Instruments in Operative Dentistry

1

معالجة نظري / ثالث اسنان كركوك

د.فاضل

2017/5/3

616

Outline:

Hand InstrumentsIntroduction

Classification

Materials

Application

Techniques

Sharpening

Powered cutting equipments

Rotary cutting instruments

Cutting Mechanism

Hazards

2

Introduction:

G.V. BlackNomenclature & numbering of hand instruments

• Cutting instruments/ excavators

• Noncutting

Designs of some early hand instruments

1728 – Pierre Fauchard invented the bow drill

1891 – Edward C Acheson –produced carborundum tools

1935 – W H Drendes - Diamond cutting instruments

3

Materials

Carbon Steel:Harder than stainless steel

Maintained better sharpness

Corrode in moist conditions

Carbon steel

4Stainless Steel

Preferred materialsRemains bright under most conditions

Loses keen edge during use much more quickly

Chromium: corrosion resistance

Carbon: hardness

Stainless Steel

5Tungsten carbide

Inserts or blades to provide more durable cutting edges (brittle).They may be soldered to steel handles

Some instruments are made with carbide to provide more durable cutting edges.6

Other alloys of nickel, cobalt, or chromium are used in the manufacture of hand instruments.

They are restricted to instruments other than those for cutting tooth structure

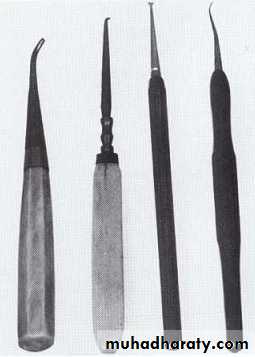

7Hardening and Tempering Heat Treatments

Heat treatment Furnace

The hardening heat treatment hardens the alloy, but it also makes it brittle, especially when the carbon content is high.Tempering heat treatment relieves strains and increases toughness.

8Classification of Instruments:- by Sturdevant

9Order

Purpose of the instrumentE.g. Excavator, scaler

Sub-order

Manner of use

E.g. Push, Pull

Class

Form of blade

E.g. Hatchet, Chisel

Angle

Number of angles in the shank: monoangle, biangle, triple-angle, quadrangle

E.g. Biangled hatchet excavator,

According to G. V. Black

10

Classification of Instruments:- by Charbeneau

Cutting instrumentsHand- hoes, chiesel etc

Rotary- burs, discs etc

Condensing instruments

Pluggers

Plastic instruments

Carvers, Burnishers

Finishing and polishing instruments

Discs, Strips

Isolation instruments

Cotton roll, Rubber dam

Miscellaneous-

Mirrors, Explorers

11

CLASSIFICATION BY MARZOUK

EXPLORING

INSTRUMENTS

REMOVAL OF

TOOTH STRUCTURE

RESTORATION

OF TEETH

To dry

To illuminate

Retraction

Probes

Separators

Mixing

Plastic

Condensing

Burnishing

Carvers

Files

Knives

Finishing

& polishing

Hand cutting

Rotary cutting

12

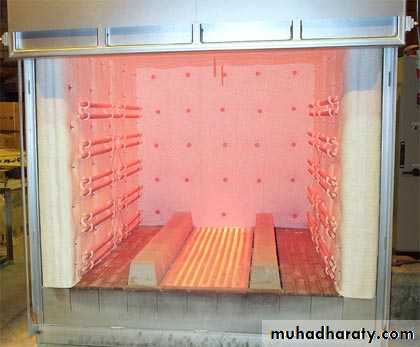

Design

13

Blade

Working part of the instrumentUsually in the form of a bevel (acute angle) that cuts into the tooth structure.

On non cutting instruments e.g. condensers the part corresponding to the blade is called the nib or face.

14

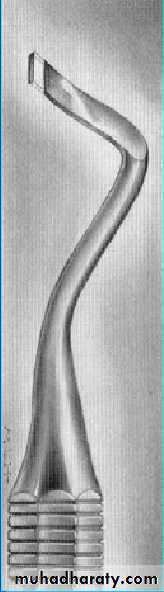

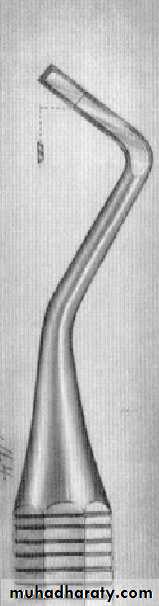

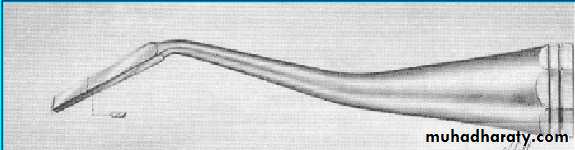

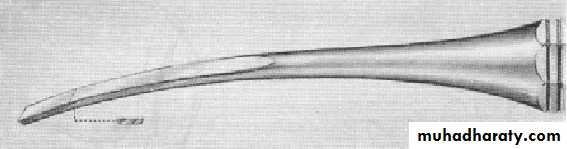

Shank

Connect the handle to the working end of the instrument.Normally smooth, round and tapered.

Mon-angle, bin-angle, triple angleBalance is accomplished by designing the angle of the shank so that the cutting edge of the blade must not be off axis by more than 1-2 mm (Sturdevant’s)/2-3 mm (Summitt)

15

Balance allows for the concentration of force onto the blade without causing rotation of the instrument.

Instruments with long blades may required two or three angles in the shank to bring the cutting edge near to the long axis of the handle

Such shanks are termed contra angled.

16

Handle/ Shaft

Serrated for better gripping and control of the instrument.• Standard Stainless steel handle: Diameter 6.4 mm approx.

• Padded handles: Diameter 8mm approx.• Larger diameter handles: 9.5 mm

17

Handles are in conjunction with the shank or it may be separable.

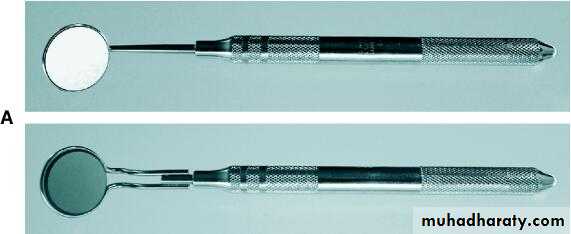

Separate type is known as cone-socket handle and allows for replacement of several working ends e.g. mirrors and condensers.18

cone-socket handle (mirror)

mirror19

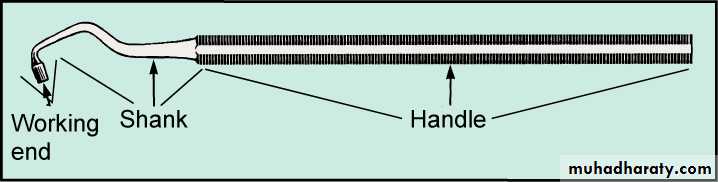

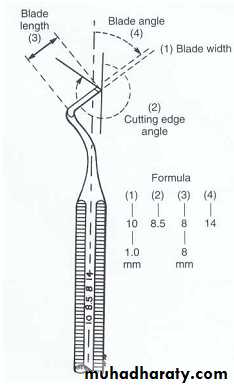

Numeric formulas

Describing the dimensions and angle of the working end.Three number formula

Four number formula:Cutting edge is not perpendicular to the long axis of the blade.

Gingival marginal trimmer

Angle former

20

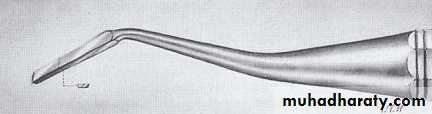

Instrument shank and

blade design85

21

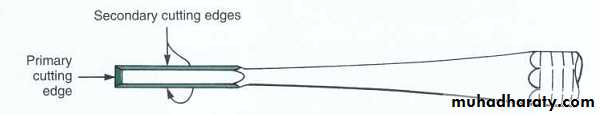

Bevels

Most hand cutting instruments have on the end of the blade a single bevel that forms the primary cutting edge.Additional two secondary cutting edges that extend from the primary cutting edge for the length of the blade.

Allows cutting in 3 directions; facial and lingual walls of the proximal cavity

22

Bibeveled instrument have two bevels that form the cutting edge;

e.g. hatched excavator23

Single beveled instrument such as spoon excavator and gingival margin trimmer are used with lateral cutting movement.

24

Enamel hatchet also as a single beveled instrument used with direct cutting motion, a planning or lateral cutting designated for right (R) and left (L) to the instrument formula.

25

The cutting edge is perpendicular to the axis of the handle

e.g. binangle chisel.Instrument with slight blade curvature e.g.Wedelstaedt chisel.

26

Removal of caries and refinement of the internal parts of the preparation.

Used primarily for cutting enamel.Cutting instrument applications

27

Excavators

• Ordinary Hatchets• Hoes

• Angle formers

• Spoons

28

Ordinary Hatchets

It has the cutting edge of the blade directedIn the same plane as that of the long axis of the handle and

Is bibeveled.

29

Used primarily on anterior teeth for

Preparing retentive areas andSharpening internal line angles, particularly in preparations for direct gold restorations .

30

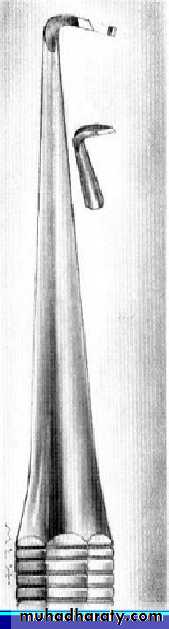

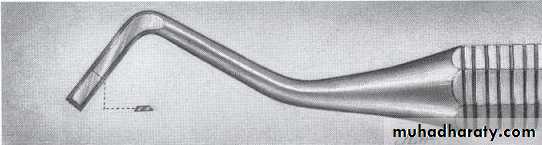

Hoe excavators

Primary cutting edge of the blade perpendicular to the axis of the handlePlaning tooth preparation walls and forming line angles.

It is commonly used in Classes III and V preparations for direct gold restorations.

31

Hoes with longer and heavier blades, with the shanks contra-angled.

For use on enamel or posterior teeth.32

The blade angle of the hoe: > 12.5 centigrades

The blade angle of chisel: ≤ 12.5 centigrades33

Angle former

It is mon-angled and has the primary cutting edge at an angle (other than 90 degrees) to the blade.It is available in pairs (right and left )

34

Used primarily for sharpening line and point angles and creating retentive features in dentin in preparation for gold restorations

Also may be used in placing a bevel on enamel margins

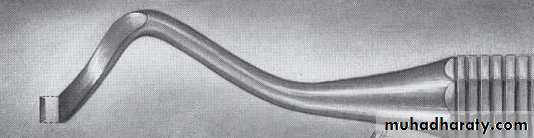

35Spoon excavators

Its blades are slightly curved, the shanks may be bin-angled or triple-angled to facilitate accessibility.

