ISSUES TO ADDRESS...

•

Stress

and

strain

: What are they and why are

they used instead of load and deformation?

•

Elastic

behavior: When loads are small, how much

deformation occurs? What materials deform least?

•

Plastic

behavior: At what point do dislocations

cause permanent deformation? What materials are

most resistant to permanent deformation?

1

•

Toughness

and

ductility

: What are they and how

do we measure them?

CHAPTER 6:

MECHANICAL PROPERTIES

• Ceramic Materials:

What special provisions/tests are

made for ceramic materials?

Many materials, when in service, are subjected to forces

or loads; examples include the aluminum alloy from which

an airplane wing is constructed and the steel in an

automobile axle.

In such situations it is necessary to know the

characteristics of the material and to design the member

from which it is made such that any resulting deformation

will not be excessive and fracture will not occur.

The mechanical behavior of a material reflects the

relationship between its response or deformation

to an applied load or force.Key mechanical design

properties are stiffness, strength, hardness, ductility, and

toughness.

Factors to be considered include the nature of the

applied

load

and

its

duration,

as

well

as

the

environmental conditions.

It is possible for the load to be tensile, compressive, or

shear, and its magnitude may be constant with time, or it

may fluctuate continuously.

Application time may be only a fraction of a second, or it

may extend over a period of many years.

Service temperature may be an important factor.

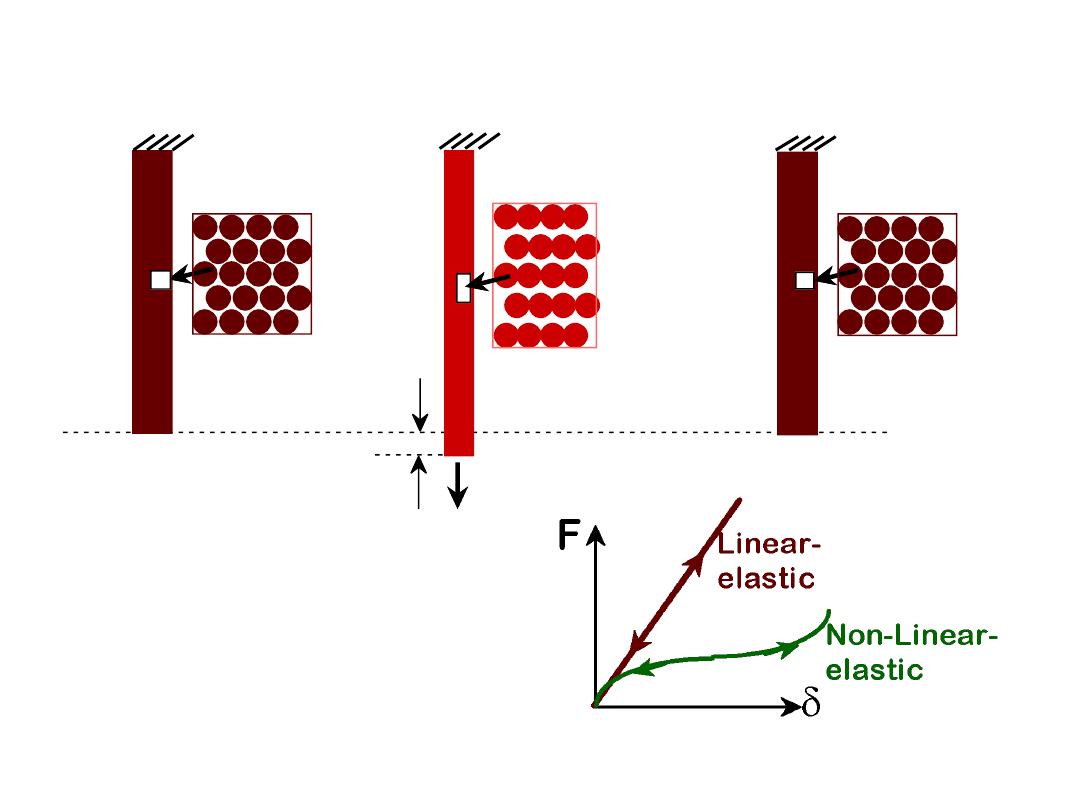

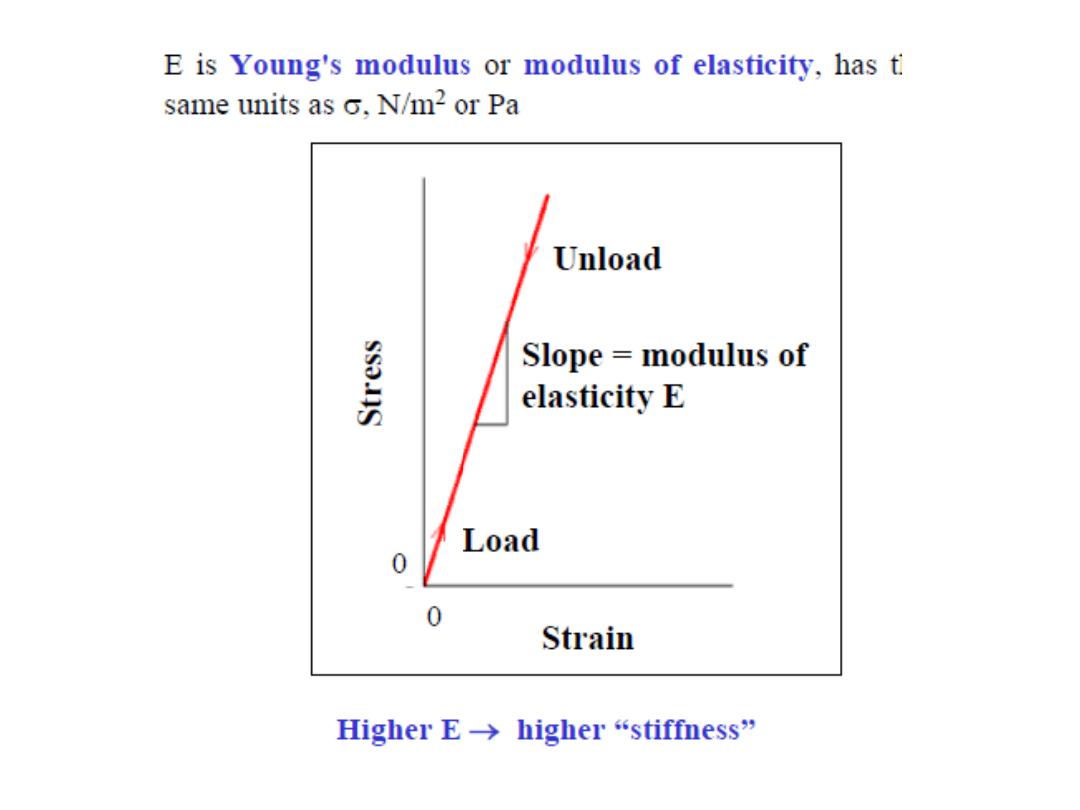

Elastic deformation

is the deformation in which stress and

strain are linearly proportional.

So, the slope of line is E which may be thought as

the stiffness or material’s resistance

to elastic deformation.

Elastic deformation is reversible (nonpermanent),

specimen returns to its original shape when

applied load is released

F

bonds

stretch

return to

initial

2

1. Initial

2. Small load

3. Unload

Elastic means

reversible

!

