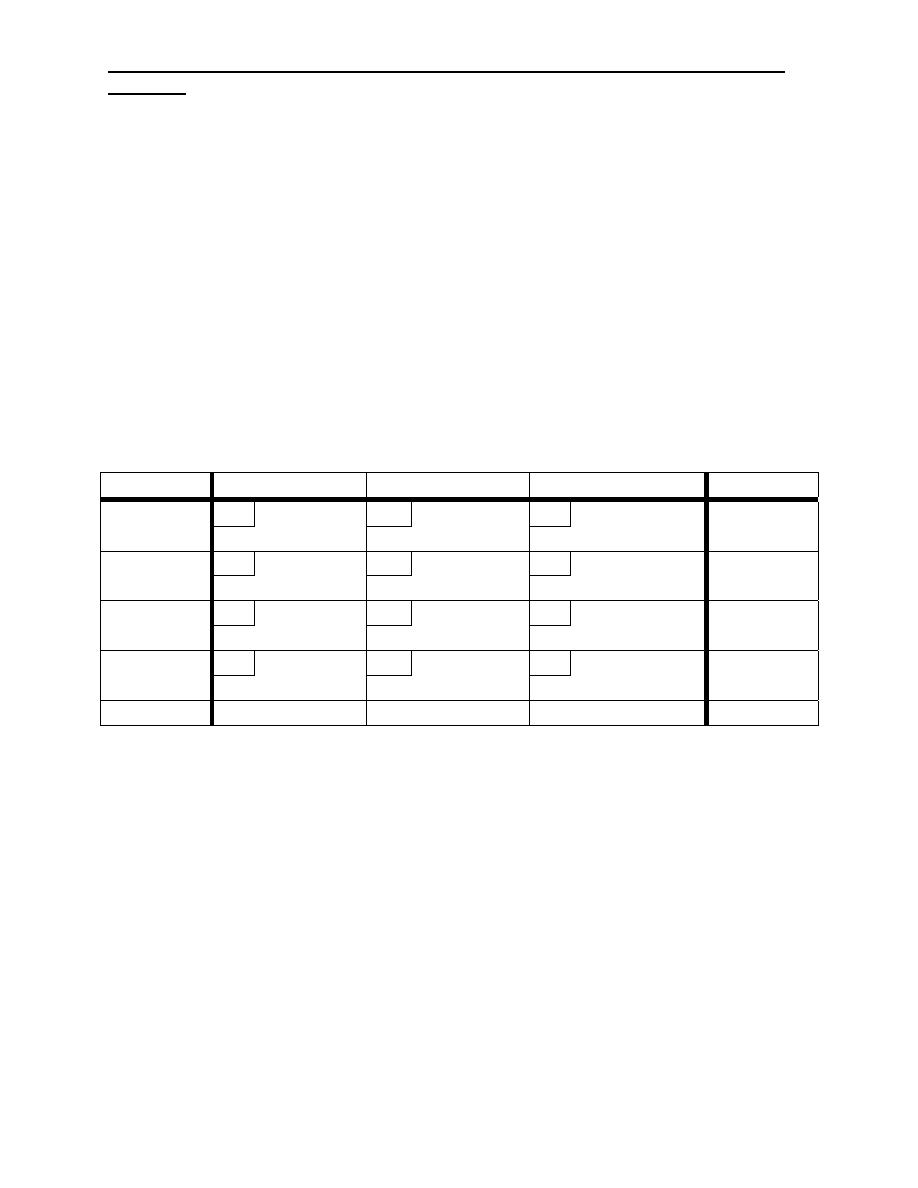

The following fig. shows volume variety relation for different

types of manufacturing systems.

Low Production volume

High

Job type

Batch production

Mass

Production

High

Variet

y

Low

After this brief introduction to types of production system and

productivity let us discuss how the productivity measured

and improved.

8

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

2.4

Measurement of productivity

Productivity measures:

There are three major types of productivity measures as

listed below:

1- Partial productivity

2- Total factor productivity

It is the ratio of net output to the sum of associate …..

3- Total productivity:

Tangible means measurable for total tangible input =value of

human, material, capital, energy and other inputs used.

Man power material

9

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

P

Machines

5- Factors affecting productivity:

1. Raw material, its nature and quality.

2. Utilization of manpower.

3. Utilization of plant, equipment and machinery.

4. Basic nature of manufacturing processes employed.

5. Efficiency of plant.

6. Volume, capacity, and uniformity of production.

6- The ways in which the productivity can be increased

summarized as under:

1) Increase manpower effectiveness at all levels.

2) Method improvement.

3) Improve basic production processes by research and

development.

4) Use better production equipment.

5) Improve / simplify product design and reduce variety.

6) Better production planning and control

.

2.1

Productivity Improvement Techniques

10

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

1) Technology based

a. CAD/CAM/CIMS

b. Robotics.

c. Laser technology.

d. Modern maintenance technology.

e. Energy technology.

f. Flexible manufacturing system (FMS).

2) Employee based

a. Incentives

b. Promotion

c. Job design

d. Quality circle

3) Material based

a. Material planning and control

b. waste elimination

c. Recycling and reuse of waste materials

d. Purchasing Logistics

4) Process based

a. Method engineering and work simplification

b. Process design

11

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

c. Human factors engineering

5) Product based

a. Reliability engineering

b. Product mix and promotion

c. Value analysis/value engineering.

6) Management based

a. Management technique

b. Communication

c. Work culture

d. Motivecation

e. Promoting group activity

Questions:

1. Write short notes on:

a) Techniques of Industrial engineering (Ans. 1.5)

b) Productivity measurement models (Ans. 2.4)

2. Define the term productivity. How is it different from

production? Give examples using your own numb (Ans.

2.1, 2.2)

3. There are six cases to increase the production. Explain in

brief. (Ans. 2.2)

12

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

4. Summarize the ways in which the productivity can be

increased. (Ans. 2.6)

5. Discuss the factors that affect productivity. (Ans. 2.5)

6. Write short notes on productivity improvement techniques.

(Ans. 2.7)

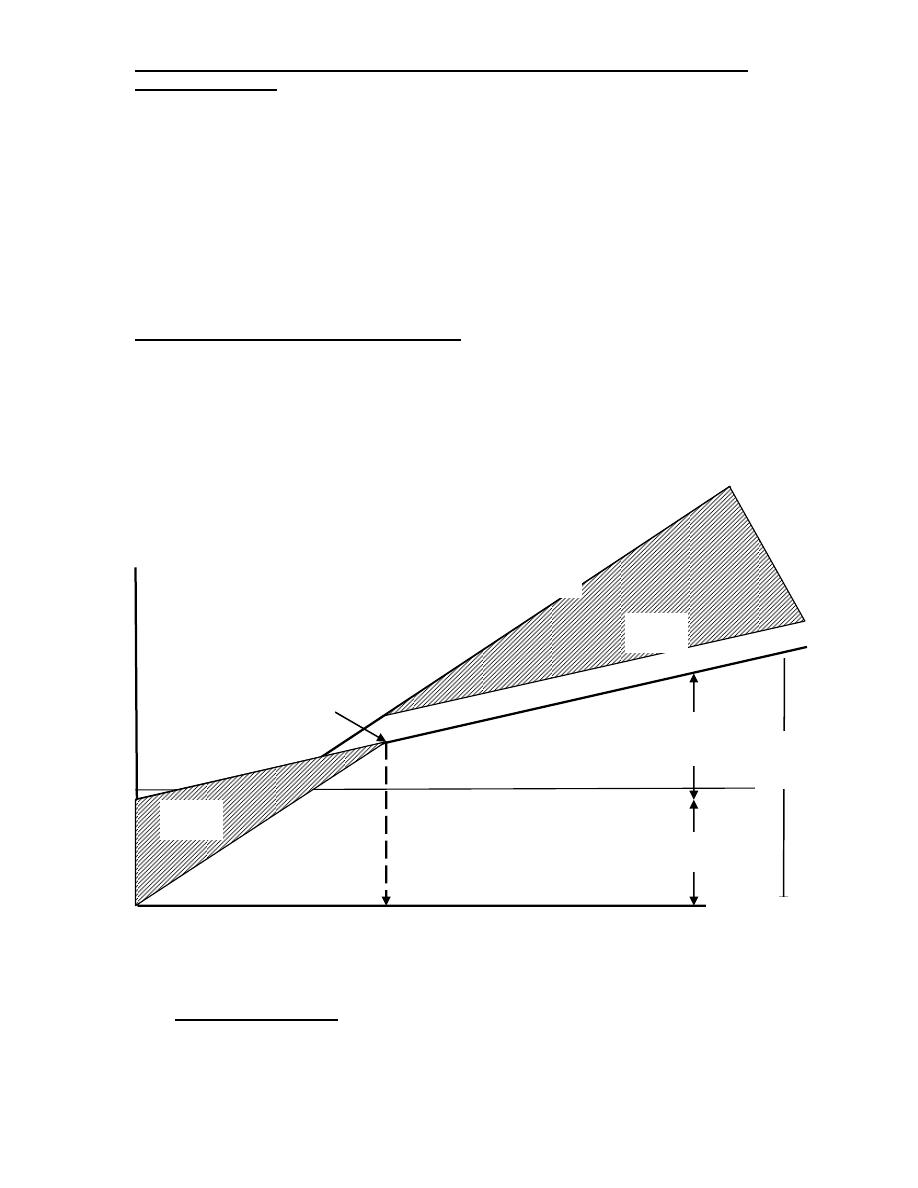

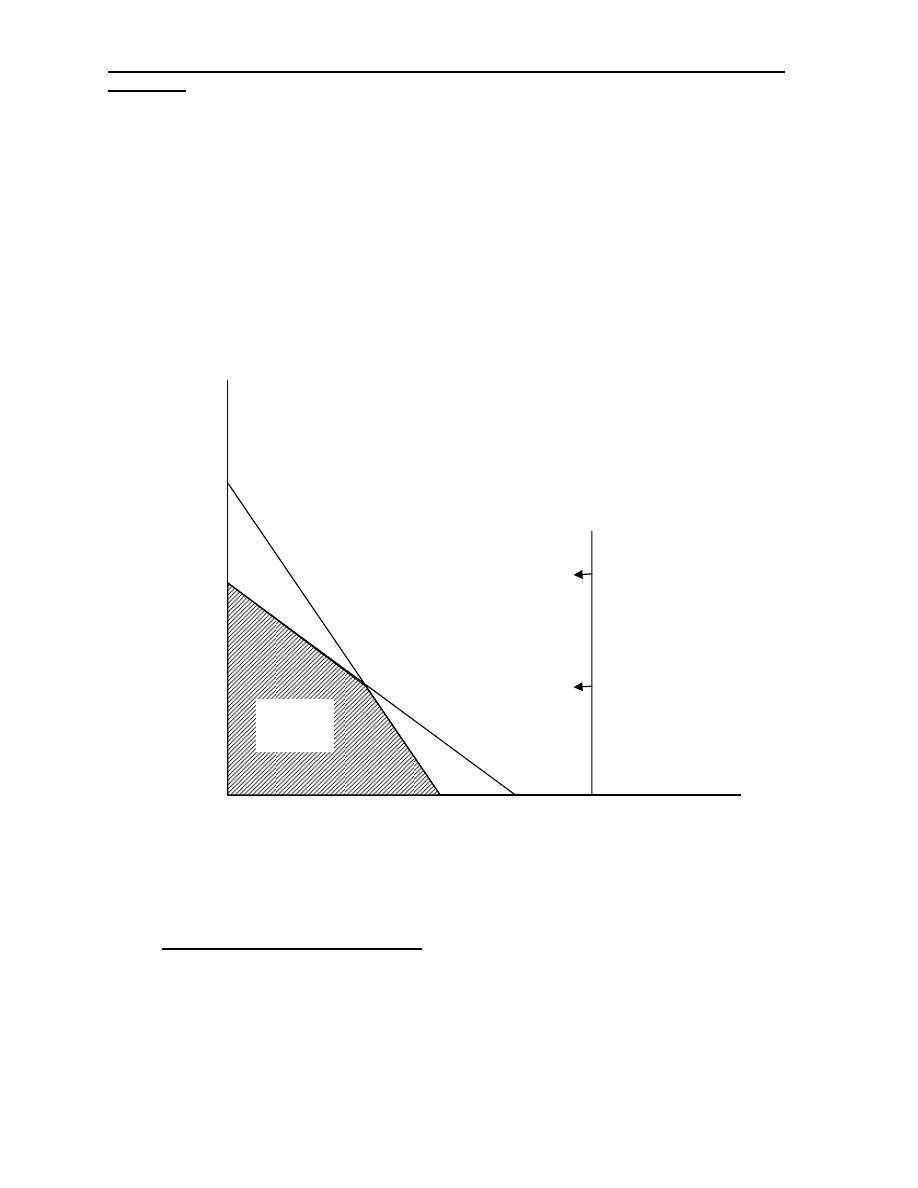

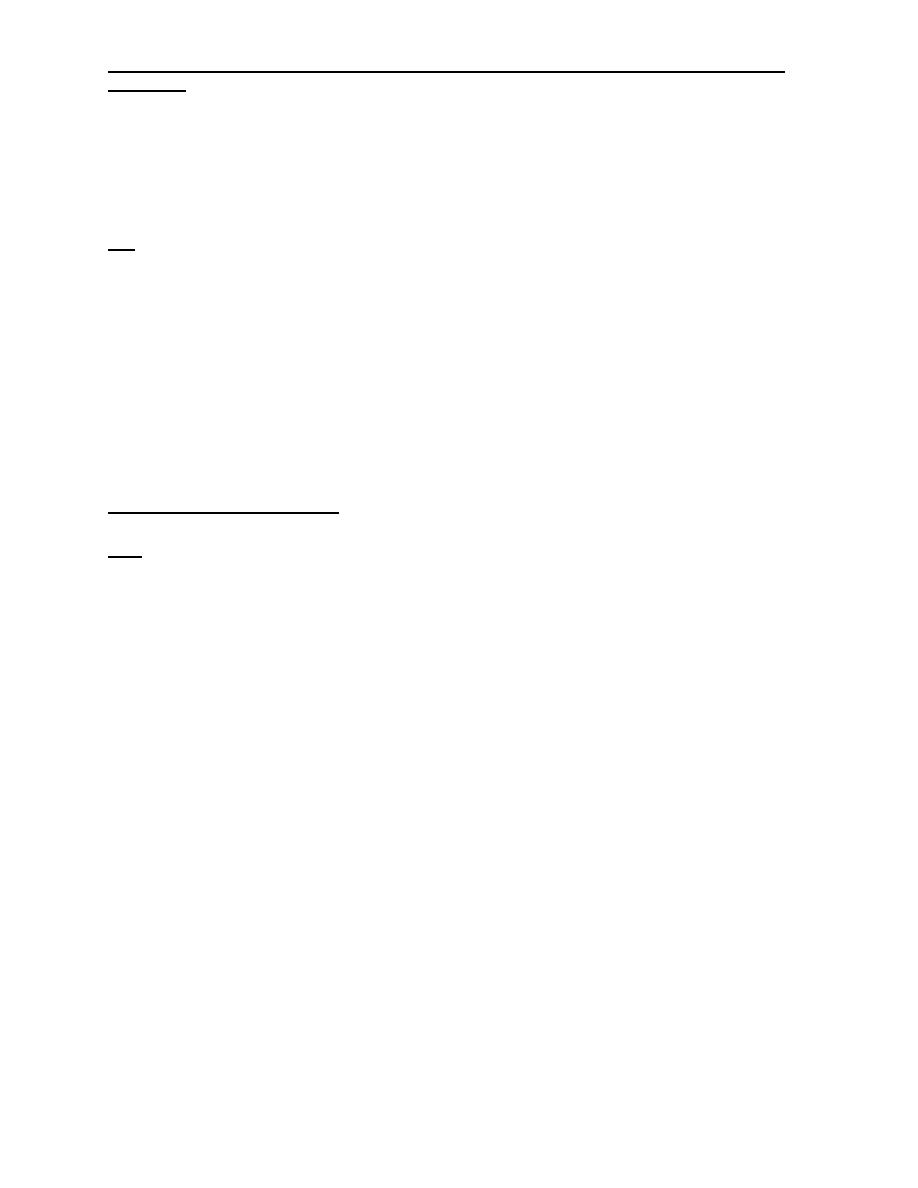

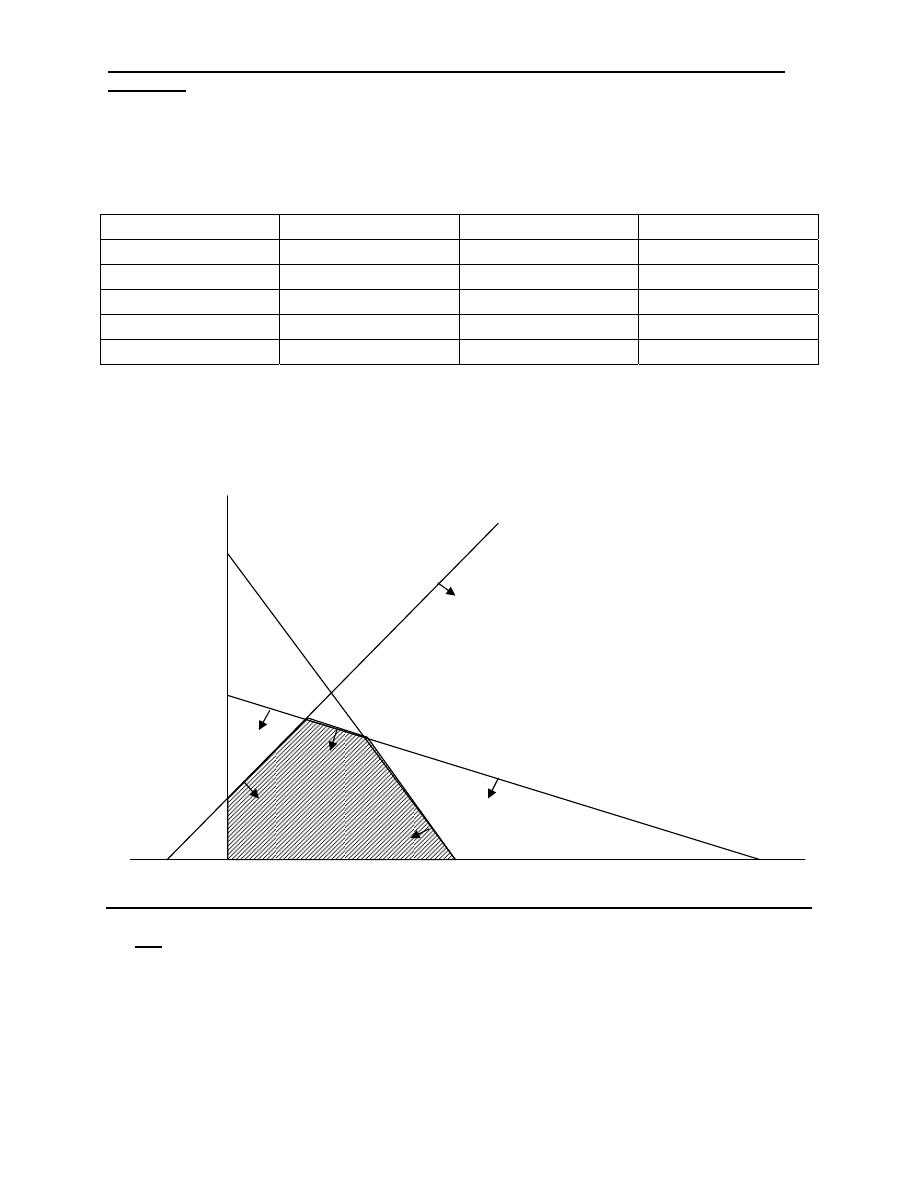

3- Break-Even analysis (B-E)

Break even production …….

At which the production cost equals income from sales. By

this value the company sets profit and below this value

suffers a loss.

