Chapter 1 - 1

Materials Science

Chapter 1: Introduction

Chapter 1 - 2

Key Objectives

1. List six different property classifications of materials that

determine their applicability.

2. (a) Cite the four components that are involved in the design,

production, and utilization of materials.

(b) Briefly describe the interrelationships between these

components.

3. Cite three criteria that are important in the materials selection

process.

4. List the three primary classifications of solid materials, and then

cite the distinctive chemical feature of each.

Chapter 1 -

MATERIALS

• Materials may be defined as substance of

which something is composed or made.

• We obtain materials from earth crust and

atmosphere.

• Examples :

Silicon and Iron constitute 27.72 and 5.00

percentage of weight of earths crust

respectively.

Nitrogen and Oxygen constitute 78.08 and

20.95 percentage of dry air by volume

respectively.

3

Chapter 1 - 4

1.1 Historical Perspective

• Materials are probably more deep-seated in

our culture than most of us realize.

• Transportation, housing, clothing,

communication, recreation, and food

production—virtually every segment of our

everyday lives is influenced to one degree or

another by materials.

Chapter 1 - 5

1.1 Historical Perspective

• The earliest humans had access to only a

very limited number of materials, those that

occur naturally: stone, wood, clay, skins, and

so on.

Chapter 1 - 6

1.1 Historical Perspective

• With time they discovered techniques for

producing materials that had properties

superior to those of the natural ones;; these

new materials included pottery and various

metals.

• Furthermore,it was discovered that the

properties of a material could be altered by

heat treatments and by the addition of other

substances.

Chapter 1 - 7

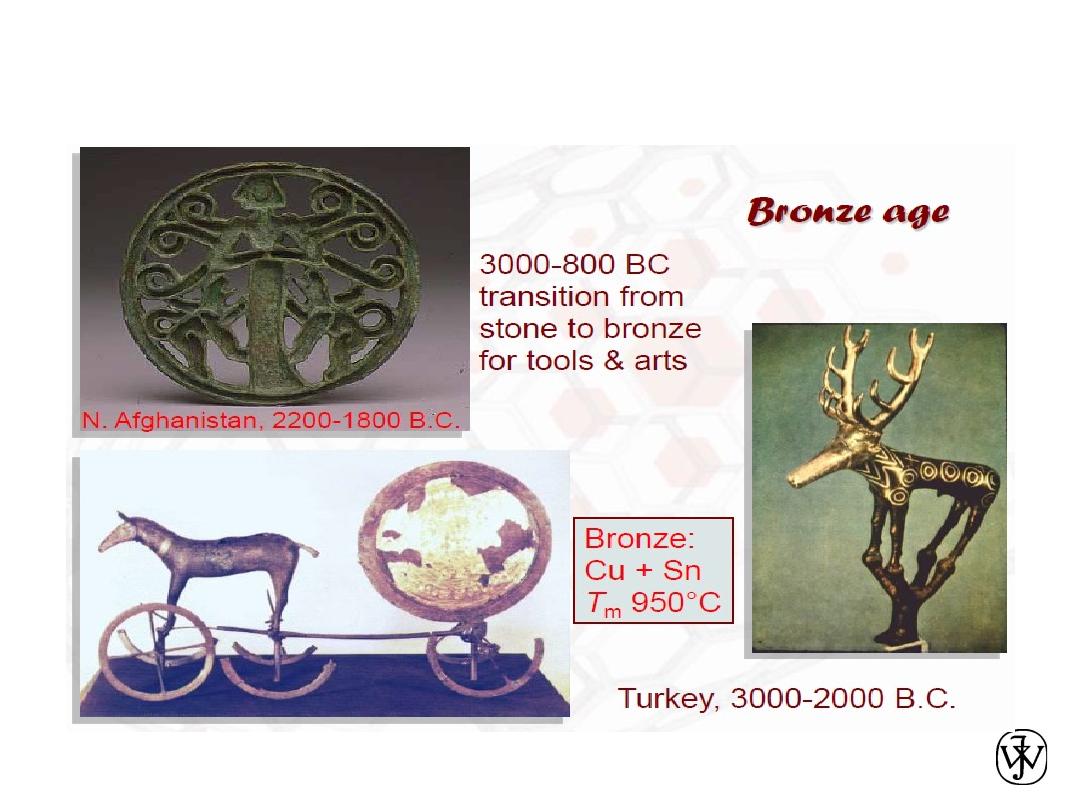

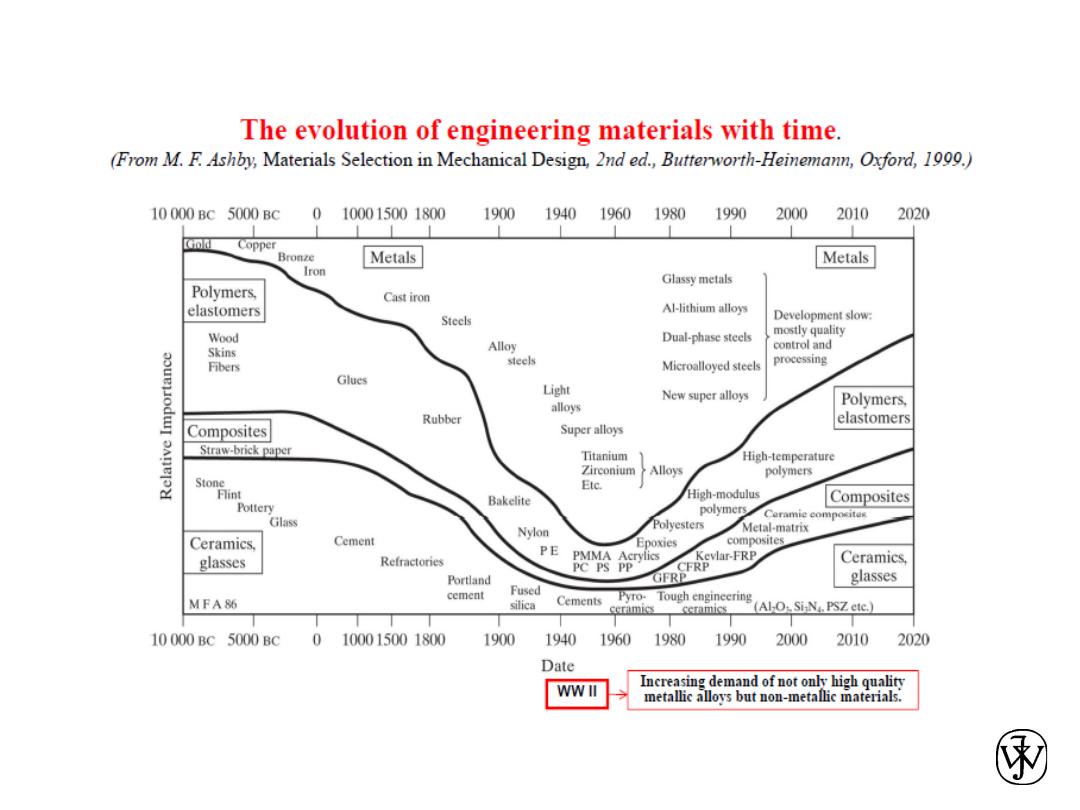

1.1 Historical Perspective

• Materials drive our society

– Stone Age: Natural materials (2.5M BC)

– Bronze Age: Processed materials (3500 BC)

– Iron Age (1000 BC)

– Now?