ELASTIC DEFORMATION

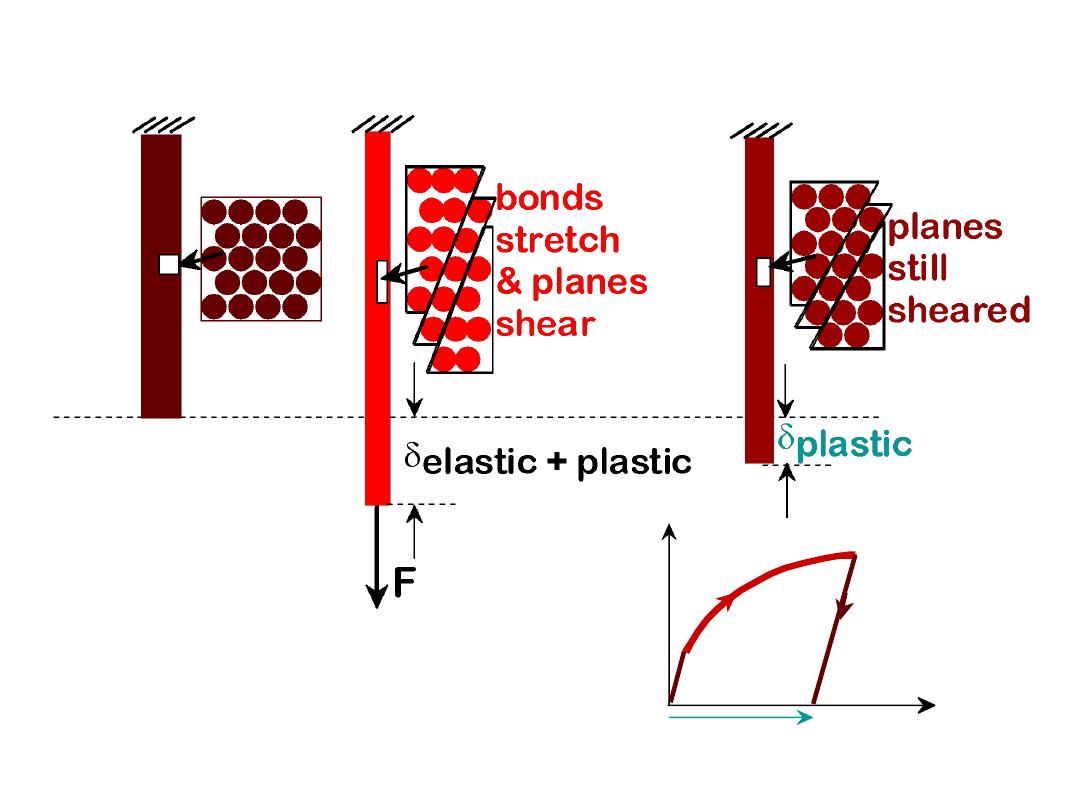

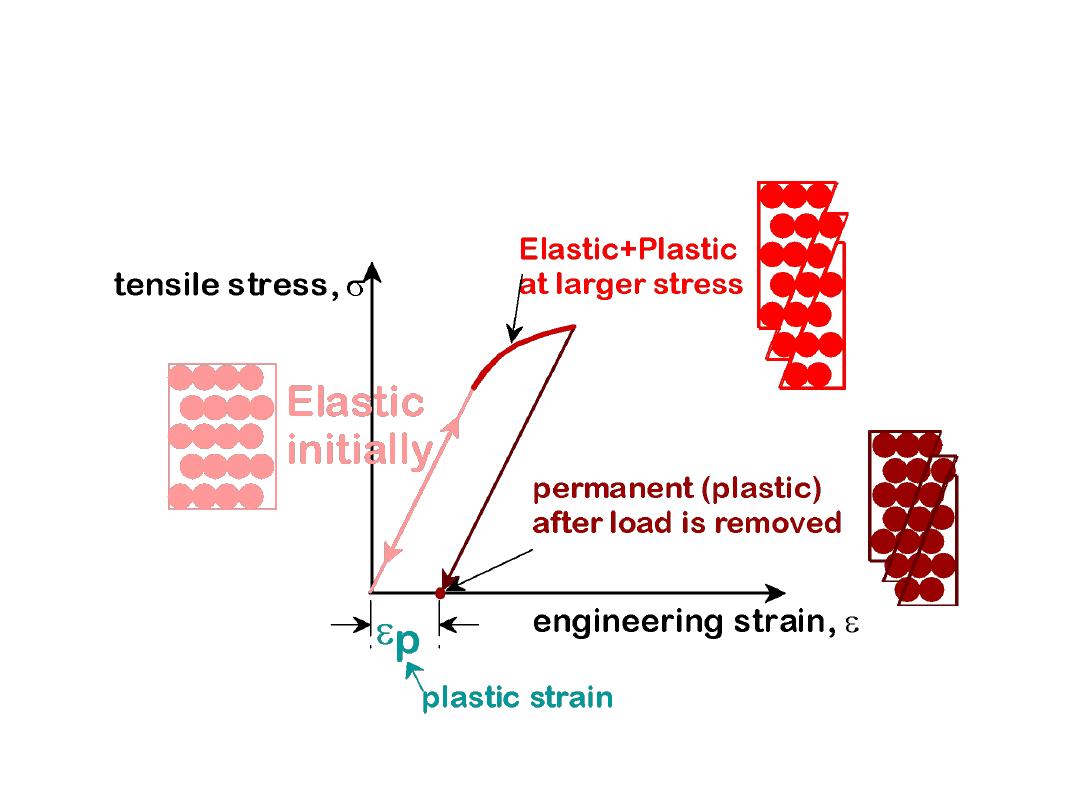

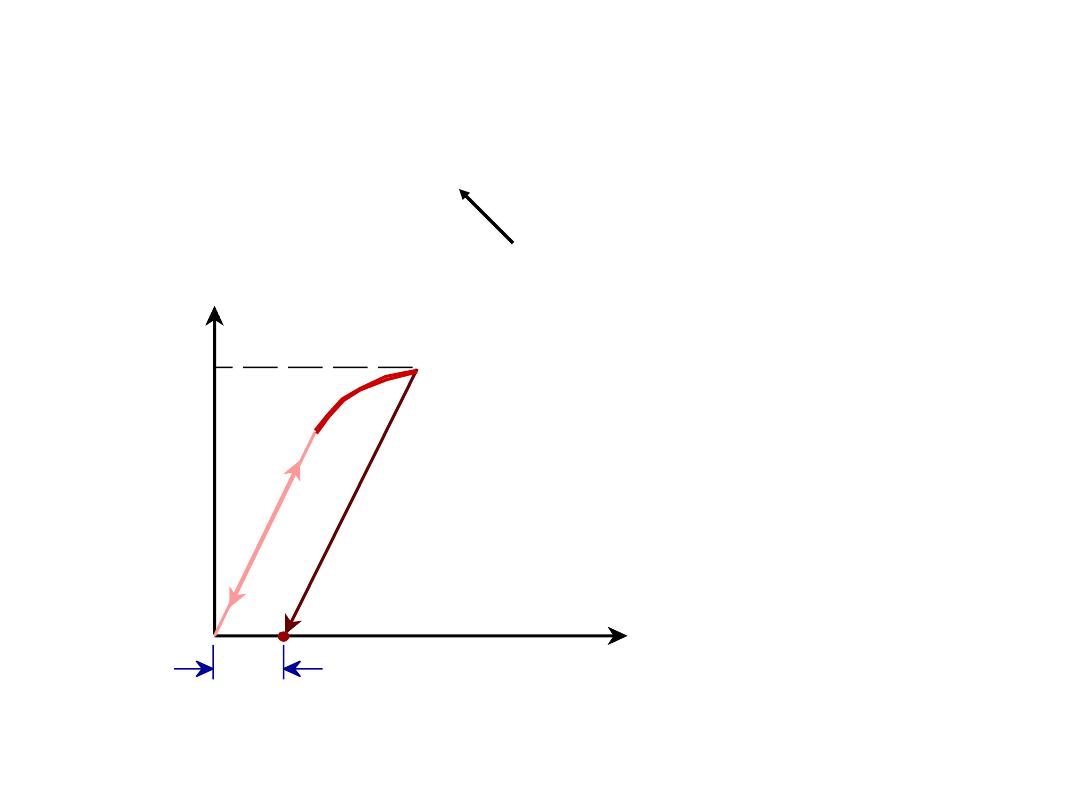

For most metallic materials, elastic deformation persists only to

strains of about 0.005.

As the material is deformed beyond this point, the stress and

strains are no longer linearly proportional

(Hook’s law is not valid) and permanent (nonrecoverable) or

plastic deformation occurs

3

1. Initial

2. Small load

3. Unload

Plastic means

permanent

!

F

linear

elastic

linear

elastic

plastic

PLASTIC DEFORMATION

(METALS)

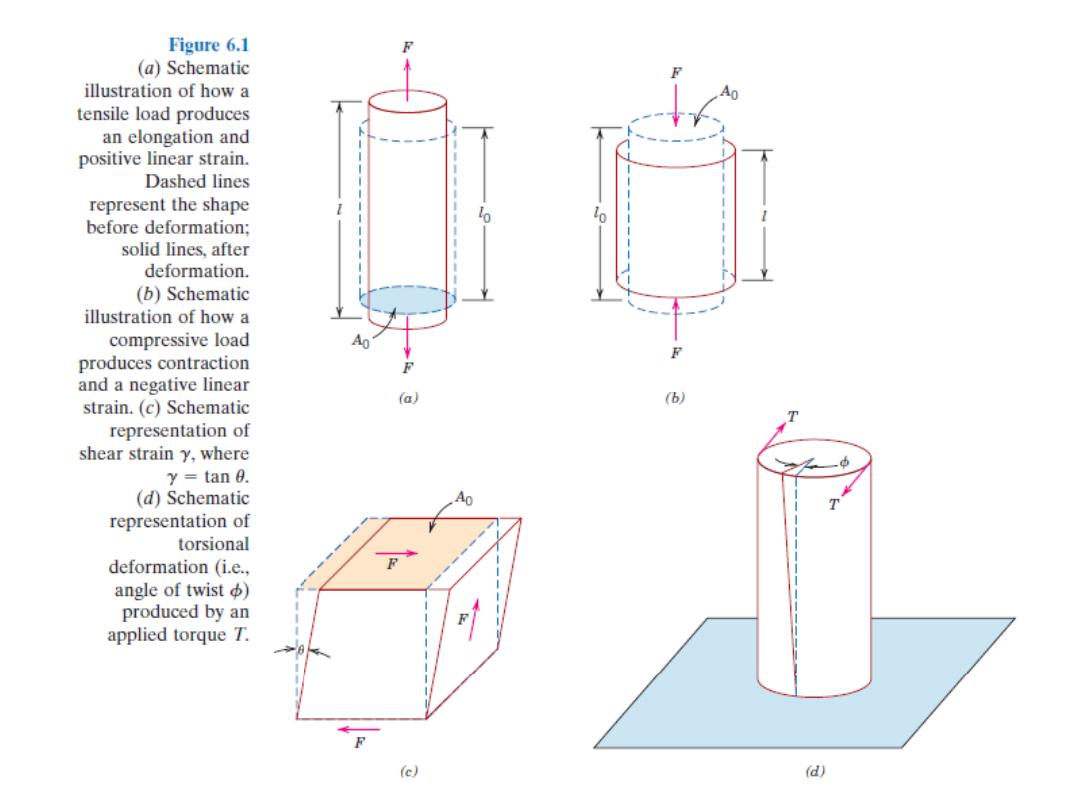

If a load is static or changes relatively slowly with time and

is applied uniformly over a cross section or surface of a

member, the mechanical behavior may be ascertained by

a simple stress

–strain test; these are most commonly

conducted for metals at room temperature.

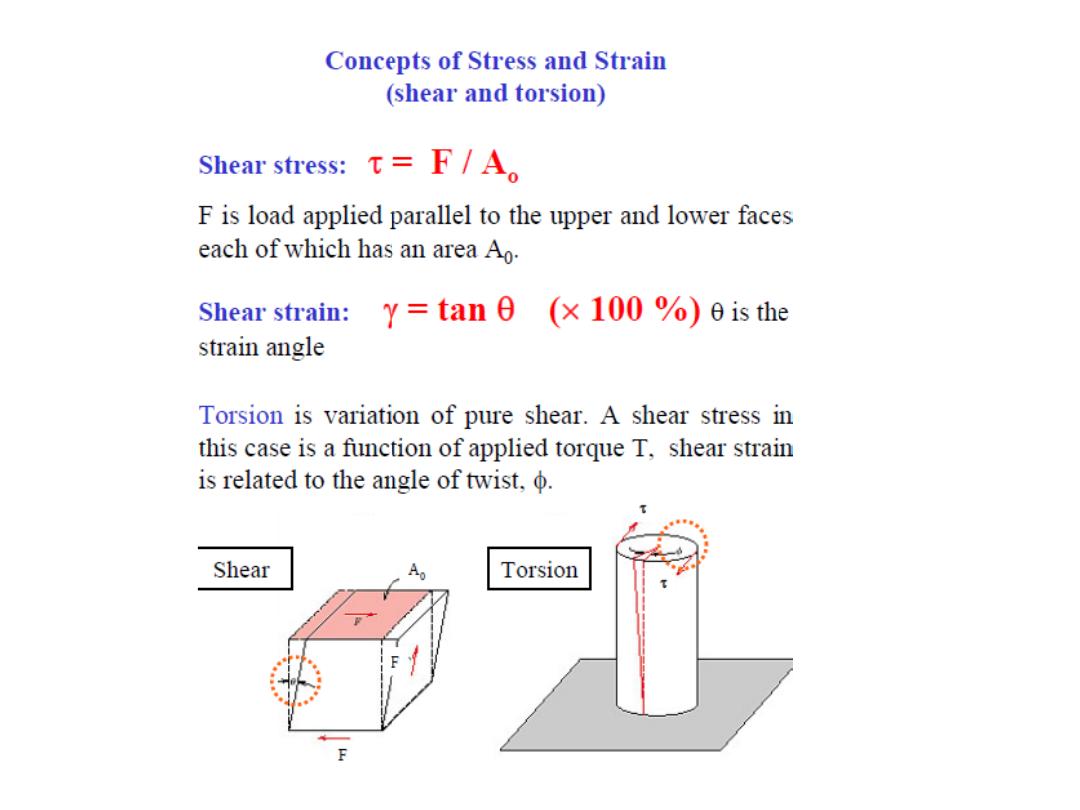

There are three principal ways in which a load may

be applied: namely, tension, compression, and shear.

One of the most common mechanical stress

–strain tests

is performed in tension. The tension test can be used to

ascertain several mechanical properties of materials that

are important in design.

Engineering stress is defined as the instantaneous load

divided by the original specimen cross-sectional area.

Engineering strain is expressed as the change in length

(in the direction of load application) divided by the

original length.