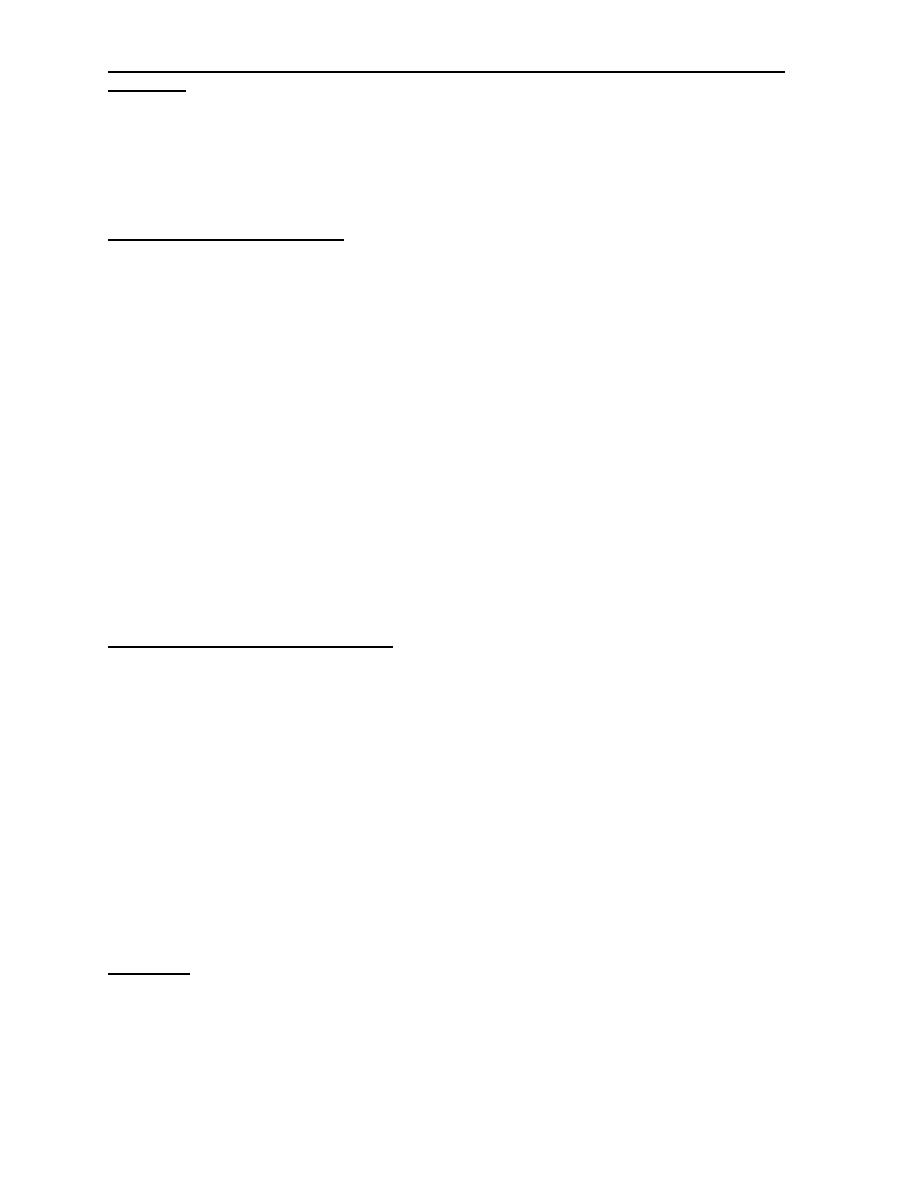

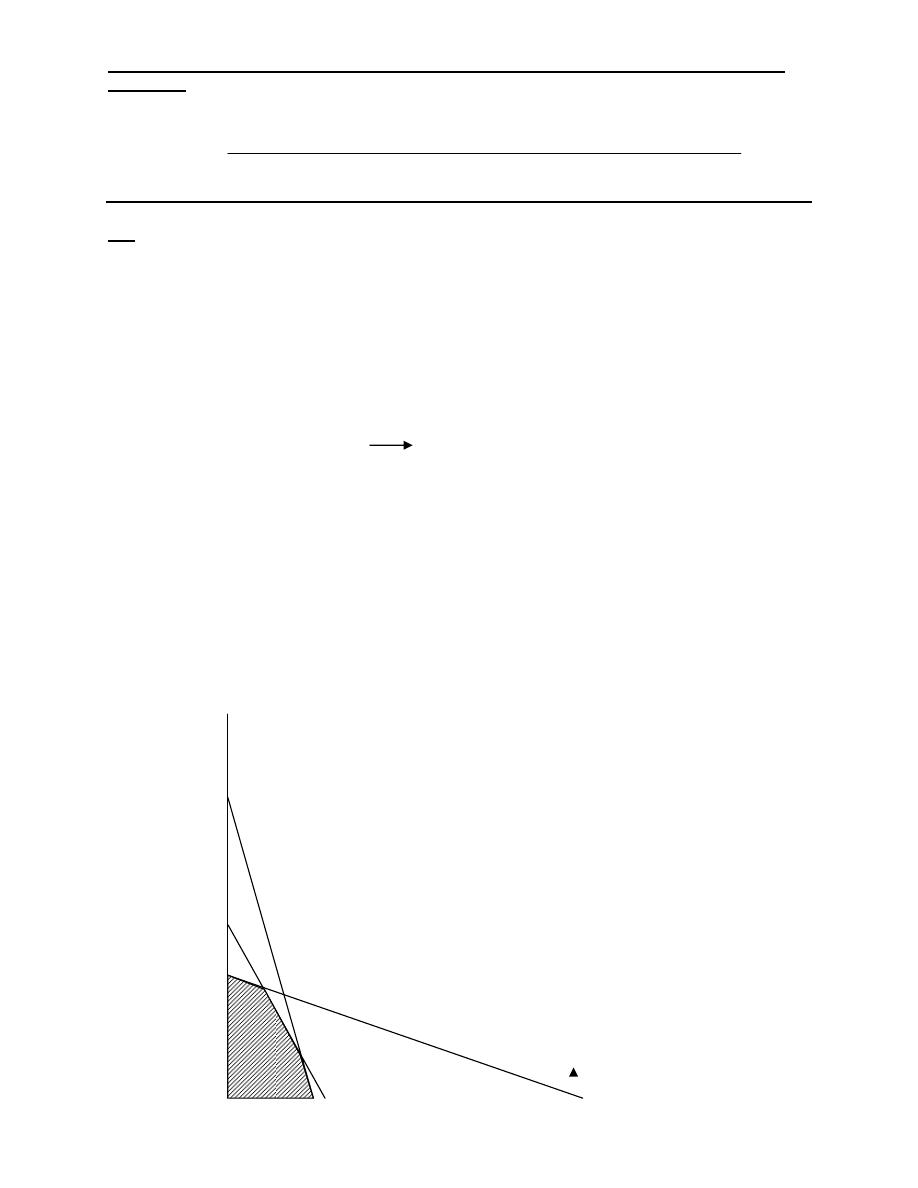

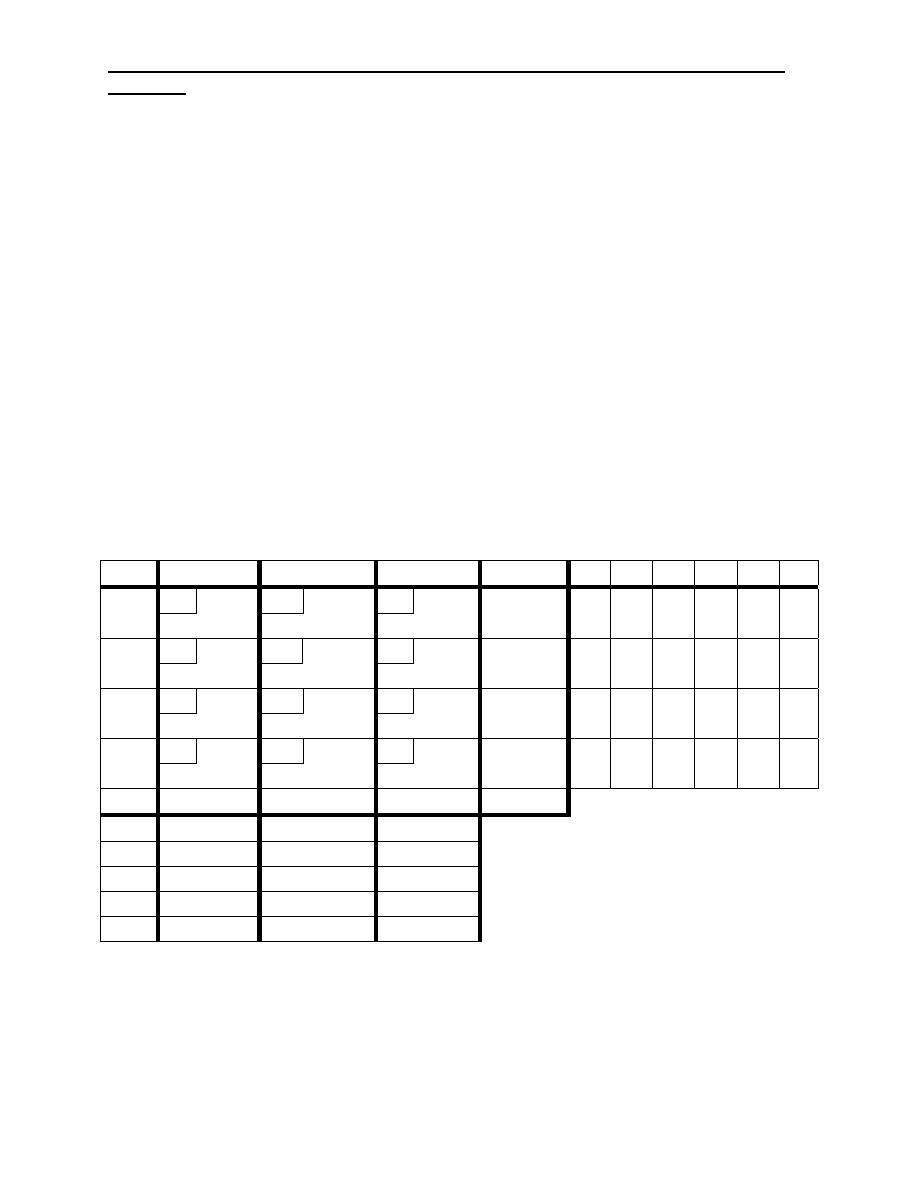

Fig. Break-Even Point (B.E.P)

Cost

Production

volume

Revenue

curve

Profit

Loss

Total

cost

Total

v.cos

F.cos

t

Cost

curve

B.E.

P

Q

3.1 Steps in B.E.P

To construct break-even point, we must know:

13

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

- Total fixed expenses at a certain target production.

- Total variable cost at the same target production.

- Total sales value at the same target production.

We find that the initially zero production rate, fixed cost will

remain as it is variable cost will be zero. The company still

suffers a loss equal to its fixed cost. As production volume

increases this loss decreases but the break-even point……

3.2 Assumptions

a) All the units remains fixed for any production volume.

b) Variable cost increase is linear.

c) Selling prices will remain constant at all levels.

d) Production and sales quantities are equal.

3.3 Formulation of linear Break-even model

This will define the minimum quantity that should be

produced without any loss or profit.

Notations:

Let Q: the quantity sold

b: price (the income per unit)

R: bQ (Revenue or income)

F: fixed cost

v: variable cost per unit

p: profit

Tc: total cost = F + vQ

14

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

P= R-Tc

Quantity increase in price by making:

- Better

product.

- Advertisement.

- New product limited by market price.

Increase in planned quantity: Increase share of market

and increase those products with high profit or increase

share of market with the increase price according to

quantity of market.

Ref: - M.I.Khan , Industrial Engineering ,2

nd

Edition ,2008

- Maynard,H.B ,”Industrial Engineering

Handbook ,new York ,2004

15

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Industrial Engineering

(IE)

Dr. Khallel Ibrahim Mahmoud

University of Technology

Electro-mechanical Engineering Dept.

Lec.

N

o

(2)

Linear Programming

Model

2011

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Linear Programming

LP is a mathematical modeling technique designed to optimize the usage of limited

resources, such as available materials, labour and machine time.

The LP model includes three basic elements:

- Decision variables that we seek to determine.

- Objective (goal) that we aim to optimize.

- Constraints that we need to satisfy.

Steps in formulating LP problems:

1- Define the objective.

2- Define the decision variables.

3- Write the mathematical function for the objective (objective function).

4- Write a one- or two- word description of each constraint.

5- Write the right – hand side (RHS) of each constraint, including the unit of

measure.

6- Write ≤, = or ≥ for each constraint.

7- Write all the decision variables on the left-hand side of each constraint.

8- Write the cofficient for each decision variable in each constraint.

Formulation of linear programming model (LP)

The general form of each model will be:

Z= c

1

x

1

+ c

2

x

2

+……. c

k

x

k

Subject to:

a

11

x

1

+ a

12

x

2

+……. a

1k

x

k

b

1

a

21

x

1

+ a

22

x

2

+……. a

2k

x

k

b

2

a

m1

x

1

+ a

m2

x

2

+……. a

mk

x

k

b

1

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

where: C

j

is a known (cost or profit) coefficient X

j

.

X

j

is an unknown variable.

a

ij

is a known constant.

b

j

is a known constant.

≤, = or ≥ for each constraint.

Example: A manager wants to know many units of each product to produce on a

daily basis in order to achieve the highest contribution to profit. Production

requirement for the products are shown in the following table

Production Departments

I II

Processing time required

for the first product

(Hours)

4 2

Processing time required

for the second product

(Hours)

2 4

Production capacity

available (Hours)

60 48

The profit is £8 for each unit of the first product and £6 for each unit of the second

product

Solution:

1- Define the objective. The problem is a maximum problem.

2- Define the decision variables. We need to determine the number of units to

be produced.

Let: X

i

be the number of units of type i (i= 1,2)

Therefore : X

1

= number of units of the first product.

X

2

= number of units of the second product.

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

X

1,

X

2

are the decision variables, when we know their values the problem will be

solved.

3- The objective function for the LP is:

Maximize Z = 8X

1

+6X

2

This means the profit Z depend on how many units (X

1,

X

2

) are manufactured. Z=

c

1

x

1

+ c

2

x

2

where c

1

, c

2

are the respective profits for each type of product. c

1

=£8

c

2

=£6 and Z = 8X

1

+6X

2

and we should select values of the decision variables

X

1,

X

2

that result in the maximum value of Z.

4- There are two constraints :

Maximum production capacity for Dep.I ≤ 60 hours

Maximum production capacity for Dep.II ≤ 48 hours

( Note: because all the constraints in this problem are maximum capacity , all

constraints are the ≤ type)

Now we have to write the coefficient for each decision variable in each constraint.

The two constraints can be expressed as:

4X

1

+2X

2

≤ 60 constraint Dep.I

2X

1

+4X

2

≤ 48 constraint Dep.II

Consider the first constraint ( Dep.I) what is the coefficient of X

1

in this constraint?

It is the processing time (Hours) required per unit of X

1

. In other word, it is the

processing time used in manufacturing each unit, first product, or 2 hours.

Similarly, the coefficient of X

2

in this first constraint is 1 hour.

Therefore the two constraints can be expressed as :

4X

1

+2X

2

≤ 60

2X

1

+4X

2

≤ 48

And the no. negatively restriction is all X

j

≥ 0 , X

1,

X

2

≥ 0

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

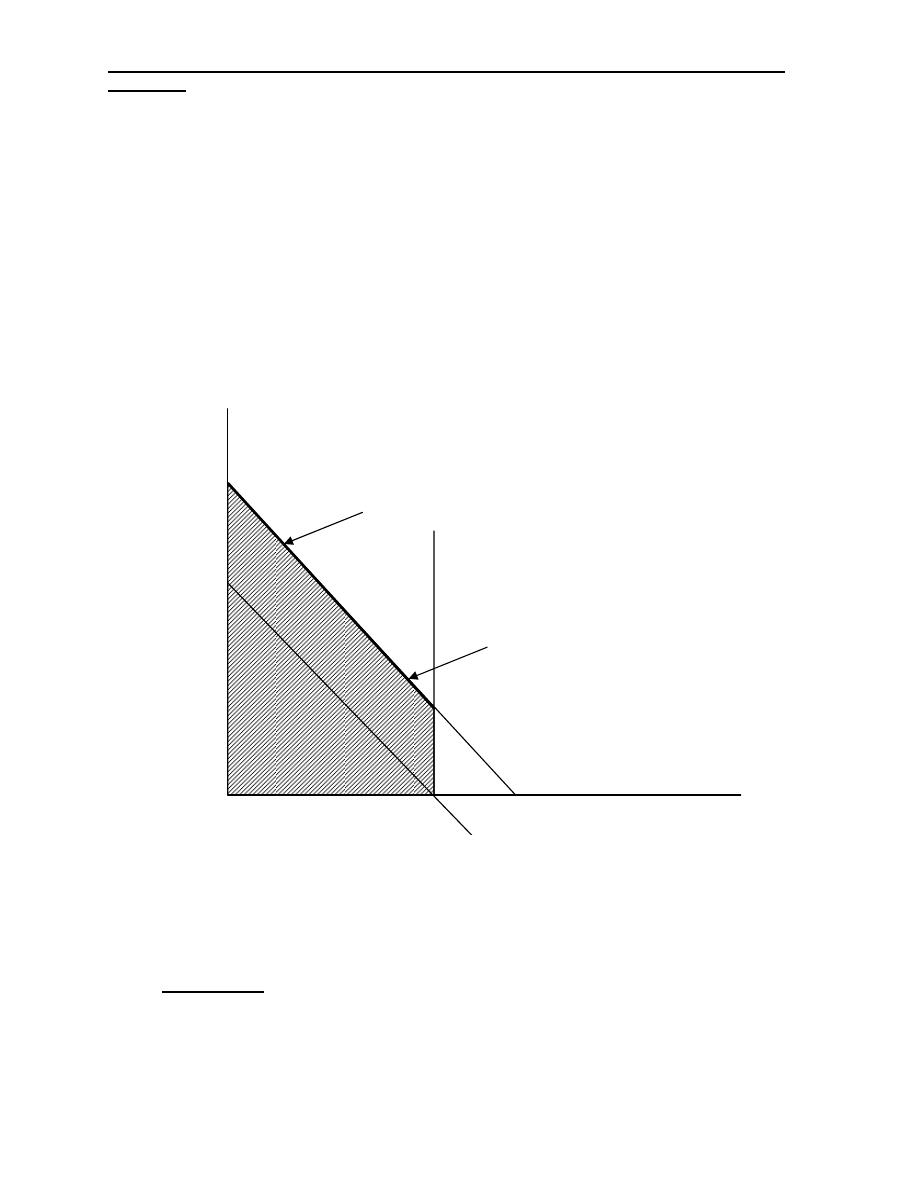

Graphical LP solution:

Steps in the graphical method

1- Formulate the objective and constraint functions.

2- Draw a graph with one variable on the horizontal axis and one on the

vertical axis.

3- Plot each of the constraints as if they were lines or equlities.

4- Outline the feasible solution space.

5- Circle the potential solution points .These are the intersections of the

constraints or axes on the inner (minimization) or outer (maximization)

perimeter of the feasible solution space.

6- Substitute each of the potential solution point values of the two decision

variables into the objective function and solve for Z.

7- Select the solution point that optimizes Z.

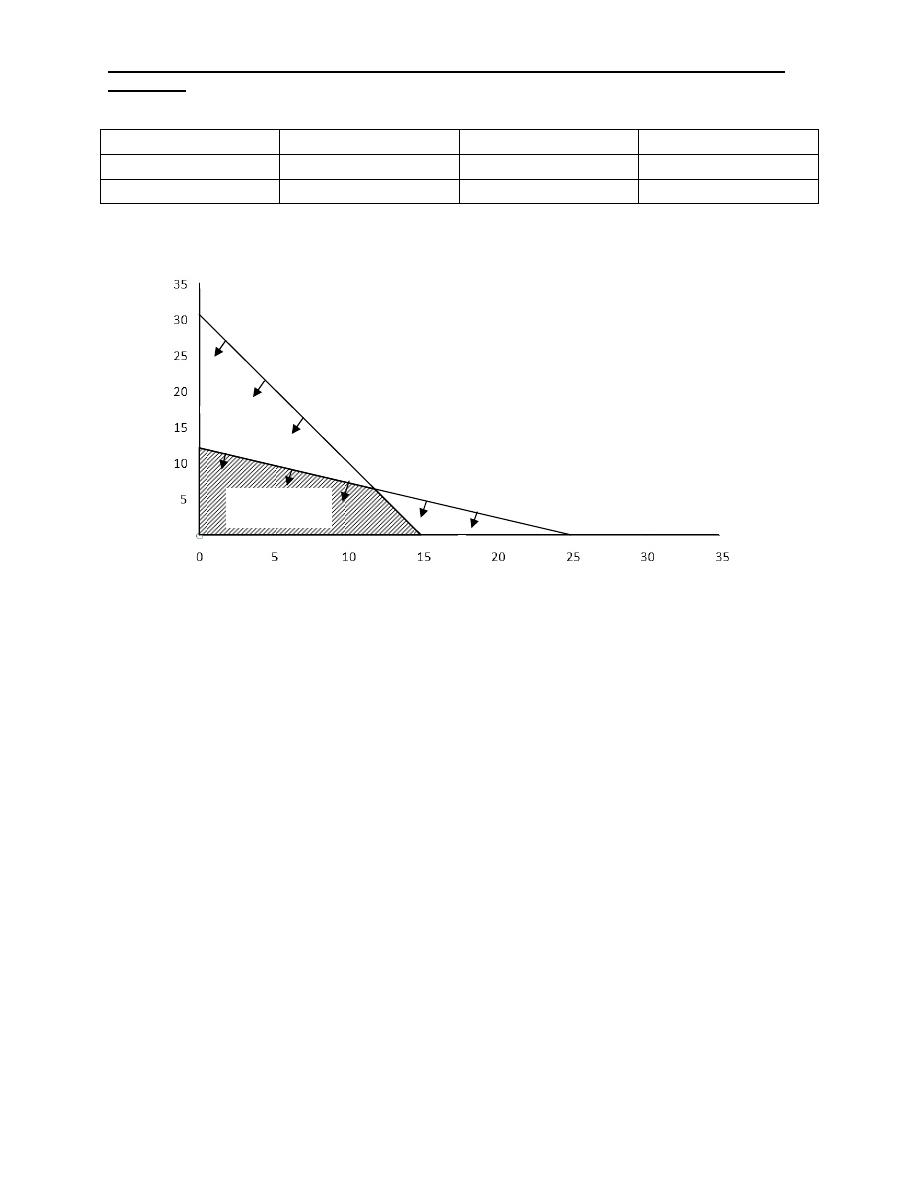

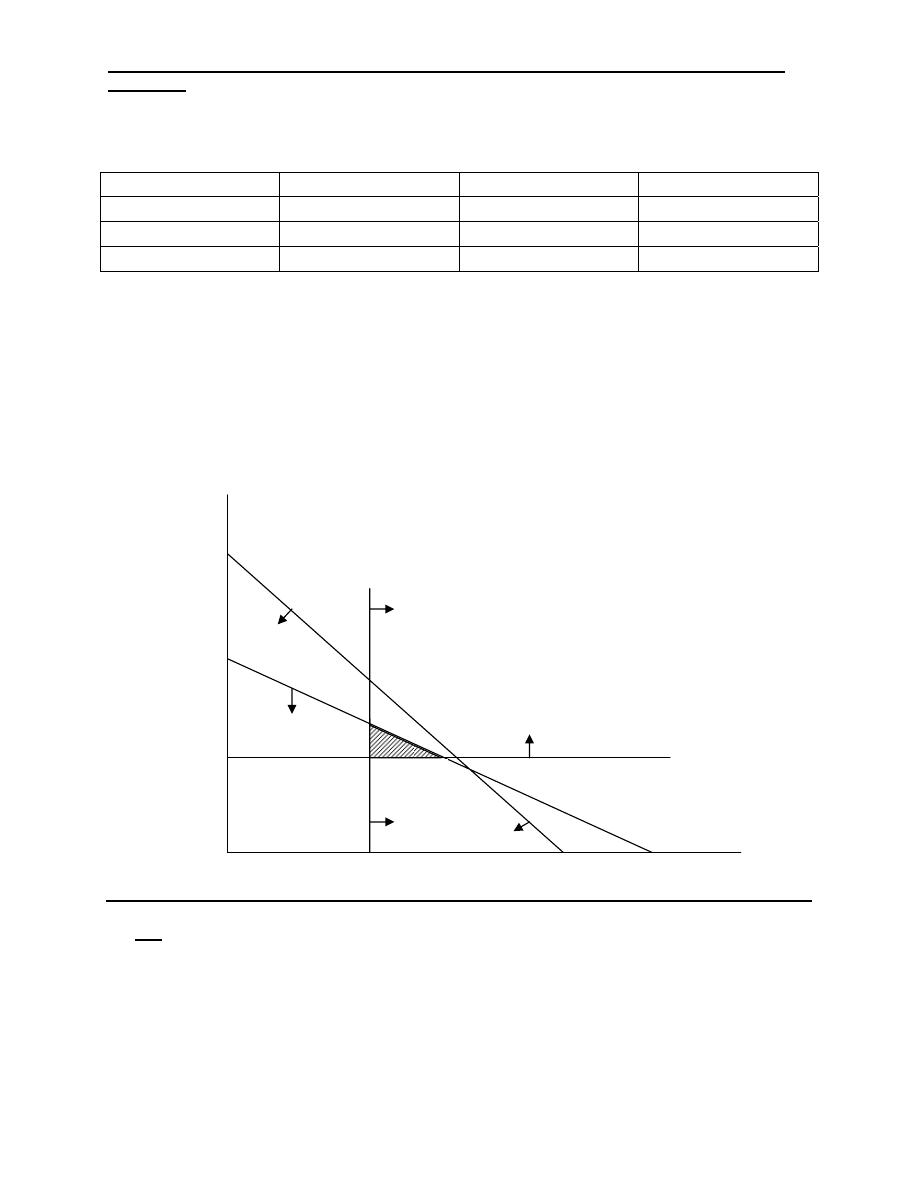

Solution of maximization model

To demonstrate the steps of the graphical solution of a maximization problem we

use the previous example:

Z = 8X

1

+6X

2

Subject to:

4X

1

+2X

2

≤ 60

2X

1

+4X

2

≤ 48

X

1

≥ 0 , X

2

≥ 0

Solution:

1- Plot the constraints (shown in the following figure) change constraints to

equalities:

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

4X

1

+2X

2

≤ 60 4X

1

+2X

2

= 60

2X

1

+4X

2

≤ 48 2X

1

+4X

2

= 48

For each constraint ( set X

1

=0 and solve for X

2

, then set X

2

=0 and solve for X

1

)

the graph the constraint as if it were an equality

4X

1

+2X

2

= 60 X

1

=15 X

2

=0

X

1

=0 X

2

=30

2X

1

+4X

2

= 48 X

1

=24 X

2

=0

X

1

=0 X

2

=12

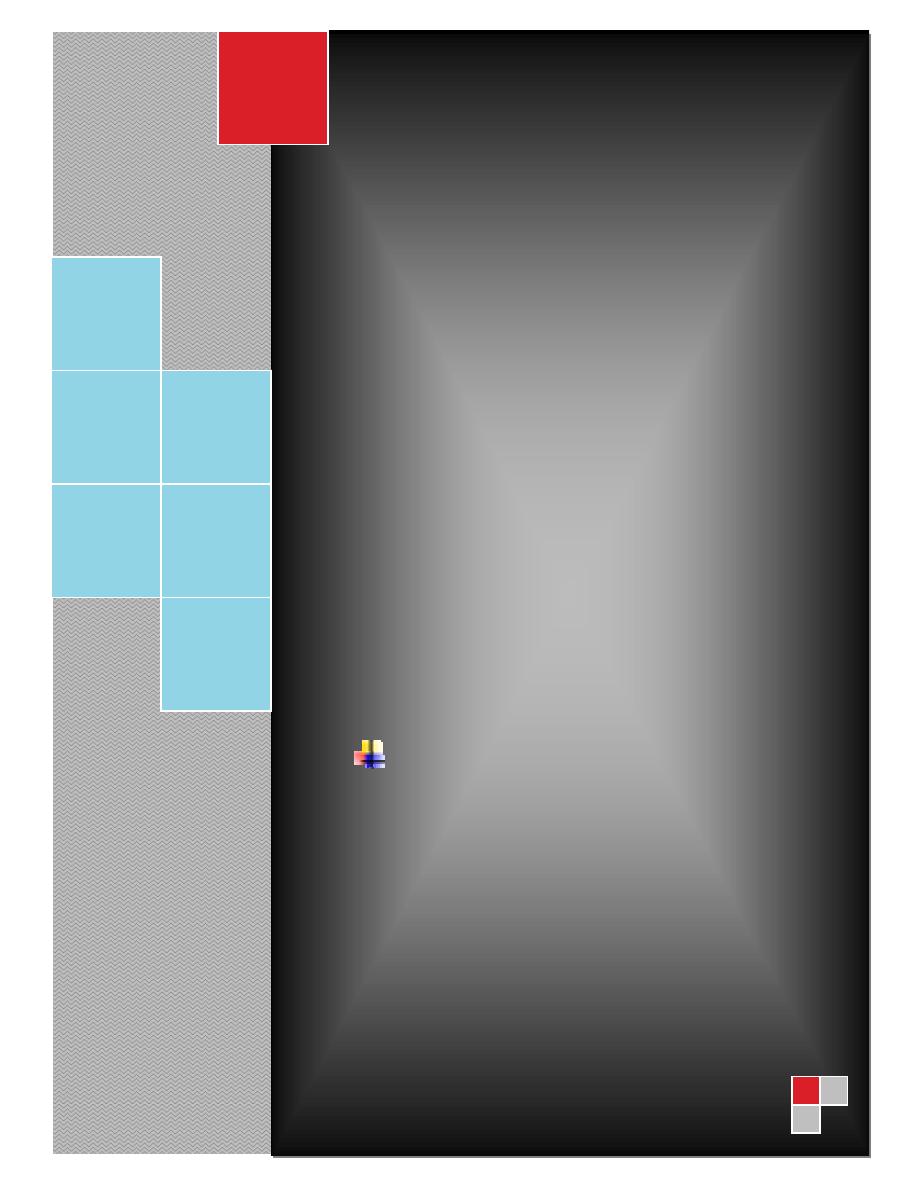

2- Outline the feasible solution space the values of X

1

and X

2

at points M,A,B

and C are four potential solutions to problem.

Note: point B can be determined as follow:

4X

1

+2X

2

= 60

(2X) 2X

1

+4X

2

= 48

4X

2

+2X

2

= 60

4X

2

+8X

2

= 96

6X

2

=36

X

2

=36/6 = 6

Then: 4X

1

+2X

2

= 60

4X

1

+2(6) = 60

4X

1

= 48

X

1

= 48/4 = 12

Points X

1

X

2

Z

M 0 0

Z=8(0)+6(0)=0

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

A 15 0

Z=8(15)+6(0)=120

B 12 16

Z=8(12)+6(6)=132

C 0 12

Z=8(0)+6(12)=72

To maximize Z, the optimal solution is point B, where X

1

=12 and X

2

=6 and

Z=£132 profit.

B

X

1

A

X

Feasible

solution space

4X

1

+2X

2

≤ 60

2X

1

+4X

2

≤ 48

C

M

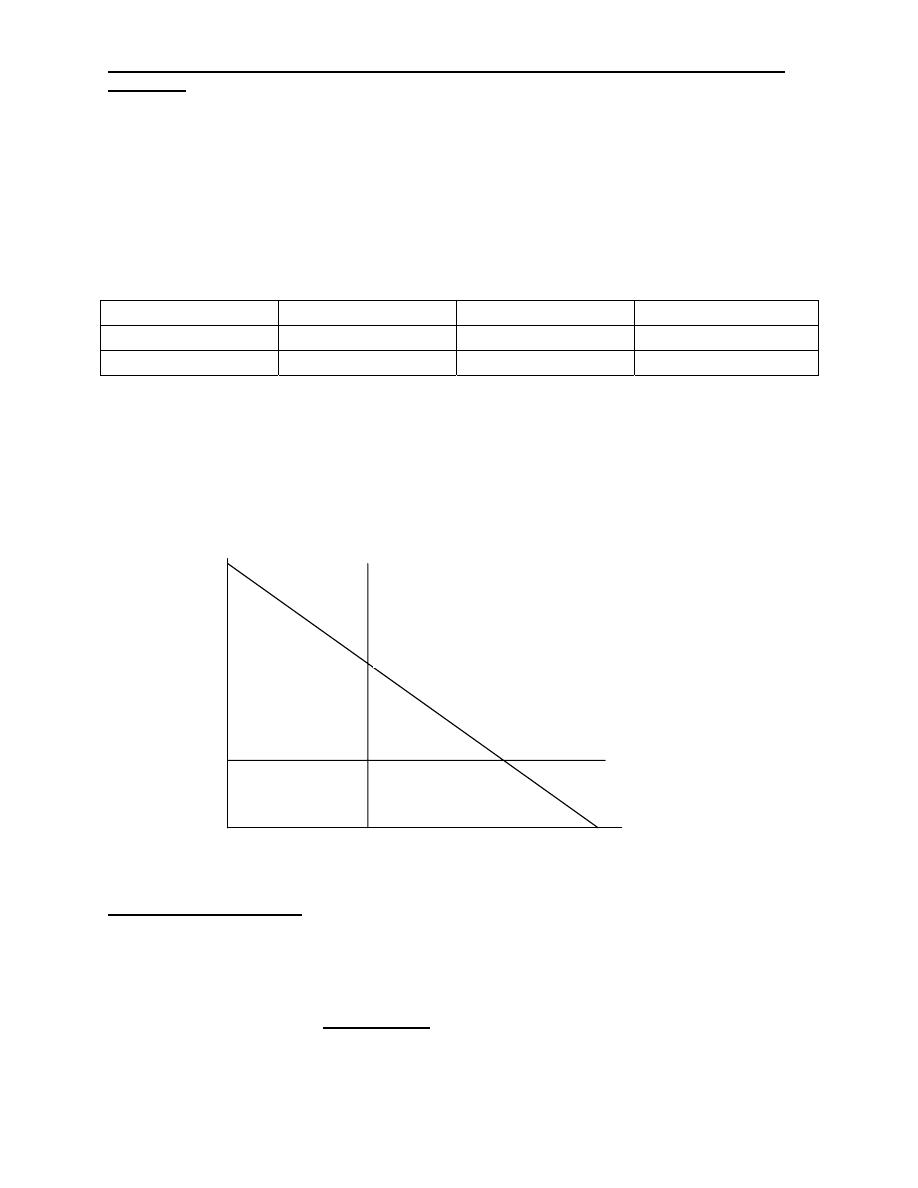

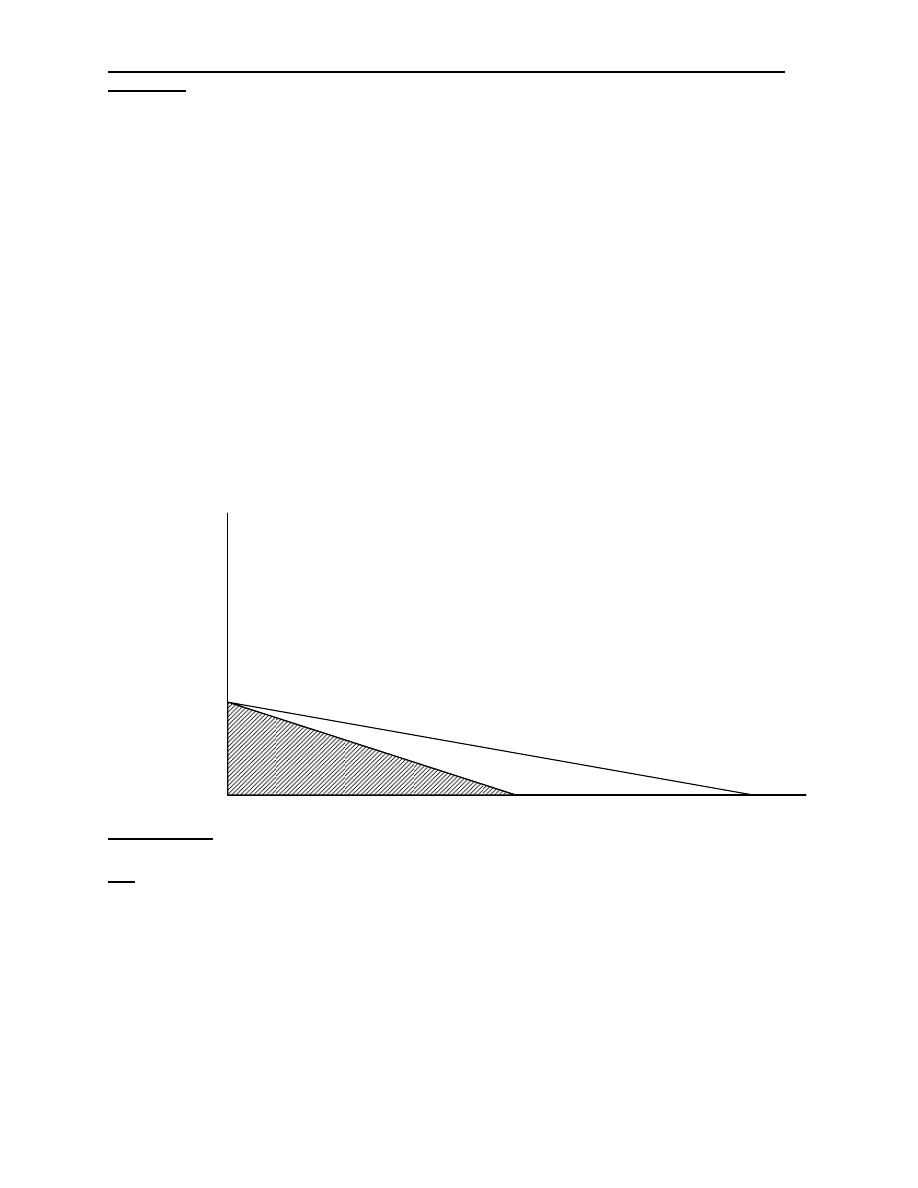

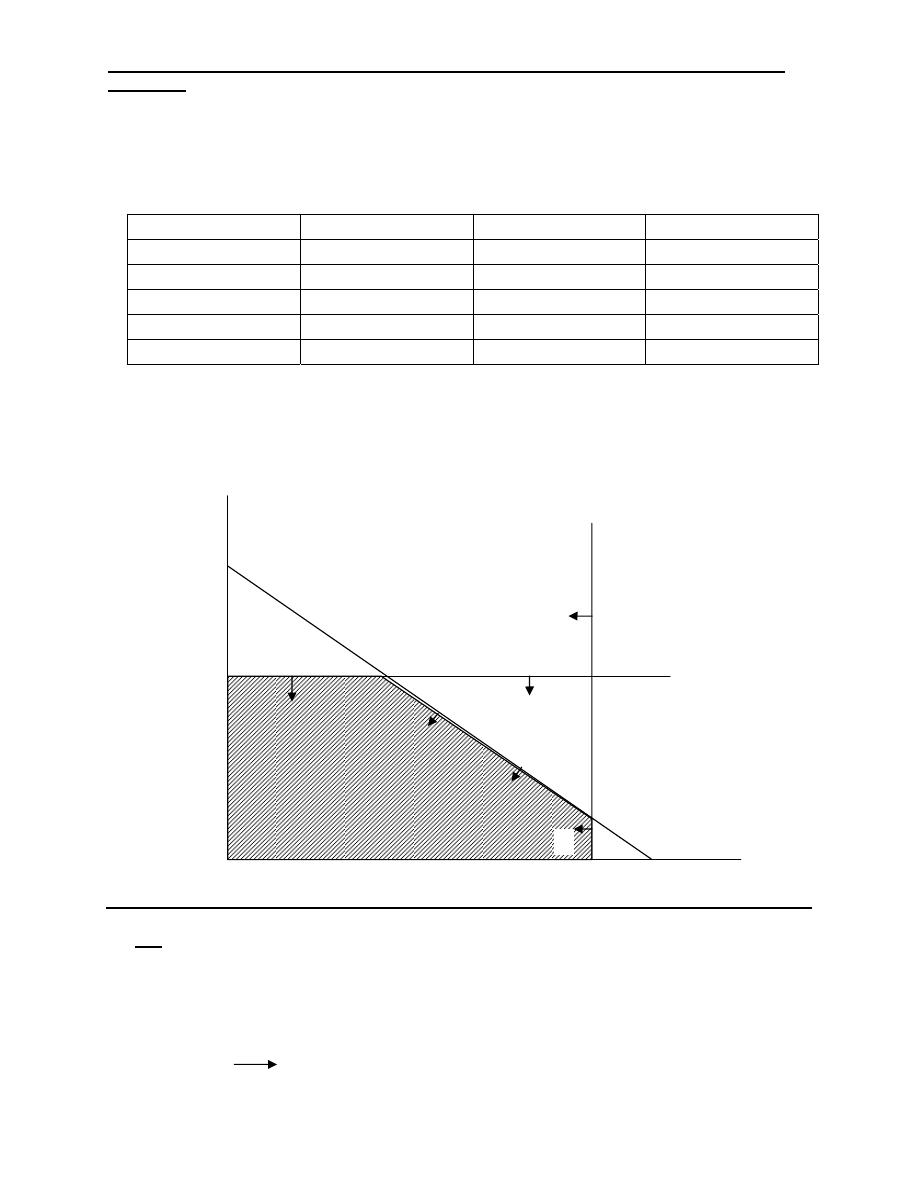

Minimization case:

Consider the following LP problem:

Min Z = 3X

1

+8X

2

Subject to:

X

1

≤ 80

X

2

≥ 60

X

1

+ X

2

=200

X

1

, X2 ≥ 0

Solved problem: X

1

=80 X

2

=60

X

1

=0 X

2

=200

X

1

=200 X

1

=0

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

B/ X

1

+ X

2

=200

X

1

=80

Then X

2

=200-80

=120

Point X

1

X

2

Z

A 0 200

3(0)+8(200)=1600

B 80 120

3(80)+8(120)=1200

Min Z=1200

X

1

=80 X

2

=120

X

2

≥60

X

20

16

12

40

40

80

80

12

16

X

A

X

1

≤80

X

1

+ X

2

=200

B

20

Special cases in LP

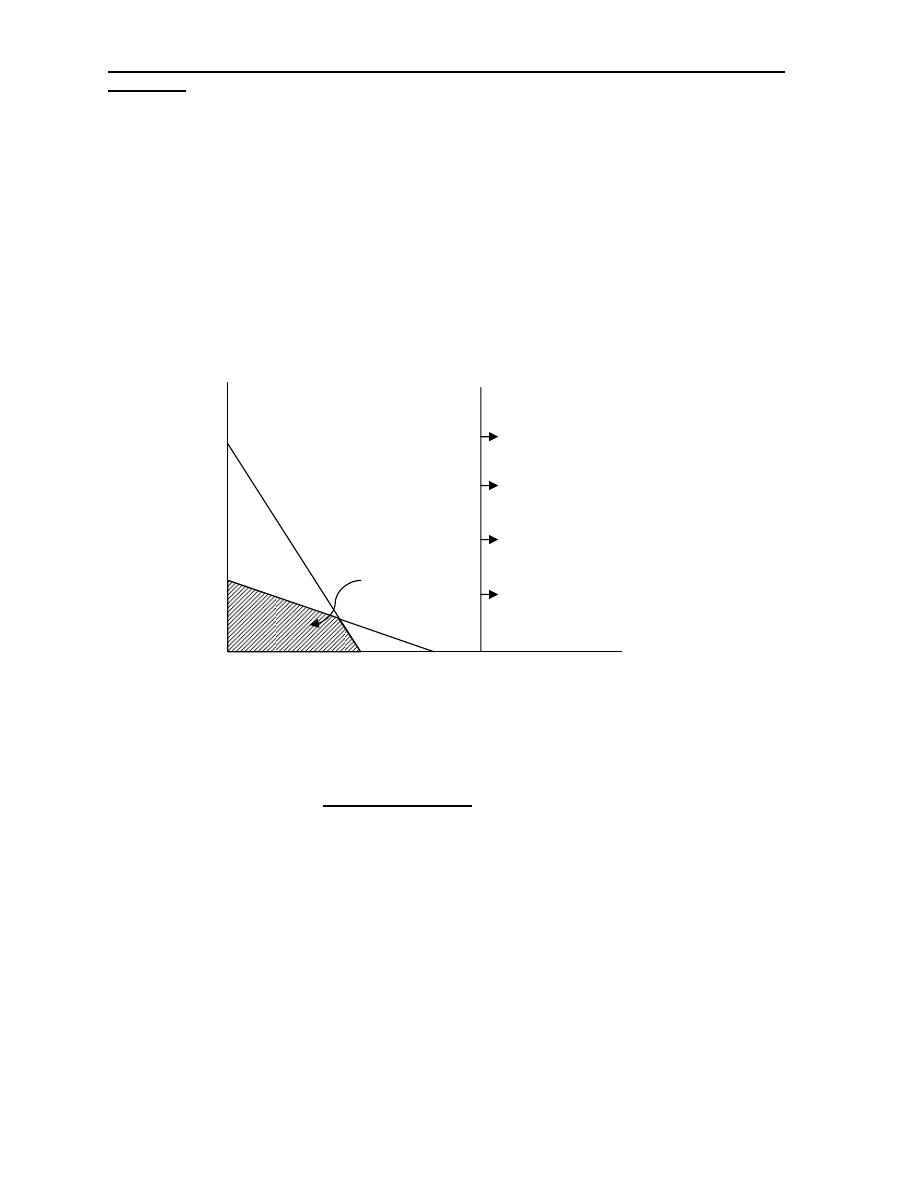

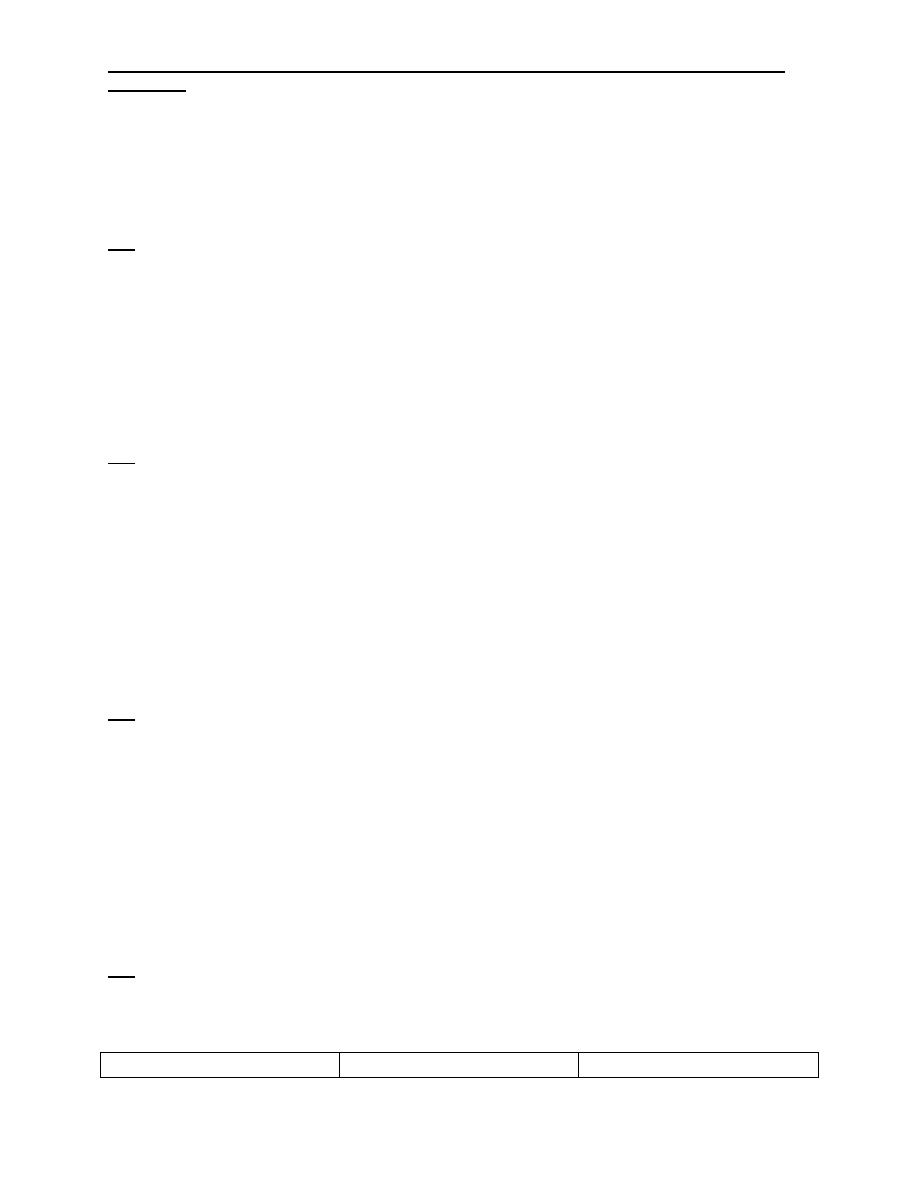

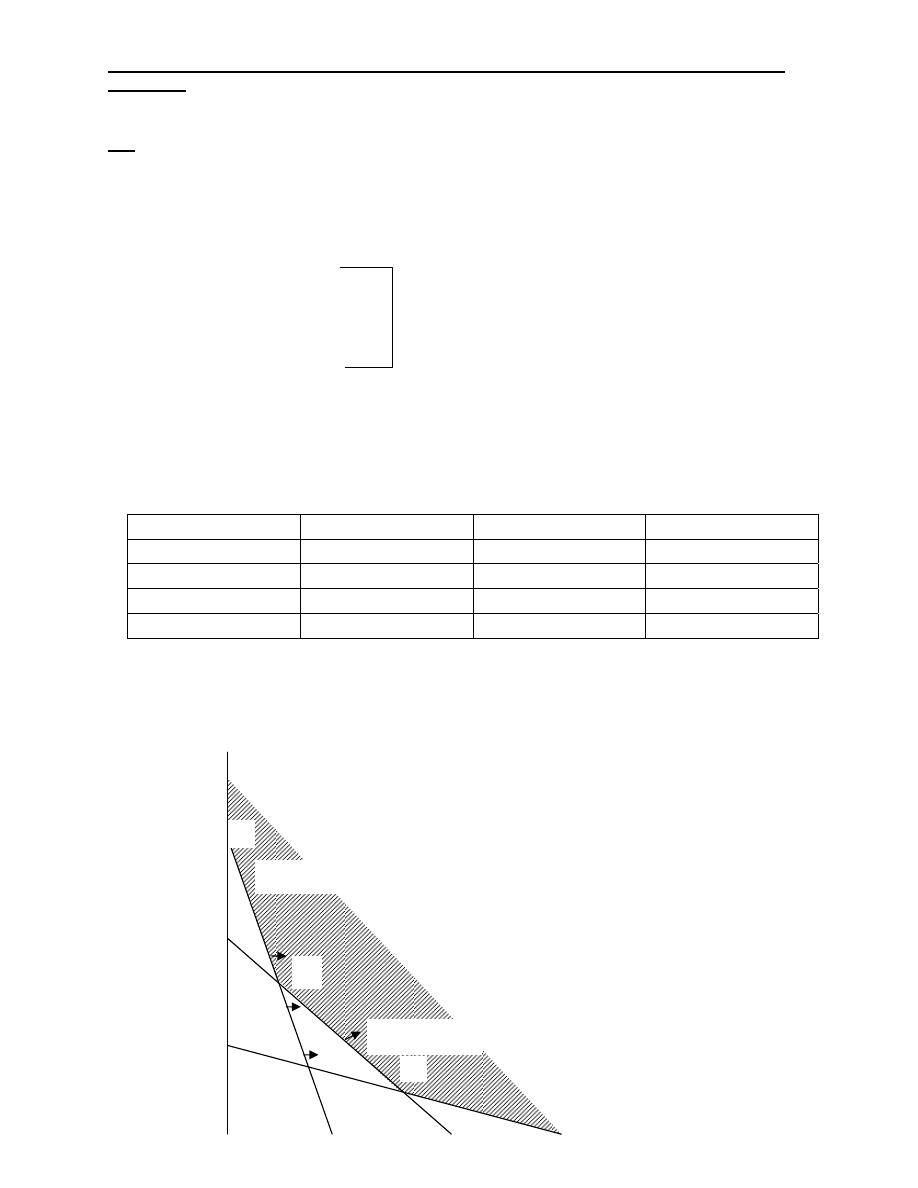

Five special cases and difficulties arise at times when using the graphical approach

to solve LP problems:

1)

Infeasibility: infeasibility is a condition that arises when

there is no solution to LP problem that satisfies all of constraints given.

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Graphically, it means that no feasible solution region exists- a situation that

might occur if the problem was formulated with conflicting constraints.

Let us consider the following three constraints: X

1

+2X

2

≥6

2X

1

+X

2

≥8

X

1

≥7

X

Region satisfying

3rd constraint

Region satisfying

first 2 constraints

X

8

6

4

2

8

6

4

2

As seen in the figure there is no feasible solution region for this problem because

of the presence of conflicting constraints.

2)

Unboundedness:

Sometimes a linear program will not have a finite solution. This means that in a

maximization problem, for example, one or more solution variables, and the profit,

can be made infinitely large without violating any constraints. If we try to solve

such a problem graphically, we will note that the feasible region is open-ended.

Let us consider a simple example to illustrate the situation.

Z = 3X

1

+5X

2

Subject to: X

1

≥ 5

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

X

2

≤ 10

X

1

+2 X

2

≥10

X

1

, X2 ≥ 0

X

X

2

≤10

Feasible Region

X

1

≥ 5

X

1

+2 X

2

≥10

15

10

5

X

5

10

15

20

As you see, because this is a maximization problem and the feasible region extends

infinitely the right, there is unboundedness or unbounded solution.

3)

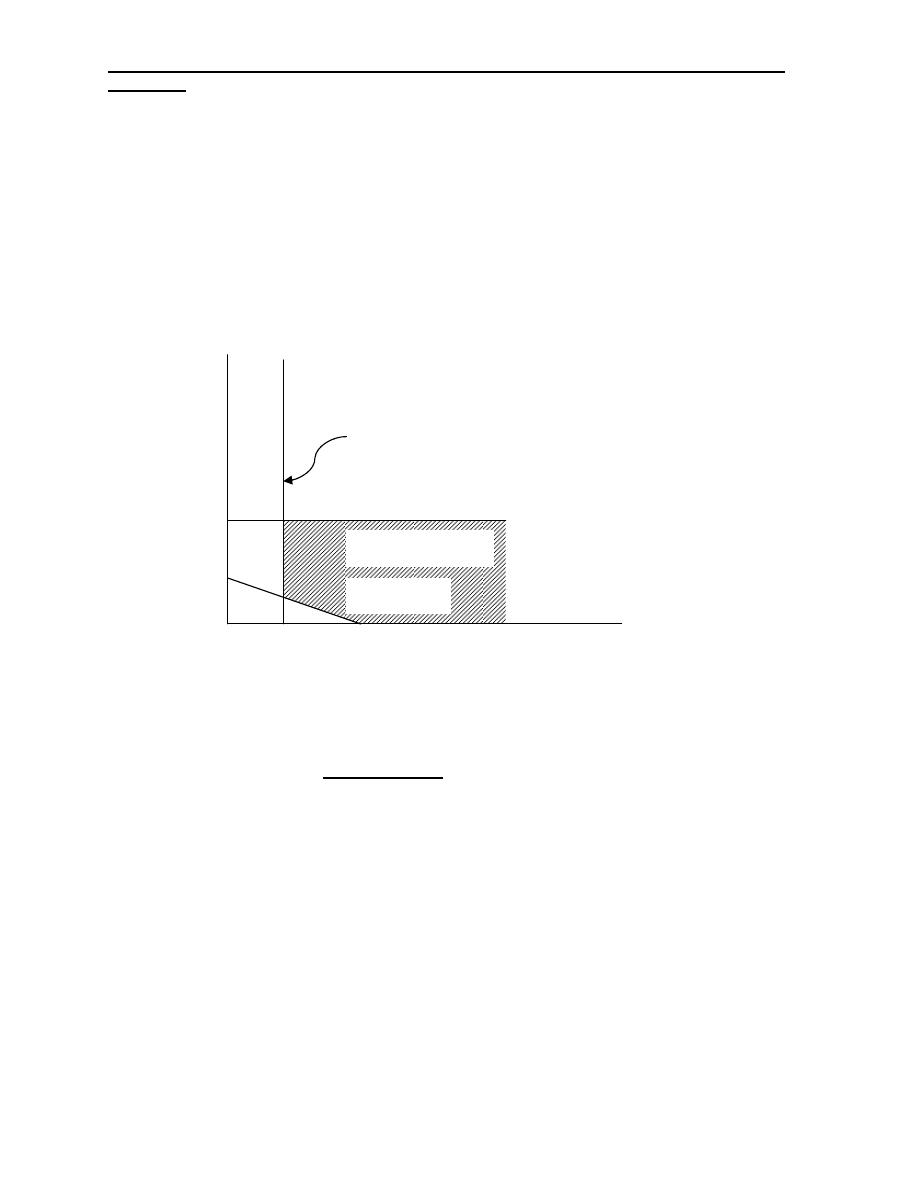

Redundancy: The presence of redundant constraints

occurs in large LP formulations, a redundant constraint is simply on that

does not affect the feasible solution region.

Let us kook at the following example:

Max Z= X

1

+2X

2

Subject to: X

1

+X

2

≤ 20

2X

1

+X

2

≤ 30

X

1

≤ 25

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

X

1

, X2 ≥ 0

X

X

1

≤25

Redundan

t

Feasibl

e

X

1

+ X

2

≤20

2X

1

+ X

2

≤30

X

35

30

25

20

15

10

5

5

10

15

20

25

30

The third constraint, X1≤25 is redundant and unnecessary in the formulation and

solution of the problem because it has no effect on the feasible region set.

4) Alternate Optimal Solutions:

An LP problem may on occasion, have two or more alternate optimal solutions.

Graphically, this is the case when the objective function’s isoprofit or isocost

line runs perfectly parallel to one of the problem’s constraints.

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Ex: Max Z= 3X

1

+2X

2

Subject to: 6X

1

+4X

2

≤ 24

X

1

≤ 3

X

1

, X2 ≥ 0

1

1

2

2

3

3

4

4

5

5

A

Isoprofit line for

12/line segment AB

6

B

Optimum solutions consists of all

combinations of X

1

,X

2

along the AB

X

Isoprofit

line for 8

X

6

As you see any point along the line between A and B provides an optimal X

1

and X

2

combination Z=12

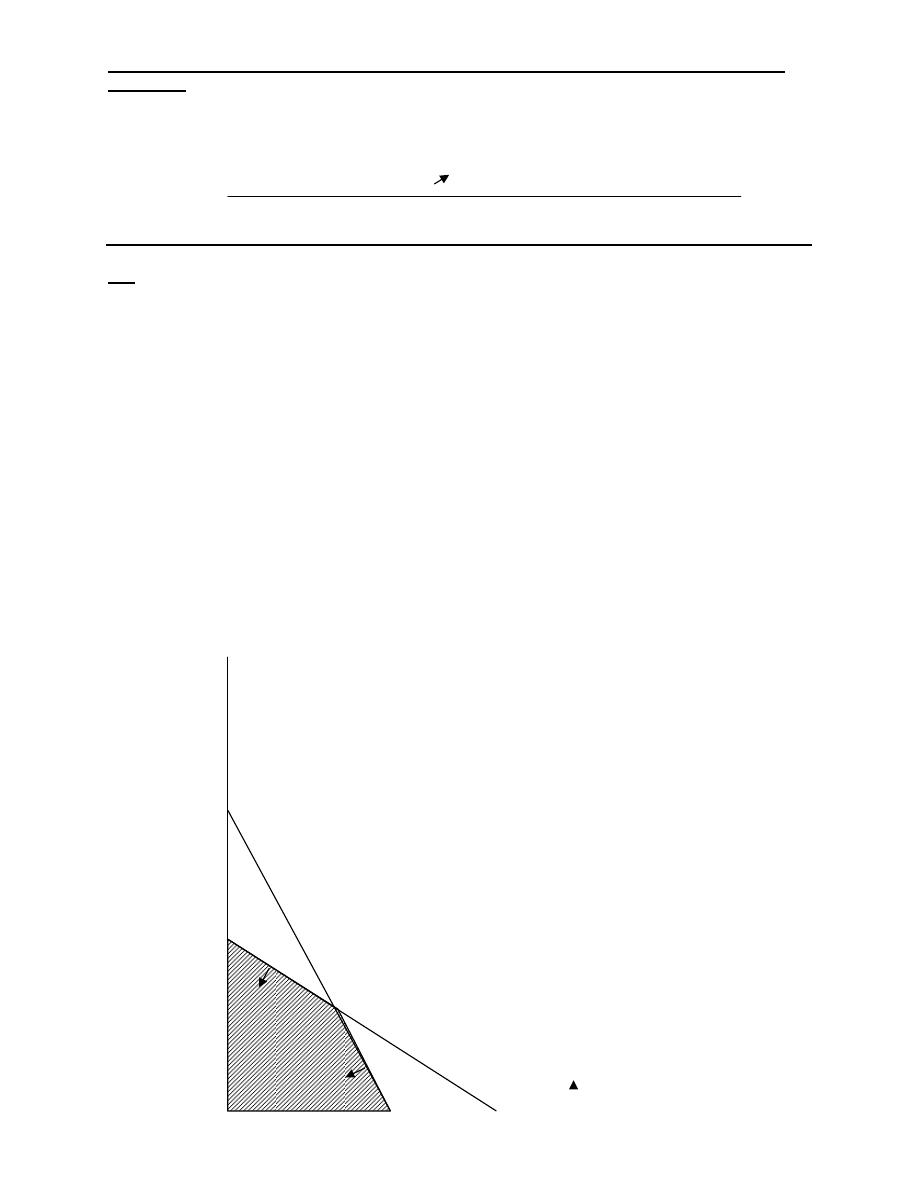

5) Degenercy:

Degenercy is a condition that arises when one of the decision variable equal zero.

Look to the following example:

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Max Z = 3X

1

+9X

2

Subject to: X

1

+4X

2

≤ 8

X

1

+2X

2

≤ 4

X

1

, X2 ≥ 0

Solution: X

1

=8 X

2

=2

X

1

=4 X

2

=2

Then: at point A

X

1

=0 X

2

=2 Max Z=18

5

X

B

A

4

3

2

1

1

2

3

4

5

6

7

8

Problems:

Q1/ Montana wood products manufacturers two high-quality products, chairs and

bookshelf units. Its profit is $15 per chair and $21 per bookshelf unit. Next week’s

production will be constrained by two limited resources, labor and wood. The labor

available next week is expected to be 920 labor hours, and the amount of wood

available is expected to be 2400 board feet. Each chair requires 4 labor hours and 8

board feet of wood. Each bookshelf unit requires 3 labor hours and 12 board feet of

wood. Management would like to produce at least 100 units of each product.

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

a-

To maximize total profit, how many chairs and bookshelf

units should be produced next week?

b-

How much profit will result?

Q2: solve graphically the following linear programming problem:

Max Z = 60X

1

+40X

2

Subject to: 2X

1

+X

2

≤ 60

X

1

≤ 25, X

2

≤ 35

X

1

, X2 ≥ 0

Q3: solve graphically:

Max Z = 10X

1

+15X

2

Subject to: 2X

1

+X

2

≤ 26

2X

1

+4X

2

≤ 56

X

1

-X

2

≥-5

X

1

, X2 ≥ 0

Q4: Consider the following problem and solve graphically:

Minimize Z = 2X

1

+4X

2

Subject to: X

1

+X

2

≤ 14

3X

1

+2X

2

≥ 30

2X

1

+X

2

≤18

X

1

, X2 ≥ 0

Q5: Tellitell Television company operates two assembly lines, line I and line II.

Each line is used to assemble the components of three types of televisions: colour,

standard and Economy. The expected daily production on each line is as:

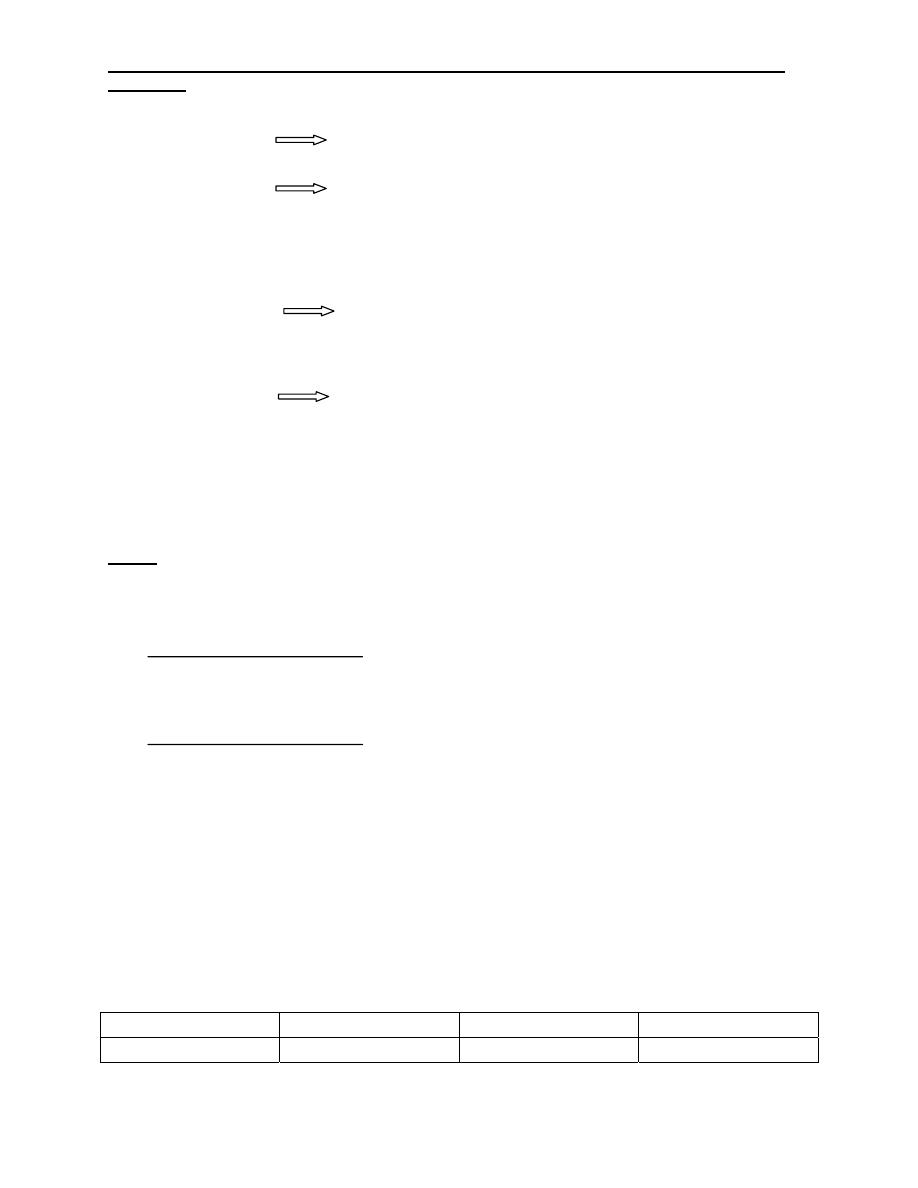

TV Model

Line I

Line II

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Colour 3

1

Standard 1

1

Economy 2

6

The daily running costs for two lines average £6000 for line I and £4000 for line II.