• Silicon Age?

• Polymer Age?

• Bio-technology, Nano-technology, etc

Chapter 1 - 8

1.1 Historical Perspective

Chapter 1 - 9

1.1 Historical Perspective

Chapter 1 - 10

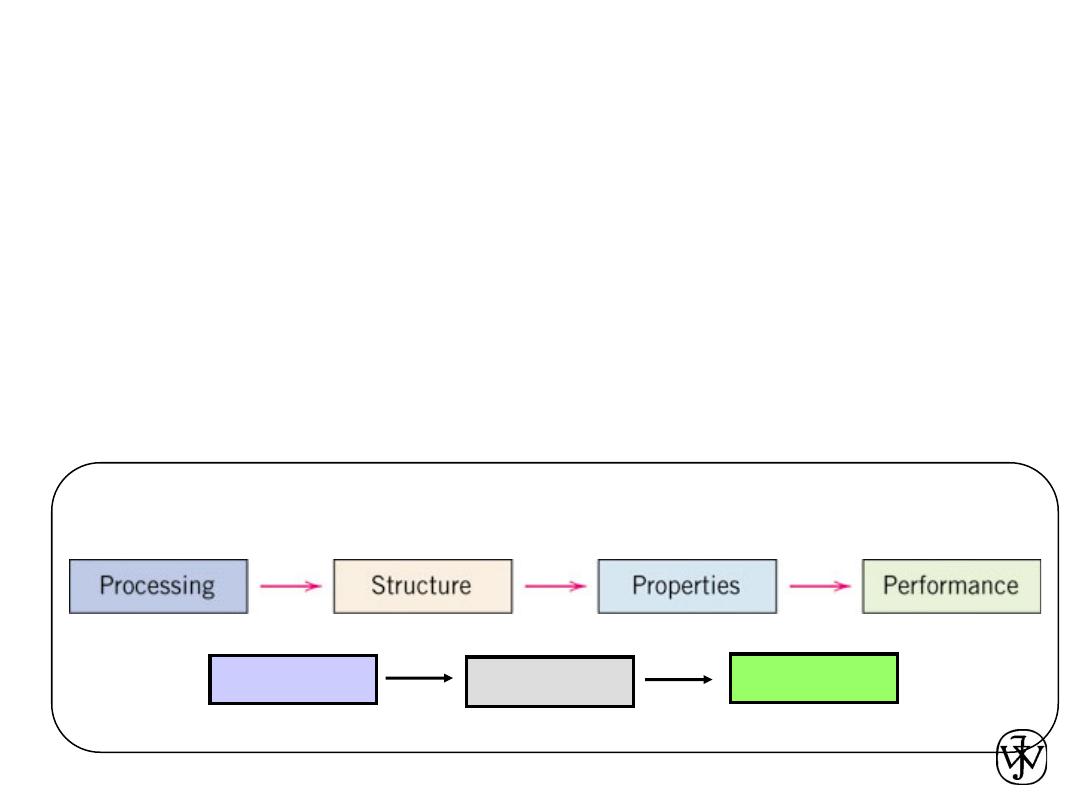

1.2 Materials Science & Materials Engineering

• Materials Science:

– involves the investigation of the

relationship between the

structures and properties of materials

• Materials Engineering:

– on the basis of the structure-property correlations,

designing

(or engineering) the structure to produce a target property

Materials Science and Engineering

Design

Production

Application

Chapter 1 - 11

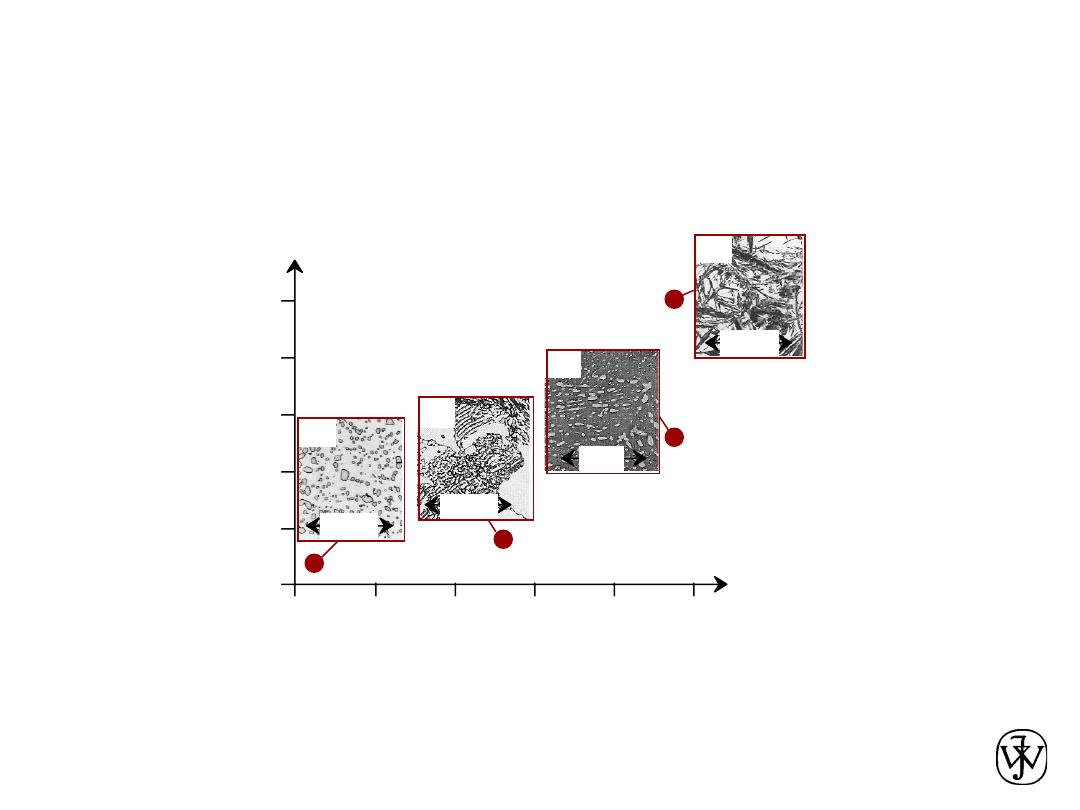

ex: hardness vs structure of steel

•

Properties

depend on

structure

Data obtained from Figs. 10.30(a)

and 10.32 with 4 wt% C composition,

and from Fig. 11.14 and associated

discussion, Callister 7e.

Micrographs adapted from (a) Fig.