The cutting edges are circular

The cutting edges are claw like.36

Left cutting and right cutting

Used mainly for removal of caries and refinement of internal opening in a cavity preparation37

bin-angled spoon

triple-angled spoon38

Cleoid spoon

39Discoid spoon

Discoid is disc shaped, with cutting edge around the blade40

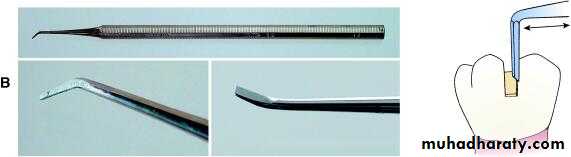

Chisels:

Straight, Monoangle, Biangle, Wedelstaedt chiselsEnamel Hatchets

Gingival Marginal Trimmers41

Straight Chisel

The straight chisel has a straight shank and blade, with the bevel on only one side.

Its primary edge is perpendicular to the axis of the handle.

(12-7-0)

42The shank and blade of the chisel also may be slightly curved (Wedelstaedt design)

11½-15-3

Biangled chisel

43Force used with chisels : straight thrust

The bin-angle and Wedelstaedt chisels:

Primary cutting edges in a plane perpendicular to the axis of the handle.

Distal bevel or a mesial (reverse) bevel.Used for cleaving undermined enamel and for shaping walls.

Instrument with three cutting motion: vertical, right and left.44

The blade with a distal bevel is designed to plane a wall that faces the blade's inside surface

The blade with a mesial bevel is designed to plane a wall that faces the blade's outside surface

45

Enamel Hatchet

It is a chisel similar in design to the ordinary hatchet excavator except that the blade is larger, heavier, and is beveled on only one sideCutting enamel

Right or Left cutting ends of the double- ended hatchet.

10-7-14

46Gingival margin trimmer

Blade is curvedBevel for cutting edge: outside of the curve

Face of instrument: inside of the curve

47

12½-100-7-14

12½-75-7-14Mesial

Distal

48

Cutting edge angle: 100 and 75 :

Inlay & Onlay preparations.

Cutting edge angle: 90 and 85 :

Amalgam preparations.49

Uses:

Beveling of the gingival margins of proximo-occlusal preparations.Beveling of the axio-pulpal line angle

Performing a gingival lock (reverse bevel), placed on the gingival seat

50

Usage of hand cutting instruments

Horizontal strokes:Long axis of blade directed between 45 & 90 degree to the surface being planed or scraped

Vertical or chopping strokes:

Pulling stroke

Hoe: beveled end or distal bevel

Pushing stroke

Hoe: contrabeveled end or mesial bevel.

51

The cutting edge of the hand instrument should always be kept sharp as

Dull instruments may cause:

1. Loss of control.2. More pain.

3. Prolonged time for the operative procedure.

4. Reduce the quality and precision of tooth

preparation.

Sharpening

52

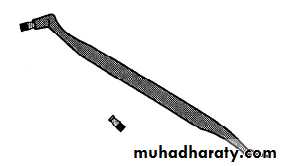

sharpening equipment

Stationary sharpening stone e.g. Arkansas stone, silicon carbide.53

Mechanical sharpener; moves at low speed while the instrument is held at the opposite angle and supported by a rest i.e. easier and less time consuming.

E.g. Rx Honing Machine

Mechanical sharpener

54

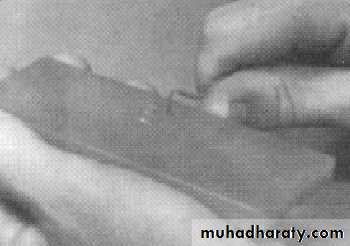

Principles of Sharpening

Sharpen instruments only after they have been cleaned & sterilizedEstablish the proper bevel angle (usually 45 degree) and the desired angle of the cutting edge to the blade.

Use light stroke pressure

Use a rest or guide whenever possible.

Remove as little metal as possible

55

Non cutting Instruments

Diagnostic instrumentsMirror

Probe or explorer

Twizzer

Plastic instruments

Amalgam instruments

Condensers

Burnisher

Carver

Amalgam carrier

56

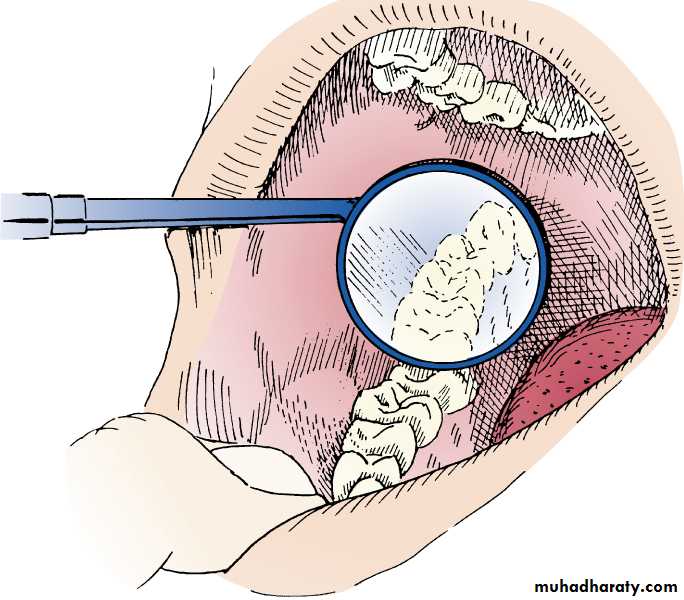

Mouth Mirror

Most common sizes used are the No. 4 (⅞ inch diameter) and No. 5. (15/16 inch diameter)

No. 2 (5/8 inch diameter): when working on posterior teeth with a rubber dam.

For clarity, reflective surface on the external surface of the glass: Front surface mirror.

57

Uses for the mouth mirror. A, Indirect vision. B, Light reflection. C, Retraction. D, Tissue protection.

A

D

C

B

58

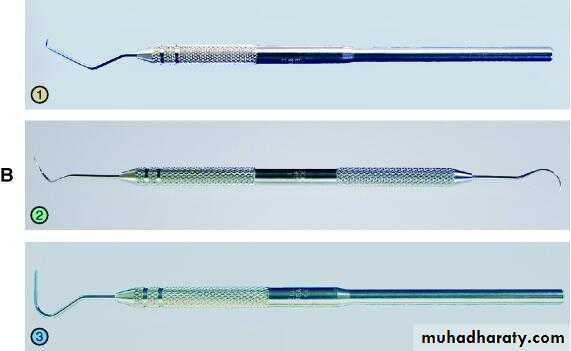

Explorers

To feel tooth surface for irregularities

To determine the hardness of exposed dentin

• Shepherd’s hook: No. 23

• Cowhorn explorer: No. 2

• No. 17: back action

59

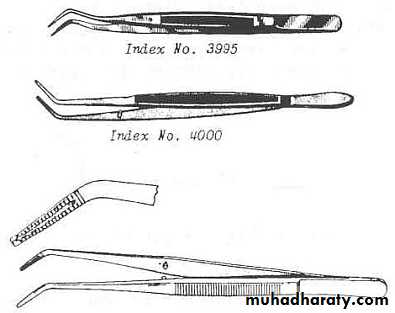

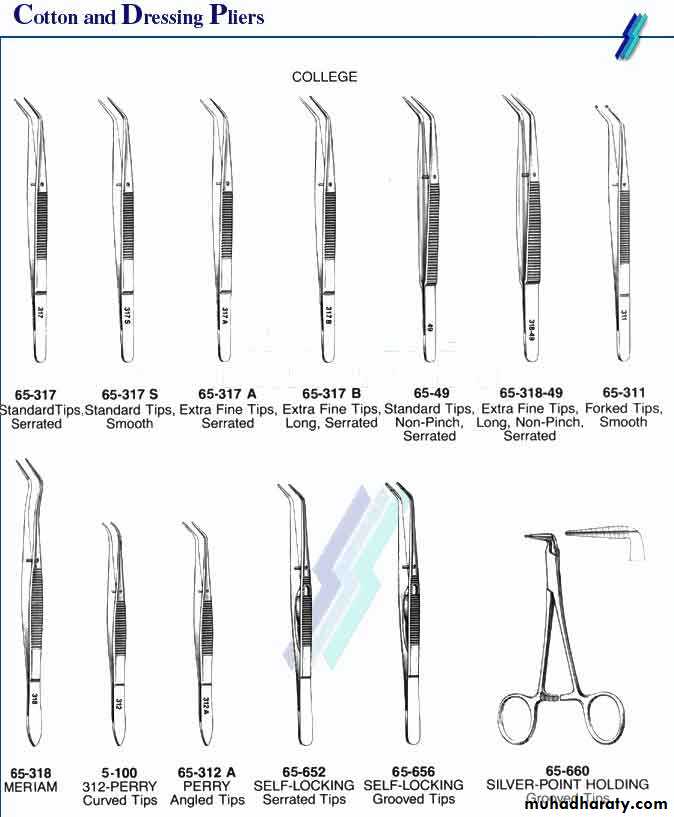

Tweezer/ cotton forceps:

Cotton forceps are used for picking up small items, cotton pellets60

61

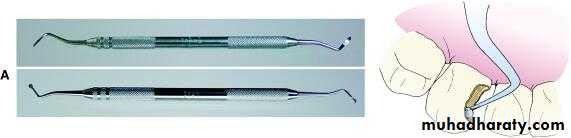

Plastic filling Instruments

To carry and shape tooth colored restorative material: Composite resin and glass ionomerFor placing of base and lining material

Hard plastic or metal.

Composite placement instrument

Designed specifically for the placement of composite restorative materials.Anodized aluminum

Teflon

Titanium nitride layer on instruments

62

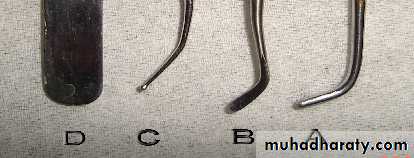

A: ash49 B:ash6 C:dycal applicator D:cement spatula.

63Amalgam Carriers

An instrument with a hollow cylinder that is filled with amalgam.

Sizes:

Mini: 1.5 mm diameter

Regular: 2.0 mm

Large: 2.5 mm

Jumbo: 3.0-3.5 mm

64

Amalgam Condensers

Various Amalgam condensers

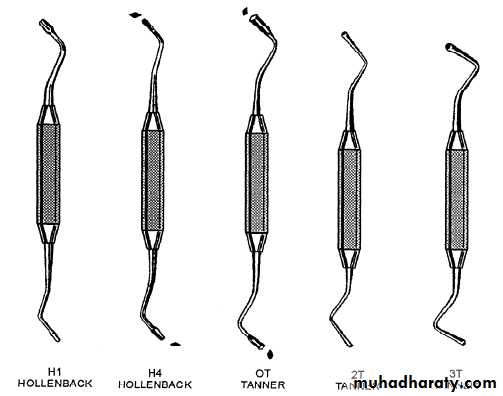

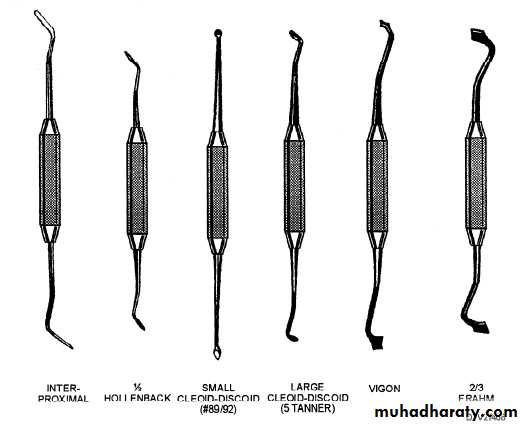

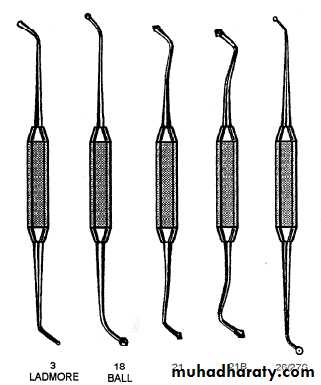

65Carvers

Hand instruments with a blade or nib used to contour the surface of filling material in their plastic state, waxes, models and patterns.Hollenback carver (knifed edged- elongated- bibevelled)

Diamond (Frahm’s) carver : Bibevelled cutedge.