It is given that the company must produce at least 24 colour, 16 standard, and 48

economy TV sets for which an order is pending.

You are required to formulate the above problem as (LP) taking the objective

function as minimization of total cost. Also determine the number of days that the

two lines should be run to meet the requirements.

Q6: Suppose two types of television sets are produced with a profit of 6 units from

each television of type II. In addition 2 and 3 units of raw materials are needed to

produce one television of type I and II respectively. And 4 and 2 units of time are

required to produce one television of type I and II respectively. If 100 units of raw

materials and 120 units of time are available. How many units of each type of

television should be produced to maximize profit?

Q7: A wood product firm uses available time at the end of each week to make

goods for stocks. Currently two products on the list of items are produced for

stock: a chopping board and a knife holder. Both items require three operations:

cutting, gluing, and finishing.

The manager of the firm has collected the following data on these products:

Time per unit (minutes)

Item Profit/unit

Cutting Gluing Finishing

Chopping

board

$2 1.4 5 12

Knife

holder

$6 0.8 13 3

The manager has also determine that during each week, 56 minutes are available

for cutting, 650 minutes are available for gluing and 360 minutes are available for

finishing.

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

a-

Determine the optimal quantities of decision variables.

b-

Which resources are not completely used by your solution?

How much of each resource is unused?

Q8: solve the following problem using graphical linear programming.

Minimize Z = 2X

1

+3X

2

Subject to: 4X

1

+2X

2

≥ 20

2X

1

+6X

2

≥ 18

X

1

+2X

2

≤12

X

1

, X2 ≥ 0

Solutions: Lec. No.2

Q1: Let X

1

: number of chairs to produce next week.

X

2

: number of bookshelves to produce next week.

Max Z = 15X

1

+21X

2

Subject to: 4X

1

+3X

2

≤920 …….. (1)

8X

1

+12X

2

≤ 2400 …….. (2)

X

1

≥100 X

2

≥100

X

1

, X2 ≥ 0

X

1

=0 X

2

=306.6

X

2

=0 X

1

=230 …………….. (1)

X

1

=0 X

2

=200

X

2

=0 X

1

=300 …………… (2)

Z= 4350 with X

1

=150 X

2

=100

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

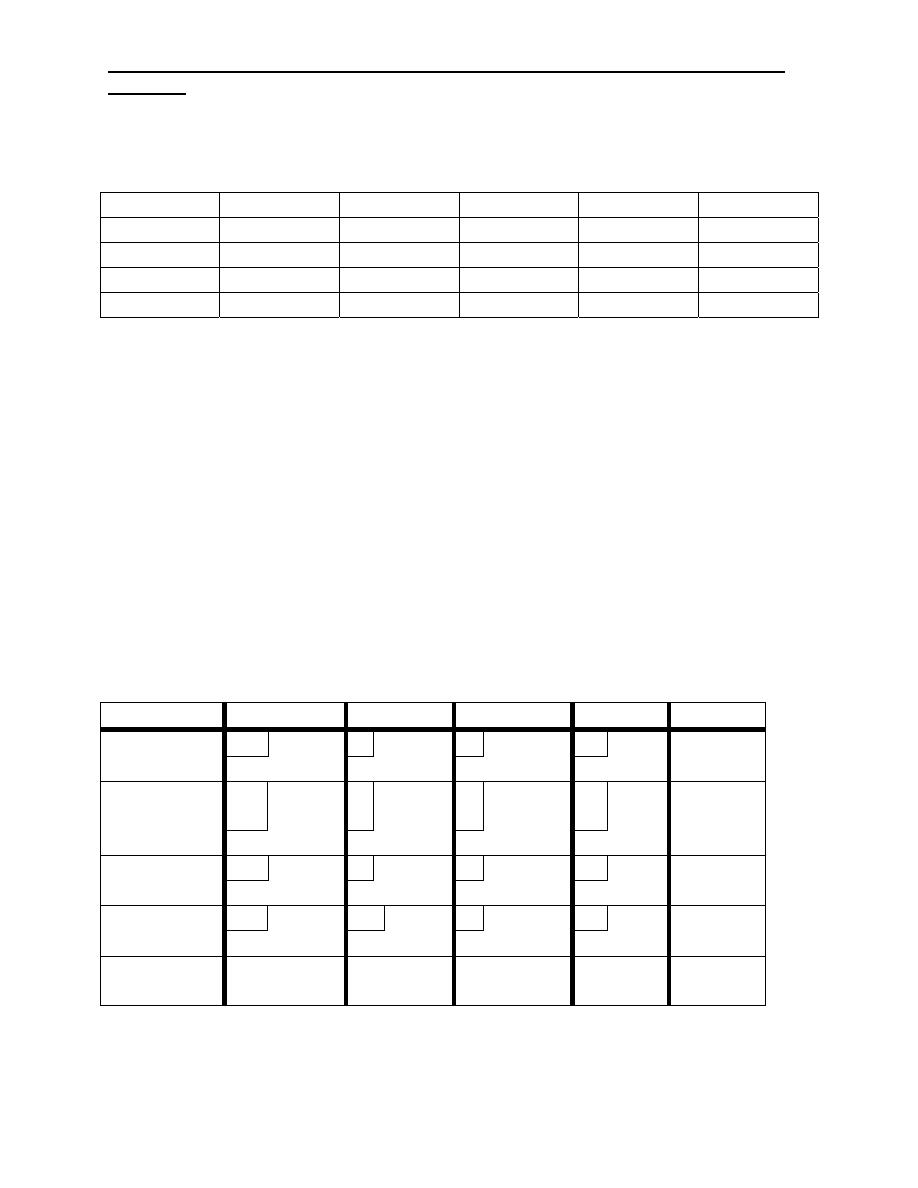

Point X

1

X

2

Z

A 100 100

3600

B 100

133.3

4299.3

C 150 100

4350

50

10

15

20

25

B

C

A

X

30

350

300

250

20

15

100

50

X

Q2: Max Z = 60X

1

+40X

2

Subject to: 2X

1

+X

2

≤60

X

1

≤25 X

2

≤35

X

1

, X2 ≥ 0

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

X

1

=0 X

2

=306.6

X

2

=0 X

1

=30

Point X

1

X

2

Z

M 0 0 0

A 0 35

1400

B 12.5 35 2150

C 25 10

1900

D 25 0 1500

B: 2X

1

+X

2

= 60 X

2

=35 X

1

= (60-35)/2 = 12.5

It is clear that Z equal to 2150 is Maximum at B when X

1

=12.5 X

2

=35.

X

X

2

≤35

X

1

≤25

C

B

2X

1

+X

2

≤60

D

X

60

50

40

A

30

20

10

M

5

10

15

20

25

30

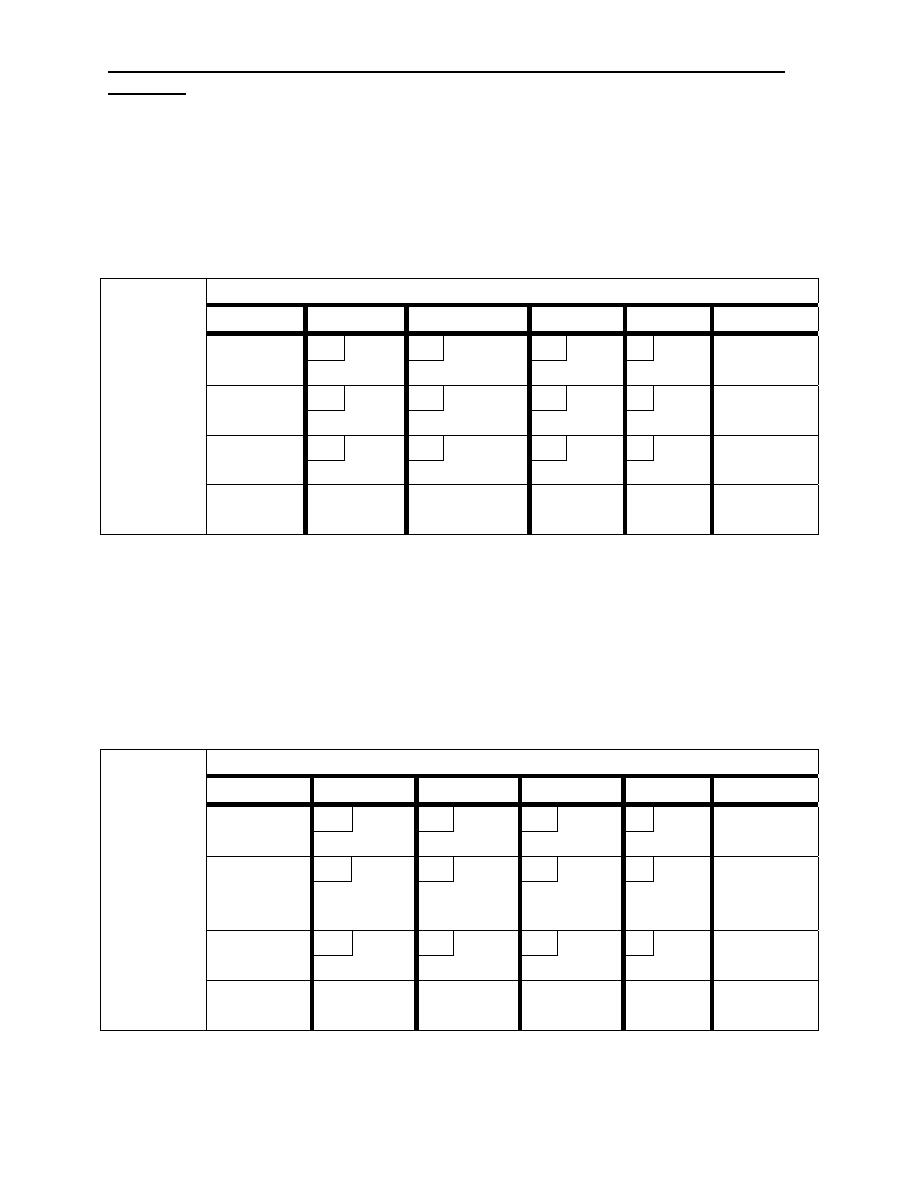

Q3: Max Z = 10X

1

+15X

2

Subject to: 2X

1

+X

2

≤26

2X

1

+4X

2

≤ 56

X

1

-X

2

≥-5 -X

1

+X

2

≤5

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

X

1

, X2 ≥ 0

X

1

=-5 X

2

=5

Point X

1

X

2

Z

M 0 0 0

A 0 5 75

B 6 11

225

C 8 10

230

D 13 0 130

Hence, Z is Maximum (230) at C.

4

4

8

8

12

12

16

16

18

20

X

-8

-4

M

28

X

A

24

B

2X

1

+4X

2

≤ 56

C

2X

1

+X

2

≤26

-X

1

+X

2

≤5

D

20

24

28

Q4: Min Z = 2X

1

+4X

2

Subject to: X

1

+X

2

≤14

3X

1

+2X

2

≥30

2X

1

+X

2

≤18

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

X

1

, X2 ≥ 0

Point X

1

X

2

Z

A 2 12 52

B 4 10 48

C 6 6 36

Thus, Z is Minimum at point C when X

1

, X

2

=6 Z=36 .

2

2

4

4

6

6

8

8

10

10

12

B

12

14

18

16

X

A

C

X

1

+X

2

≤14

3X

1

+2X

2

≥30

2X

1

+X

2

≤18

14

X

16

18

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Q5: Let X

1

= the number of days the line I is run.

X

2

= the number of days the line II is run.

Min Z = 6000X

1

+4000X

2

Subject to: 3X

1

+X

2

≥24

X

1

+X

2

≥16 Production Requirement

2X

1

+6X

2

≥48

X

1

, X2 ≥ 0

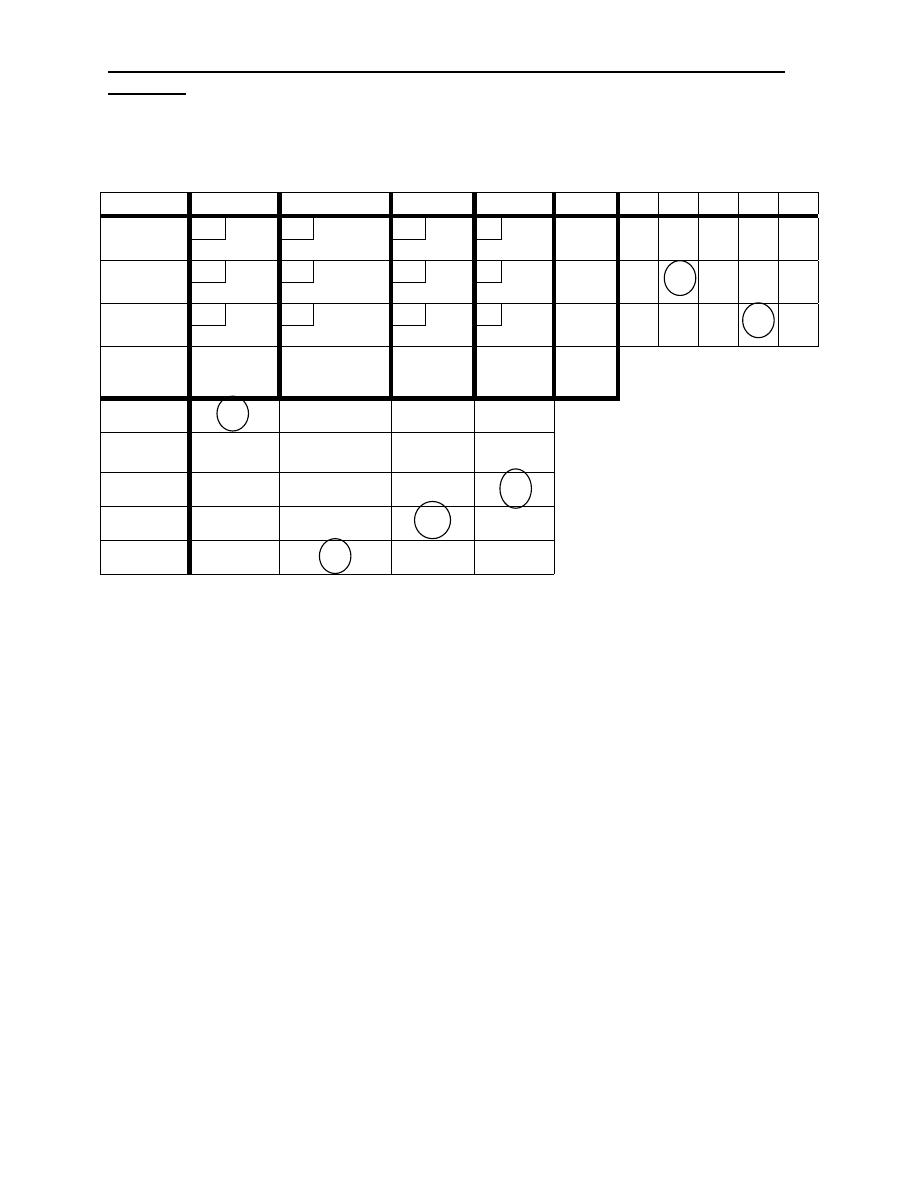

Point X

1

X

2

Z

A 0 24

96000

B 4 12

72000

C 12 4

88000

D 24 0

144000

Thus, to Minimize cost, line I should be run for 4 days and line II for 12 days.

4

8

12

16

20

B

24

X

1

+X

2

≥16

3X

1

+X

2

≥24

28

X

C

A

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

2X

1

+6X

2

≥48

D

X

4

8

12

16

20

24

Q6: let X

1

: be the number of units of type I produced.

X

2

: be the number of units of type II produced.

Max Z = 6X

1

+4X

2

Subject to: 2X

1

+3X

2

≤100 (raw material time)

4X

1

+2X

2

≤ 120

X

1

, X2 ≥ 0

The optimum solution at point C (X

1

=20, X

2

=30) Hence, 20 units of type I and 20

units of type II should be produced to yield a maximum profit of

Z=6(20)+4(20)=200

10

20

30

40

50

B

60

C

80

D

70

X

2

X

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

A

1

2

30

50

40

70

60

80

Q7: Let board = X

1

holder= X

2

Max = 2X

1

+6X

2

Subject to: 1.4X

1

+0.8X

2

≤56 …………… (1)

5X

1

+13X

2

≤ 650 ………………. (2)

12X

1

+3X

2

≤ 360 ………………. (3)

a) The solution at point A X

1

=0 X

2

=50

Z= 2(0) +6(50) = 300

b) Cutting: 56- 0.8(50) = 15 minutes. (40,0) (0,70) ………… (1)

Gluing: 13X50=650 650-650=0 (130,0) (0,50) …………… (2)

Finishing: 3X50=150 360-150=210 minutes. (30,0) (0,120) ………… (3)

X

20

40

60

80

10

B

120

A

140

C

X

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

D

20

4

60

10

80

14

12

16

Q8: The optimum solution X

1

=4.2 and X

2

=1.6

Minimum Z=2(4.2)+3(1.6) = 13.2

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

Industrial Engineering

(IE)

Dr. Khallel Ibrahim Mahmoud

University of Technology

Electro-mechanical Engineering Dept.

Lec.

N

o

(3)

Linear Programming

Model

Simplex Method

2011

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

Simplex Method

The linear programming situation with two decision variables

is easy tackled by a graphical method of solution. However

most practical linear programming problem contain more

than two decision variables. Graphic representation is

difficult (three dimensional) and requires more time for the

determination of an optimal solution. The solution method in

such cases is the simplex method. The simplex method is an

iterative procedure that consists of moving from one basic

feasible solution to another in such a way that the value of

the objective function does not decrease (in the

maximization problem). This process continue until an

optimal solution is reached, if one exist.

The steps required to solve the problem – maximizing

are:

Step 1

: Define the problem in standard form. This indicates

the construction of a linear programming model.

Step 2

: convert the inequalities into equation by insert slack

variables.

Step 3

: Construct a matrix of the coefficients of these

equations.

Step 4

: This step amends the previous feasible solution so

as to improve the profit.

The simplex method will be illustrated with the following

example.

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

Example

/ Consider the following LP:

Maximize Z= 6X

1

+8X

2

Subject to:

2X

1

+5X

2

≤ 40

8X

1

+4X

2

≤ 80

X

1

,X

2

≥ 0

Step 1

/ Conversion of inequalities into equations Add slack

variables to remove inequalities

2X

1

+5X

2

+S

1

= 40

8X

1

+4X

2

+ S

2

= 80

Where S

1

,S

2

slack variables (surplus) putting X

1

=0 and X

2

=0 we get

S

1

= 40 , S

2

= 80

Max Z =6X

1

+8X

2

+oS

1

+ oS

2

Subject to:

2X

1

+5X

2

+S

1

+ oS

2

= 40

8X

1

+4X

2

+ oS

1

+ S

2

= 80

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

Step 2/

Construct the simplex tableau. The standard form

can be summarized in a compact tableau form as:

Coefficient

of OF

variables

in basis

Basic

variables

Values of

basic

variables

Coefficient of OF

variables

(Cj)

( Cj)

(A)

(q)

6

X

1

8

X

2

0

S

1

0

S

2

0 S

1

40 2

5

1

0

0 S

2

80 8

4

0

1

Zj 0

0

0

0

0

Cj-Zj 6

8

0

0

Initial solution: X

1

= 0

X

2

= 0

S

1

= 40

S

2

= 80

Z = 0

Zj:

Zj (q) = 40(0) + 80(0) = 0

Zj (X

1

) = 2(0) + 8(0) = 0

Zj (X

2

) = 5(0) + 4(0) = 0

Zj (S

1

) = 1(0) + 0(0) = 0

Zj (S

2

) = 0(0) + 1(0) = 0

Cj – Zj :

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

(Cj – Zj) X

1

= 6-0 =6 , (Cj – Zj) S

1

= 0-0 =0

(Cj – Zj) X

2

= 8-0 =8 , (Cj – Zj) S

2

= 0

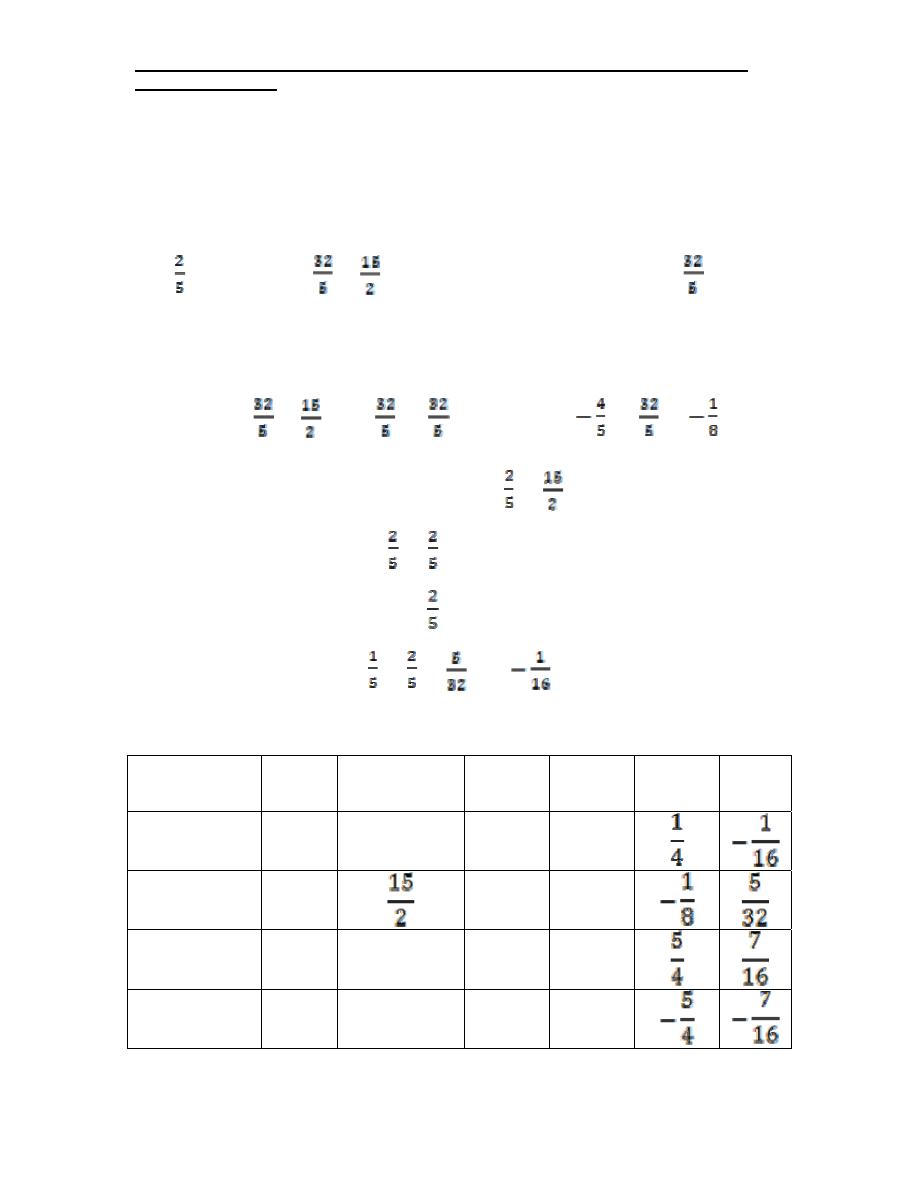

Step 3/

identify the pivot column

X

2

has max positive value (8) Thus the entering variable will

be X

2

in the new solution

Step 4/

identify the pivot row

,

, the smallest value = 8

Thus, S

1

, is the leaving variable. Replacing the leaving

variable S

1

with the entering variable X

2

produces the new

basic solution (X

2

, S

2

) and the pivot element = 5

Types:

1. Pivot row : new pivot row = current pivot row ÷ pivot

element

2. All other rows , including Z:

new row = (Current row) – (its pivot column

coefficient)X(new pivot row)

Type 1

: computation is divide the pivot row (S

1

– row) by the

pivot element (5) .Thus the new row:

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

Type 2

: Computation is applied to the remaining row (S

2

-

row) as follow:

80 – (4X8) = 48

8 – (4X 2/5) = 32/5

4- (4X1) = 0

0 – (4X1/5) = -4/5

1 – (4X0) = 1

The new tableau corresponding to the new basic solution

(X

2

,S

2

) thus becomes:

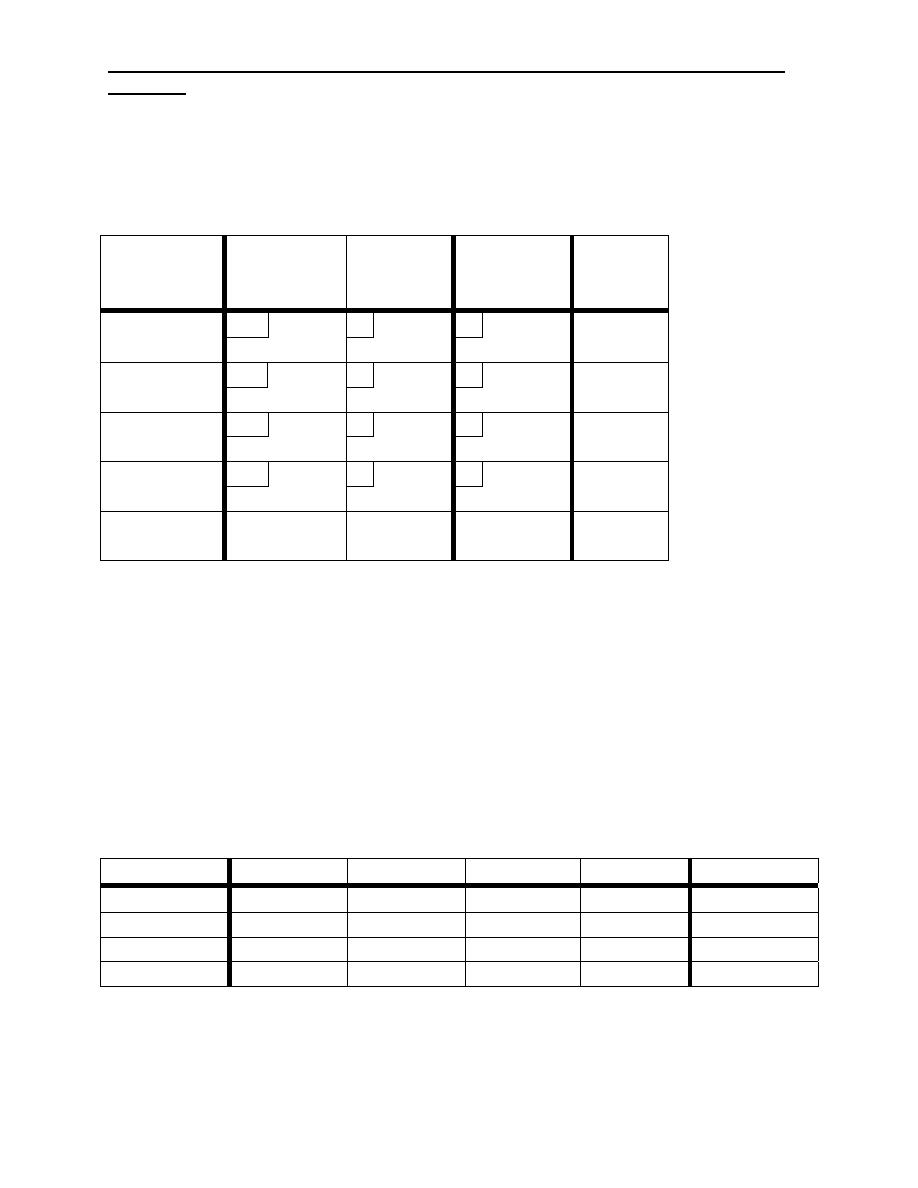

( Cj)

(A)

(q)

6

X

1

8

X

2

0

S

1

0

S

2

8 X

2

8

1

0

0 S

2

48

0

1

Zj

64

8

0

Cj-Zj

0

0

Observe that the new tableau yields the new basic solution

(X

2

=8 , S

2

= 48 ) with the new value of Z = 64 . An

examination of the last tableau shows that it is not optimal

solution because the variable X

1

has a positive coefficient in

the (Cj-Zj) row ( )

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

An increase in X

1

is advantageous because it will increase

the value of Z. Thus , X

1

is the entering variable.

Next, we determine the leaving variables as follow :

8 ÷ = 20 , 48 ÷ = , Thus the pivot element =

S

2

is the leaving variable , X

1

is the entering variable . and

the new pivot row :

48 ÷ = , ÷ = 1 , 0 ,

÷ =

new X

2

– row : 8- ( X )= 5

- ( X 1) = 0

1- ( X0 ) = 1

- ( X ) =

These Computations produce the following tableau:

( Cj)

(A)

(q)

6

X

1

8

X

2

0

S

1

0

S

2

8 X

2

5 0

1

6 S

2

1 0

Zj

85 6

8

Cj-Zj 0 0

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

Since none of the C

j

-Z

j

row coefficient associated with the

basic variables is positive , the last tableau is optimal.

The optimum solution can be read from the simplex tableau

in the following manner

Decision variables

Optimum value

X

1

15/2 = 7.5

X

2

5

Z 85

The M- Method ( Big – M)

In the previous example , starting the simplex iterations at a

basic feasible . For the LP

s

in which all the constraints are of

the (≤) type, the stacks offer a convenient starting basic

feasible solution. A natural question then arises : How can

we find a starting basic solution for models that involve (=)

and (≥) constraints?

The most common procedure for starting LP

s

that do not

have convenient slacks is to use artificial variables and the

closely related method is proposed for effecting this result :

the M-Method (Big- M).

The M-Method starts with the LP

in the standard form. For

any equation (i) that does not have a slack , we augment an

artificial variable (A

i

) and assign them a penalty in the

objective function to force them to zero level at a later

iteration of the simplex algorithm.

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

Given M is a sufficiently large positive value, the variable A

i

is penalized in the objective function using -MA

i

in the case

of maximization and +MA

i

in the case of minimization.

The following example provides the details of the method:

Min Z = 3X

1

+ 8X

2

Subj. to:

X

1

≤ 80, X

2

≥ 60 , X

1

+ X

2

= 200 , X

1

, X

2

≥ 0

Step1

/ for convenient inequalities into equalities:

X

1

+ S

1

= 80

X

2

- S

2

= 60

X

1

+ X

2

= 200

Putting X

1

, X

2

= 0 we get S

1

= 80 S

2

=- 60

Therefore, we introduce artificial variables and the above

constraints can be written as:

X

1

+ S

1

= 80

X

2

- S

2

+ A

1

= 60

X

1

+ X

2

+ A

2

= 200 A

1

, A

2

Artificial variables

Now addition of this artificial variable destroy the equality

required by the L.p model . Therefore, A

1

, A

2

must not

appear in the final solution . To achieve this it is assigned a

very large penalty (TM) since Z is to be minimized in the

objective function . Therefore we get:

X

1

+ S

1

+0S

2

+0A

1

+0A

2

= 80

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

X

2

+ 0S

1

-S

2

+A

1

+0A

2

= 60

X

1

+ X

2

+0S

1

+0S

2

+0A

1

+A

2

= 200

Min Z = 3X

1

+ 8X

2

+0S

1

+0S

2

+MA

1

+MA

2

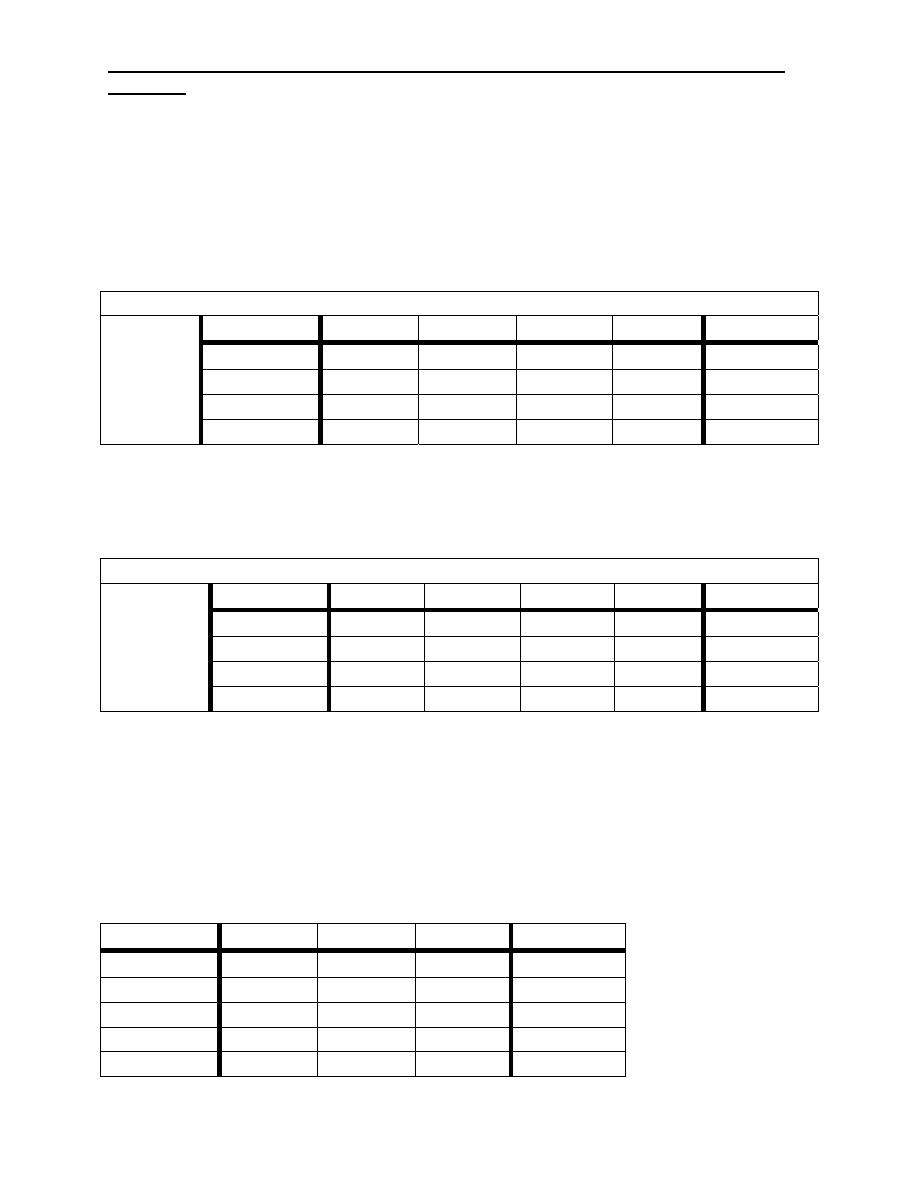

( Cj)

(A)

(q)

3

X

1

8

X

2

0

S

1

0

S

2

M

A

1

M

A

2

0 S

2

80 1 0 1

0

0

0

M A

1

60 0 1 0

-1

1

0

A

2

200 1 1 0 0

0

1

M Z

260M

M

2M

0

-M

M

M

Cj-

Zj

3-M

8-2M

0

M

0

0

Step 2

/ identify the pivot column:

This is done by selecting the none basic variable having the

largest negative value in Cj-Zj .

When all the elements in the Cj-Zj row are positive or zero

the optimal solution is reached .

Step3

/ identify the pivot row:

80/0 = 0 , 60/1 = 60 , 200/1 = 200

Pivot = 1 A

1

X

1

X

2

/ 60/1 , 0 , 1/1 , 0 , -1/1 , 1, 0

Row S

1

: will be remain , Row A

2

/200-(1X60) = 140

1- (1X0) = 1

1-( 1X1) = 0

0- (1X0) = 0

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

0-(1X-1) = 1

0-(1X1) = -1

1-(1X0) = 1

( Cj)

(A)

(q)

3

X

1

8

X

2

0

S

1

0

S

2

M

A

1

M

A

2

0 S

1

80 1 0 1

0

0

0

8 X

2

60 0 1 0

-1

1

0

M A

2

140 1 0 0 1

-1

1

Zj

480+

140M

M 8 0

M-8

8-M

M

Cj-

Zj

3-M

0 0

8-M

2M-

8

0

As Cj-Zj is positive under same column the current basic

feasible solution is not optimal and needs to be improved .

Step4

/ Identify the pivot row after identify the pivot column

80/1 = 80 , 1 , 0 , 1 , 0 , 0 , 0

Row X

2

will remain

Row A

2

: 140 – (1X80) = 60

1- (1X1) = 0

0 – (1X0) = 0

0 – (1X1) = -1

1 – (1X0) = 1

-1 – (1X0) = -1

1 – (1X0) = 1

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

Step5

/ create the new tableau

( Cj)

(A)

(q)

3

X

1

8

X

2

0

S

1

0

S

2

M

A

1

M

A

2

3 X

1

80 1 0 1

0

0

0

8 X

2

60 0 1 0

-1

1

0

M A

2

60 0 0

-1

1

-1

1

Zj

720+

60M

3 8

3-M

M-8

8-M

M

Cj-

Zj

0

0

M-3

8-M

2M-

8

0

As Cj-Zj is positive under same column the current solution

is not optimal and need to improve.

Step6

/ identify the pivot column , and pivot row.

80/0 , 60/-1 , 60/1 = 60 A

2

S

1

S

2

: 60 , 0 , 0 , -1 , 1 , -1 , 1

Row X

1

: will be remain

Row X

2

:60- (-1X60) = 120

0- (-1X0) = 0

1- ( -1X0) = 1

0- (-1X-1) = -1

-1 – (-1X1) = 0

1- (-1X-1) = 0

Industrial Engineering (IE) - Dr. Khallel

Ibrahim Mahmoud

0 – (-1X1) = 1

( Cj)

(A)

(q)

3

X

1

8

X

2

0

S

1

0

S

2

M

A

1

M

A

2

3 X

1

80 1 0 1

0

0

0

8 X

2

120 0 1 -1

0

0

1

0 S

2

60 0 0

-1

1

-1

1

Zj

1200

3

8

-5

0

0

8

Cj-

Zj

0

0

5

0

M

M-

8

As Cj-Zj is either positive or zero under all column, the

solution is an optimal solution.

X

1

= 80 , X

2

= 120 , S

2

= 60 , Z= 1200

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Industrial Engineering (IE)

Dr. Khallel Ibrahim Mahmoud

University of Technology

Electro-mechanical Engineering Dept.

Lec.N

o(4)

The Dual Model

The assignment model

2011

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

The dual Problem

The LP model we develop for a situation is referred to as the primal problem. The

dual problem is a close relates mathematical definition that can be derived directly

from the primal problem.

Consider a linear programming problem concerned with the maximization of an

objective function Z with n decision variables and M constraints (primal). The dual

this problem is concerned with minimization of the value of the objective function

Ź with M decision variables and n constraints. Thus a maximization problem

becomes minimization in the dual and vice verse.

In the mathematical form the primal can be stated as:

Max Z= C

1

X

1

+ C

2

X

2

+ ………. +C

n

X

n

Subject to:

a

11

x

1

+a

12

x

2

+ ……………….. + a

1n

x

n

≤ b

1

a

21

x

1

+a

22

x

2

+ ……………….. + a

2n

x

n

≤ b

2

a

m1

x

1

+a

m2

x

2

+ ……………….. + a

mn

x

n

≤ b

m

X

1

≥ 0 X

2

≥ 0 ………… X

n

≥ 0

The dual of this problem may be expressed in the following form:

Min Ź= b

1

y

1

+ b

2

y

2

+ ………. +b

m

y

m

Subject to:

a

11

y

1

+a

12

y

2

+ ……………….. + a

m1

y

n

≥ c

1

a

12

y

1

+a

22

y

2

+ ……………….. + a

m2

y

m

≥ c

2

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

a

1m

y

1

+a

2n

y

2

+ ……………….. + a

mn

y

m

≥c

n

y

1

≥ 0 y

2

≥ 0 ………… y

m

≥ 0

the variables and constraints of the dual problem can be constructed symmetrically

from the primal problem as follows:

1- A dual variable is defined for each of the m primal constraint equations.

2- A dual constraint is defined for each primal of the n primal variables.

3- The left-hand-side coefficients of the dual constraint equal the constraint

(column) coefficient of the associated primal variable. Its right – hand side

equals the objective coefficient of the same primal variable.

4- The objective coefficient of the dual equal the right- hand side of the primal

constraint equations.

The following examples demonstrate the implementation of these rules.

Ex/ Consider the primal model:

Max Z =6X

1

+ 8X

2

St.to: 2X

1

+5X

2

≤40

8X

1

+4X

2

≤80

X

1 ,

X

2

≥ 0

The dual of this problem as:

Min Ź = 40Y

1

+80Y

2

St. to: 2Y

1

+8Y

2

≥6

5Y

1

+4Y

2

≥8

Y

1

, Y

2

≥ 0

The solution of the dual problem can be obtained by using simplex minimization

procedures.

Min Z = 40 Y

1

+80 Y

2

+oS

1

+oS

2

+MA

1

+MA

2

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Subject to: 2y

1

+8y

2

- s

1

+A

1

= 6

5y

1

+ 4y

2

- s

2

+ A

2

= 8

40 80 0 0 M M

C

j

A q

Y

1

Y

2

S

1

S

2

A

1

A

2

M A

1

6 2 8 -1 0 1 0

M A

2

8 5 4 0 -1 0 1

Z

j

14M 7M 12M -M -M M

M

C

j

-Z

j

40-7M

80-12M

M M 0

0

80 Y

2

¾ ¼ 1 -1/8 0 1/8 0

M A

2

5 4 0 ½ -1

-1/2 1

Z

j

60+5M 20+4M

80

1/2M-10

-M 10-1/2M

M

C

j

-Z

j

20-4M 0 10-1/2M

M

1/2M-10 0

80 Y

2

7/16 0 1 -5/32

1/16

5/32 -1/16

40 Y

1

5/4 1 0 1/8

-1/4

-1/8 1/4

Z

j

85 40 80 -7.5 -5 7.5 5

C

j

-Z

j

0 0 7.5

5

M-7.5

M-5

ﺣﻞ اﻟﻨﻤﻮذج اﻷوﻟﻲ

)

primal

(

آﺎن آﻤﺎ ﻳﻠﻲ

:

6 8 0 0

C

j

A q

X

1

X

2

S

1

S

2

8 X

2

5 0 1 ¼ -1/16

6 X

1

7.5

1 0 -1/8

5/32

Z

j

85 6 8 5/4

7/16

C

j

-Z

j

0 0 -5/4

-7/16

Dual Primal

S

1

= 7.5

X

1

= 7.5

S

2

= 5

X

2

= 5

Y

1

= 5/4

S

1

= 5/4

Y

2

= 7/16

S

2

= 7/16

Ź = 85

Z = 85

Ex1/ Obtain the dual of the following LP:

Max Z =5X

1

+ 10X

2

+8X

3

St.to: 3X

1

+ 5X

2

+2X

3

≤60

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

4X

1

+ 4X

2

+4X

3

≤72

2X

1

+ 4X

2

+5X

3

≤100

X

1 ,

X

2

,X

3

≥ 0

Solution: Min Ź = 60Y

1

+72Y

2

+100Y

3

St. to: 3Y

1

+4Y

2

+2Y

3

≥5

5Y

1

+4Y

2

+4Y

3

≥10

2Y

1

+4Y

2

+5Y

3

≥8

Y

1

, Y

2

, Y

3

≥ 0

Ex2/ Consider the following LP and write the associated dual problem:

Max Z =7X

1

+ 5X

2

St.to: 3X

1

+X

2

≤48

2X

1

+X

2

≤40

X

1 ,

X

2

≥ 0

Min Ź = 48Y

1

+40Y

2

St. to: 3Y

1

+2Y

2

≥7

Y

1

+Y

2

≥5

Y

1

, Y

2

≥ 0

Ex3/ Write the dual for each of the following primal problem:

Max Z =10X

1

+ 12X

2

St.to: X

1

+X

2

≥15

X

1

= 6

X

2

≤ 8

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Solution: X

1

+X

2

≥15

X

1

≤ 6 -X

1

≥ -6

X

1

≥6

X

2

≤ 8 -X

2

≥-8

Min Z = 10X

1

+ 12X

2

Sub. To: X

1

+X

2

≥15

X

1

≥6

-X

1

≥ -6

-X

2

≥-8

X

1 ,

X

2

≥ 0

Thus, the dual : Max Ź = 15Y

1

+6Y

2

-6Y

3

- 8Y

4

St. to: 3Y

1

+4Y

2

+2Y

3

≥5

Y

1

+Y

2

-Y

3

≤10

Y

1

-Y

4

≤12

Problems

Write the dual for each of the following problems:

1) Min Z = 10X

1

+ 16X

2

Sub. To: X

1

+X

2

=100

X

1

≤800

X

2

≥400

2) Min Z = 3X

1

+ 8X

2

Sub. To: X

1

+X

2

=200

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

X

1

≤80

X

2

≥60

3) Max Z = 23X

1

+ 32X

2

Sub. To: 10X

1

+6X

2

≤2500

5X

1

+10X

2

≤2000

X

1

+2X

2

≤500

4) Write the primal problem for the following:

Min Ź = 60Y

1

+72Y

2

+100Y

3

St. to: 3Y

1

+4Y

2

+2Y

3

≥5

5Y

1

+4Y

2

+4Y

3

≥10

2Y

1

+4Y

2

+5Y

3

≥8

Y

1

, Y

2

, Y

3

≥ 0

The assignment model

Suppose a company has M jobs that must be completed and it has at least n

workers who can perform any of the M jobs but possibly in a different amount of

time. Which worker should be assigned to each job to minimize the overall time to

complete all M jobs, if each worker is assigned to one and only one job. This is the

classical assignment problem.