10.19;; (b) Fig. 9.30;;(c) Fig. 10.33;;

and (d) Fig. 10.21, Callister 7e.

ex: structure vs cooling rate of steel

•

Processing

can change

structure

H

ar

dn

ess

(B

H

N

)

Cooling Rate (ºC/s)

100

200

300

400

500

600

0.01 0.1

1

10

100 1000

(d)

30

µm

(c)

4

µm

(b)

30

µm

(a)

30

µm

Structure-Property Relationship – Example #1

Chapter 1 - 12

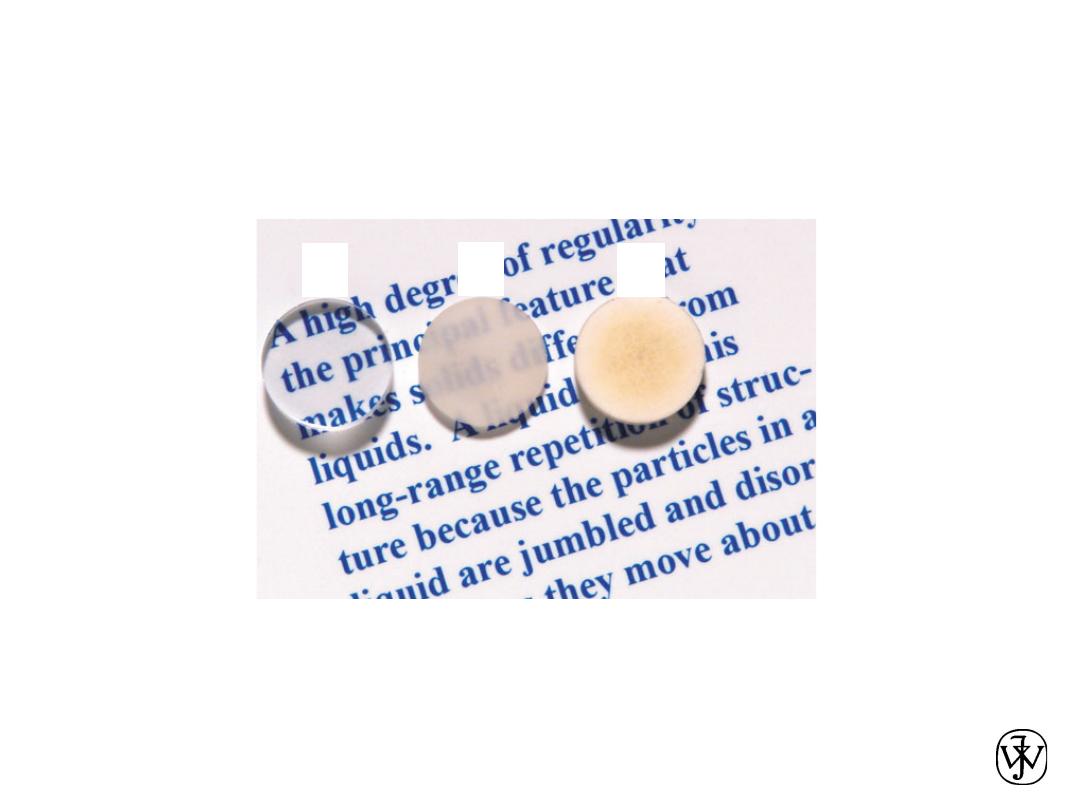

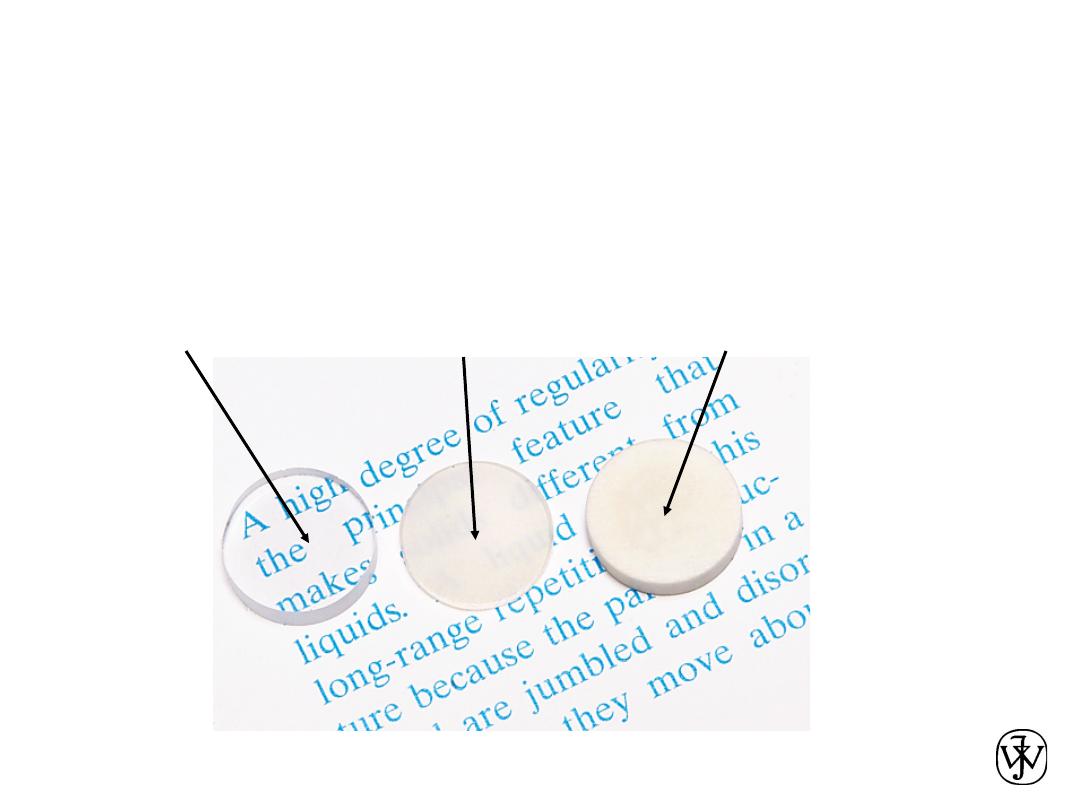

Structure-Property Relationship – Example #2

• A: Single crystal – transparent

• B: Polycrystal – translucent

• C: Porous polycrystal - opaque

A

B

C

•

Three thin disks (A, B, and C) of aluminum oxide (alumina, Al

2

O

3

) –

same material

but

different microstructures

, and hence,

different optical

properties

(light-transmittance characteristics).

Chapter 1 - 13

1.

Pick

Application

Determine required

Properties

2.

Properties

Identify candidate

Material(s)

3.

Material

Identify required

Processing

Processing: changes structure and overall shape

ex: casting, sintering, vapor deposition, doping

forming, joining, annealing.

Properties: mechanical, electrical, thermal,

magnetic, optical, deteriorative.

Material: structure, composition.

The Materials Selection Process

Chapter 1 - 14

1.3 Structure

• Structure of a material relates to the arrangement of its internal

components.

– Subatomic structure

: electrons within the individual atoms

and interactions with their nuclei (Ch. 2)

– Atomic level

: structure encompasses the organization of

atoms or molecules relative to one another (Ch. 3)

– Microscopic level

: large groups of atoms that are normally

agglomerated together (Ch. 4)

– Macroscopic level

: structural elements that may be viewed

with the naked eye

Chapter 1 - 15

1.4 Classification of Properties

• Property: the kind and magnitude of response to a specific

imposed stimulus

• Properties of solid materials:

– Mechanical

: relate deformation to an applied load or force;;

elastic modulus, strength, etc (Ch. 6, 7, 8, etc)

– Electrical

: electrical conductivity (Ch. 18)

– Thermal

: heat capacity and thermal conductivity (Ch. 19)

– Magnetic

: response of a material to the application of a

magnetic field (Ch. 20)

– Optical

: response to electromagnetic or light radiation;; index

of refraction, reflectivity (Ch. 21)

– Deteriorative

: the chemical reactivity of materials (Ch. 17)