Ward’s ‘C’ carver

Discoid Cleoid

Interproximal carver

66

67

Burnishers

Burnishing of the amalgam on the margins of the cavity,Shaping metal matrix band to have more desirable contours for restoration.

To bend cast gold restoration (inlay or onlay) near the margin of the prepared cavity to narrow the gap between gold and the tooth.

68

Burnishers

69Disposable brush

Used with etching and bonding procedures associated with composite resins.

70

Accessory Instruments

ScissorsUsed for cutting dental dam material, retraction cord, and stainless steel crowns.

Crown and bridge scissors

Dappen Dish

Hold certain liquid dental materials during a procedure.71

Howe Pliers

Also referred to as 110 pliers. Useful for holding items, for carrying cotton products to and from the oral cavity, removing the matrix band, and placing and removing the wedge.Guards

Interproximal wedges to protect soft tissues from contact with sharp rotary cutting instruments.72

Preset restorative tray

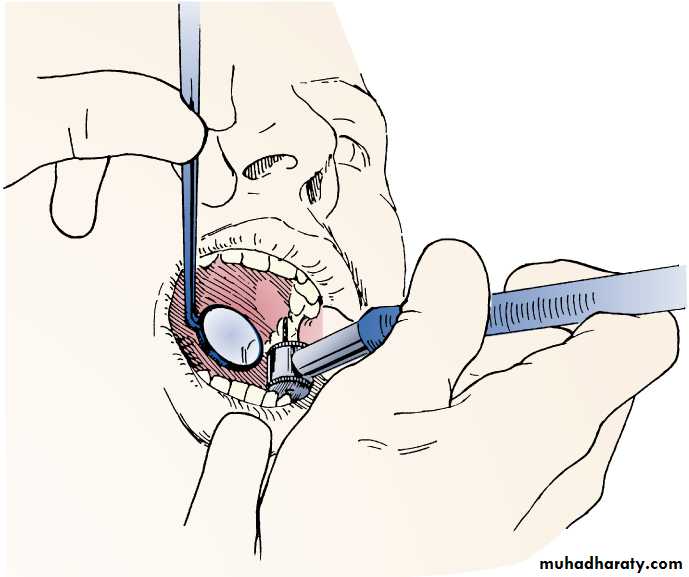

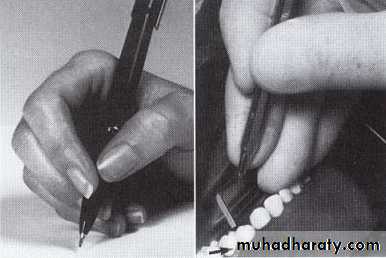

73There are four grasps used with the hand

instruments:Modified pen.

Inverted pen.Palm and thumb.

Modified palm and thumb.Instrument grasp

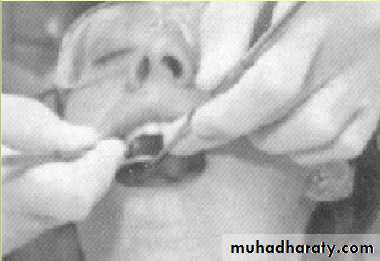

74Modified pen grasp

pen grasp

Modified pen grasp75

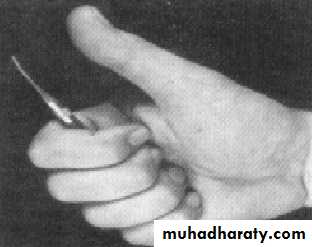

Inverted pen grasp

If the hand is rotated so that the palm faces more toward the operator.Used in the lingual and labial surfaces of anterior teeth.

inverted pen grasp

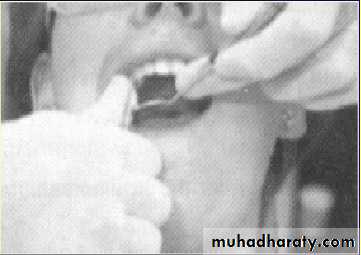

76Palm and thumb grasp

The handle of the instrument is placed on the palm of the hand and grasped by all the fingers while the thumb is free of the instrument and rest on the nearby tooth of the same arch.Preparing incisal retention in a class III preparation on a maxillary incisor.

77

Palm and thumb grasp

The same as in palm and thumb grasp but the thumb is rested on the tooth being prepared.Used in the upper arch.

78

Powered cutting equipments

79

Characteristics:

• Speed• Surface feet per unit time of contact that the tool has with the work to be cut or revolutions per minute

• According to Marzouk:

• Ultra low speed: 300-3000 RPM

• Low speed: 3000-6000 RPM

• Medium High Speed 20,000-45,000 RPM

• High Speed 45,000-1,00,000 RPM

• Ultra High Speed > 1,00,000 RPM

80

According to Charbenau:

• Conventional or low speed: below 10,000 RPM

• Increased or high speed: 10,000-1,50,000 RPM

• Ultraspeed: above 1,50,000 RPM

• According to Sturdevant:

• Low or slow speeds: below 12,000 RPM

• Medium/Intermediate speeds: 12,000 to 2,00,000 RPM

• High/ Ultrahigh speeds: above 2,00,000 RPM

81

Pressure:

P=F/ALow speed: 2-5 pounds of force

High speed: 1 pound of force

Ultra high speed: 1-4 ounces of force

Heat Production

Directly proportional to the Pressure, RPM, and area of tooth in contact113˚ F : Pulpitis & pulp necrosis.

130˚ F : Permanent damage of pulps.

82

Brown et al: Temperature of dentin at a distance of 0.5 mm from a high speed bur cutting dry to be 245˚F (118˚C).

Even in non vital teeth, dry cutting at high speed should be avoided, since the thermal stresses will cause microfractures in the enamel. This could contribute to marginal failure of the restoration.

Higher water velocity.

Clean head system

83Greater flow of water coolant is required to prevent clogging when diamonds are used under increased pressure.

42 psi is the optimal air pressure to achieve peak performance

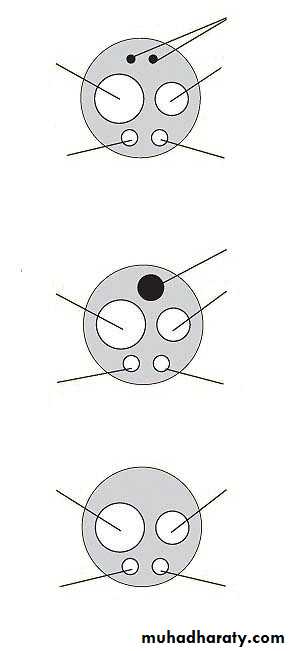

Optic

Drive airSpray water

Exhaust air

Spray air

Optic

Drive air

Spray water

Exhaust air

Spray air

6-pin

5-hole

84

Vibration:

Equipment used & the speed of rotation

Excessive vibration: annoyance to the patient, operator fatigue and rapid wear of instruments.Torque:

Ability of the hand piece to withstand lateral pressure on the revolving tool without decreasing its speed or reducing its cutting efficiency.85

Friction:

Occurs in the moving parts of the hand piece especially the turbine.Friction is reduced by equipping the hand piece with ball bearings, needle bearings, glass and resin bearings.

Ceramic Ball Bearings:

40% lighter and 3 times harder than conventional bearings, they offer an extended turbine life, reduced operation noise, and less vibration.86

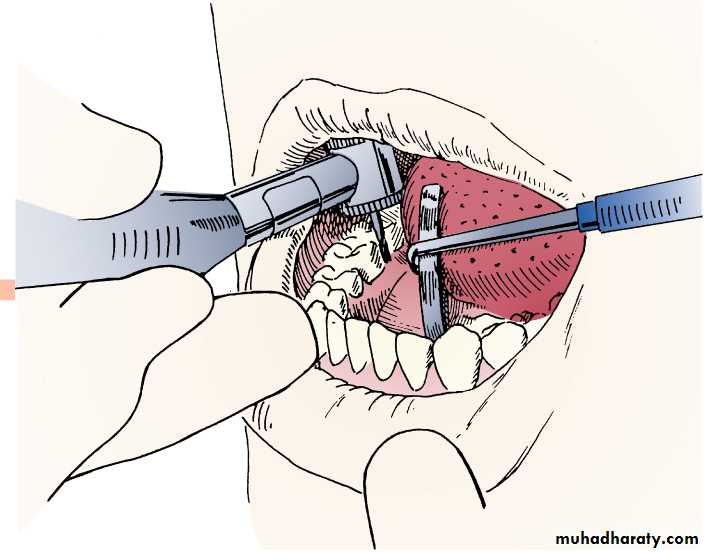

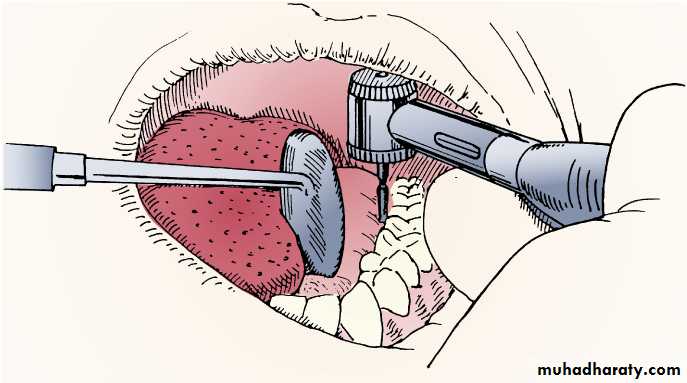

Handpieces:

Two basic types of handpieces, the straight handpiece and contra angle handpiece.The straight is used more frequently for laboratory work, while contra angle used in the oral cavity.

High speed techniques are generally preferred for cutting enamel and dentin.

87

Penetration through enamel and extension of the cavities outline are more efficient at high speed.

Small diameter burs should be used in the high speed handpiece.

High speed generates considerable heat during cutting, even with small diameter burs and should be used with water coolant and high efficiency evacuation

88

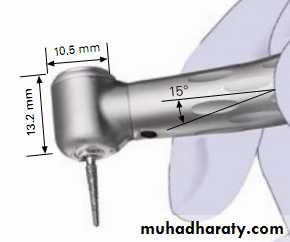

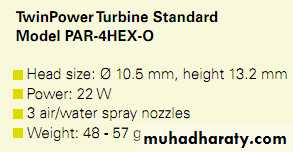

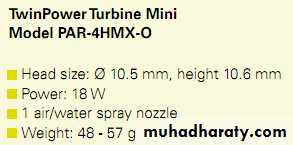

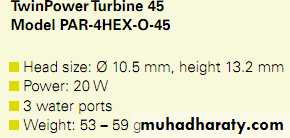

Design:

This model is the choice for limited access or when treating children.