4

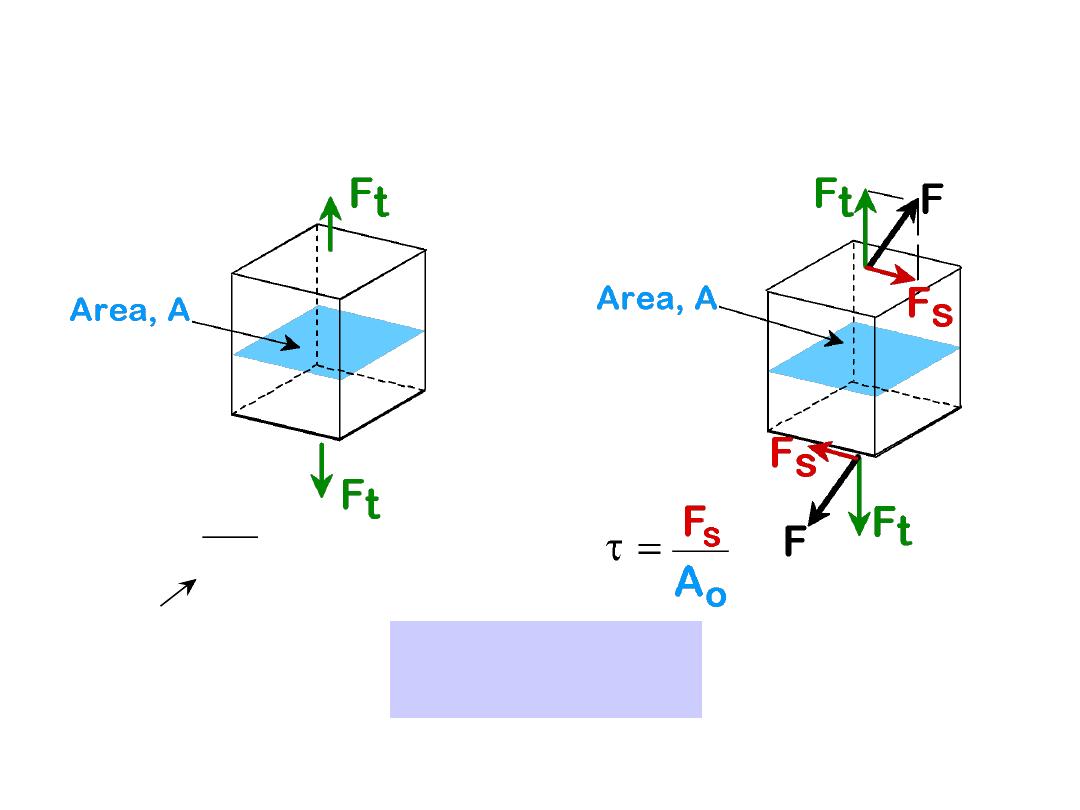

•

Tensile

stress,

s:

•

Shear

stress,

t:

s

F

t

A

o

original area

before loading

Stress has units:

N/m

2

or lb/in

2

ENGINEERING STRESS

F is the instantaneous load applied perpendicular to the specimen cross section,

in units of newtons (N) or pounds force (lbf)

8

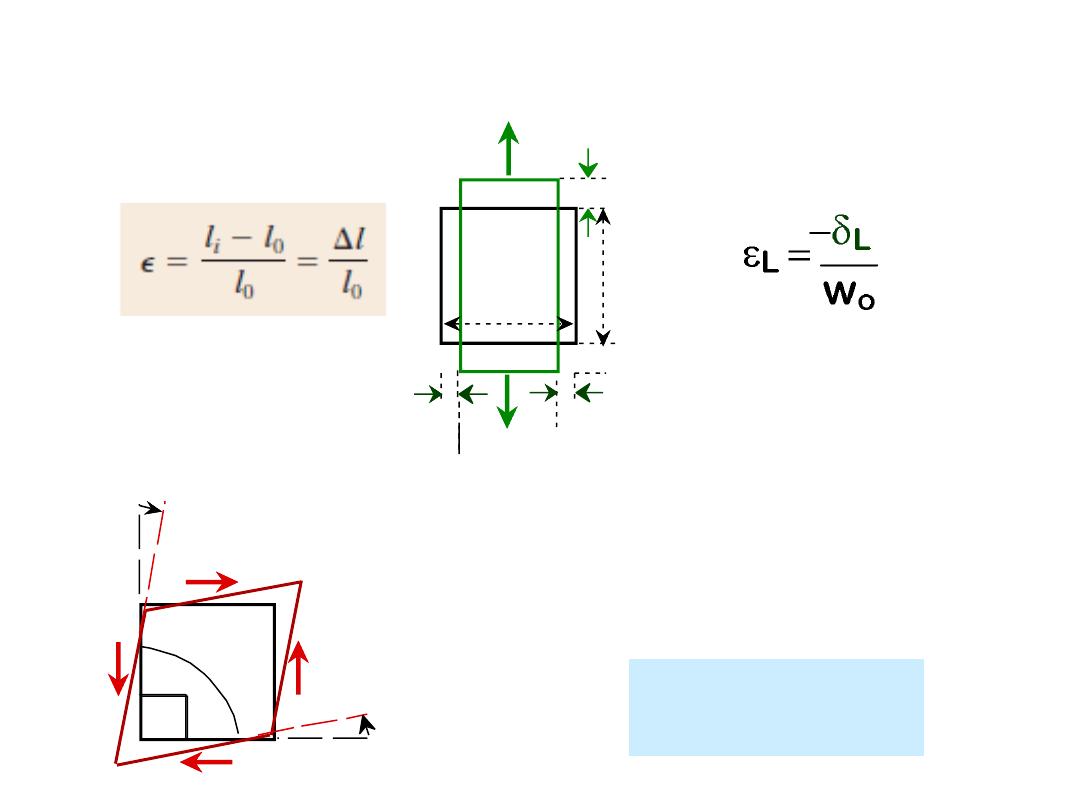

•

Tensile

strain:

•

Lateral

strain:

•

Shear

strain:

/2

/2

/2 -

/2

/2

/2

L

/2

L

/2

L

o

w

o

= tan

Strain is always

dimensionless.

ENGINEERING STRAIN

l

0

is the original length

before any load is

applied,

li

is

the

instantaneous length.

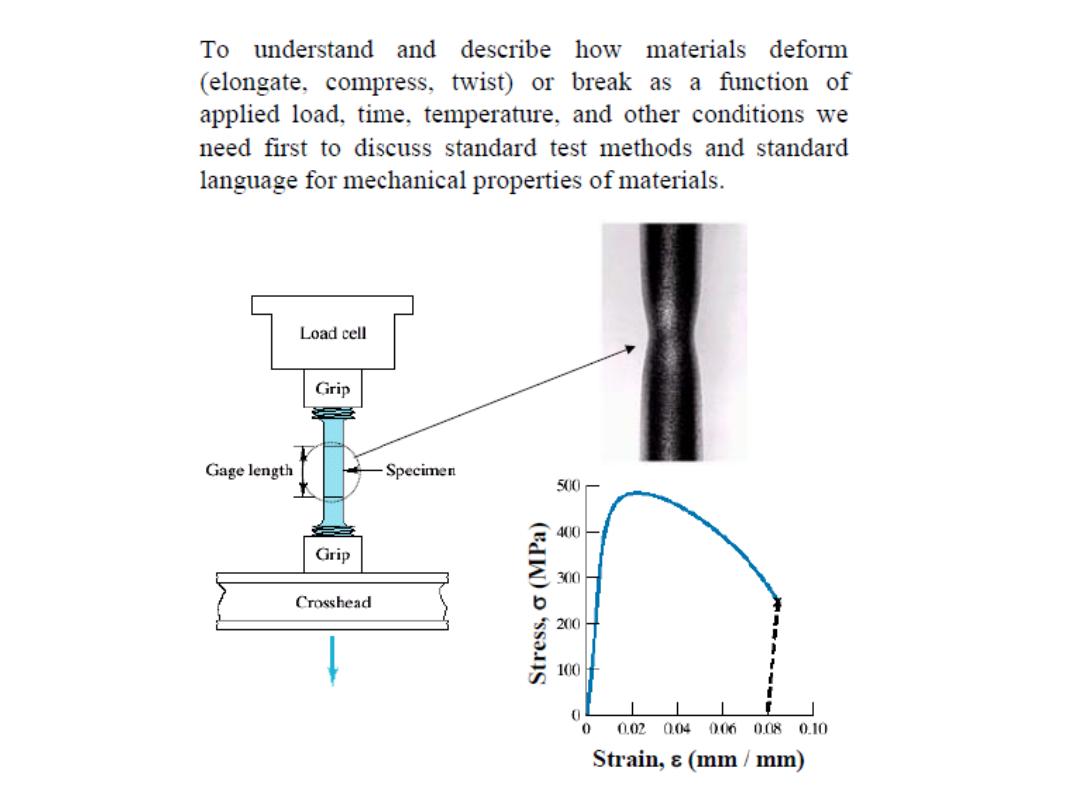

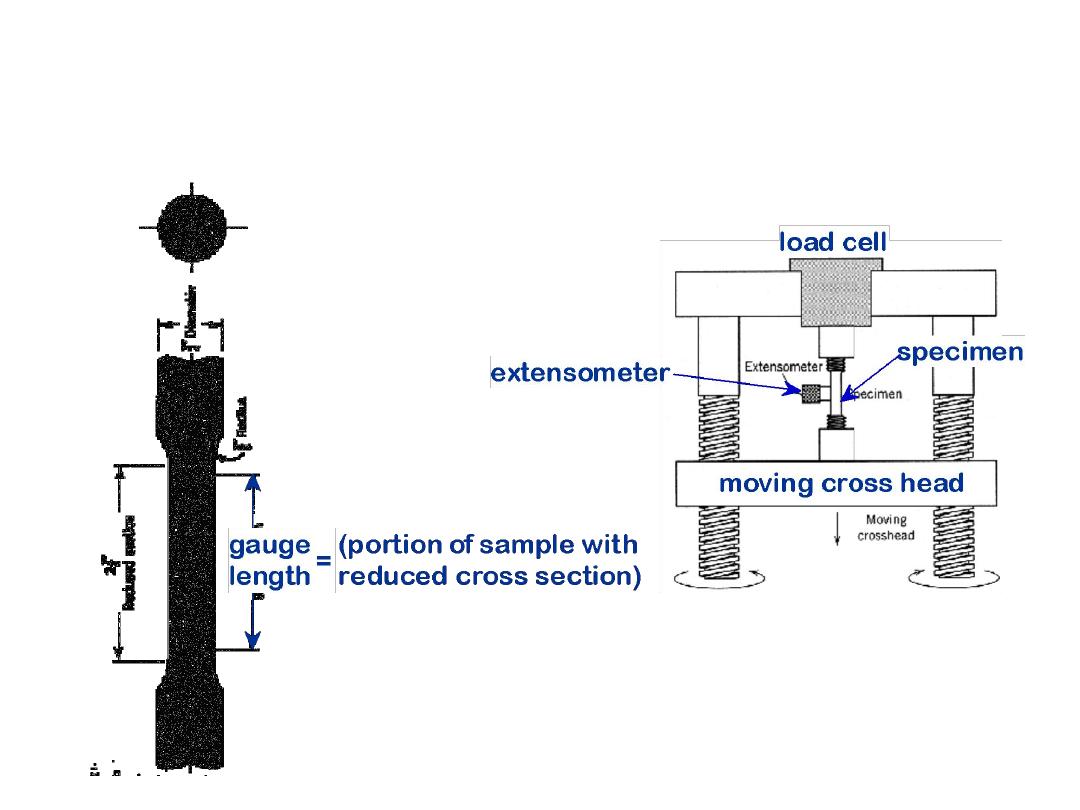

A standard tensile specimen is shown in Figure.

Normally, the cross section is circular, but rectangular

specimens are also used. This

“dogbone” specimen

configuration

was

chosen

so

that,

during

testing,

deformation is confined to the narrow center region

(which has a uniform cross section along its length), and

also to reduce the likelihood of fracture at the ends of the

specimen.

The tensile testing machine is designed to elongate the

specimen at a constant rate and to continuously and

simultaneously measure the instantaneous applied load (with a

load cell) and the resulting elongations (using an extensometer).

A stress–strain test typically takes several minutes to perform

and is destructive; that is, the test specimen is permanently

deformed and usually fractured.

• Typical tensile specimen

9

• Other types of tests:

--compression:

brittle

materials (e.g., concrete)

--torsion:

cylindrical tubes,

shafts.

• Typical tensile

test machine

Adapted from Fig. 6.2,

Callister 6e.

Adapted from Fig. 6.3,

Callister 6e.

(Fig. 6.3 is taken from H.W. Hayden,

W.G. Moffatt, and J. Wulff,

The

Structure and Properties of

Materials, Vol. III, Mechanical

Behavior, p. 2, John Wiley and Sons,

New York, 1965.)