Chapter 1 - 16

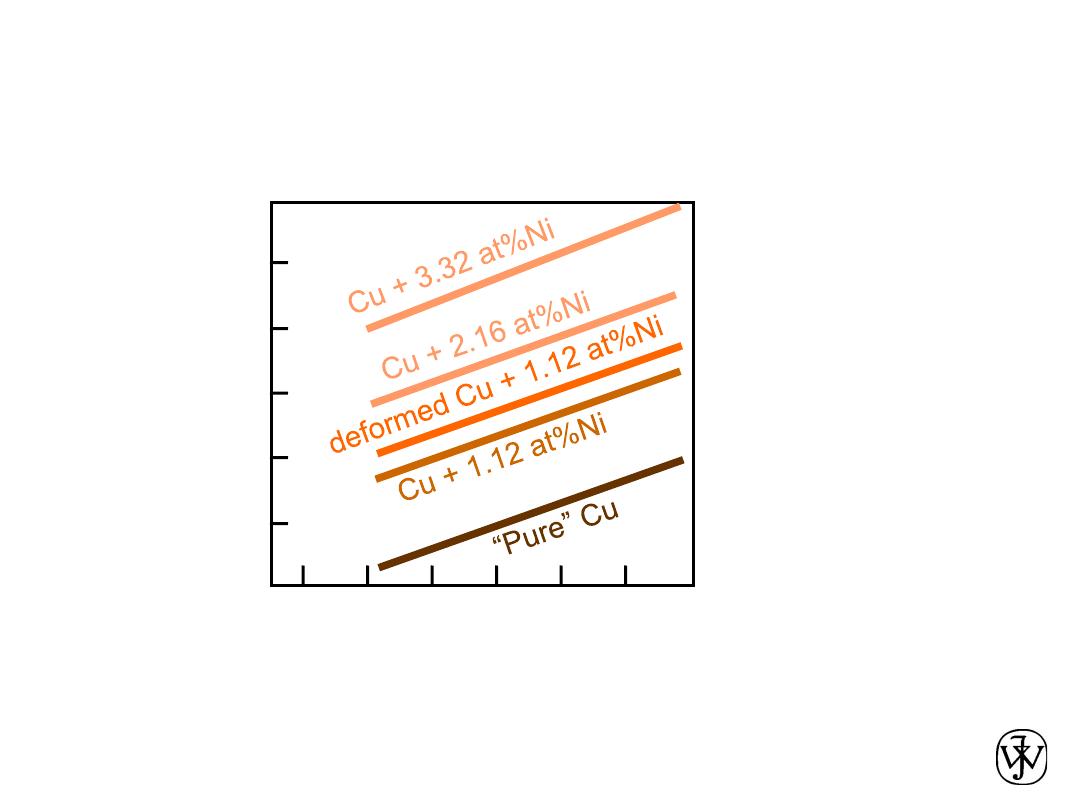

ELECTRICAL

• Electrical Resistivity of Copper:

• Adding “

impurity

” atoms to Cu increases

resistivity

.

•

Deforming

Cu increases

resistivity

.

Adapted from Fig. 18.8, Callister 7e.

(Fig. 18.8 adapted from: J.O. Linde,

Ann Physik 5, 219 (1932);; and

C.A. Wert and R.M. Thomson,

Physics of Solids, 2nd edition,

McGraw-Hill Company, New York,

1970.)

T (°C)

-200

-100

0

1

2

3

4

5

6

R

esi

st

ivi

ty

, r

(1

0

-8

Oh

m

-m)

0

Chapter 1 - 17

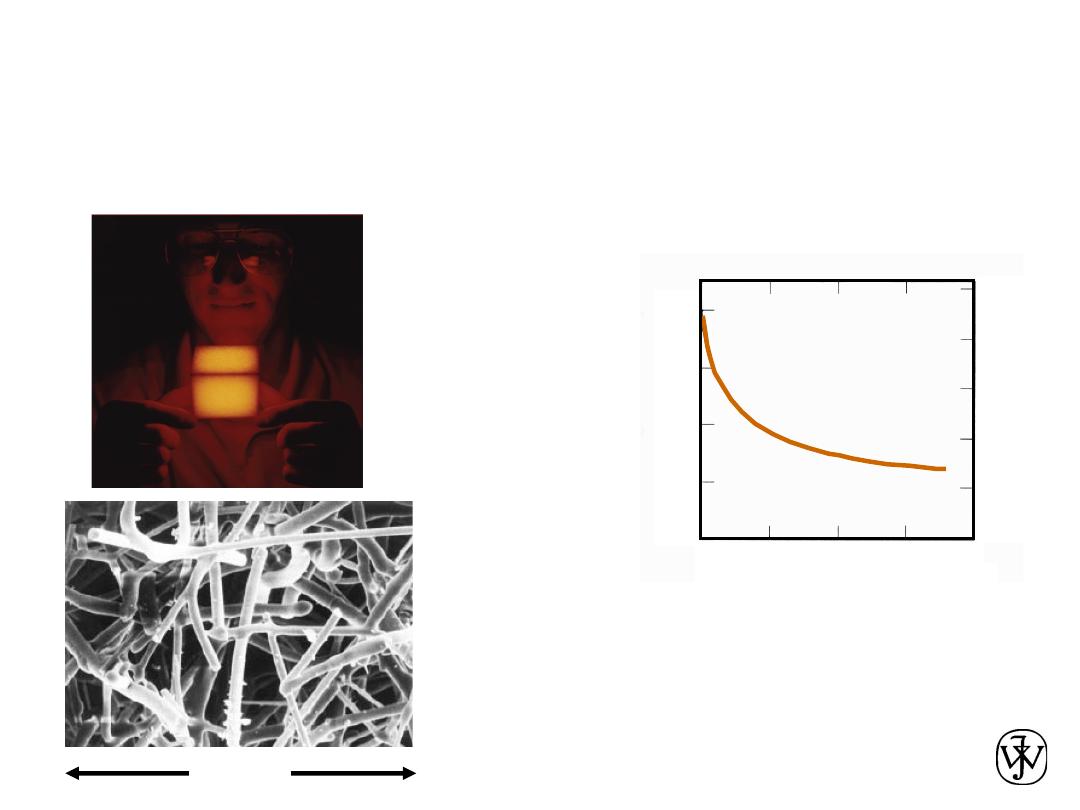

THERMAL

• Space Shuttle Tiles:

--Silica fiber insulation

offers low

heat conduction

.

•

Thermal Conductivity

of Copper:

--It decreases when

you add zinc!

Adapted from

Fig. 19.4W, Callister

6e. (Courtesy of

Lockheed Aerospace

Ceramics Systems,

Sunnyvale, CA)

(Note: "W" denotes fig.

is on CD-ROM.)

Adapted from Fig. 19.4, Callister 7e.

(Fig. 19.4 is adapted from Metals Handbook:

Properties and Selection: Nonferrous alloys and

Pure Metals, Vol. 2, 9th ed., H. Baker,

(Managing Editor), American Society for Metals,

1979, p. 315.)

Composition (wt% Zinc)

T

he

rm

al

C

on

du

ct

ivi

ty

(W/

m

-K)

400

300

200

100

0

0

10

20

30

40

100

µm

Adapted from chapter-

opening photograph,

Chapter 19, Callister 7e.

(Courtesy of Lockheed

Missiles and Space

Company, Inc.)