Rear-facing exhaust vents direct air flow away from the surgical site for patient protection

89

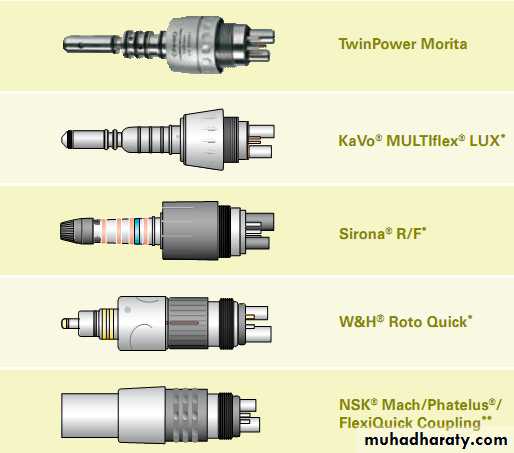

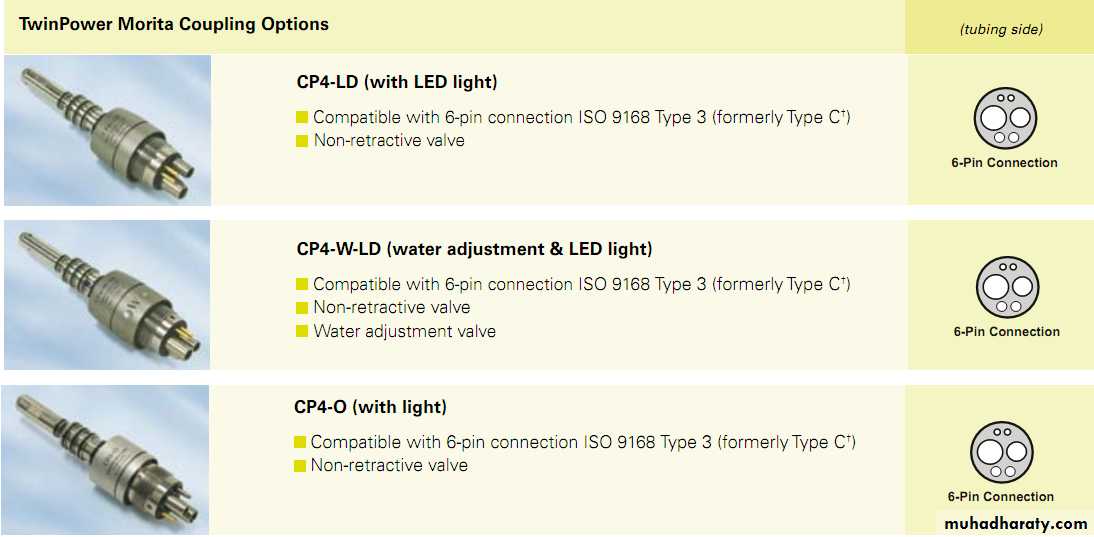

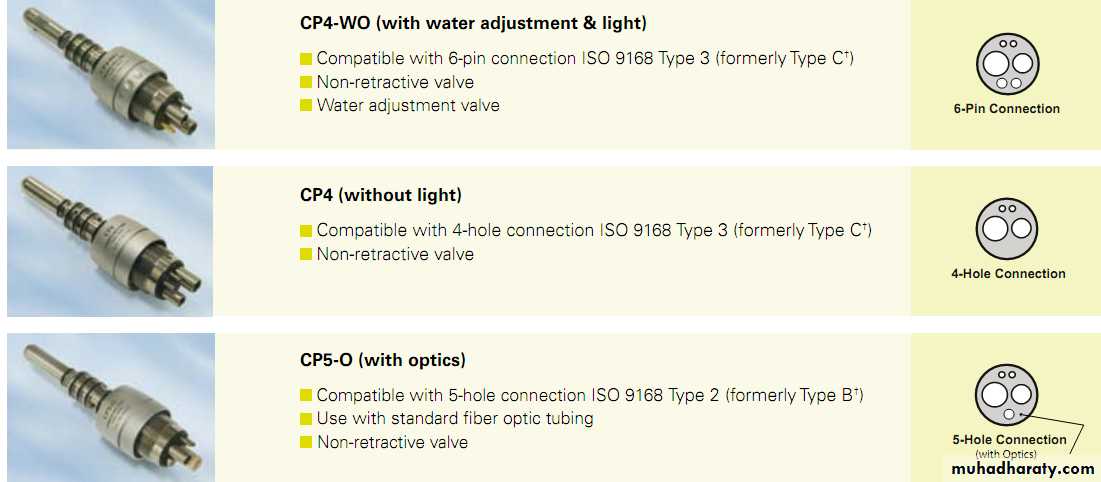

Commonly used couplings

90

91

92

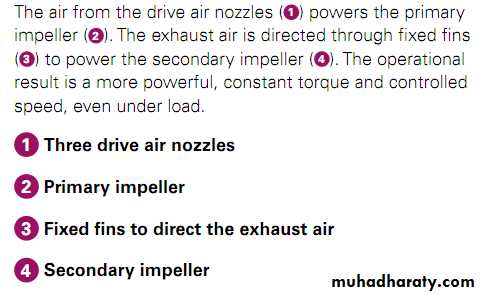

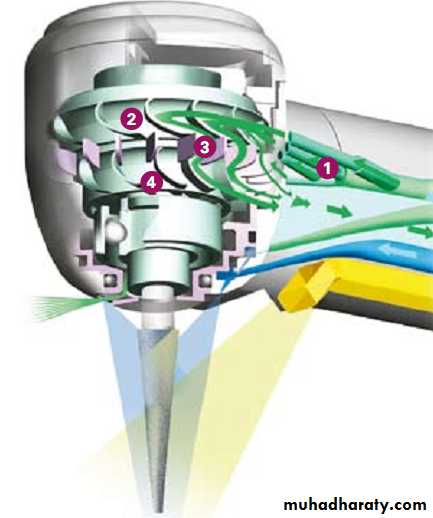

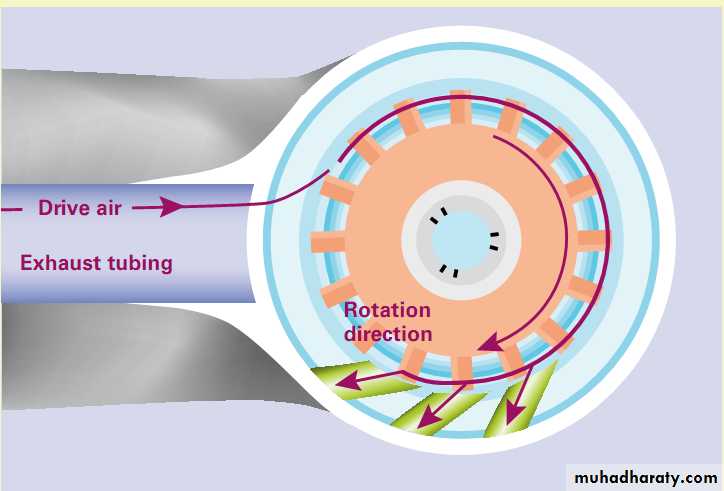

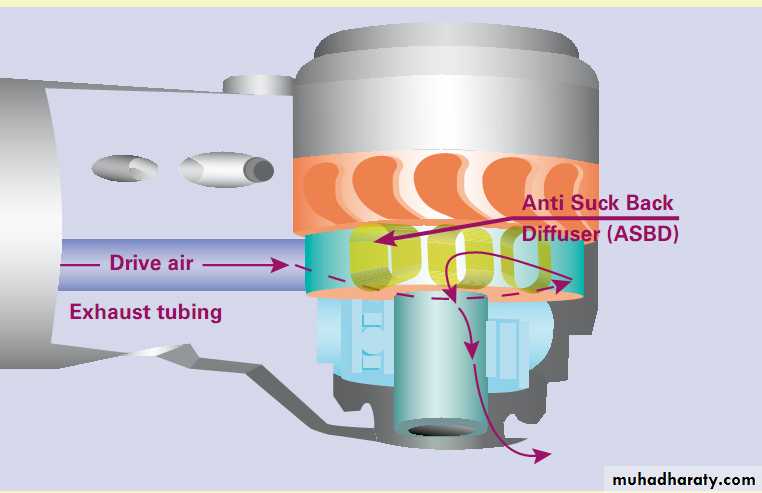

Zero Suck Back Technology

Prevents the intake of aerosol and other particles when it is stopped.Drive air flows into an Anti Suck Back Diffuser (ASBD) within the capsule.

Air in the ASBD is pressurized through centrifugal force created by the impeller rotation.Through the centrifugal force and rotation of the impeller, air continues to flow into the ASBD and remains pressurized even after drive air is stopped.

The pressurized air in the ASBD is released to the outside at the bottom of the head

93

Low-Speed Handpiece

DesignStraight in appearance.

Standard length and “short.”

Speed ranges from 10,000 to 30,000 rotations per minute (rpm).

Operates the rotary instrument in either a forward or backward movement.

94

Uses of the low-speed handpiece

IntraoralRemoval of soft decay and fine finishing of a cavity preparation.

Finishing and polishing of restorations.

Coronal polishing and removal of stains.

Extraoral

Trimming and contouring temporary crowns.

Trimming and relining of removable partials and dentures.

Trimming and contouring of orthodontic appliances.

95

Low-Speed Attachments

Straight attachment receives a long‑shank laboratory bur, the contra-angle attachment, and the prophy angle attachment.Contra-angle attachment receives latch type rotary instruments and mandrel.

96Prophylaxis Angle

Used during polishing procedures to hold the prophy cup and bristle brush.Two types

Plastic disposable “prophy” angle

Metal “prophy” angle

97

High-Speed Handpiece

DesignOne-piece unit with a slight curve in appearance.

Operates from air pressure.

Operates at speeds up to 450,000 rpm.

Maintains a water-coolant system.

Friction-grip locking system for rotary instruments.

Fiber-optic lighting.

Cellular Glass Optics

98Uses of the high-speed handpiece

Removes decay.Removes an old or faulty restoration.

Reduces the crown portion of the tooth for the preparation of a crown or bridge.

Prepares the outline and retention grooves for a new restoration.

Finishes or polishes a restoration.

Sections a tooth during a surgery.

99

Ultrasonic Handpiece

DesignAttached to the dental unit.

Powered by electricity.

Attachments are similar in appearance to scaling instruments.

Delivers a pulsating spray of water.

100

Uses of the ultrasonic handpiece

Removes calculus.Removes stain.

Removes bonding materials from a tooth surface after orthodontic appliances are removed.

Removes cement after orthodontic bands are removed.

101

Laser Handpiece

Design

Uses a laser light beam instead of rotary instruments.