STRESS-STRAIN TESTING

Stress

–Strain Behavior

• A material that is stressed first undergoes elastic, or

nonpermanent, deformation.

• When most materials are deformed elastically, stress and strain

are proportional

— that is, a plot of stress versus strain is linear.

• For tensile and compressive loading, the slope of the linear

elastic region of the stress

–strain curve is the modulus of elasticity

(E), per

Hooke’s law.

• For a material that exhibits nonlinear elastic behavior, tangent

and secant moduli are used.

• On an atomic level, elastic deformation of a material corresponds

to the stretching of interatomic bonds and corresponding slight

atomic displacements.

• For shear elastic deformations, shear stress and shear strain are

proportional to one another.The constant of proportionality is the

shear modulus (G).

• Elastic deformation that is dependent on time is termed

anelastic.

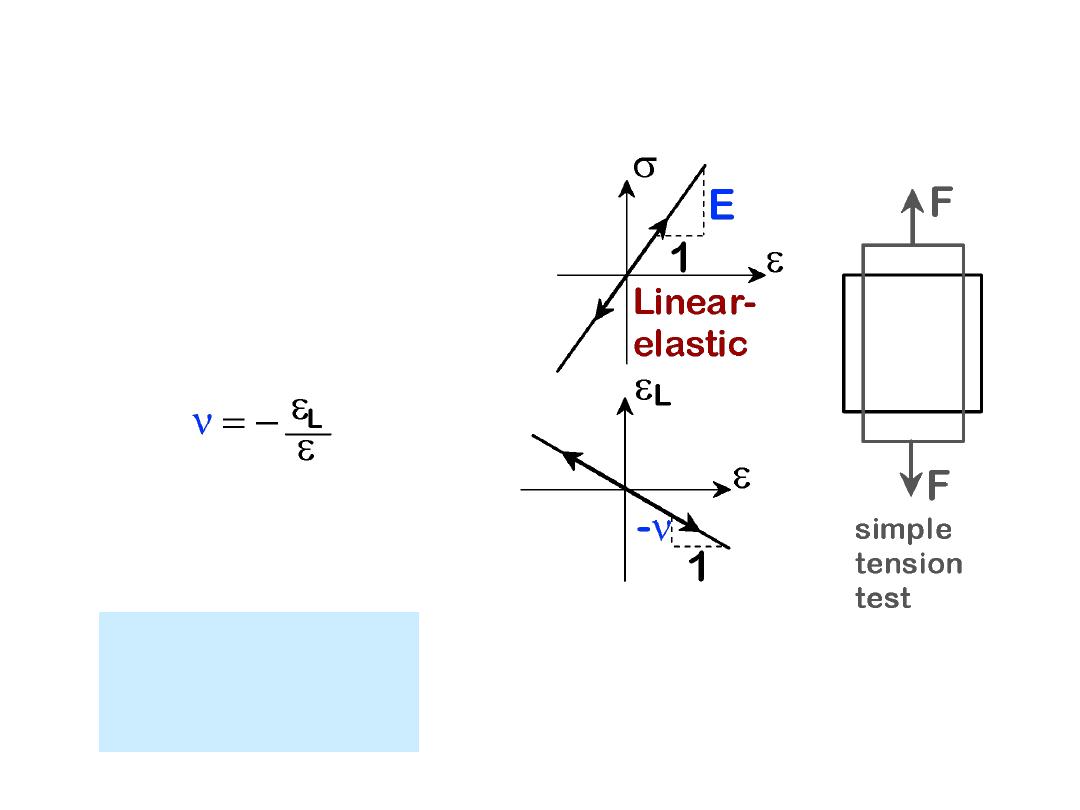

Another elastic parameter, Poisson’s ratio (v),

represents the negative ratio of transverse and

longitudinal strains

•

Modulus of Elasticity, E

:

(also known as Young's modulus)

10

•

Hooke's Law

:

s =

E

e

•

Poisson's ratio,

n

:

metals:

n ~ 0.33

ceramics: ~0.25

polymers: ~0.40

Units:

E: [GPa] or [psi]

n: dimensionless

LINEAR ELASTIC PROPERTIES

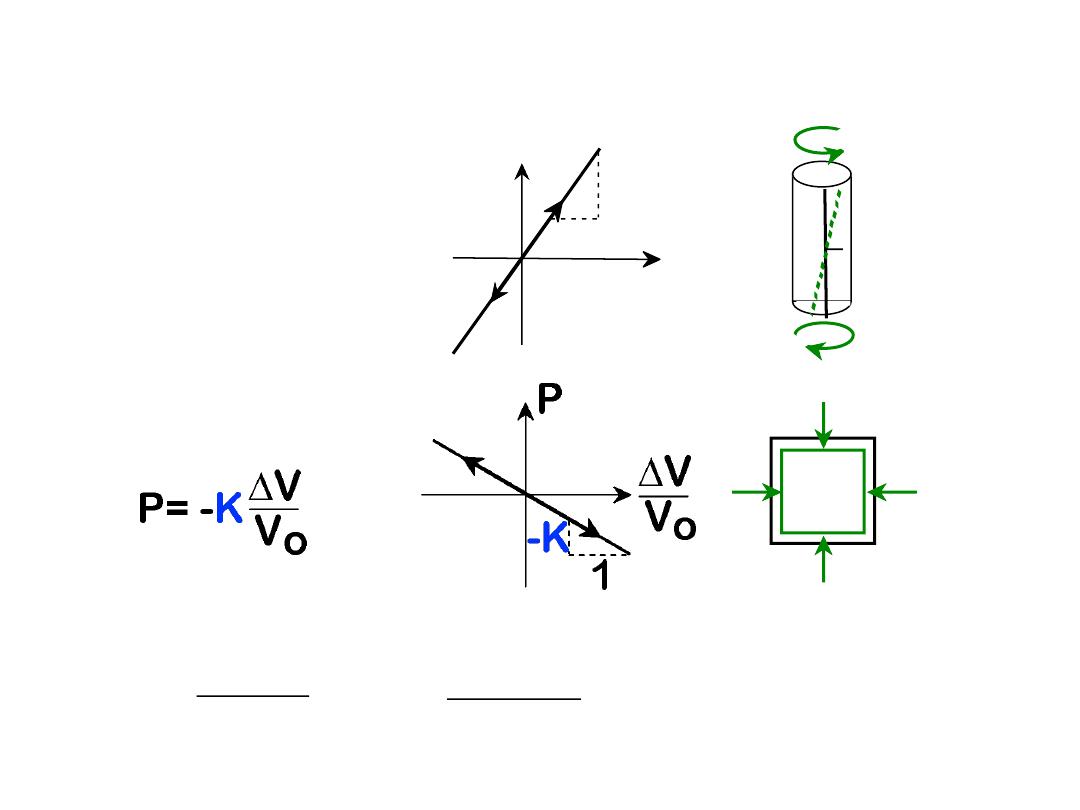

• Elastic

Shear

modulus, G:

12

t

1

G

t =

G

• Elastic

Bulk

modulus, K:

• Special relations for isotropic materials:

P

P

P

M

M

G

E

2(1

n)

K

E

3(1

2n)

simple

torsion

test

pressure

test: Init.

vol =V

o

.

Vol chg.

=

DV

OTHER ELASTIC PROPERTIES

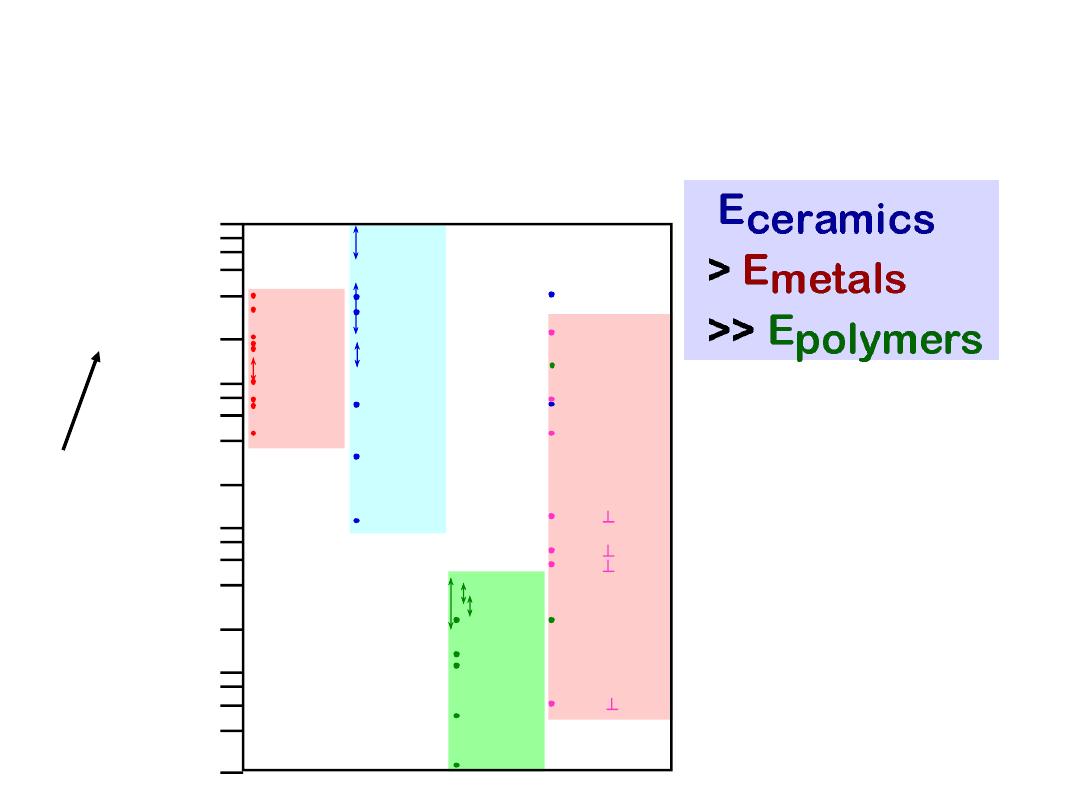

13

0.2

8

0.6

1

Magnesium,

Aluminum

Platinum

Silver, Gold

Tantalum

Zinc, Ti

Steel, Ni

Molybdenum

Graphite

Si crystal

Glass-soda

Concrete

Si nitride

Al oxide

PC

Wood( grain)

AFRE( fibers)*

CFRE*

GFRE*

Glass fibers only

Carbon fibers only

Aramid fibers only

Epoxy only

0.4

0.8

2

4

6

10

20

40

60

80

100

200

600

800

1000

1200

400

Tin

Cu alloys

Tungsten

<100>

<111>

Si carbide

Diamond

PTFE

HDPE

LDPE

PP

Polyester

PS

PET

CFRE( fibers)*

GFRE( fibers)*

GFRE(|| fibers)*

AFRE(|| fibers)*

CFRE(|| fibers)*

Metals

Alloys

Graphite

Ceramics

Semicond

Polymers

Composites

/fibers

E(GPa)

109 Pa

YOUNG’S MODULI:

COMPARISON

15

• Simple tension test:

(at lower temperatures, T < T

melt

/3)

PLASTIC (PERMANENT)

DEFORMATION

16

• Stress at which

noticeable

plastic deformation has

occurred.