Chapter 1 - 18

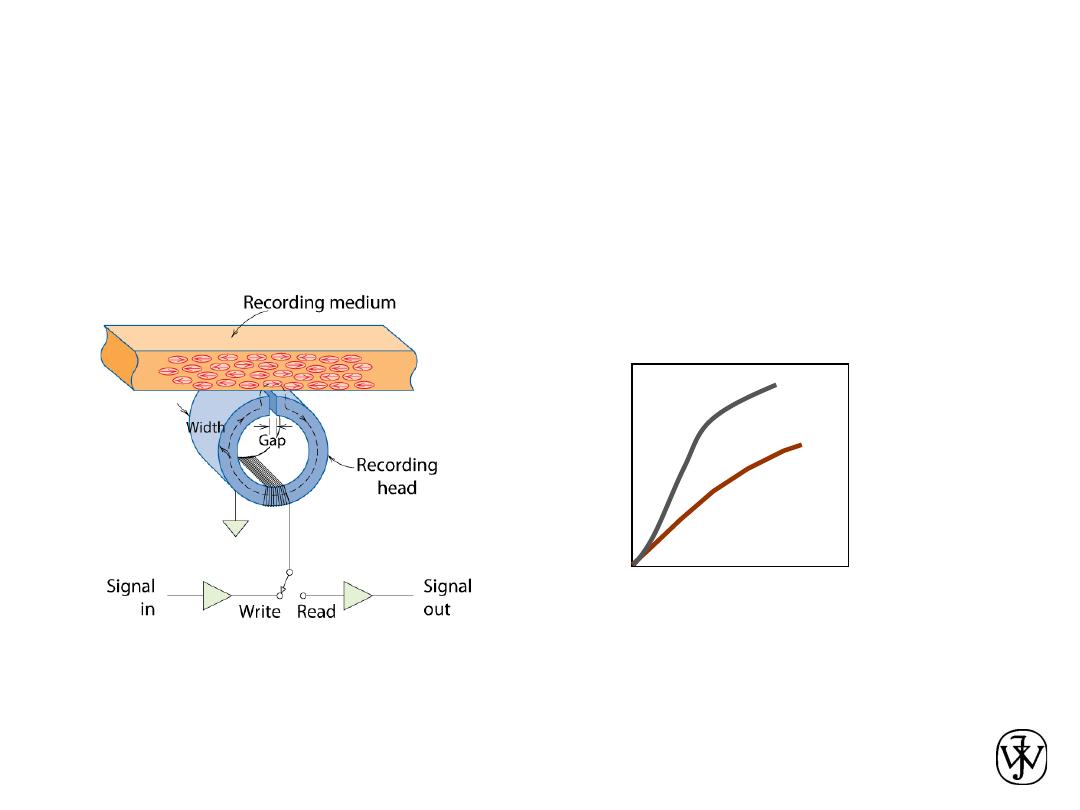

MAGNETIC

•

Magnetic Permeability

vs. Composition:

--Adding 3 atomic % Si

makes Fe a better

recording medium!

Adapted from C.R. Barrett, W.D. Nix, and

A.S. Tetelman, The Principles of

Engineering Materials, Fig. 1-7(a), p. 9,

1973. Electronically reproduced

by permission of Pearson Education, Inc.,

Upper Saddle River, New Jersey.

Fig. 20.23, Callister 7e.

(Fig. 20.23 is from J.U. Lemke, MRS Bulletin,

Vol. XV, No. 3, p. 31, 1990.)

•

Magnetic Storage

:

--Recording medium

is magnetized by

recording head.

Magnetic Field

M

ag

ne

tiza

tio

n

Fe+3%Si

Fe

Chapter 1 - 19

•

Transmittance

:

--Aluminum oxide may be transparent, translucent, or

opaque depending on the material structure.

Adapted from Fig. 1.2,

Callister 7e.

(Specimen preparation,

P.A. Lessing;; photo by S.

Tanner.)

single crystal

polycrystal:

low porosity

polycrystal:

high porosity

OPTICAL

Chapter 1 - 20

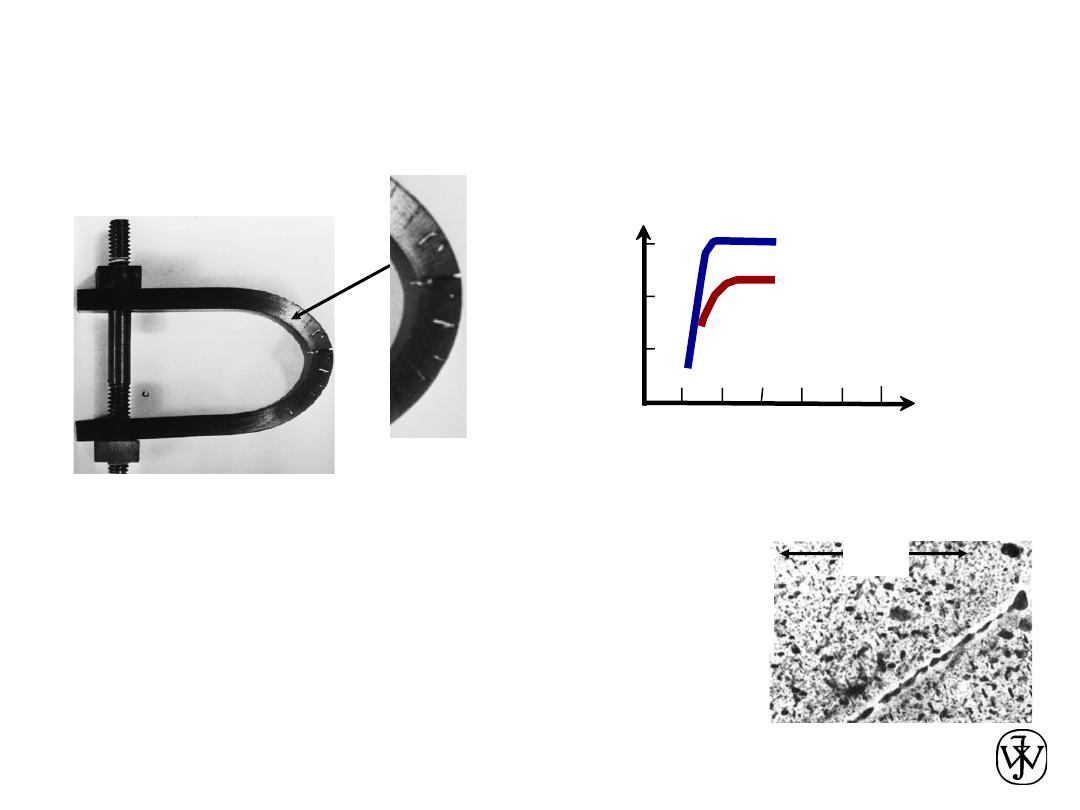

DETERIORATIVE

• Stress & Saltwater...

--causes cracks!

Adapted from chapter-opening photograph,

Chapter 17, Callister 7e.

(from Marine Corrosion, Causes, and

Prevention, John Wiley and Sons, Inc., 1975.)

4

µm

--material:

7150-T651 Al "alloy"

(Zn,Cu,Mg,Zr)

Adapted from Fig. 11.26,

Callister 7e. (Fig. 11.26 provided courtesy of G.H.

Narayanan and A.G. Miller, Boeing Commercial

Airplane Company.)

• Heat treatment:

slows

crack speed in salt water!