The laser is conducted through a fiber‑optic cable.Resembles a standard handpiece.

Maintains a water-coolant system.

Maintains an air-coolant system

102

Uses:

Cauterizes soft tissue.Vaporizes decayed tooth structure.

Advantages:

Usually painless.Patient usually does not require anesthesia.

Proceed with procedure faster.

Disadvantage:

Cannot be used on teeth with existing restorations.103

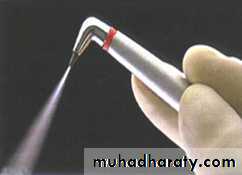

Air-Abrasion Handpiece

DesignSmall version of a sandblaster.

Compressed air at pressure of 7 to 11 atm (40 to 140 psi)Produces a high‑pressure delivery of aluminum oxide particles (of 20 to 50 pm) through a small probe.

104

Uses:

Prepares teeth for sealants.Removes external stains.

Class I through class VI preparations.Endodontic access.

Crown margins.

Prepares a tooth surface for the cementation of a cast restoration, such as a crown or veneer.105

Disadvantages:

More effective on hard normal dentine than soft dentine affected dentineWhen using composite, the air abrasion doesn’t provide the micromechanical roughness needs for retention thus needs acid-etchant.

Loss of tactile sensation.

106Possible iatrogenic damage especially on the cementum and root dentine.

Can induce asthma –> thus needs high volume suctionCan’t remove amalgam restoration.

Can’t perform massive reduction for crown.

107Laboratory Handpiece

DesignOperates at speeds up to 20,000 rpm.

Uses laboratory burs.Provides greater torque than handpieces used intraorally.

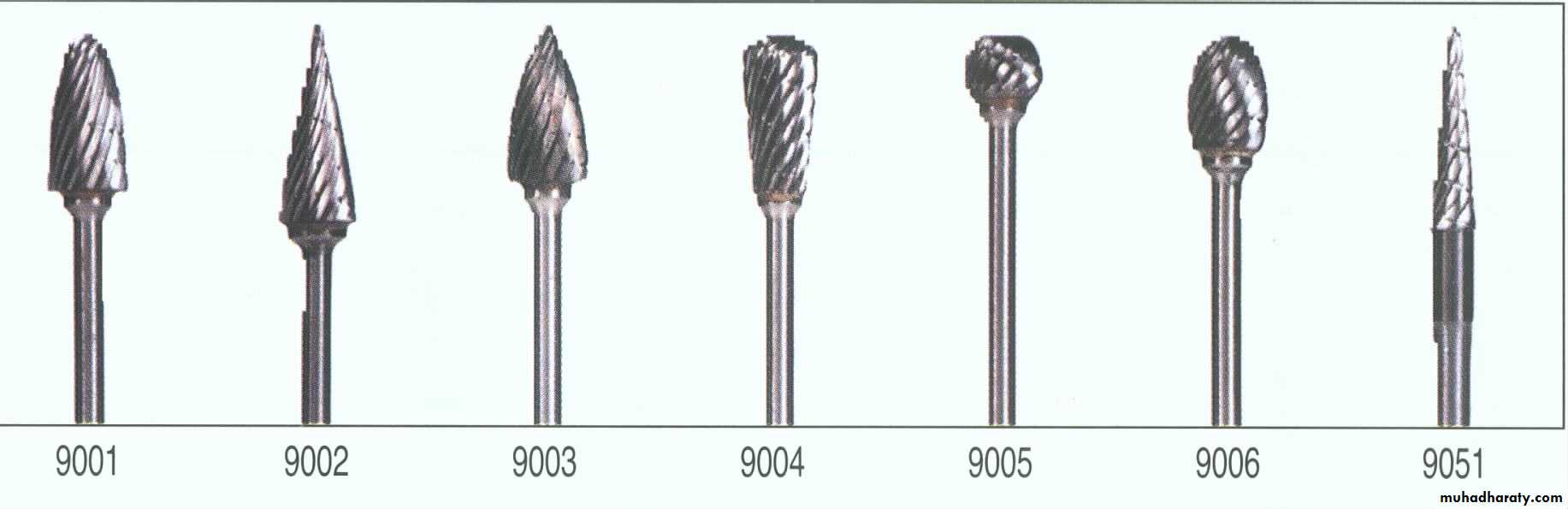

108Rotary instruments

CuttingAbrasive

Carbide burs

Made from1- tungsten carbide

2- steel carbide

1- Diamond burs

2- Discs3- Stones

4- Rubber wheels

109

According to composition:

• Steel burs• Tungsten Carbide burs

• According to mode of attachment to handpiece

• Latch type

• Friction grip type

• According to handpiece they are designed for;

• Clockwise

• Anticlockwise

110

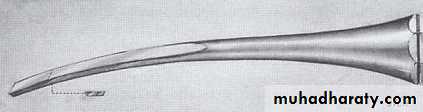

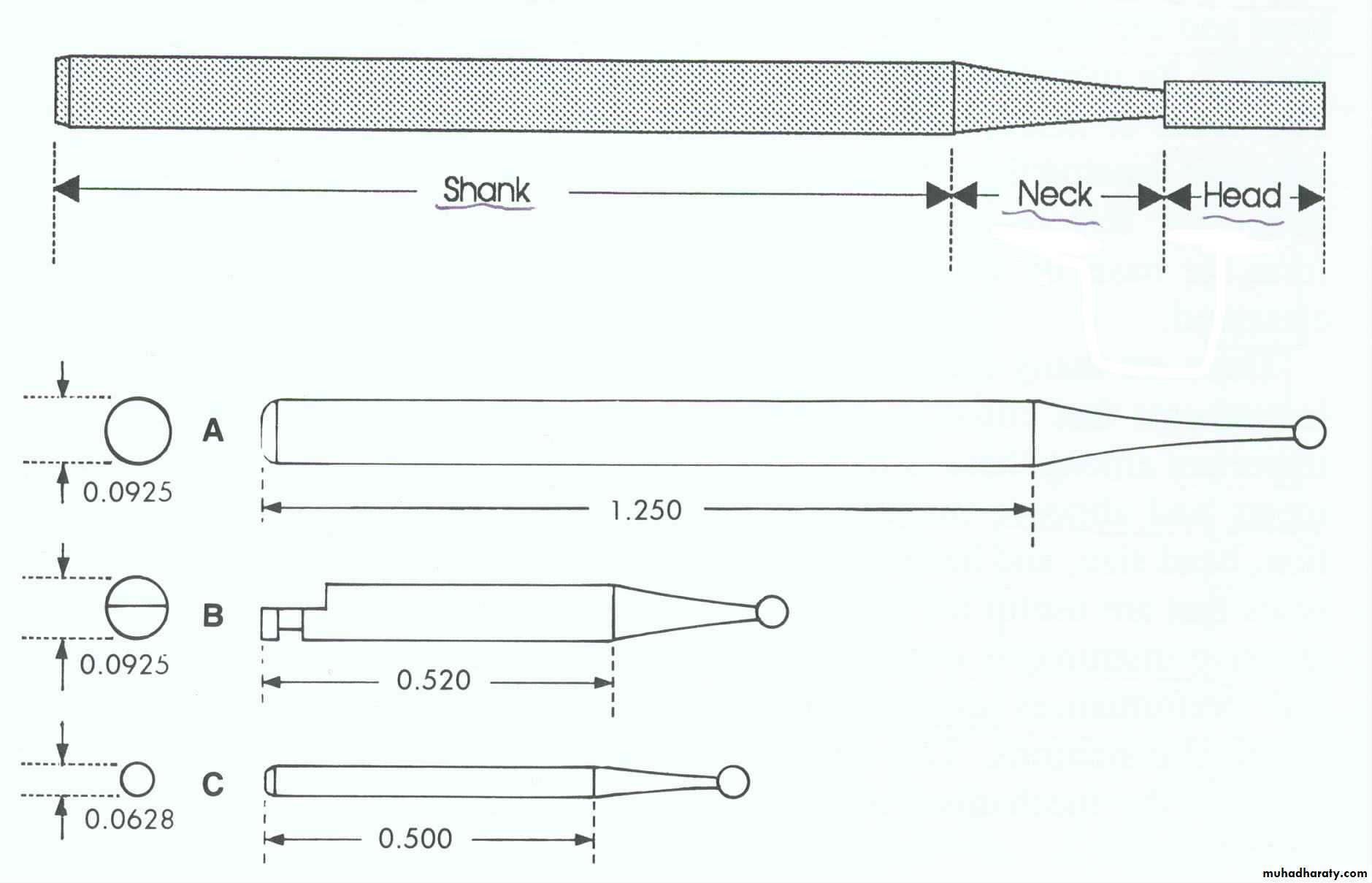

Rotary instruments consist of three parts :

1- shank

2- neck (shaft)

3- head

head

shaftShank

111

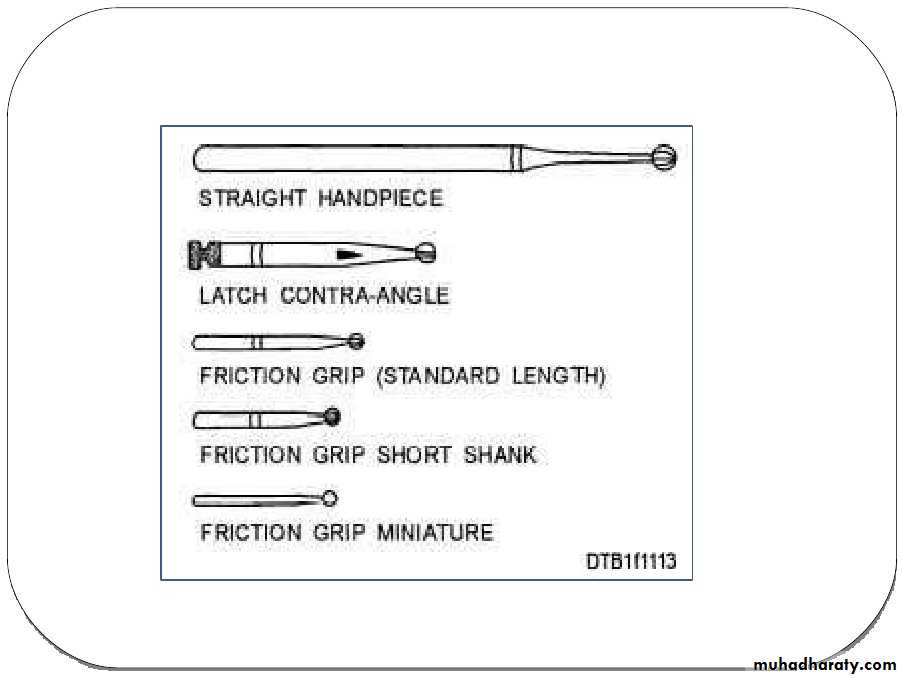

Shank design

Long shank – used for straight hand piece (low speed)Short latch shank – used for contra-angle (low speed)

Friction grip shank - used for high speed hand piece112

113

114

Dental Burs

A group of instruments that can turn on an axis with different speed of rotation to perform different types of work.The characteristics of this work are either cutting , abrasive, finishing or polishing.