when

e

p

= 0.002

tensile stress,

s

engineering strain,

e

sy

ep = 0.002

YIELD STRENGTH,

s

y

17

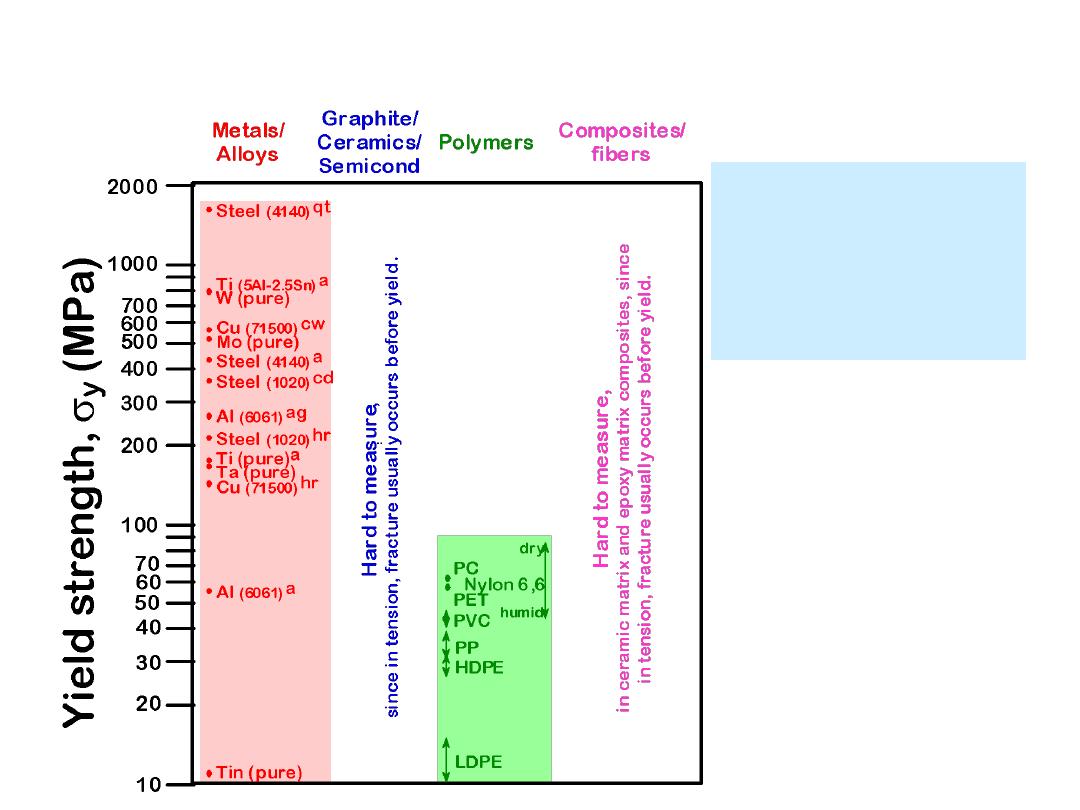

Room T values

sy(ceramics)

>>

sy(metals)

>>

sy(polymers)

Based on data in Table B4,

Callister 6e

.

a = annealed

hr = hot rolled

ag = aged

cd = cold drawn

cw = cold worked

qt = quenched & tempered

YIELD STRENGTH: COMPARISON

18

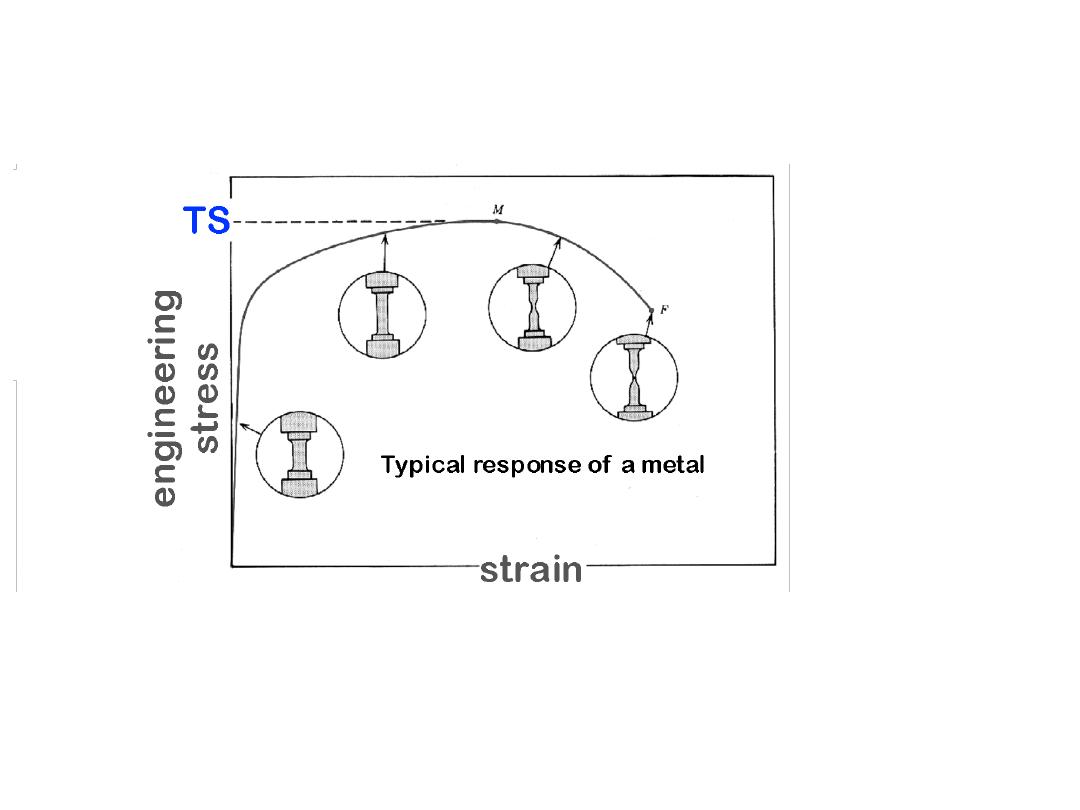

• Maximum possible engineering stress in tension.

• Metals:

occurs when noticeable

necking

starts.

• Ceramics:

occurs when

crack propagation

starts.

• Polymers:

occurs when

polymer backbones

are

aligned and about to break.

Adapted from Fig. 6.11,

Callister 6e.

TENSILE STRENGTH, TS

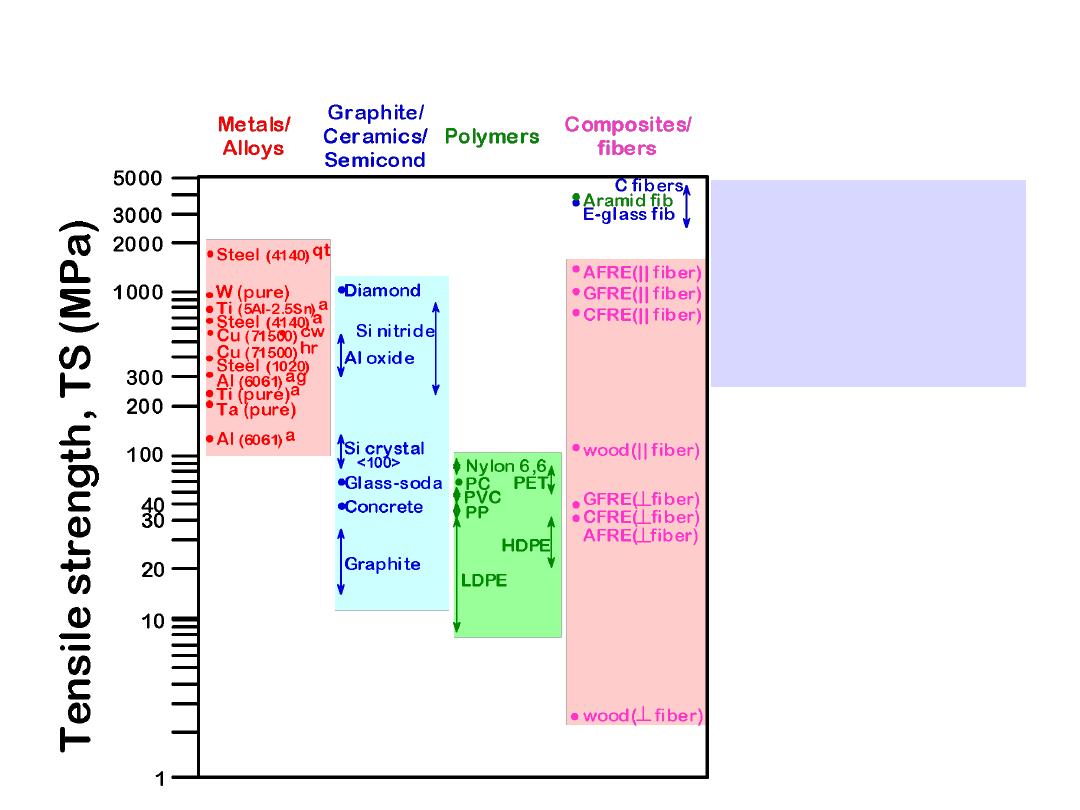

19

Room T values

TS(ceram)

~

TS

(met)

~

TS(comp)

>>

TS(poly)

Based on data in Table B4,

Callister 6e

.

a = annealed

hr = hot rolled

ag = aged

cd = cold drawn

cw = cold worked

qt = quenched & tempered

AFRE, GFRE, & CFRE =

aramid, glass, & carbon

fiber-reinforced epoxy

composites, with 60 vol%

fibers.

TENSILE STRENGTH:

COMPARISON

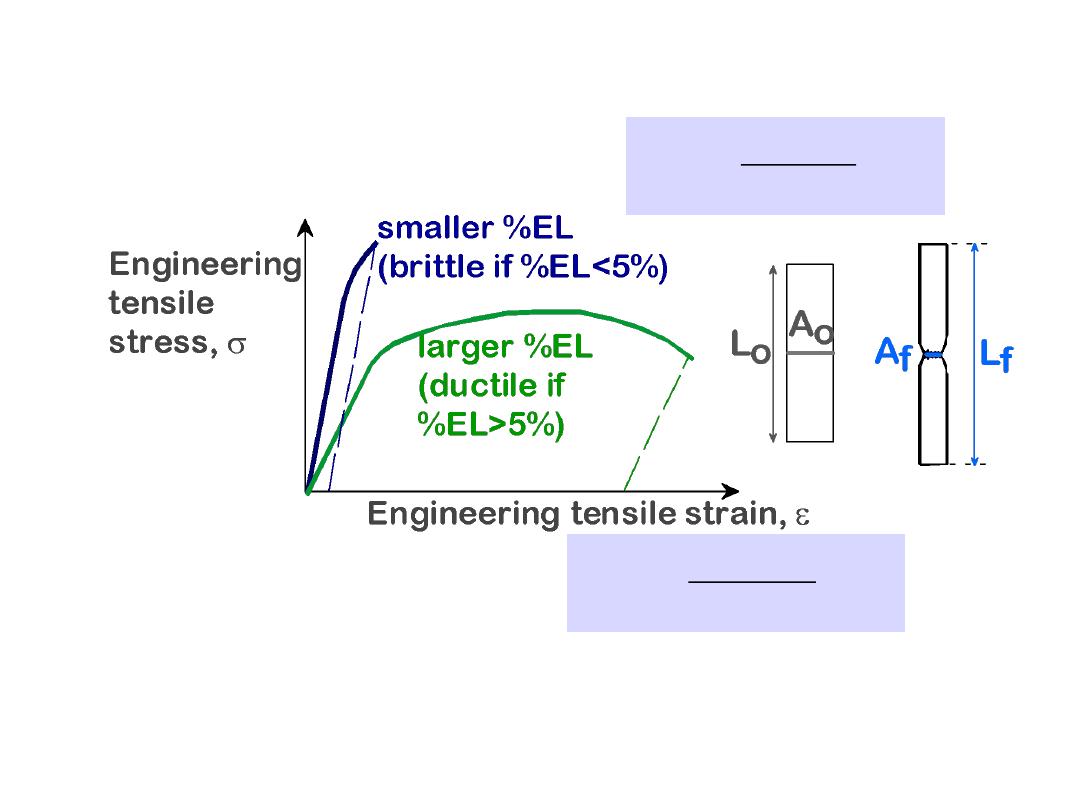

Ductility

is another important mechanical property. It

is a measure of the degree

of plastic deformation that has been sustained at

fracture. A metal that experiences

very little or no plastic deformation upon fracture is

termed brittle.