Adapted from Fig. 11.20(b), R.W. Hertzberg, "Deformation and

Fracture Mechanics of Engineering Materials" (4th ed.), p. 505, John

Wiley and Sons, 1996. (Original source: Markus O. Speidel, Brown

Boveri Co.)

“held at

160ºC for 1 hr

before testing”

increasing load

cr

a

ck

sp

e

e

d

(

m

/s)

“as-is”

10

-10

10

-8

Alloy 7178 tested in

saturated aqueous NaCl

solution at 23ºC

Chapter 1 - 21

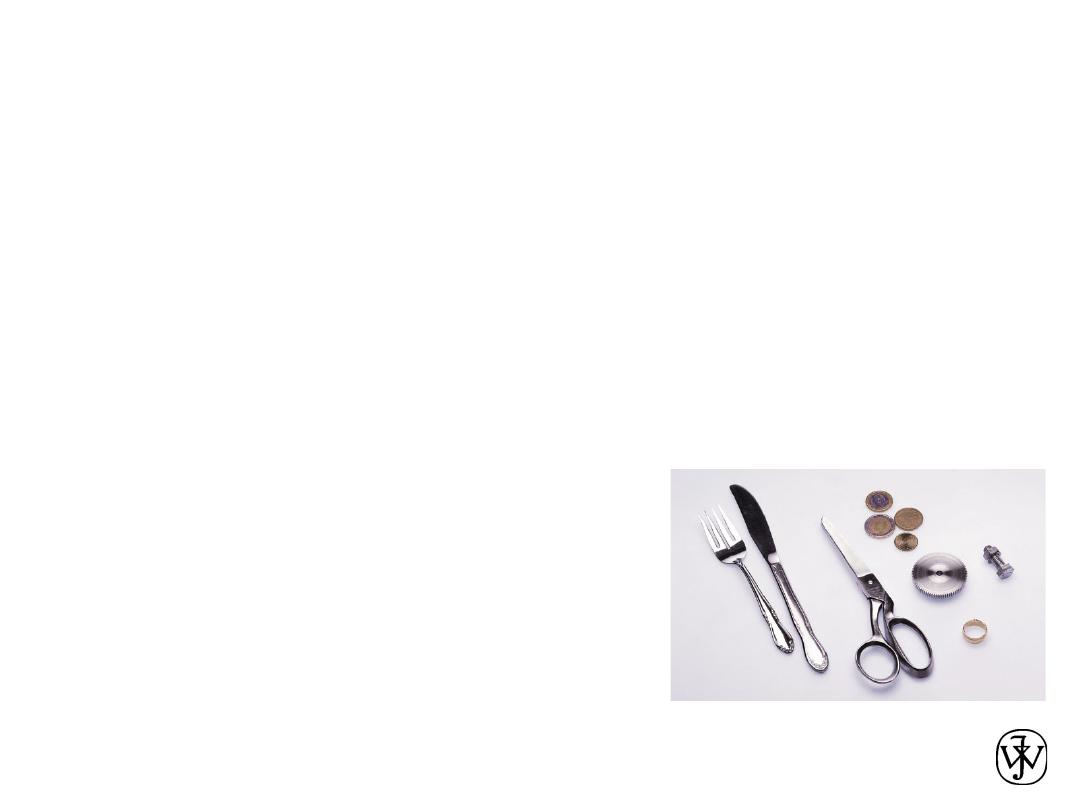

1.5 Types of (Solid) Materials

•

Three basic classifications based on chemical makeup and atomic

structure:

Metals

,

Ceramics

, and

Polymers

.

•

In addition to these basic three: composites, advanced materials, etc.

•

Metals

:

– Metallic elements: Fe, Al, Cu, Ti, Au, Ni, etc.

– Metallic bonding

– Strong, ductile

– high thermal & electrical conductivity

– opaque, reflective.

Chapter 1 - 22

•

Ceramics

:

– compounds of metallic & non-metallic elements (oxides, carbides,

nitrides, sulfides)

– Al

2

O

3

, SiO

2

, SiC, Si

3

N

4

, traditional ceramics (porcelain), cement,

glass, etc

– Ionic bonding (refractory)

– Brittle, glassy, elastic

– non-conducting (insulators)

Chapter 1 - 23

•

Polymers

:

– Polyethylene, nylon, poly(vinyl chloride) (PVC), etc

– Covalent bonding à sharing of electrons

– Soft, ductile, low strength, low density

– thermal & electrical insulators

– Optically translucent or transparent.

Chapter 1 - 24

•

Composites:

– Composed of two (or more) of the basic materials

– Ceramic-fiber reinforced metal-matrix composites (MMC), carbon-

fiber-reinforced polymer (CFRP), etc

– Combination of properties

Chapter 1 - 25

1.6 Advanced Materials

• Advanced materials: materials for so-called

high-tech

applications

– Electronic equipment

– computers

– Spacecraft

– Aircraft

– Military rocketry

– Semiconductors

– Biomaterials

– Smart materials

– Nano-engineered materials

Chapter 1 - 26

Example – Smart Materials

• These materials are able to sense changes in their

environments and then respond to these changes in

predetermined manners.

• Sensors, actuators, etc.

• Actuators made of smart materials change shape,

position, natural frequency, or mechanical

characteristics in response to changes in

temperature, electric fields, and/or magnetic fields.

Chapter 1 - 27

Example – Smart Materials

•

Shape memory alloys

(SMA):

– Metals that, after having been deformed, revert back to their

original shapes when temperature is changes (Ch. 10.9)

•

Piezoelectric ceramics

(PZT):

– Expand and contract in response to an applied electric field (or

voltage)

– Or, they generate an electric field when their dimensions are

altered (Ch. 18.25)

•

Magnetostrictive materials

:

– Similar to PZT except that they are responsive to magnetic fields

•

Electrorheological and magnetorheological fluids

:

– Liquids that experience dramatic changes in viscosity upon the

application of electric and magnetic fields

Chapter 1 - 28

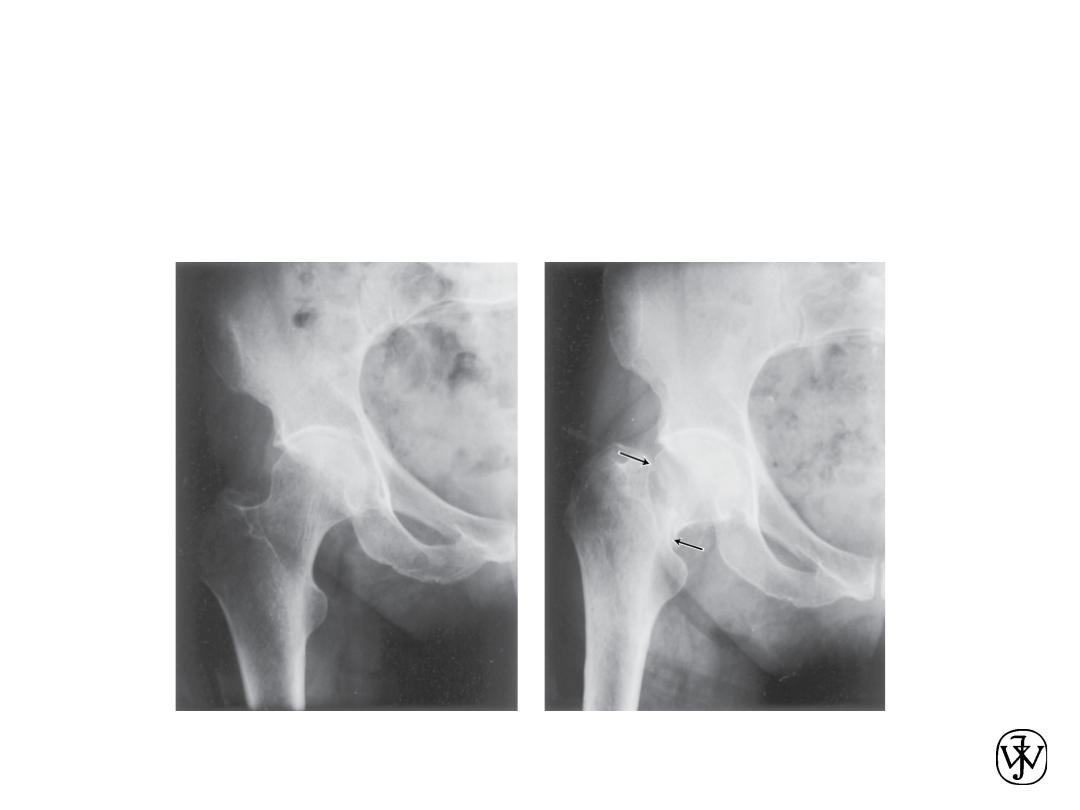

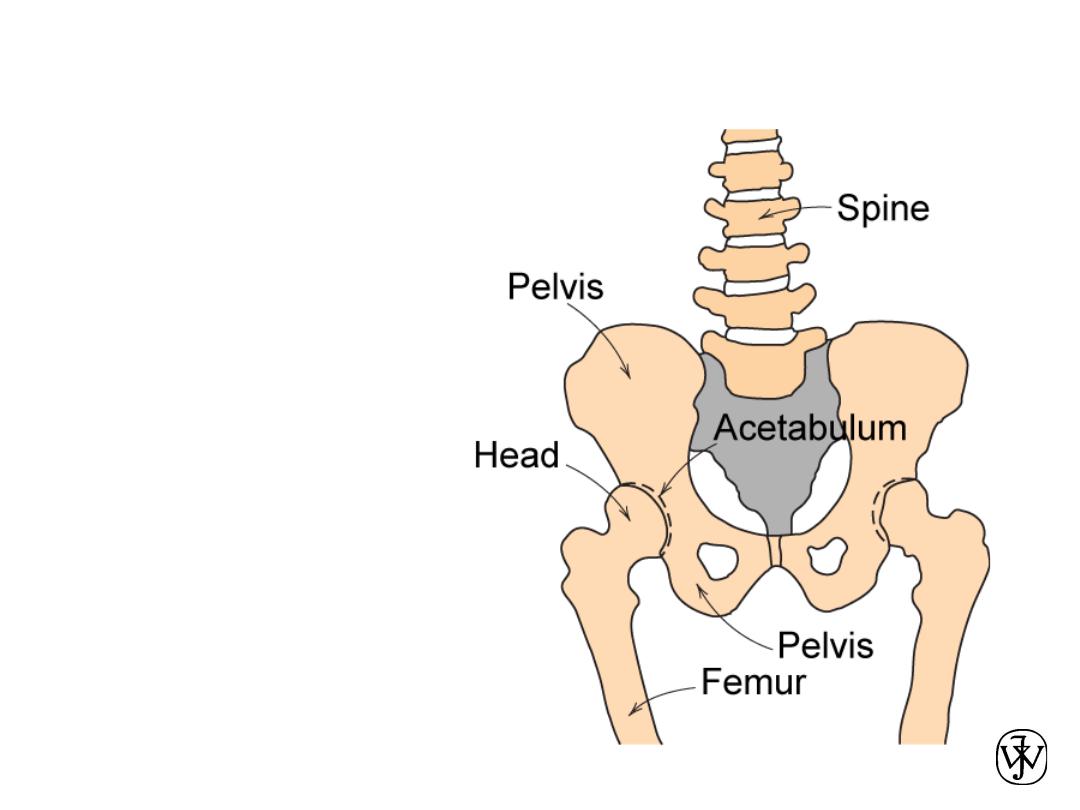

Example – Hip Implant

• With age or certain illnesses joints deteriorate.

Particularly those with large loads (such as hip).

Adapted from Fig. 22.25, Callister 7e.

Chapter 1 - 29

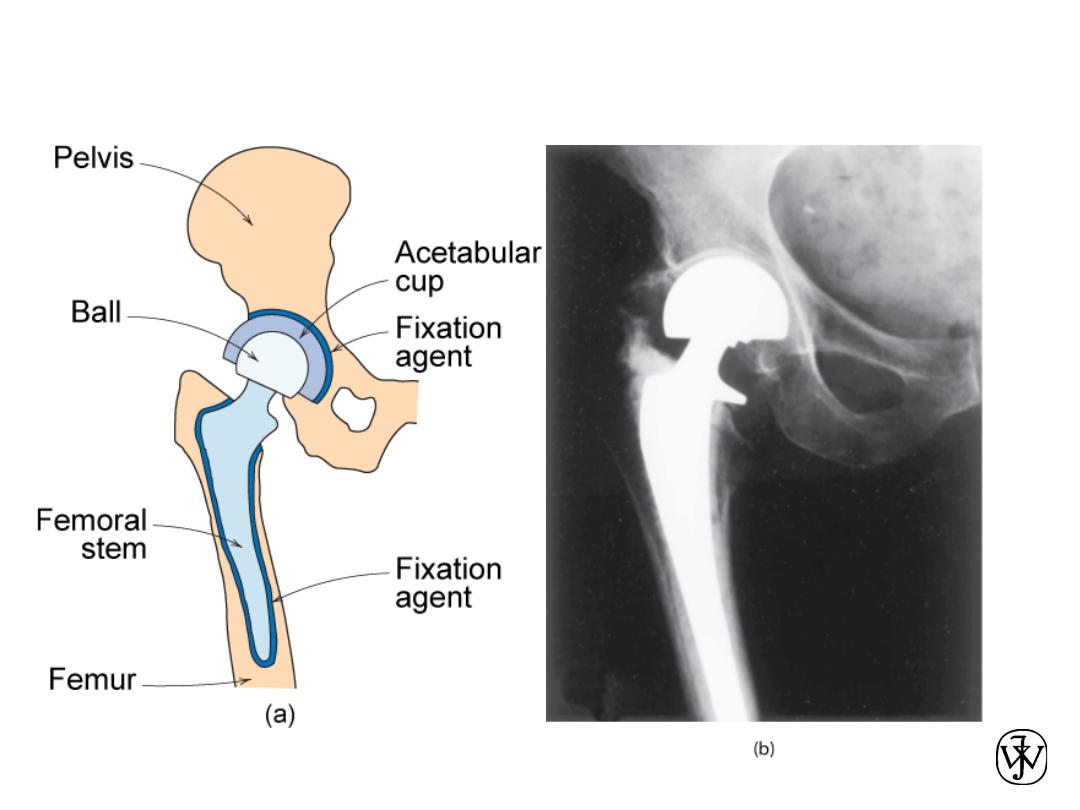

Example – Hip Implant

• Requirements

– mechanical

strength (many

cycles)

– good lubricity

– biocompatibility

Adapted from Fig. 22.24, Callister 7e.