Steel burs cut human dentin at low speeds, but dulls rapidly at higher speeds or when cutting enamelSteel necks bends easily causing vibration

115Carbide burs

Burs possess blades that shear (cut) tooth structure.

They are used for making precise intracoronal preparation features such as placing groove, and boxes.

Used for smoothing surface in enamel and dentin

They are not used for bulk reduction because to producing undulations on the tooth surface

116

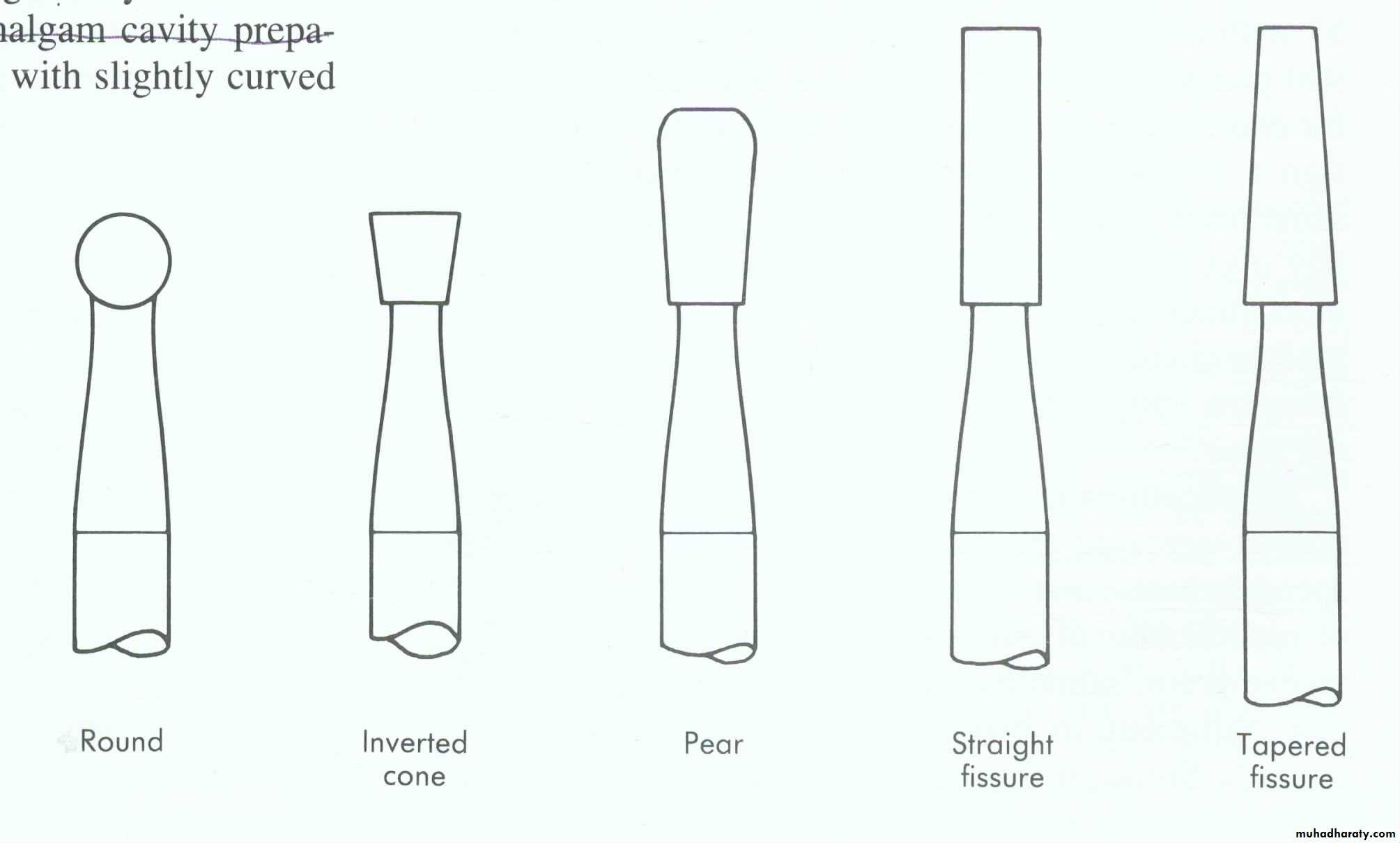

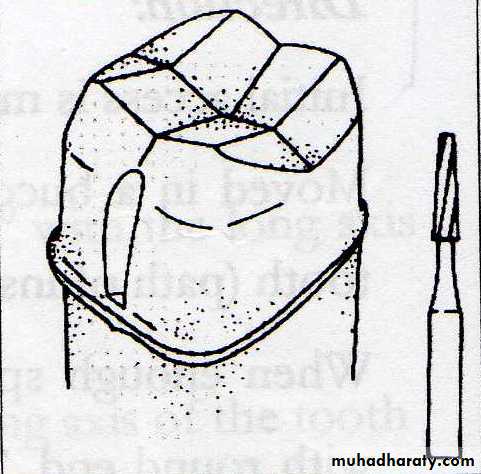

Shapes:

Round Bur:Initial entry into the tooth

Extension of the preparation

Retentive features and caries removal

Inverted cone bur

Undercuts in the tooth preparation

Pear shaped bur

Tooth preparation for amalgam, gold foil.

Straight fissure bur

Tooth preparation for amalgam

Tapered fissure bur

Tooth preparation for indirect restorations.

117

Basic bur head shapes

118Coarse-cut

Regular –cut

Fine Cut

119

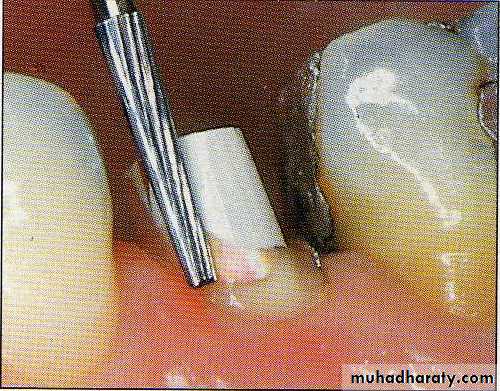

Twelve-fluted carbide bur

Its used for highly smoothing of prepared surfaces of toothBecause of its blades in a diagonal to the instrument shaft

Its have a torpedo shape

120

Plain fissure bur

Its tapered and cylinder shape its used for placing groove and boxes and they also used for finishing of preparation.Groove seating

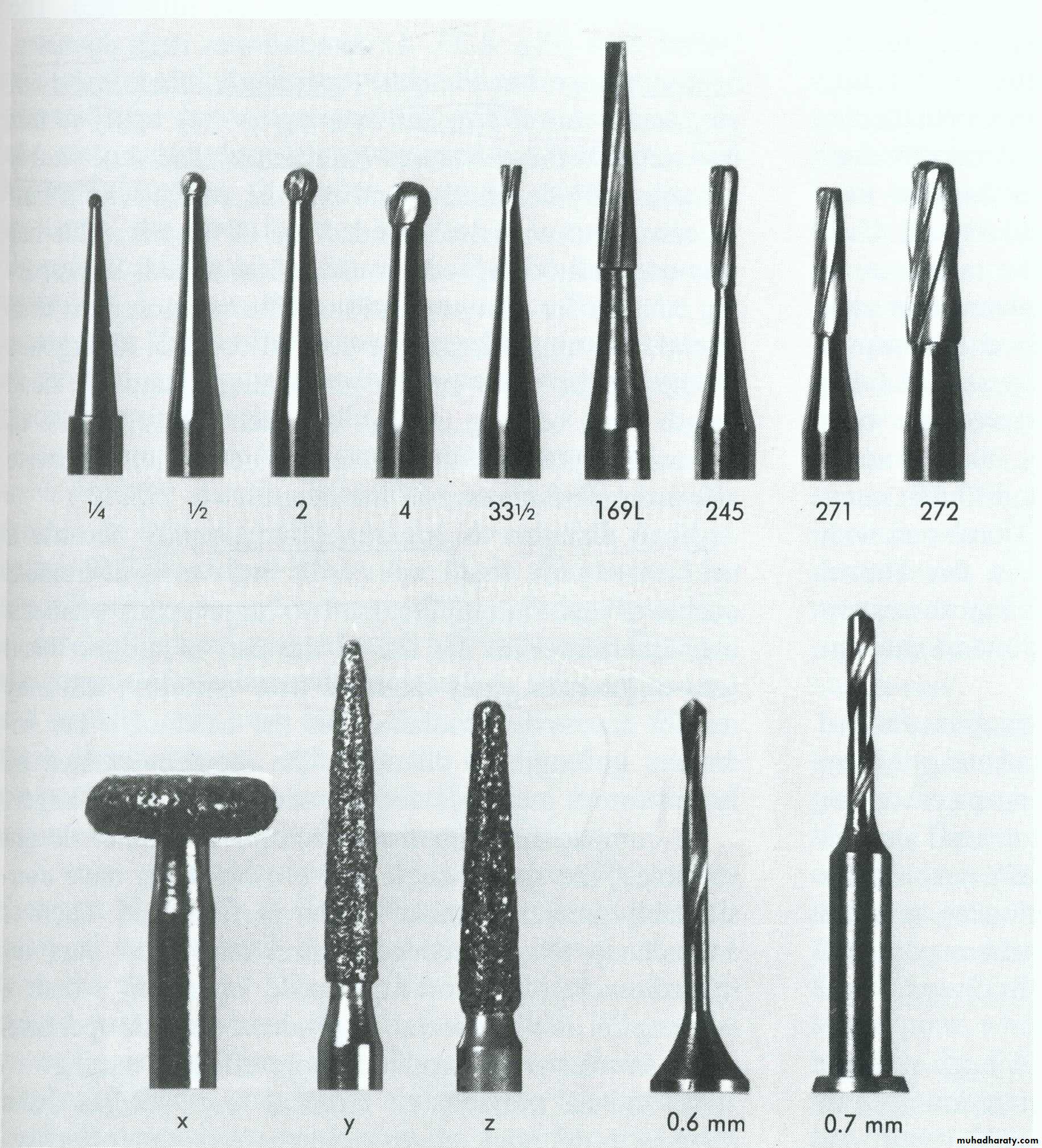

121Bur numbering systems

In the united states the burs have been traditionally described in term of arbitrary i.e. numerical code

eg, 2 =1 mm diameter round bur,

34 = 0.8mm inverted,

57 = 1mm diameter straight fissure

Number 500 is added to indicate cross cutting

Number 900 is added to indicate end-cutting onlySo no. 57 ,557 and 957 are all had the same head size

122Iso system(international standard organization)

FDI (Federation dentaire internationale)Usually tend to use head shape name and size

(in tenth of a millimeter)Eg. Round 010 = 1mm diameter

Straight fissure plain 010 = 1mm diameter

Inverted cone 008=0.8mm diameter

123124

Shapes & diameters of regular carbide burs used for tooth preparation

RoundBur size: 1/16 1/8 ¼ ½ 1 2 3 4 5 6 7 8 9 11

Diameter: 0.30 0.40 .50 .60 .80 1.0 1.2 1.4 1.6 1.8 2.1 2.3 2.5 3.1

Inverted cone

Bur size: 33½ 34 35 36 37 39 40

Diameter (mm): .6 .8 1.0 1.2 1.4 1.8 2.1

Straight Fissure:

Bur size: 55½ 56 57 58 59 60

Diameter (mm): .60 .80 1.0 1.2 1.4 1.6

Straight fissure, round end:

Bur size: 1156 1157 1158

Diameter (mm): .80 1.0 1.2

Tapered fissure:

Bur size: 168 169 170 171

Diameter (mm): .80 .90 1.0 1.2

125

Tapered fissure, rounded end

Bur size: 1169 1170 1171

Diameter (mm): .90 1.0 1.2

Pear:

Bur size: 329 330 331 332

Diameter (mm): .60 .80 1.0 1.2

Long inverted cone, rounded corners (amalgam preparation)

Bur size: 245 246

Diameter (mm): .80 1.2

End-cutting:

Bur size: 956 957

Diameter (mm): .80 1.0

126

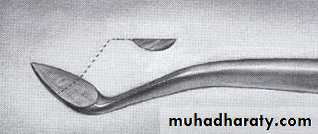

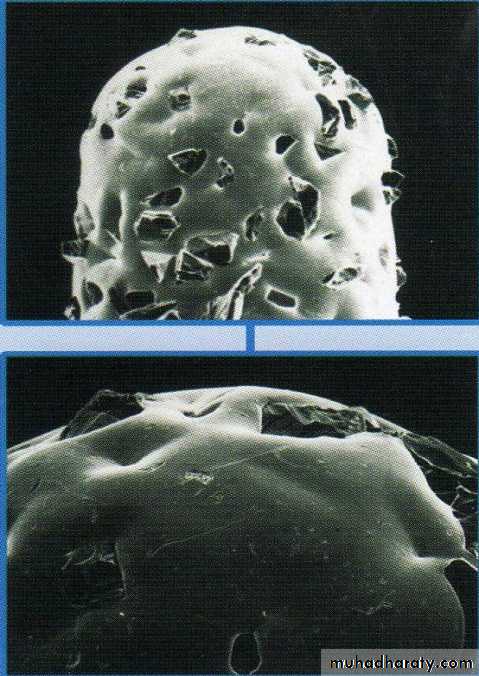

Bur head design:

The number of blades on a bur is always evenNumber of blades on an excavating bur may vary from 6 to 8 t0 10.

Finishing bur: 12 to 40 blades127

Concentricity:

Measurement of the symmetry of the bur head.Runout:

Test measuring the accuracy with which all blade tips pass through a single point when the instrument is rotated.Average value of clinically acceptable run-out is about 0.023 mm

Is the primary cause of vibration128

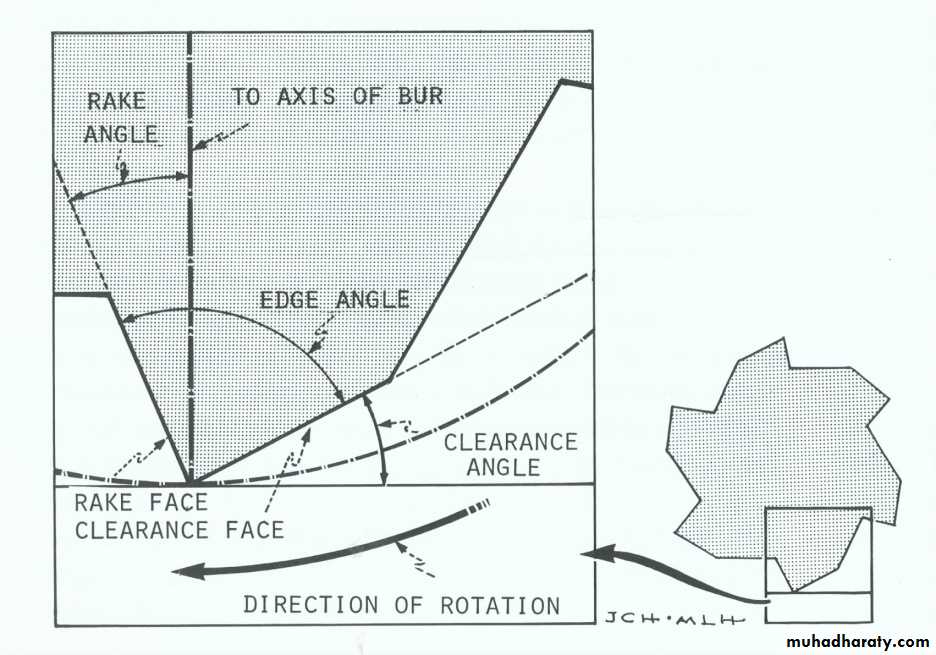

Bur blade design

129

Rake angle:

Angle that the face of the bur tooth makes with the radial line.Radial rake angle: radial line & the tooth face coincide.

Negative rake angle: blade face is leading the radial line

• Increases the life expectancy of the bur & provides for the most effective performance in low and high speed ranges.Positive rake angle:

Produce acute edge angle130

Edge angle:

In the range of 90˚ to provide strength to the blade & longevity of cutting efficiency of the bur.Land: plane surface immediately following the cutting edge.

Flute/ Chip space:Space between successive bur teeth or the blades of the bur.

Provides an exit for removal of the fractured matter and creates a clearance angle.

131

Clearance angle:

Angle between the back of the blade and the tooth surface.

If a land is present on the bur:• Primary clearance angle: the angle the land will make with work.

• Secondary clearance angle: the angle between the back of the bur tooth and work.

• Radial clearance angle: is formed when the back surface of the bur tooth is curved.

Provides clearance between the work & the cutting edge to prevent the tooth back from rubbing on the work.

132

Abrasive instruments

Head consists of small angular particles of hard substance embedded in a soft binder (ceramic, metal, shellac, rubber).Diamond abrasives

Other abrasives –Silicon carbide (carborundum), aluminium oxide, garnet, quartz, pumice, cuttlebone.

Deposited by Electroplating, sintering or microbrazing.

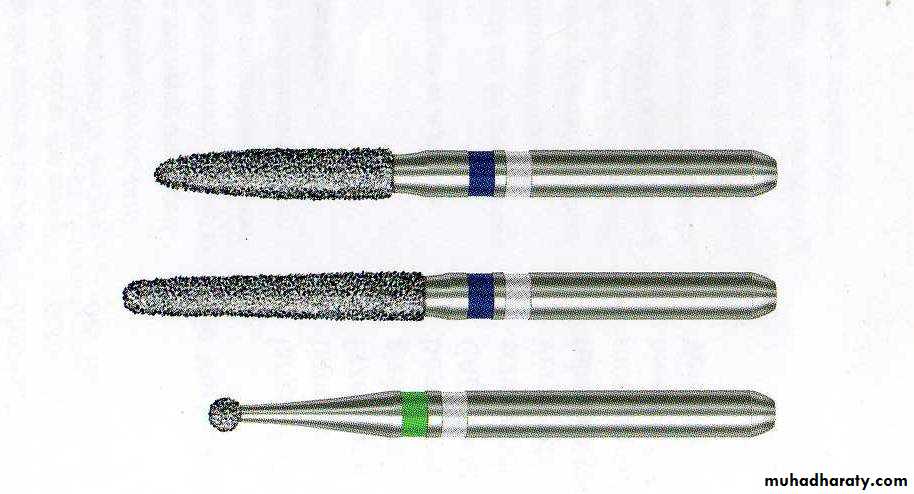

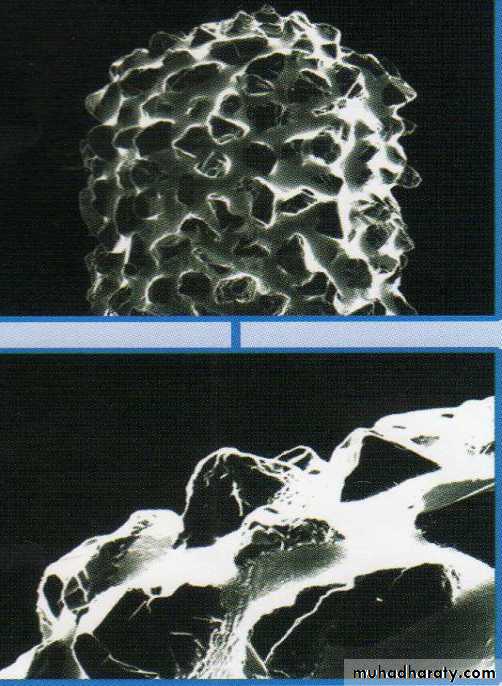

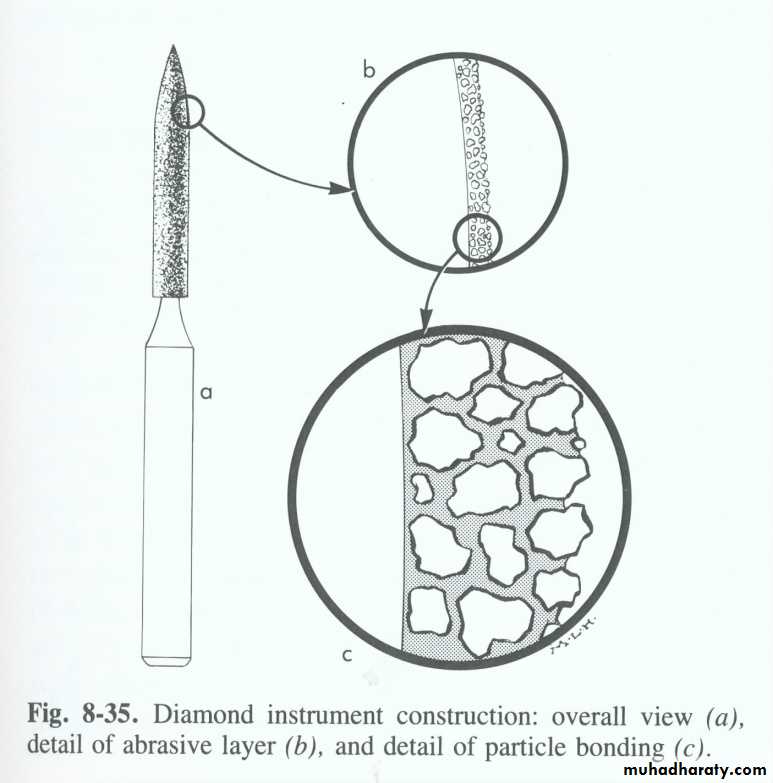

133Diamond stones

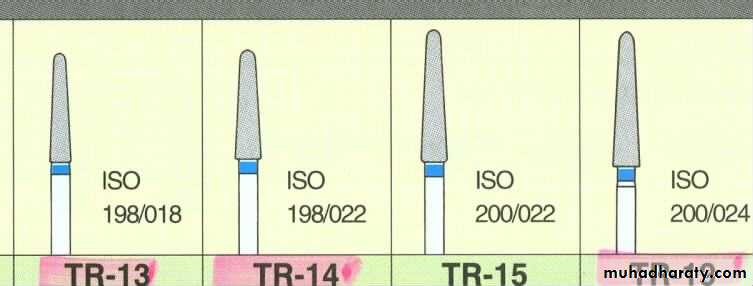

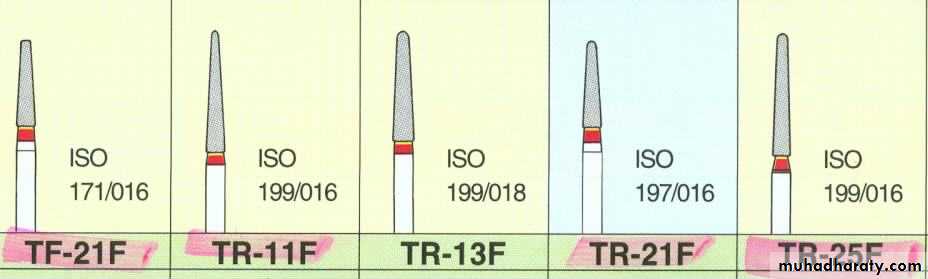

These are made from diamond chips bonded to blanks (heads). Diamonds used for grinding enamel and dentin surfacesDiamond burs may divided according to :