• Plastic tensile strain at failure:

20

• Another ductility measure:

%AR

A

o

A

f

A

o

x100

• Note:

%AR and %EL are often comparable.

--Reason: crystal slip does not change material volume.

--%AR > %EL possible if internal voids form in neck.

%EL

L

f

L

o

L

o

x100

Adapted from Fig. 6.13,

Callister 6e.

DUCTILITY, %EL

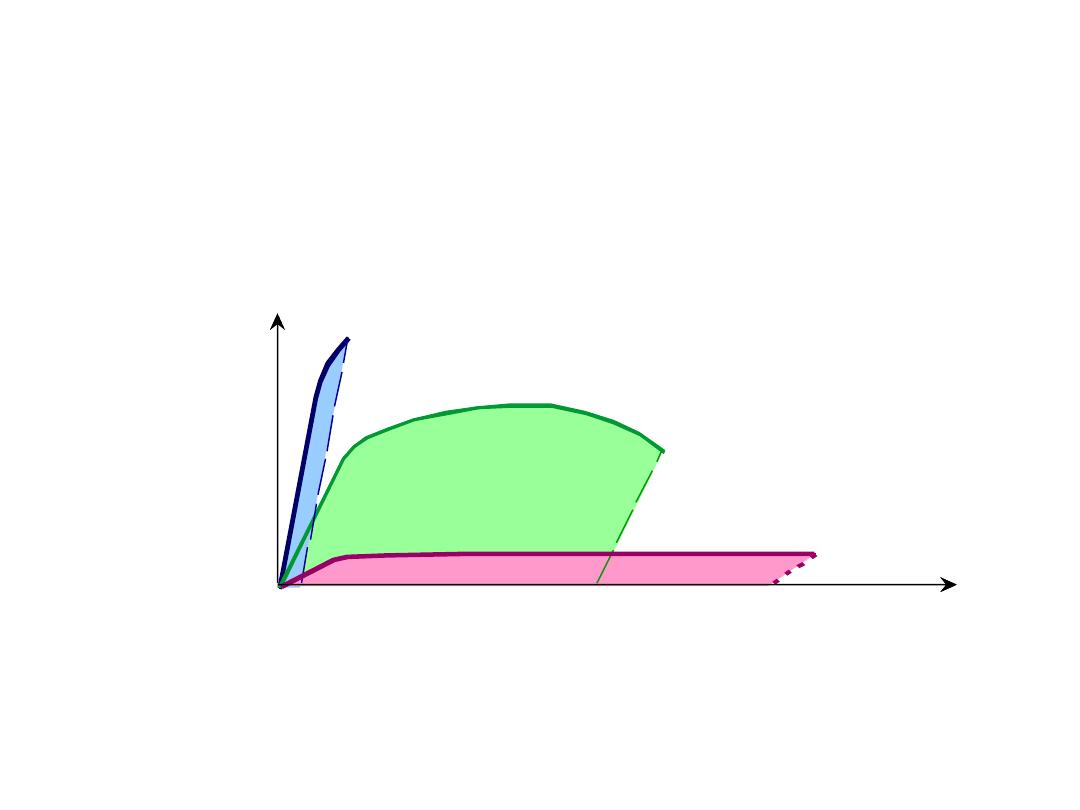

Toughness

is a mechanical term that may be used in several

contexts. For one, toughness (or more specifically, fracture

toughness) is a property that is indicative of a material’s

resistance to fracture when a crack (or other stress-

concentrating defect) is present.

Because it is nearly impossible (as well as costly) to

manufacture materials with zero defects (or to prevent damage

during service), fracture toughness is a major consideration for

all structural materials.

Another way of defining toughness is as the ability of a material

to absorb energy and plastically deform before fracturing.

• Energy to break a unit volume of material

• Approximate by the area under the stress-strain

curve.

21

smaller toughness-

unreinforced

polymers

Engineering tensile strain,

e

Engineering

tensile

stress,

s

smaller toughness (ceramics)

larger toughness

(metals, PMCs)

TOUGHNESS

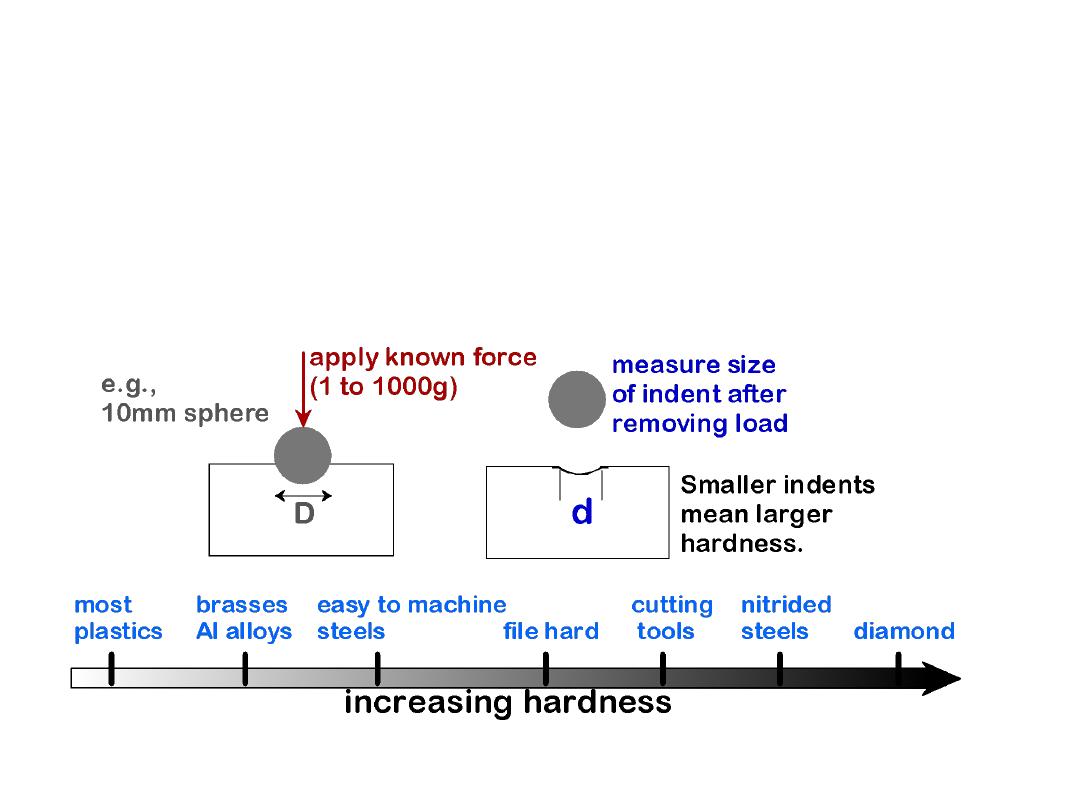

Another mechanical property that may be important to

consider is

hardness,

which is a measure of a

material’s

resistance to localized plastic deformation (e.g., a small dent

or a scratch).

Early hardness tests were based on natural minerals with a

scale constructed solely on the ability of one material to

scratch another that was softer.

A qualitative and somewhat arbitrary hardness indexing

scheme was devised, termed the Mohs scale, which ranged

from 1 on the soft end for talc to 10 for diamond.

Quantitative hardness techniques have been developed over

the years in which a small indenter is forced into the surface

of a material to be tested, under controlled conditions of load

and rate of application.

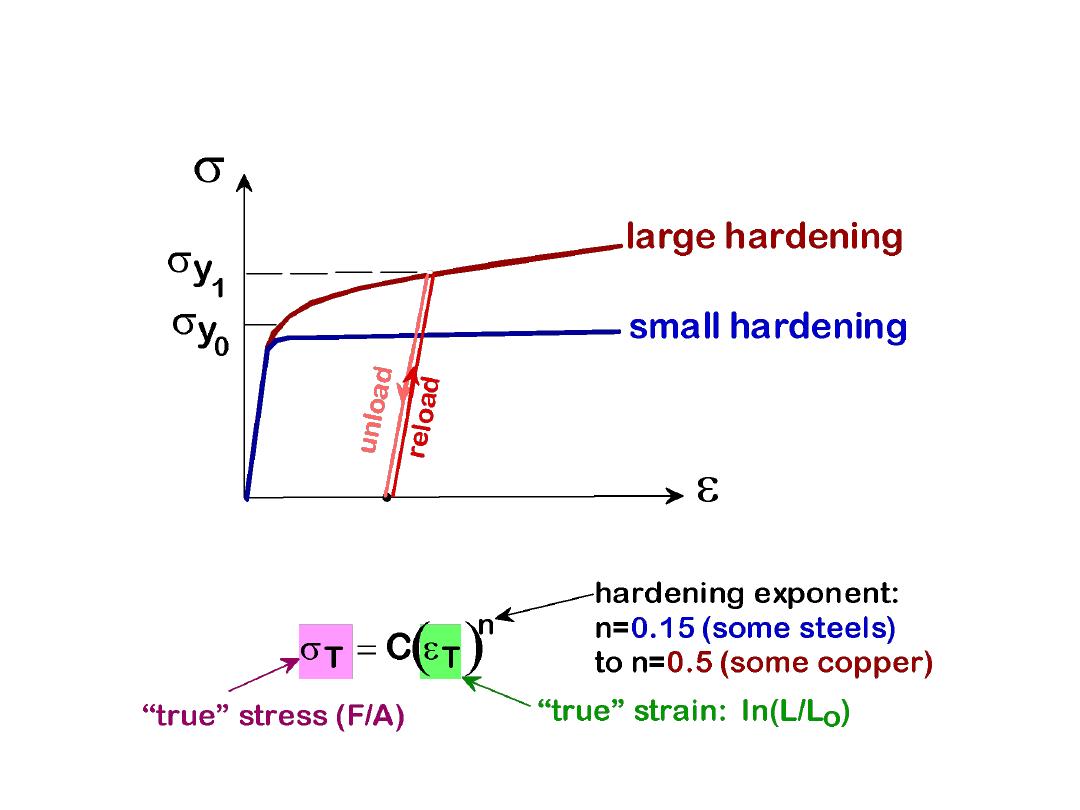

• An increase in

s

y

due to plastic deformation.

