Mixing and packing of acrylic dough

Separating MediaSeparating Media Is Applied To The Dewaxed Mold Space Prior To Packing The Acrylic Resin

Objectives:

Prevent Water From Mold Entering Into Resin Which May Affect The Rate Of Polymerisation.

Prevent Monomer Penetrating Into Mold Material , causing Plaster To Adhere To The Resin And Producing A Rough Surface.

Packing the mold with acrylic resin: Acrylic resin is a resinous plastic material of various esters of acrylic acid. It is used as a denture base material.It is formed of a powder and liquid. *Powder: is polymethyl methacrylate (polymer) + Benzoyl peroxide (initiator) +pigments.*Liquid: is methyl methacrylate (monomer) + hydroquinone (inhibitor) Powder and liquid are mixed in A ratio of 3 to 1 by volume for an average sized dentureAcrylic resin (polymethyl methacrylate) is the material of choice for complete denture construction for its desirable qualities:- Good esthetics- Cheap- Easy to process

Heat cured acrylic resin

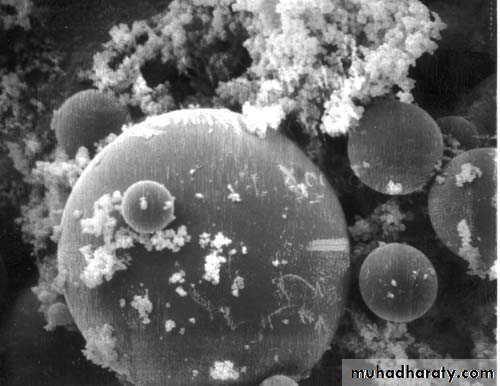

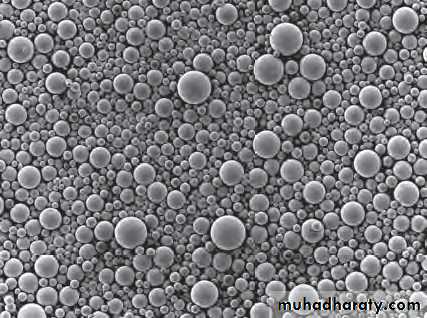

Powder ( can have limitless life)Beads or granules of polymethyl methacrylate

Initiator (benzoyl peroxide)

Pigments/dyes (colour vitality as cadmium, iron, organic dyes)

Optical opacifiers (tio2/zno)

Plasticizers (ethyl acrylate (internal), dibutylphthalate (external) to make dough easier)

Synthetic fibres (nylon)

Coloured fibres (blood vessels)

Liquid ( in dark bottle, avoid contamination by

powder)

Methyl methacrylate monomer

Inhibitor (hydroquinone)

Crosslinking agent

(diethylene glycol dimethacrylate, (1,4 butylene glycol dimethacrylate)

Bead Polymer

Packing procedure for acrylic resin:

• 1. Make sure that the hands and all mixing equipments are clean. Acrylic resin can become contaminated easily by foreign body that may change the color of the material and its physical properties.• 2. Mixing the acrylic resin:

•

On mixing the polymer and monomer the mix passes through 4 stages:

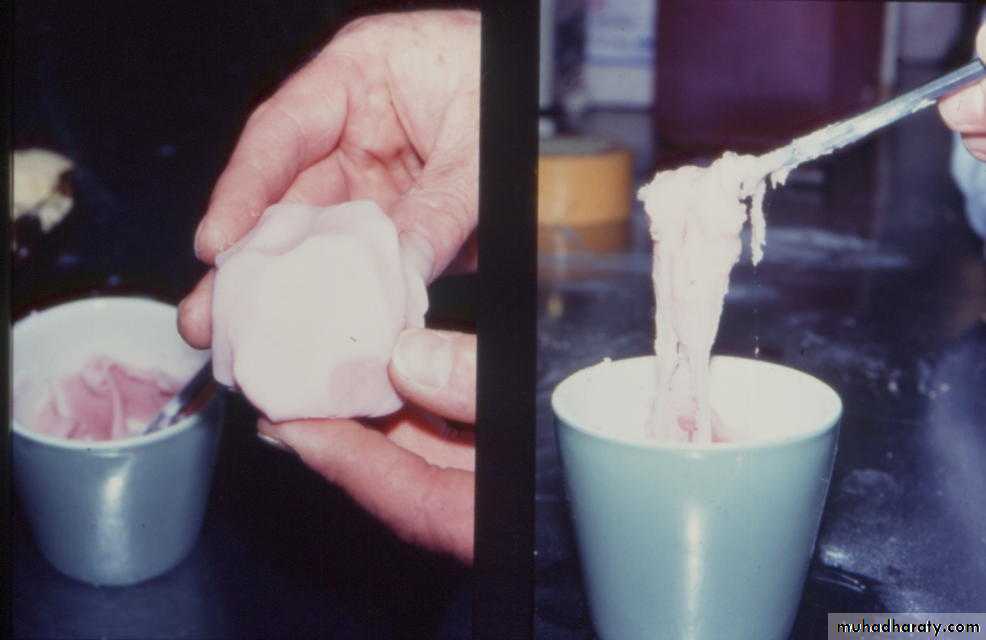

• A sandy stage : where a fluid mass occur due to the settling of the polymer into the monomer.• A stringy stage: where the monomer starts to attack the polymer. In this stage the mix is tacky, sticky and adheres to the sides of the mixing jar.

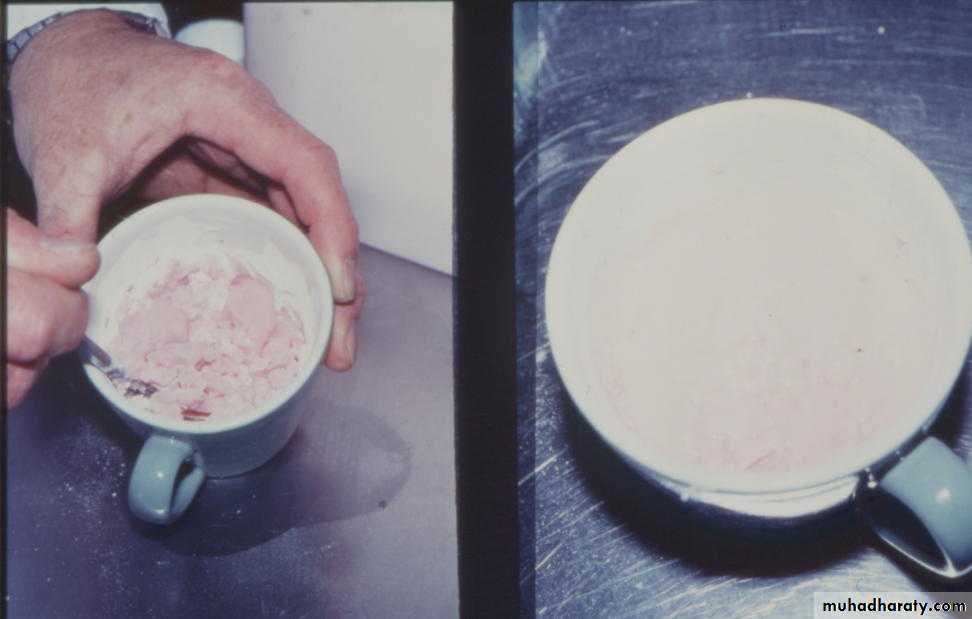

Smooth dough like stage: where the monomer diffuses into the polymer. Here, the material is more cohesive and has lost much of its ‘tackiness’. It can be moulded like plasticine and does not adhere to the sides of the mixing vessel.

• The time to reach stage 3 (dough forming time) depends on:

• 1. Solubility of the polymer into the monomer

• 2. Size of the polymer particles. The smaller the size the shorter the time.

• Rubber like stage: further penetration of the monomer into the polymer. In this stage the acrylic resin cannot be packed or molded being too stiff.