Chapter 1 - 30

Example – Hip Implant

Adapted from Fig. 22.26, Callister 7e.

Chapter 1 - 31

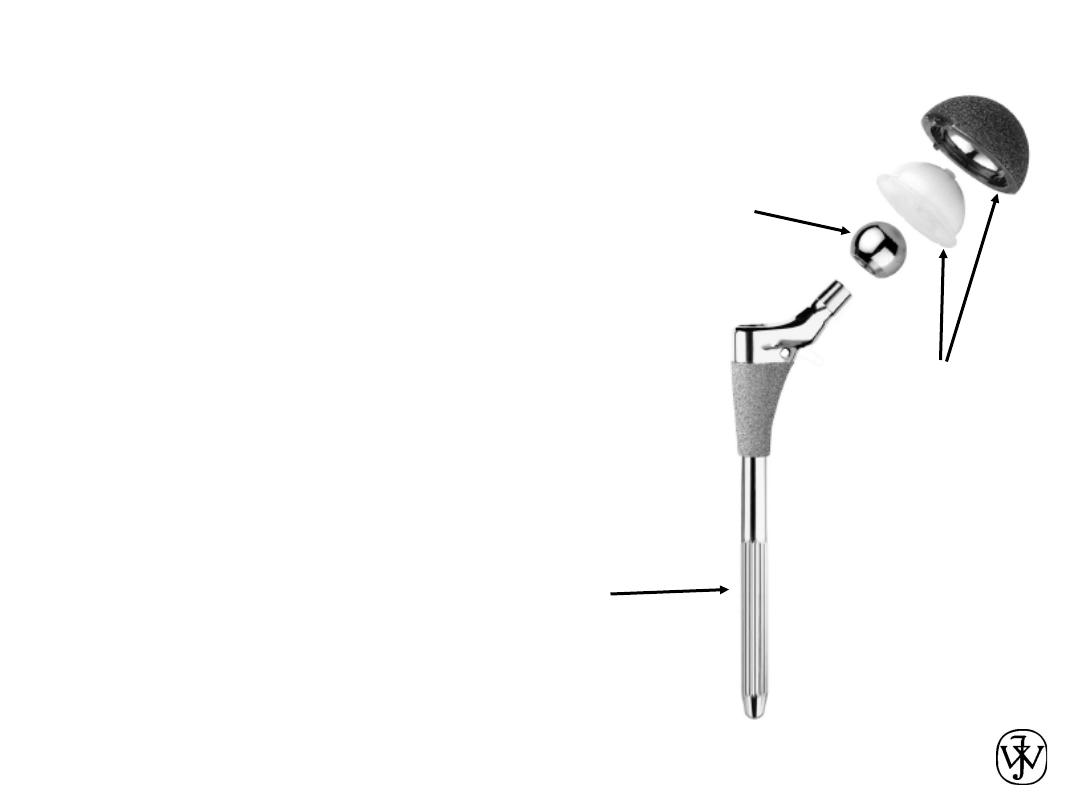

Hip Implant

• Key problems to overcome

– fixation agent to hold

acetabular cup

– cup lubrication material

– femoral stem – fixing agent

(“glue”)

– must avoid any debris in cup

Adapted from chapter-opening photograph,

Chapter 22, Callister 7e.

Femoral

Stem

Ball

Acetabular

Cup and Liner

Chapter 1 -

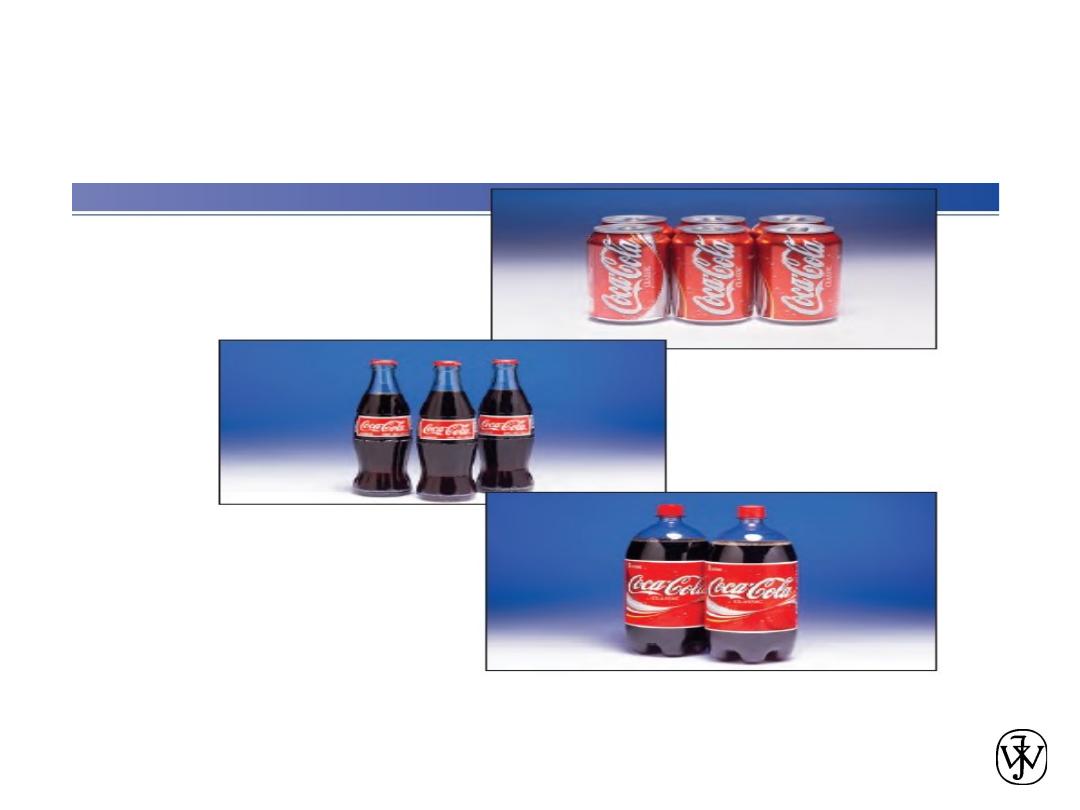

Example : How to choose the right

material?

32

Chapter 1 -

Example : How to choose the right

material?

• One common item that presents some

interesting material property requirements is

the container for carbonated beverages.

• The material used for this application must

satisfy the following constraints:

• (1) provide a barrier to the passage

• of carbon dioxide, which is under pressure in

• the container;;

• (2) be nontoxic, unreactive with thebeverage,

and, preferably be recyclable;;

33

Chapter 1 -

• (3) be relatively strong, and capable of

surviving a drop from a height of several feet

when containing the beverage;;

• (4) be inexpensive and the cost to fabricate

the final shape should be relatively low;;

• (5) if optically transparent, retain its optical

clarity;; and

• (6) capable of being produced having

different colors and/or able to be adorned

with decorative labels.

34

Chapter 1 -

• All three of the basic material types—metal

(aluminum), ceramic (glass), and polymer

(polyester plastic)

• All of these materials are nontoxic, and

unreactive with beverages.

35

Chapter 1 - 36

• Use the right material for the job.

• Understand the relation between

properties

,

structure

, and

processing

.

• Recognize new design opportunities offered

by materials selection.

Course Goals:

SUMMARY