1- coarseness ( medium grit - fine grit )

2- shape

Medium grit

Fine grit

134Diamond particle size:

1) Coarse: 125~150 um2) Medium: 88~125 um

3) Fine: 60~74 um

4) Very fine: 38~44 um

Diamond instruments consists of three parts:

A metal blank,

The powdered diamond abrasive

A metallic bonding material that holds the diamond powder onto the blank

135

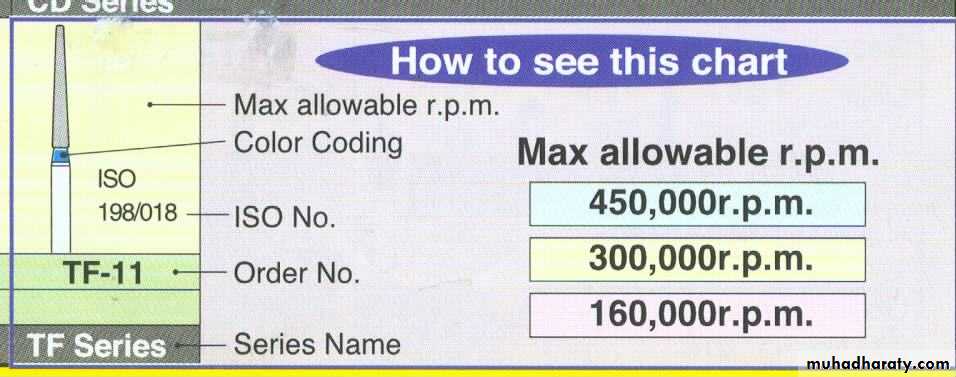

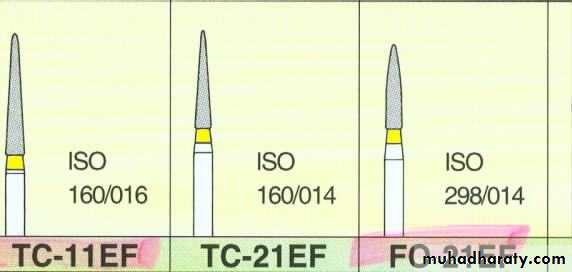

Color coding:

Coarse: 120-150µ

Standard: 106-125µ

Fine: 53-63µExtra- fine: 20-30µ

TF: Taper flat end; TR: Taper round end; TC: Taper conical end; FO: Flame Ogival end; SF: Straight flat end; SO: Straight Ogival end; BR: Ball round; WR: wheel round edge;Green

Blue

Red

Yellow

136

137

Discs, Mandrel, Stones, and Wheels

138

Moulded abrasive instrument –

Manufactured by pressing a uniform mixture of abrasive and matrix around roughened end of shank,Points and stones; finishing & polishing

Coated abrasive instrument –

Disks that have a thin layer of abrasive cemented to a flexible backing.surface contouring, finishing

139

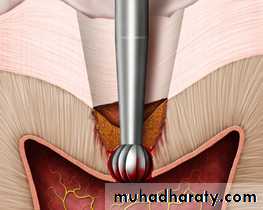

SmartPrep Instruments

• SmartPrep Instruments (Smart Bur, Polymer Bur)

• Medical polymer that has the ability to remove decayed dentine while keeping the healthy dentin.• Its hardness is less than healthy dentine while harder than the carious dentin.

• Ability to self-limit(selectively)

It will only cut what is carious and if it’s in contact with healthy dentin the bur will only wear away (when extensive force isn’t used).

140

Advantages:

ConservativeMinimal to none disease transfer (because its single use only).

No need for Local Anesthesia.

For Students to start with first clinical cases.

141

Disadvantages:

Single-patient-use = Expensive.

Technique sensitive ( too much pressure and you will cut the healthy dentine)The bur breaks down when it touches enamel.

It can sometimes leave large amounts of decayed tissue (use caries dye to locate the left amount.Access should be done by a different type of bur that can penetrate the enamel.

142Cutting Mechanisms

Bladed Cutting:Brittle fracture: crack production, by tensile loading.

High speed cutting, especially of enamel

Ductile fracture: plastic deformation, by shear.

Low speed cutting.

Abrasive Cutting:

Diamonds are most efficient when used to cut brittle materials, are superior to burs for removal of the dental enamel.

Burs are generally preferred for cutting ductile materials such as dentin.

143

Cutting Recommendations

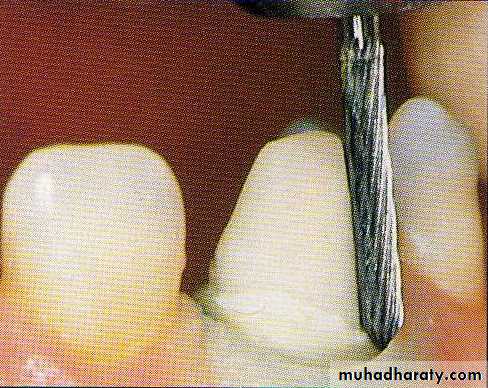

Use of contra-angled handpiece, air-water spray for cooling, high operating speed (above 200,000 rpm), light pressure.Carbide burs are better for end- cutting, produce lower heat, and have more blade edges per diameter for cutting.

Diamonds are more effective than burs for both intracoronal & extracoronal tooth preparations, beveling enamel margins on tooth preparation, & enameloplasty.

144

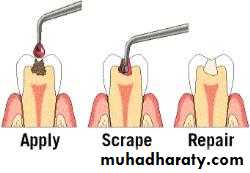

Chemo-Mechanical Caries Removal

Carisolv (Chemo‐mechanical caries removal )Composition:

0.5% sodium hypochlorite and 0.1 M amino acids “Glutamine, leucine and lycine”

This is a technique used to remove caries and decay with minimal invasive techniques.

Hypochlorite: dissolves the decayed dentine

Amino acid: buffering solution to prevent damage to the healthy tissue.

[The amino acid and hypochlorite will react with the denatured Collagen Tissue of dentine (Infected dentine) making soft and easily removed with hand instruments.]

145

Advantages:

Less anesthesia is used

Useful for children, dental‐phobic patients.Useful for removing root or coronal caries in easily accessible areas.

Removes the smear layer and doesn’t affect the bond strength of the adhesive materials.

No histological effect on the pulp even with direct contact.

146

Ozone treatment

Ozone gas has a high oxidation potential and is effective against bacteria, viruses, fungi, and protozoa.Capacity to stimulate blood circulation, platelets, and immune response.

Ozone is used in dentistry in gaseous, ozonated water and as ozonated oilsOzone has been proven to halt root caries and also reverse lesions (pit and fissure carious lesions) by allowing the natural remineralisation process to proceed.

Remineralised lesions are known to be more resistant to further dissolution than sound tooth surfaces.

147

Disruption of the protected ecological niche of the micro-flora allows remineralisation from the saliva.

Intracanal irrigants in endodontic treatment.

Treatment of alveolitis, avascular osteonecrosis of the jaw, and herpes virus infection.Inhibits plaque formation: periodontal surgical and maintenance phase.

Used in dental unit water line to disinfect water.Advantage of ozone therapy is it is an atraumatic, biologically based treatment.

148O3 delivered from the HealOzone unit: (2100 ppm O3, 615 ml/min) through a hand piece with a silicone cup that sealed the tooth.

Once sealed, the device automatically delivered the O3 for the treatment group for 10 seconds followed by 10 seconds vacuum.

Recall:

After one and three months.

Prophylaxis of teethRe-examination using the DIAGNOdent® and ECM readings.

Ozone treatment repeat on each of these two recall visits.

149

Hazards with cutting Instruments

Pulpal Precautions:Mechanical vibration, heat, desiccation, loss of dentinal tubule fluid, and or transection of odontoblastic processes.

Pulpal sequelae (recovery or necrosis) take from 2 weeks to 6 months or longer, depending upon extent and degree of trauma.

150

The remaining tissue is effective in protecting the pulp in proportion to the square of its thickness.

Steel burs produce more heat than carbide burs because of inefficient cutting.

Dull instruments will plug debris, do not cut efficiently and result in heat production.151

When used without coolants, diamond instruments generate more damaging heat than carbide burs.

Air alone as coolant: much lower heat capacity than water, desiccates dentin, damage odontoblasts.

152

Soft tissue precautions:

Lips, tongue and cheeks of the patient.Good access and visibility.

Isolation of the operating site: rubber dam, retraction type saliva ejector tip.Wait for the instrument to stop or extremely careful while removing the handpiece from the mouth.

Large disc

Sudden reflex by the patients.Hand excavators: soft caries removal in the deep preparation may lead to mechanical pulp exposure: round bur at low speed.

153

Eye Precautions

Airborne particles, old restorations, tooth structure, bacteria, debris.Strong high volume evacuation.

Ear Precautions:

Loud noise: mental and physical distress, increase accident proneness, reduce overall eficiency.Noise level in excess of 75 db, 1000 to 8000 cps(frequency) may cause hearing damage.

154

Inhalation Precautions

Amalgams or composites produce submicron particles and vapor.Alveolar irritation and tissue reactions.

During cutting or polishing: thermal decomposition of polymeric restorative materials (sealants, acrylic resins, composites) : Monomers.Mask : do not filter either mercury or monomer vapors

155

Conclusion:

The removal and shaping of the tooth structure are essential aspects of restorative dentistry. Modern high speed instruments has eliminated the need of many hand instruments, but hand cutting instruments are still important for finishing many tooth preparations and thus they remain as an essential part of the armamentarium for quality restorative dentistry.156

References:

• Sturdevant’s Art & Science of Operative Dentistry :4th edition• Fundamentals of Operative Dentistry; James B. Summitt; 3rd edition.

• Operative Dentistry of Modern Theory and Practice: M K Marzouk

• Black GV. A work on Operative Dentistry. Chicago: Medico-Dental Publishing, 1908

• Dental Hand Instruments, 2003: Elsevier Science (USA). ISBN 0-7216-9770-4

• Fundamentals of Tooth Preparation: Shillingburg

• Journal of Interdisciplinary Dentistry / Jul-Dec 2011 / Vol-1 / Issue-2

157