The time taken to reach the dough stage is called the doughing time whilst the time for which the material remains at the dough stage and is mouldable is termed the working time.

The transitions from ‘sandy’ to ‘stringy’ to ‘dough’ and eventually rubbery and hard stages are due to physical changes occurring within the mix. Smaller polymer beads dissolve in monomer causing a gradual increase in viscosity of the liquid phase. Larger beads absorb monomer and swell, thus depriving the liquid phase of monomer and causing a further increase in viscosity. During this period the monomer remains unpolymerised.

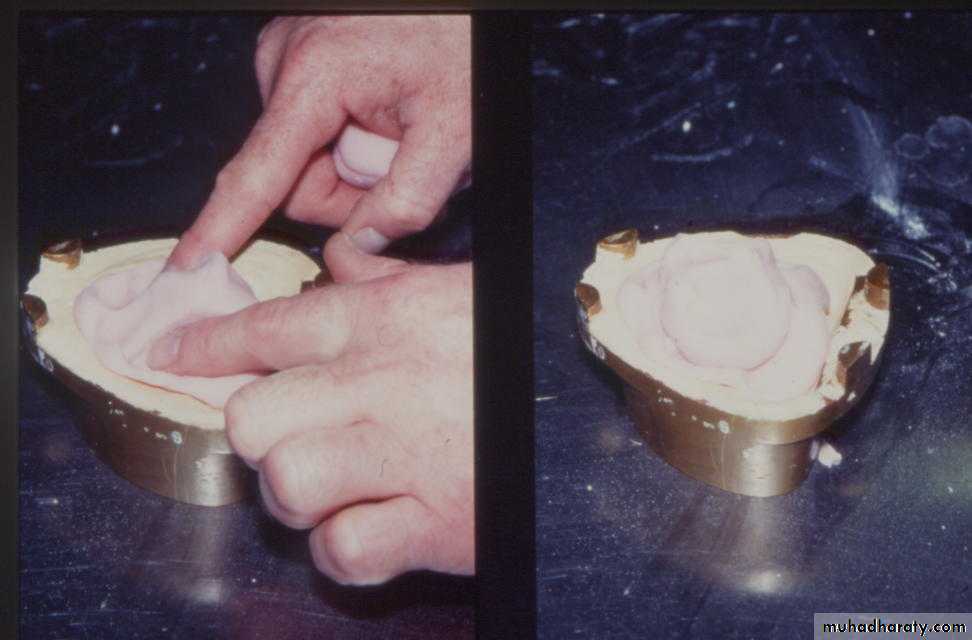

3. Pack the material in the upper half of the flask being sure to press it well around the teeth.

4. Use enough material to insure overpacking on the first closure.

5. Place two pieces of wet cellophane over the acrylic resin.

6. Put the lower half of the flask in position and press the flask together using hand pressure.

7. Place the flask in a bench press and close it very slowly to give the acrylic resin time to flow.

8. Remove the flask from the press and open it carefully. Trim off the excess acrylic (flash) with a sharp knife.

This is called trial closure. If insufficient flash is observed , it indicates insufficient amount of resin was placed in the mold. So remove the cellophane and add more resin.

9-Trial closure is repeated until all excess material is removed and the metal edges of the flask are in complete contact.

10-Final closure: open the flask, paint the cast with separating medium, remove the cellophane sheets and close the flask under the press until metal to metal contact is reached.

11- Flasks Are Secured In Clamp And Placed Aside For 30mins (bench curing).

WHY?

Permits equilization of pressure.Allows time for uniform dispersion of monomer.

Helps in better bonding of tooth with base material.

The applied pressure has three important functions:

It ensures that dough flows into every part of the mould.It enables excess dough to be used, thus causing an effective reduction in the polymerisation shrinkage.

It prevents the formation of a ‘raised bite’ on the denture by giving a base which is too thick.

The use of insufficient dough in the mould or the application of insufficient pressure during curing can lead to porosity voids dispersed throughout the whole mass of the denture base. This is known as contraction porosity.