The general assignment model with n workers and M jobs is represented in the

following matrix:

jobs

1 2 M b

j

1

2

n

C

11

C

21

C

n1

C

12

C

22

C

n2

C

1m

C

2m

C

nm

1

1

1

workers

ai 1 1 1

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

The element C

ij

represents the cost of assigning worker i to job j (i= 1,2,…..,n)

(j= 1,1,…..,m).

If we let:

X

ij

= 0 if worker i is not assigned to job j

1 if worker i is assigned to job j

C

ij

= efficiency associated with assigning worker i to job j.

Then mathematically the assignment problem can be stated as:

Minimize (maximize): Z=

ij

X

ij

Subject to:

for j= 1,2,………, m

for i= 1,2,………, n

X

ij

= 0 or 1 for al i and j

The following is a step by step algorithm that uses the Hungarian method to solve

the general assignment problem.

Step 1: for the original cost matrix, identify each row’s minimum, and subtract it

from all the entries of the row.

Step 2: For the matrix resulting from step 1, identify each column’s minimum, and

subtract it from all the entries of the column.

Step 3: Draw the minimum number of horizontal and vertical lines in the last

reduced matrix that will cover all the zero entries. If the number is equal the

columns or rows the feasible assignment can be found, otherwise go to step 4.

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Step 4: Select the smallest uncover element, and subtract it from every uncovered

element, then add it to every element at the intersection of two lines. And repeat

step 3 until the feasible assignment found.

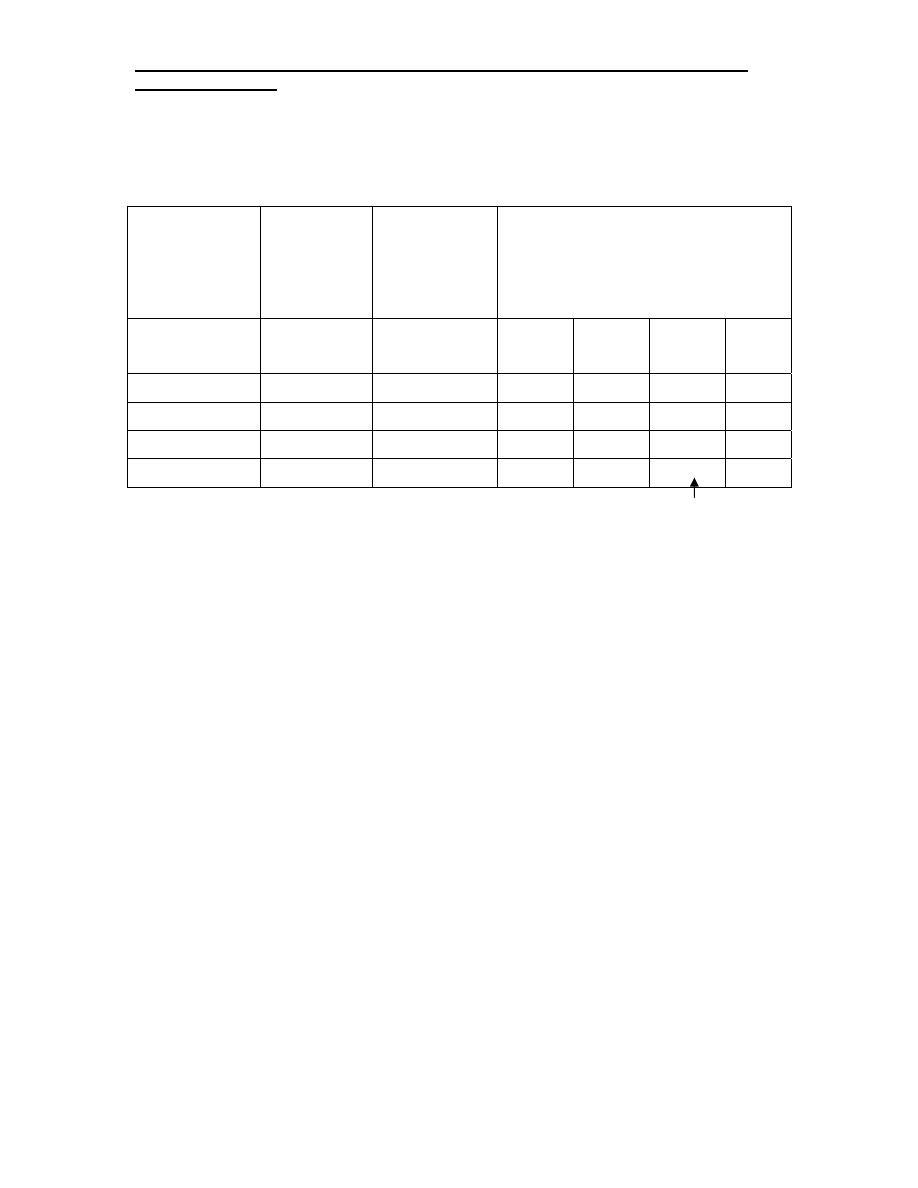

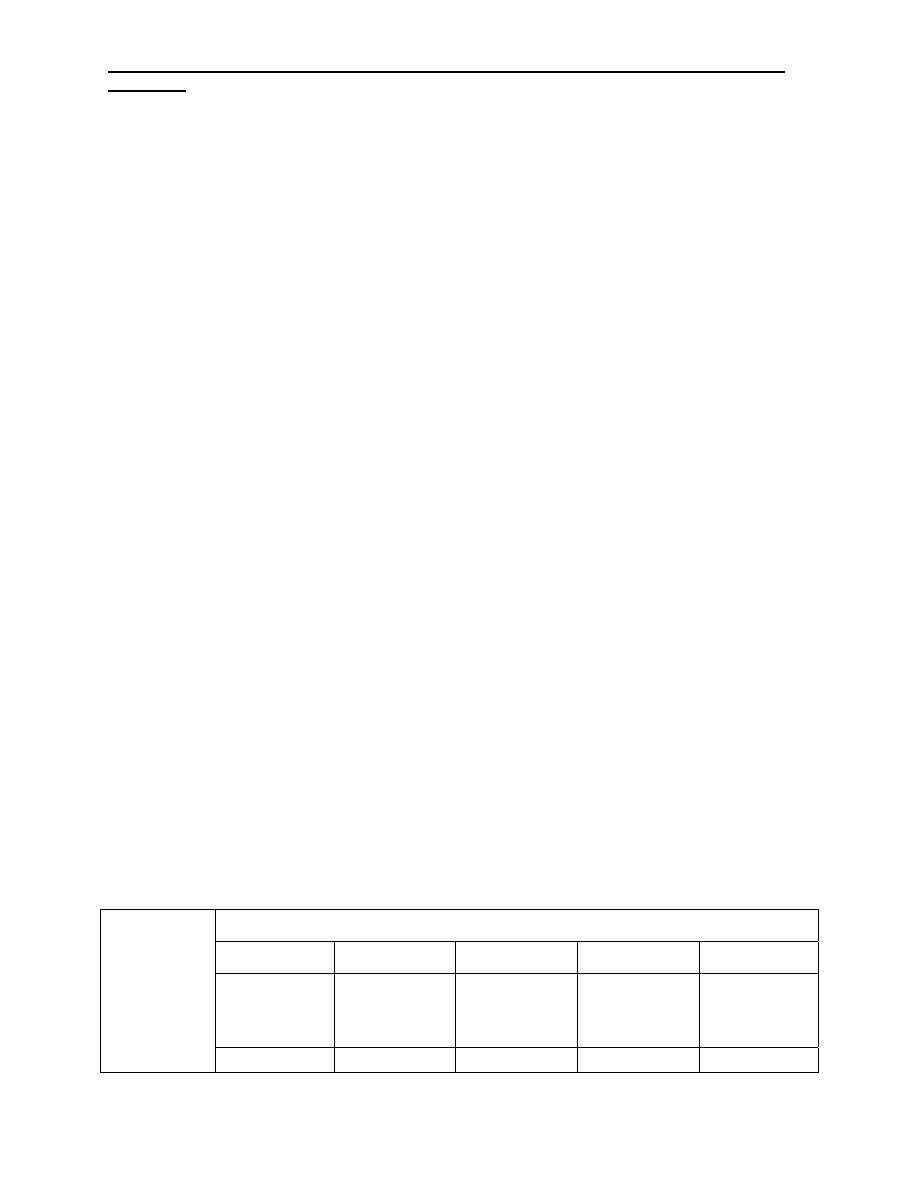

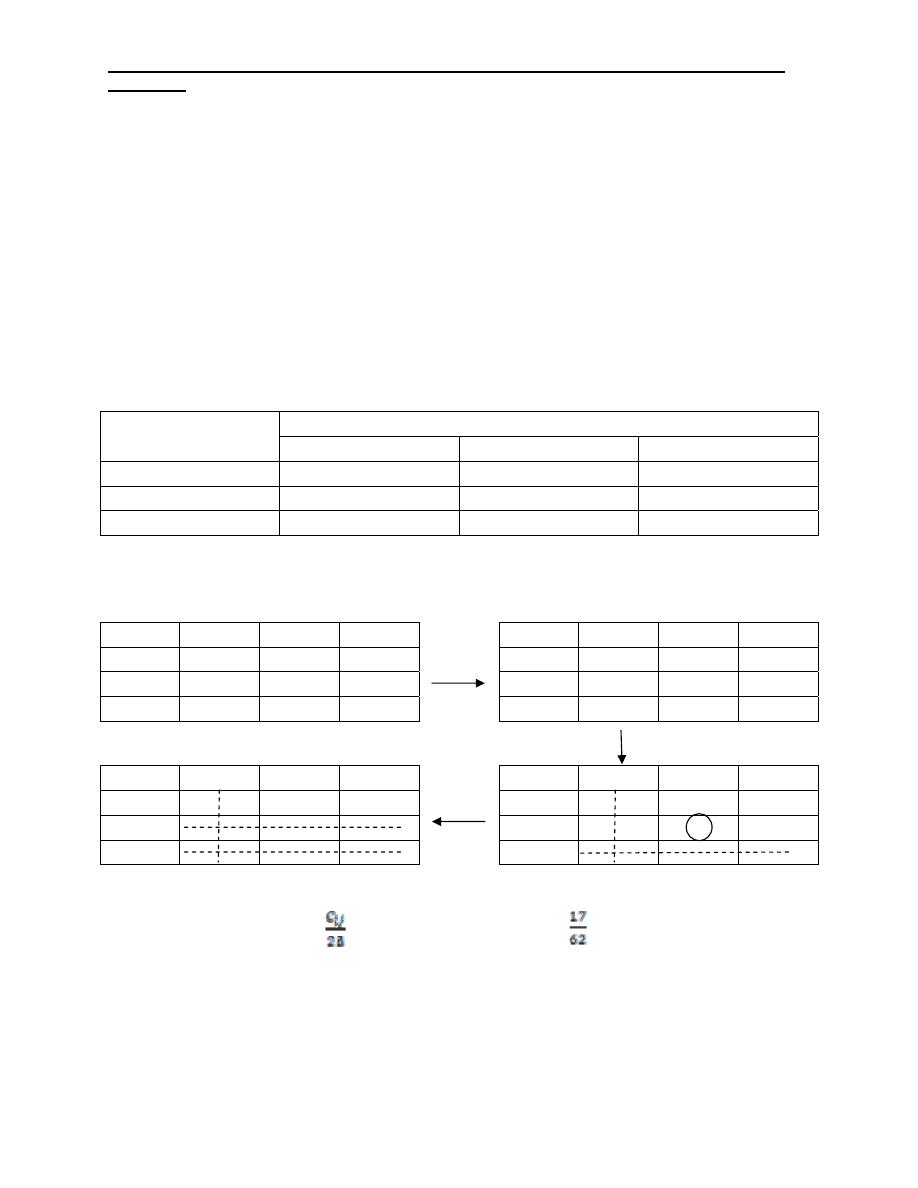

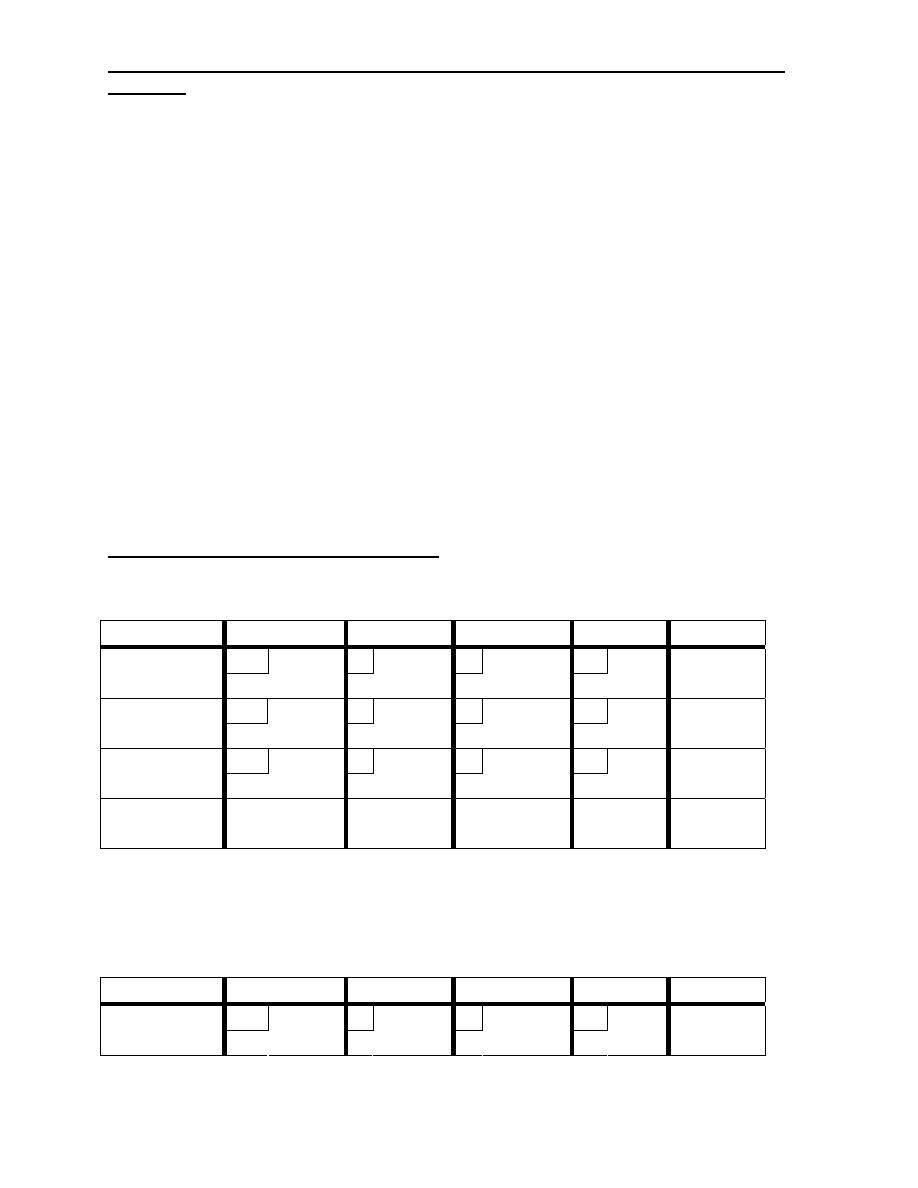

For example, suppose that three jobs must be assigned to three machines, each

machine must be assigned to only one job, and each job must be assigned to only

one machine.

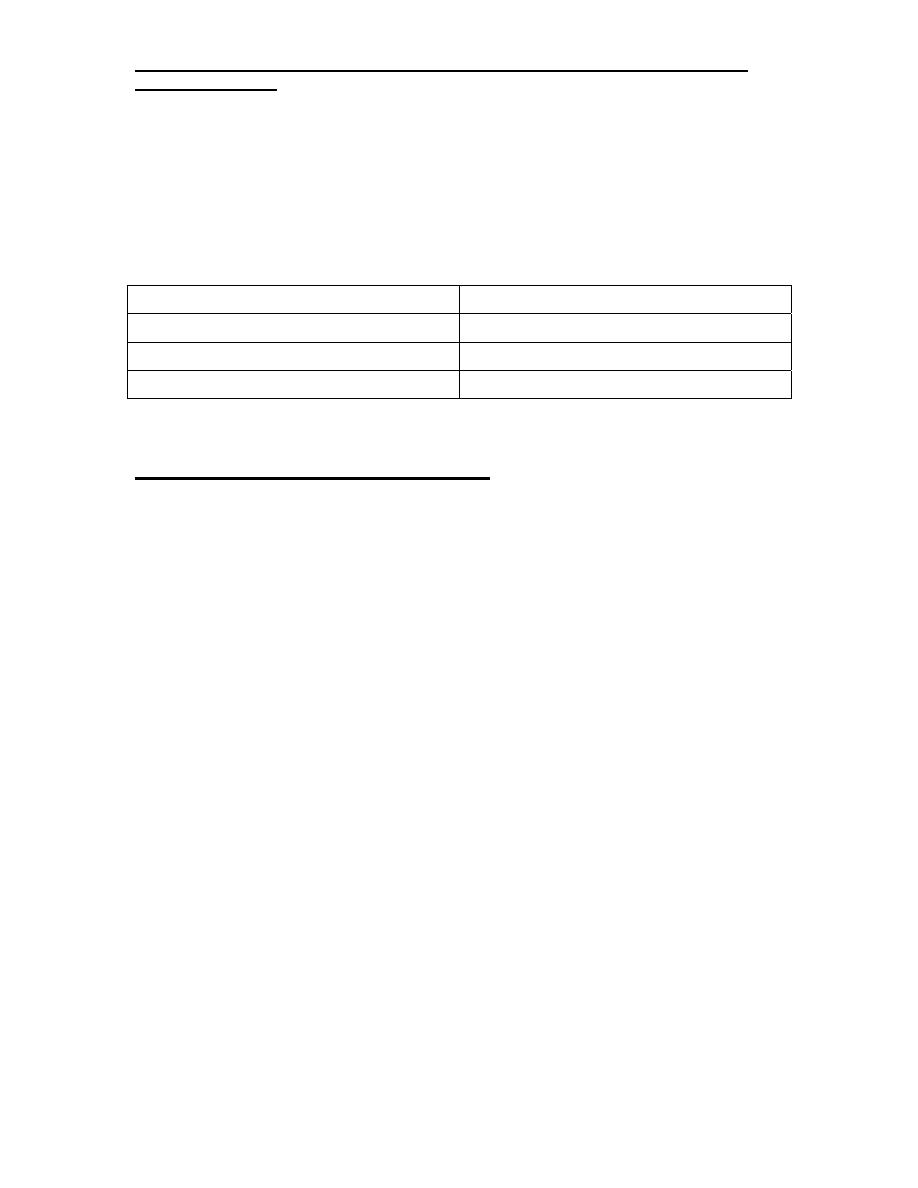

The costs are shown below. Solve the problem by using the Hungarian algorithm.