22

• Curve fit to the stress-strain response:

HARDENING

23

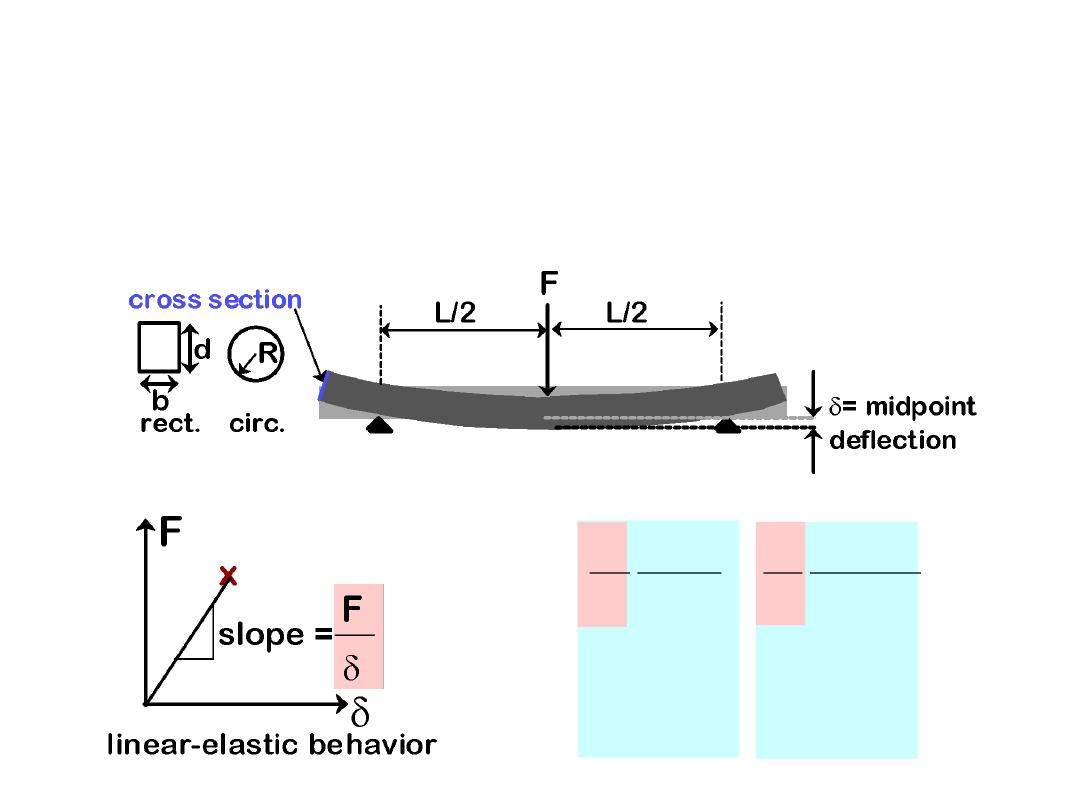

•

Room T behavior is usually elastic, with brittle failure.

•

3-Point Bend Testing

often used.

--tensile tests are difficult for brittle materials.

•

Determine elastic modulus according to:

E

F

L

3

4bd

3

F

L

3

12

R

4

rect.

cross

section

circ.

cross

section

Adapted from Fig.

12.29,

Callister 6e.

MEASURING ELASTIC MODULUS

24

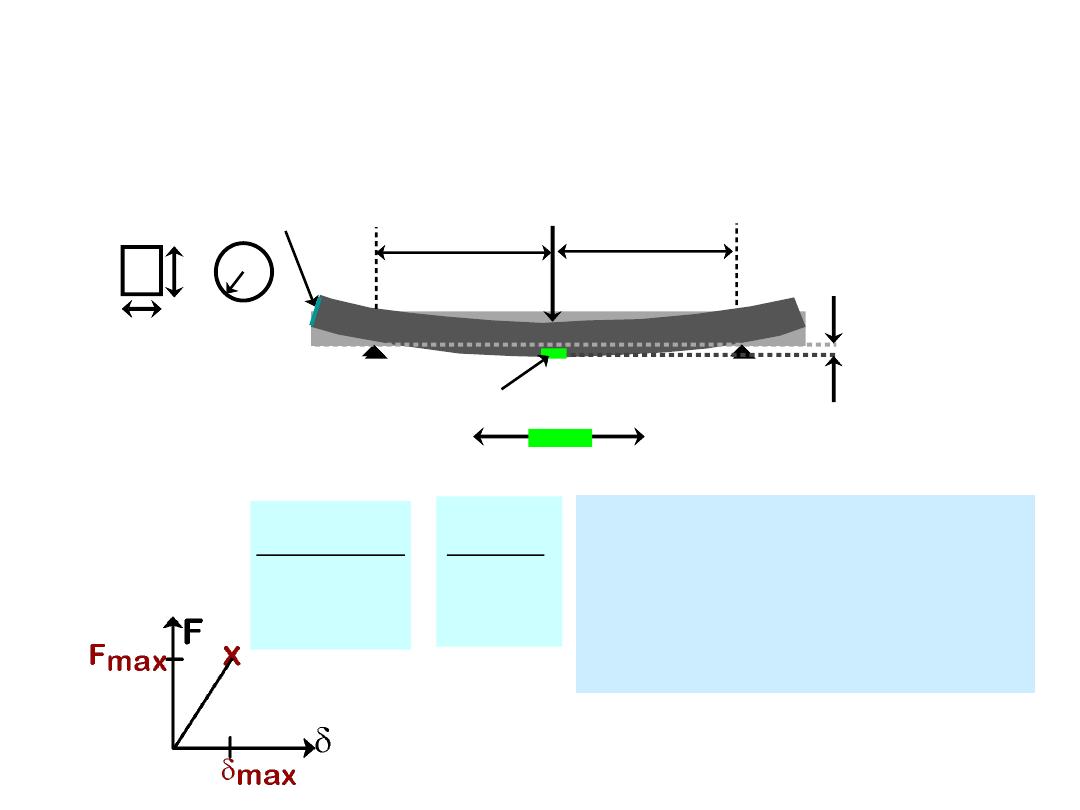

•

3-point bend test to measure room T strength.

F

L/2

L/2

cross section

R

b

d

rect.

circ.

location of max tension

•

Flexural strength:

rect.

s

fs

s

m

fail

1.5F

max

L

bd

2

F

max

L

R

3

•

Typ. values:

Material

sfs(MPa) E(GPa)

Si nitride

Si carbide

Al oxide

glass (soda)

700-1000

550-860

275-550

69

300

430

390

69

Adapted from Fig.

12.29,

Callister 6e.

Data from Table 12.5,

Callister 6e.

MEASURING STRENGTH

25

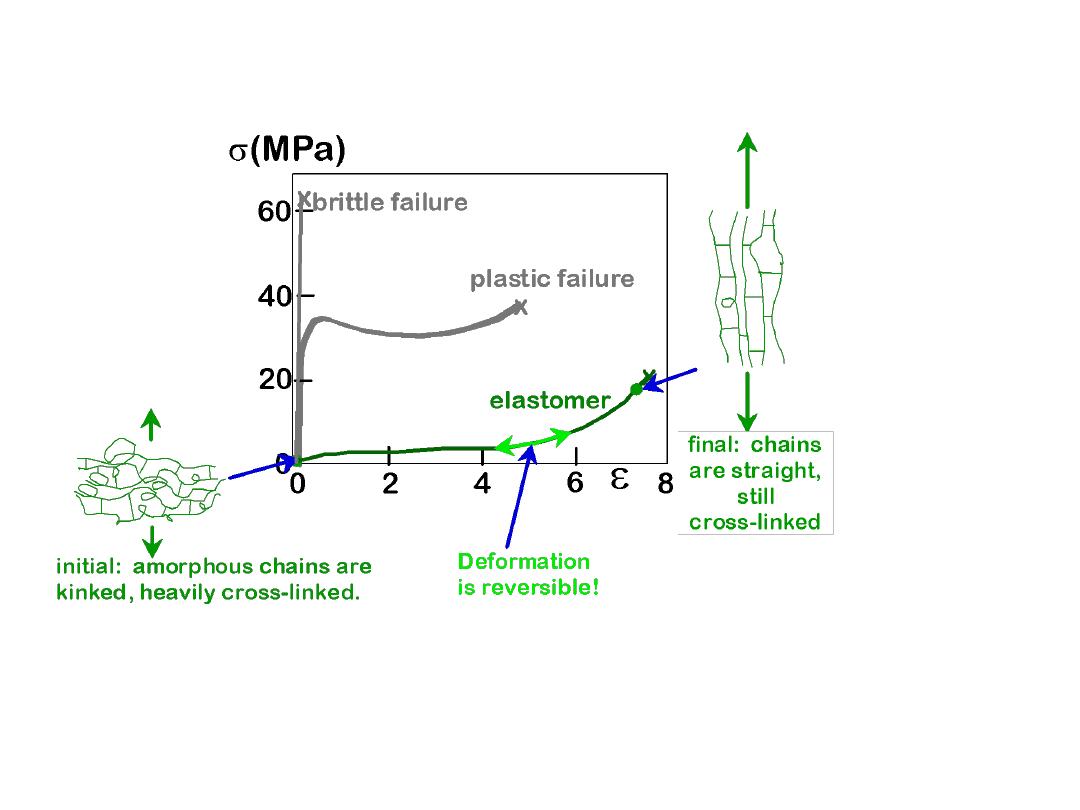

• Compare to responses of other polymers:

--brittle response

(aligned, cross linked & networked case)

--plastic response

(semi-crystalline case)

Stress-strain curves

adapted from Fig.

15.1,

Callister 6e.

Inset figures along

elastomer curve

(green) adapted from

Fig. 15.14,

Callister

6e. (Fig. 15.14 is from

Z.D. Jastrzebski,

The

Nature and Properties

of Engineering

Materials, 3rd ed.,

John Wiley and Sons,

1987.)

TENSILE RESPONSE: ELASTOMER

CASE

26

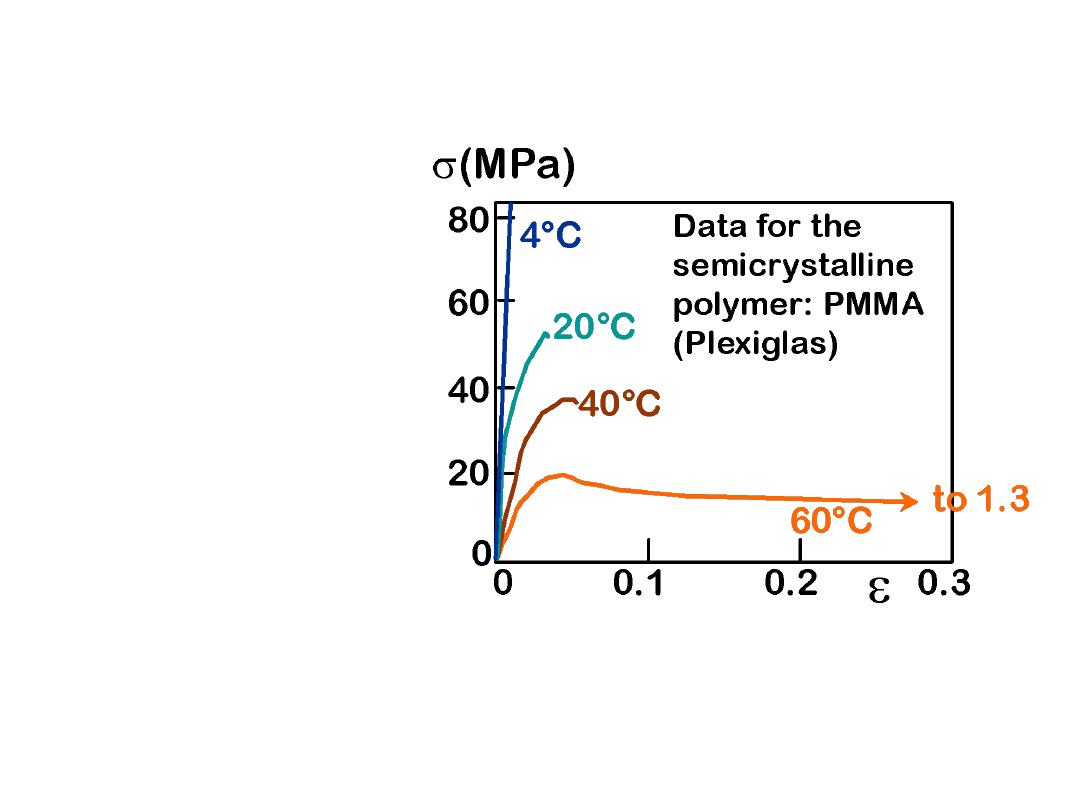

• Decreasing T...

--increases E

--increases TS

--decreases %EL

• Increasing

strain rate...

--same effects

as decreasing T.

Adapted from Fig. 15.3,

Callister 6e. (Fig. 15.3 is from T.S. Carswell

and J.K. Nason, 'Effect of Environmental Conditions on the

Mechanical Properties of Organic Plastics",

Symposium on Plastics,

American Society for Testing and Materials, Philadelphia, PA, 1944.)

T AND STRAIN RATE:

THERMOPLASTICS

27

•

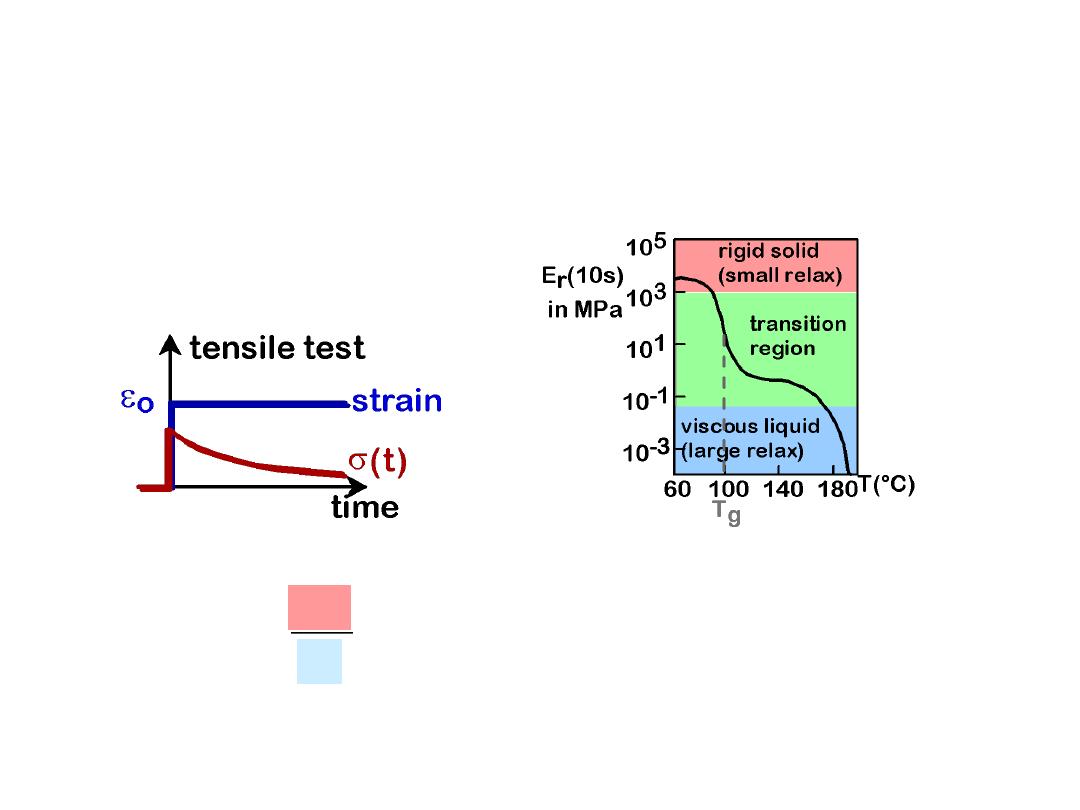

Stress relaxation test

:

E

r

(t )

s(t )

e

o

--strain to

e

o

and hold.

--observe decrease in

stress with time.

•

Relaxation modulus

:

• Data:

Large drop in E

r

for T > T

g

.

(amorphous

polystyrene)

•

Sample T

g

(C) values:

PE (low M

w

)

PE (high M

w

)

PVC

PS

PC

-110

- 90

+ 87

+100

+150

Adapted from Fig.

15.7,

Callister 6e.

(Fig. 15.7 is from

A.V. Tobolsky,

Properties and

Structures of

Polymers, John

Wiley and Sons,

Inc., 1960.)

Selected values

from Table 15.2,

Callister 6e.

TIME DEPENDENT

DEFORMATION

• Resistance to permanently indenting the surface.

• Large hardness means:

--resistance to plastic deformation or cracking in

compression.

--better wear properties.

28

Adapted from Fig. 6.18,

Callister 6e. (Fig. 6.18 is adapted from G.F. Kinney, Engineering Properties

and Applications of Plastics, p. 202, John Wiley and Sons, 1957.)

HARDNESS

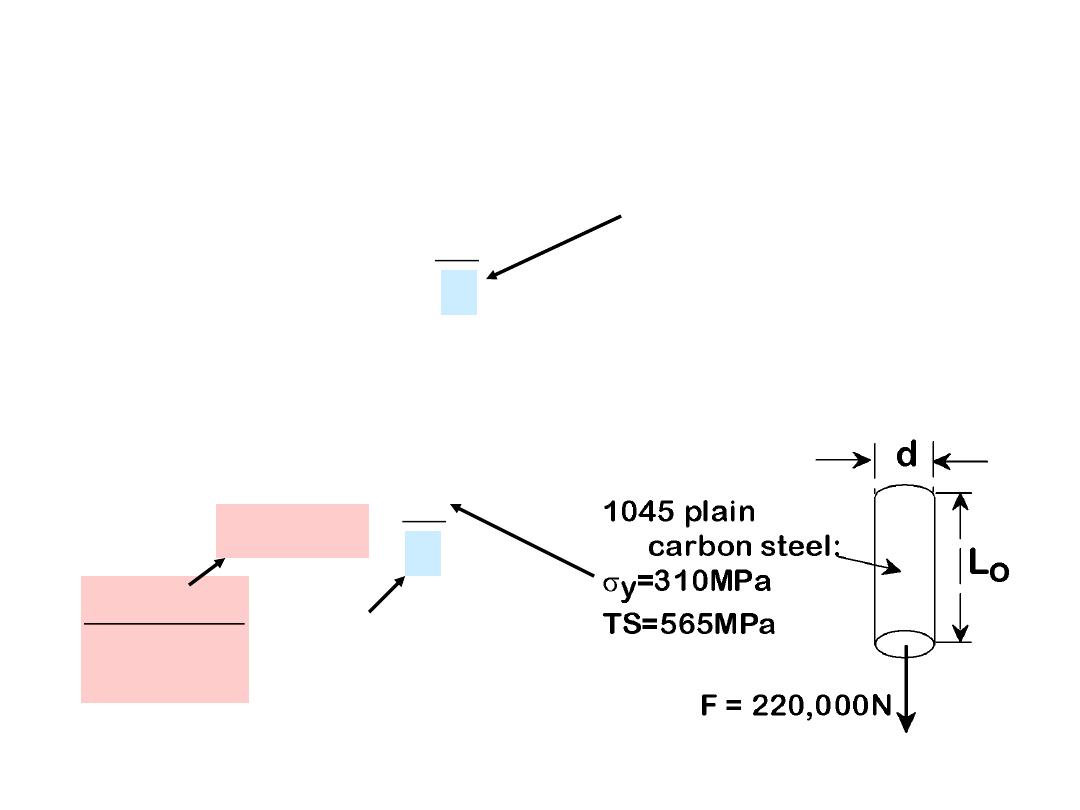

• Design uncertainties mean we do not push the limit.

•

Factor of safety, N

29

s

working

s

y

N

Often N is

between

1.2 and 4

• Ex:

Calculate a diameter, d, to ensure that yield does

not occur in the 1045 carbon steel rod below. Use a

factor of safety of 5.

s

working

s

y

N

220, 000N

d

2

/ 4

5

DESIGN OR SAFETY FACTORS

41

Thermal Expansion

Materials change size when temperature

is changed

)

(

α

initial

final

initial

initial

final

T

T

linear coefficient of

thermal expansion (1/K or 1/

°C)

T

initial

T

final

initial

final

T

final

>

T

initial

42

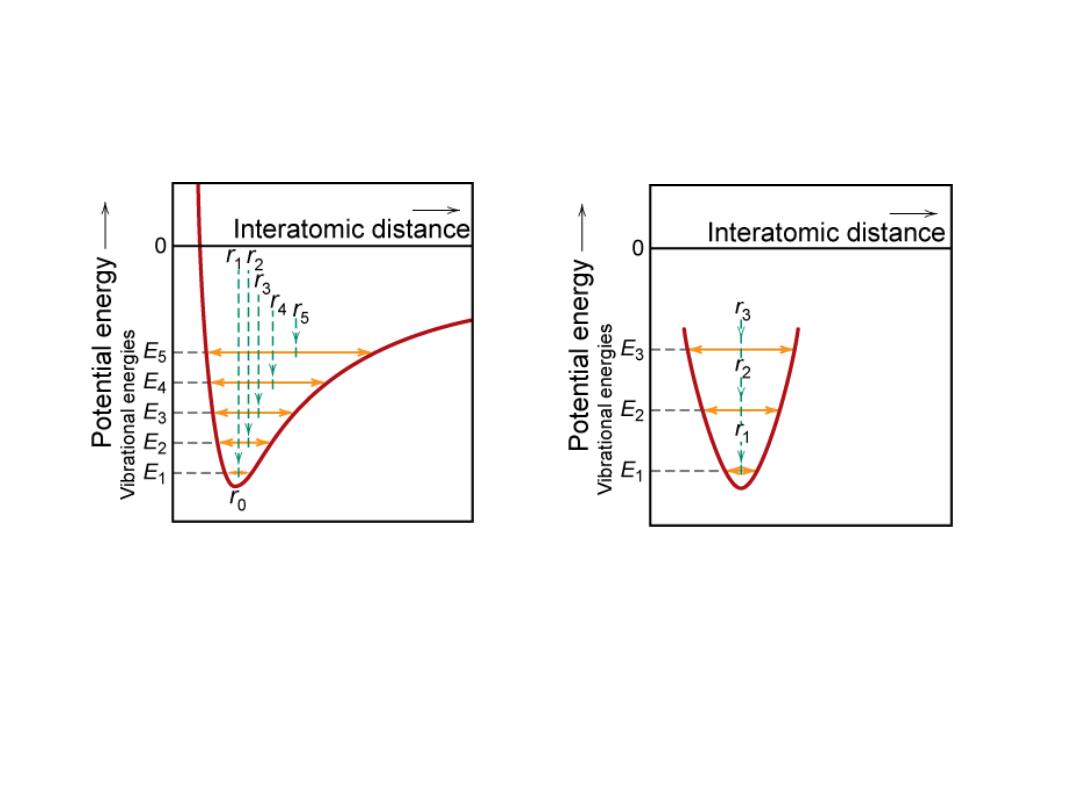

Atomic Perspective: Thermal Expansion

Asymmetric curve:

-- increase temperature,

-- increase in interatomic

separation

-- thermal expansion

Symmetric curve:

-- increase temperature,

-- no increase in interatomic

separation

-- no thermal expansion

43

Coefficient of Thermal Expansion: Comparison

• Q: Why does

a

generally decrease

with increasing

bond energy?

Polypropylene

145-180

Polyethylene

106-198

Polystyrene

90-150

Teflon

126-216

• Polymers

• Ceramics

Magnesia (MgO)

13.5

Alumina (Al

2

O

3

)

7.6

Soda-lime glass

9

Silica (cryst. SiO

2

)

0.4

• Metals

Aluminum

23.6

Steel

12

Tungsten

4.5

Gold

14.2

a

(10

-6

/

C)

at room T

Material

Polymers have larger

a

values because of

weak secondary bonds

inc

re

as

ing

a

44

• Occur due to:

-- restrained thermal expansion/contraction

-- temperature gradients that lead to differential

dimensional changes

Thermal Stresses

Ea (T

0

T

f

)

Ea DT

Thermal stress

s

•

Stress

and

strain

: These are size-independent

measures of load and displacement, respectively.

•

Elastic

behavior: This reversible behavior often

shows a linear relation between stress and strain.

To minimize deformation, select a material with a

large elastic modulus (E or G).

•

Plastic

behavior: This permanent deformation

behavior occurs when the tensile (or compressive)

uniaxial stress reaches

s

y

.

30

•

Toughness

: The energy needed to break a unit

volume of material.

•

Ductility

: The plastic strain at failure.

SUMMARY