Machines

Jobs

M1 M2 M3

A 25 31 35

B 15 20 24

C 22 19 17

Solution:

M1

M2

M3

M1

M2

M3

A 10 12 18

A 0 2 8

B 0 1 7

B 0 1 7

C 7 0 0

C 7 0 0

M1

M2

M3

M1

M2

M3

A 0 1 7

A 0 2 8

B 0 0 6

B 0

1 7

C 8 0 0

C 7 0 0

The assignment A-M

1

, B-M

2

20 , C-M

3

Min Z = 62

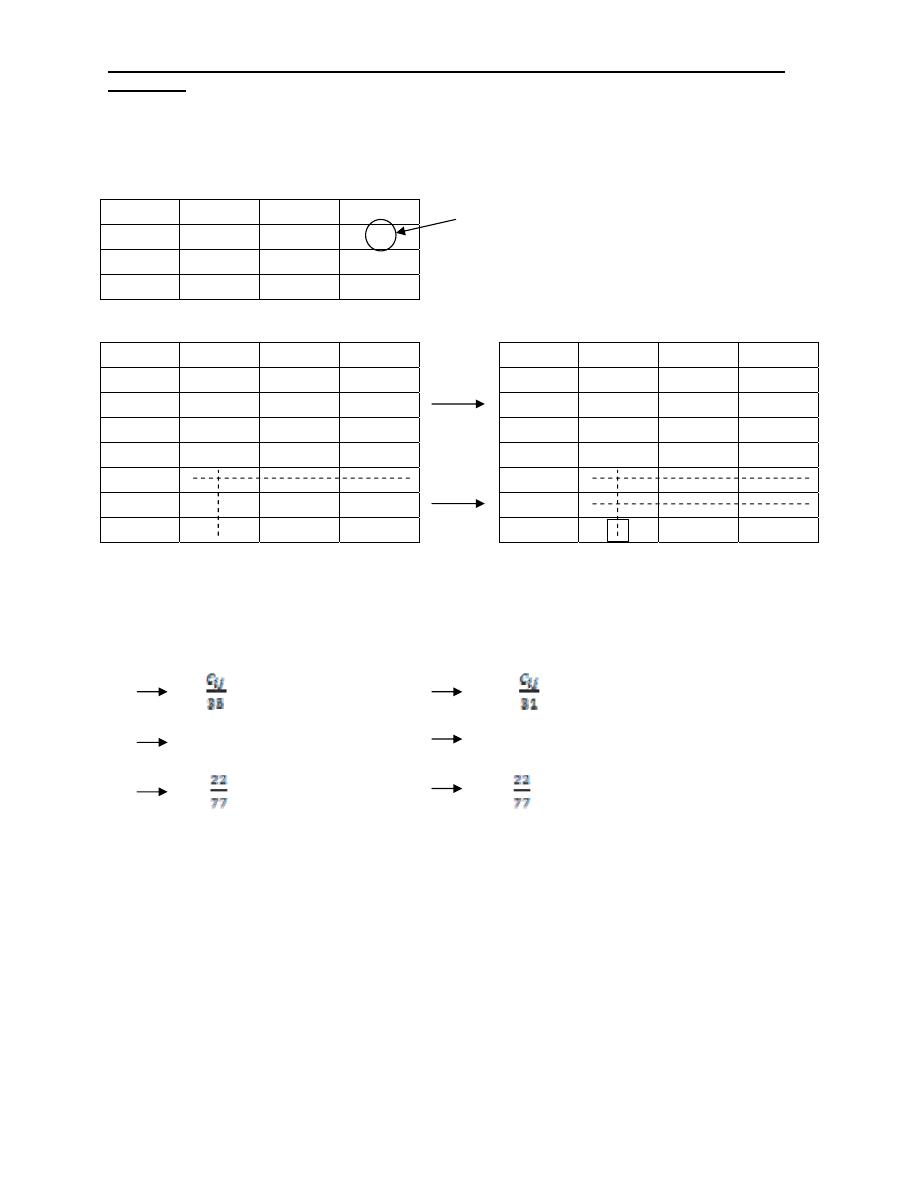

Maximization case:

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Use the Hungarian method to solve the same problem for the maximum

productivity.

Job

M1

M2

M3

A

25

31

35

B 15 20 24

C 22 19 0

M1

M2

M3

M1

M2

M3

A 10 4 0

A 0 0 0

B 20 15 11

B 10 11 11

C 13 16 18

C 3 12 18

M1

M2

M3

M1

M2

M3

A 0 0 0

A 1 0 0

B 0 1 1

B 0 0 0

C 0 9 15

C 0 8 14

C

ij:

No. of units produced per hour

Max C

ij

= 35

The final assignment :( two solution)

First Second

A M

3

A M

2

B M

2

20 B M

3

24

C M

1

C M

1

Unbalanced cases

If M≠N When M > N added dummy column with C

ij

= 0

Max or Min When M < N added dummy row with C

ij

= 0

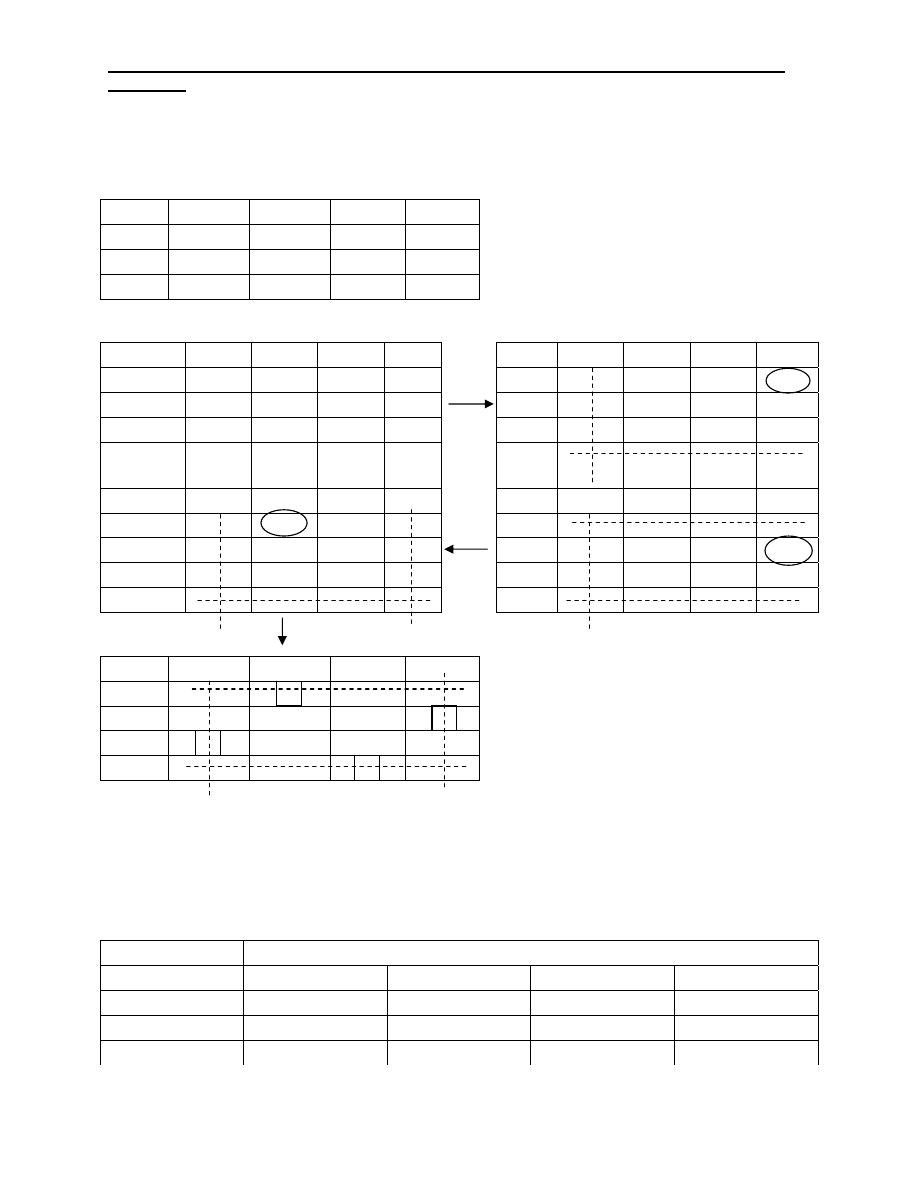

Example 1:

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Use the Hungarian algorithm to solve the assignment problem having the following

time table.

Solution:

Job M1 M2 M3 M4

J1 80 110 120

100

J2 50 160 130 80

J3 50 100 230

150

M1 M2 M3 M4

M1 M2 M3 M4

J1 80

110

120

100

J1 0 30 40

20

J2 50

160

130

80

J2 0 110

80

30

J3 50

100

230

150

J3 0 50

180

100

Dummy

J4

0 0 0

0

J4 0 0 0 0

M1 M2 M3 M4

M1 M2 M3 M4

J1 10 10 20 0

J1 0 10 20 0

J2 0 80

50

0

J2

0 90

60

10

J3 0 20

150

70

J3

0 30

160

80

J4

30

0

0

0

J4 20 0 0 0

M1 M2

M3

M4

J1 0 0 10

0

J2 0 70 40 0

J3 0 10 140

70

J4 40 0 0 10

The optimal assignment:

J1 – M2 110

J2 – M4 80

J3 – M1 50

J4 – M3 0

_________

240

Note: M<N

So we added dummy row with

C

ij

= 0

Example 2: Use the Hungarian algorithm to solve the following assignment

problem for the total maximum productivity.

Machines

Task M1 M2 M3 M4

T1 20 60 50 55

T2 60 30 80 75

T3 80 100 90 80

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

T4 65 80 75 70

T5 70 65 60 65

Example 3/ suppose four people can each perform any one of four different jobs

but possibly in different amount of time. The following table gives the

corresponding time to perform the various jobs. Which person should be assigned

to each job to minimize the total time to perform all four jobs?

Time to perform jobs

Person

1 2 3 4

A 2 10 9 7

B 15 4 14 8

C 13 14 16 11

D 4 15 13 9

Solution:

Ex 2: first solution, Cij

320

____

T5 – M1 70

T4 – M3 75

T3 – M2 100

Second solution, Cij

T1 – M5 0

T2 – M4 75

T1 – M5 0

T2 – M3 80

T3 – M2 100

T4 – M4 70

T5 – M1 70

____

320

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Industrial Engineering (IE)

Dr. Khallel Ibrahim Mahmoud

University of Technology

Electro-mechanical Engineering Dept.

Transportation Model

Lec.N

o(5)

2011

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Transportation Model

Introduction

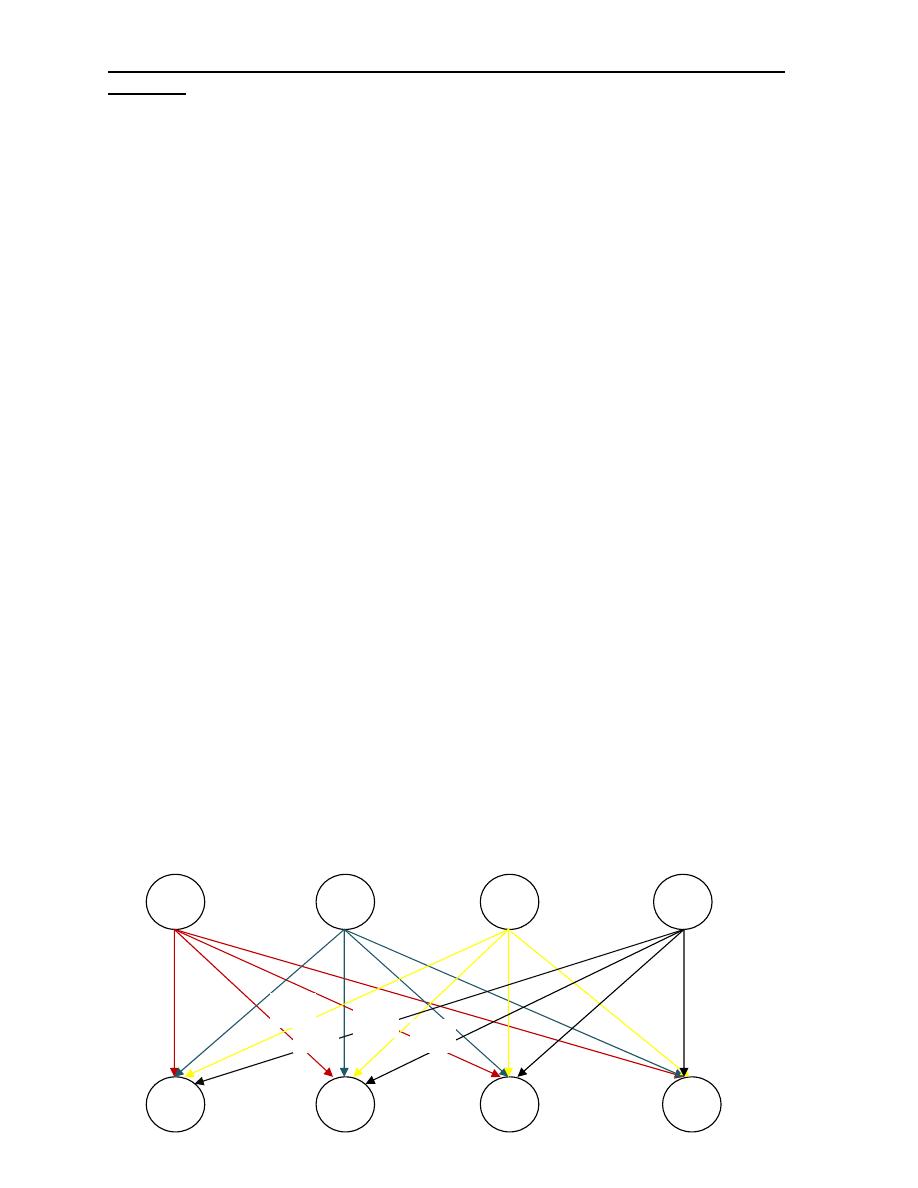

The transportation model is a special class of the linear programming problem. It

deals with the solution in which an item is shipped from sources (e.g. factories) to

destinations (e.g. warehouses). The objective is to determine the amounts shipped

from each source to each destination that minimize the total shipping cost while

satisfying both the supply limits and the demand requirements.

The Mathematical Model

The general problem can be presented by the network.

-

There are M sources. S

1

,S

2

…………..S

m

-

And n destinations. D

1

,D

2

…………..D

n

-

The arcs linking the sources and destinations represent the routes between

the sources and the destinations.

-

The transportations cost per unit = C

ij

and the amount shipped = X

ij

-

The amount of supply at source i is ai and the amount of demand at

destination j is bj.

The objective of the model is to determine the unknown X

ij

that will minimize the

total transportation cost, while satisfying all the supply and demand restrictions.

a

1

a

2

a

i

Units of supply

a

m

S

1

S

2

S

i

S

Sources

D

D

D

j

x

m

x

13

c

m

c

13

c

12

x

12

x

11

D

c

11

Destination

b

1

b

2

b

j

b

n

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

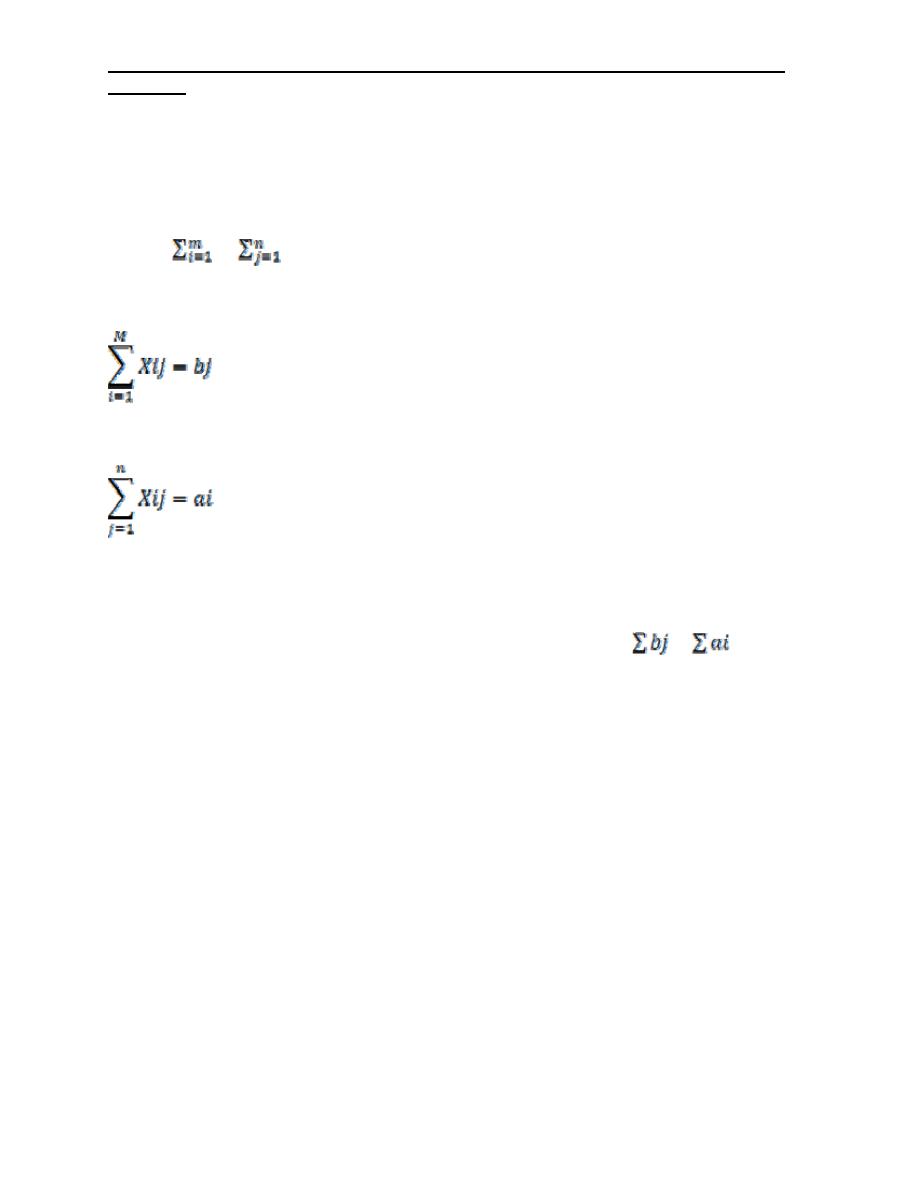

Objective Function:

Min Z:

C

ij

X

ij

Units of demand

Subject to:

j = 1,2,………………n

i = 1,2,………………m

1)

Determination of the starting

solution. The transportation model is always balanced (

=

) i.e. the

sum of supply= the sum of the demand. Thus, the model has Mth-1 basis

variables.

The special structure of the transportation problem allows securing a nonartificial

starting basic solution using one of three methods:

a-

North-west- corner method.

(N.W.C)

b-

Least-cost method. (L.C.M)

c-

Vogal method.

A)

N.W.C. method:

The method starts at the North West – corner cell of the tableau (variable X

11

).

Step 1: Allocate as much as possible to the select cell, and adjust the associated

amounts of supply and demand by subtracting the allocated amount.

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

Step 2: Cross out the row or column with zero supply or demand to indicate that no

further assignments can be made in that row or column. If both the row and

column net to zero simultaneously, cross out one only, and leave a zero supply

(demand) in the uncrossed-out row (column).

Step3: If exactly one row or column is left uncrossed-out, stop. Otherwise, move to

the cell to the right if a column has just been crossed or the one below if a row has

been crossed out. Go to step1.

Example1:

In the following transportation problem use the north west- corner method

(N.W.C) to find the starting solution.

S/D D

1

D

2

D

3

Supply

S

1

5 3 10

150

S

2

3 9 8 70

S

3

11 10 7 80

S

4

6 13 6 40

Demand 160 120

60 340/340

Solution:

S/D D

1

D

2

D

3

ai

5 3 10

S

1

150

150

3 9 8

S

2

10

60

70

11 10

7

S

3

60

20

80

6 13 6

S

4

40

40

bj 160 120

60 340/340

Z= 5X150 + 3X10 + 9X60 + 10X60 +7X20 + 6X40

= 2300 M+N-1=6

B)

Least-Cost method:

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

The Least-cost method finds a better starting solution by concentrating on the

cheapest routes. Instead of starting with the North West cell, we start by assigning

as much as possible to cell with the smallest unit cost (ties are broken arbitrary).

We then cross out the satisfied row or column, and adjust the amounts of supply

and demand accordingly. If both a row and a column are satisfied simultaneously,

only one is crossed out. Next, we always look for the uncrossed-out cell with the

smallest unit cost and repeat the process until we are left at the end with exactly

one uncrossed out row or column.

Example 2: the least -cost is applied to example (1)

S/D D

1

D

2

D

3

ai

5 3 10

S

1

30

120

150

3 9 8

S

2

70

70

11 10 7

S

3

20

60

80

6 13 6

S

4

40

40

bj 160 120

60 340/340

Z= 5X30 + 3X120 + 3X70 + 11X20 + 7X60 + 6X40

= 1600

C)

Vogal Method

Vogal method is an improved of version of the least cost method that generally

produces better starting solutions.

Step 1: For each row (each column) determine a penalty measure by subtracting

the smallest unit cost element in the row (column) from the next smallest unit cost

element in the same row (column).

Step 2: Identify the row or column with the largest penalty. Break ties arbitrarily.

Allocate as much as possible to the variable with the least unit cost in the selected

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

row or column. Adjust the supply and demand and cross out the satisfied row or

column.

Step 3: a) If exactly one row or column with supply or demand remains uncrossed

out, stop.

b) If one row or column with positive supply (demand) remains uncrossed out,

determine the basic variables in the row (column) by the least-cost method, stop.

c) If all the uncrossed out rows and columns have (remaining) zero supply and

demand, determine the zero basic variables by the least-cost method.

d) Otherwise, go to step 1.

Example 3: Solve the transportation model of example (1) by using vogal method.

S/D D

1

D

2

D

3

ai V

1

V

2

V

3

V

4

V

5

V

6

5

3

10

S

1

30

120

150

2

5

3

9

8

S

2

70

70

5

5

5

11

10

7

S

3

20

60

80 3 4 4 4

4

6

13

6

S

4

40

40 0 0 0 0 0

bj 160 120

60 340/340

V

1

2

6

1

V

2

2 1

V

3

3 1

V

4

5

V

5

Z= 5X30 + 3X120 + 3X70 + 11X20 + 7X60 + 6X40

= 1600

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

This solution happens to have the same objective value (1600) as in the Least-cost

method (L.C). usually, however vogal method is expected to produce better

starting solutions for the transportation method.

Stepping Stone Method (S.S)

After determining the starting ( using any of the three methods) we use one of the

following method :

1.

Stepping stone method.

2.

Modified distribution method.

So to solve a transportation problem, we first find an initial solution ( values of X

ij

)

and then improve the initial solution by reducing the cost through successive

iterations until the minimum cost solution is found.

Example:

S/D D

1

D

2

ai

6 3

S

1

70

8 7

S

2

100

bj 90 80

170/170

By using the N.W.C

S/D D

1

D

2

ai

6 3

S

1

70

70

8 7

S

2

20

80

100

bj 90 80

170/170

Z= 60X70 + 8X20 + 7X80

80

+

6 -

70

S

1

D

= 1140

Industrial Engineering (IE) - Dr. Khallel Ibrahim

Mahmoud

S/D D

1