Machines Simulation Lab/ AC Driver

Of 2

1

|

P a g e

Date: Experiment-2

Variable speed drives for asynchronous motor

(AC Driver)

Aim: To enable students to develop competence in operating and

troubleshooting a control system that includes industrial drive and to show

the running and operation response of 3-phase squirrel cage induction motor

with different conditions.

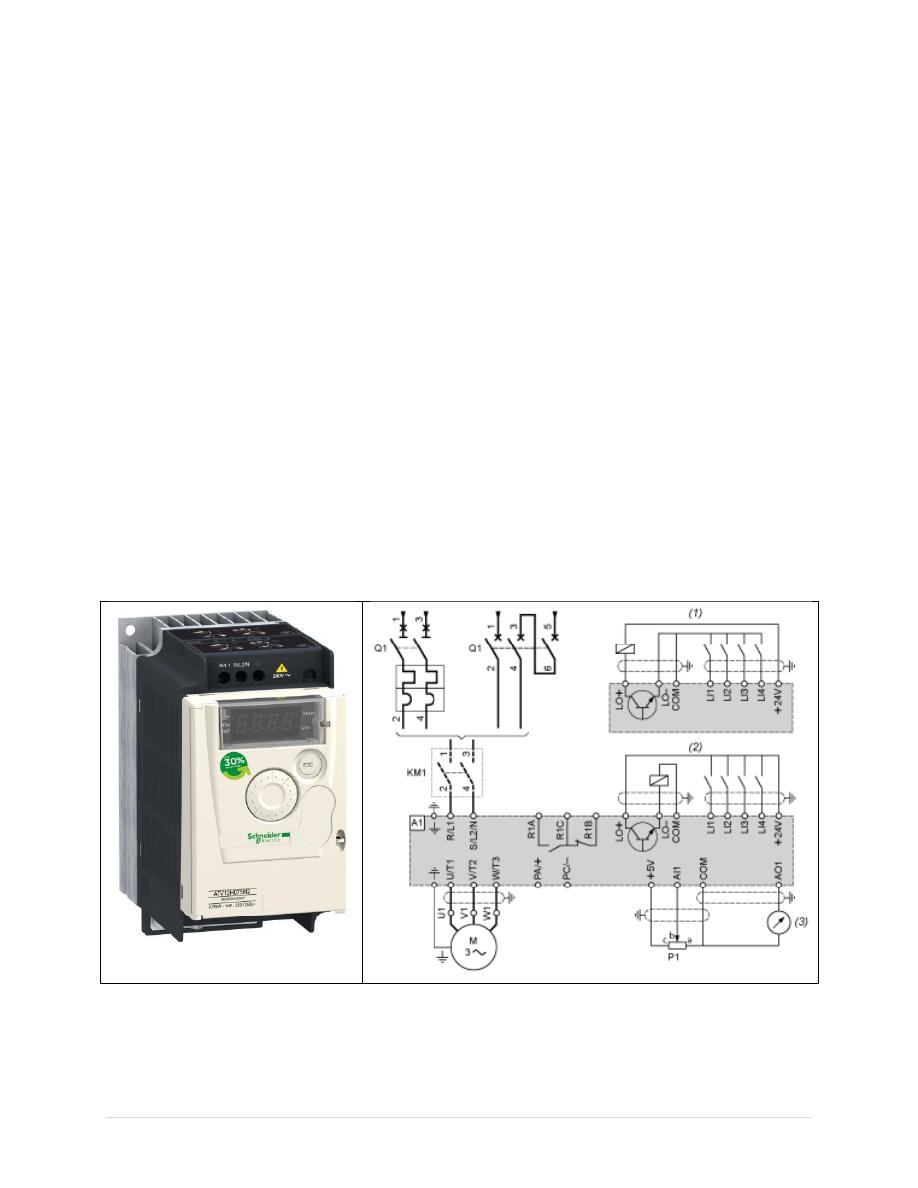

Introduction: The Schneider AC variable speed drive ATV12 - 2.2kW- 240V -

3hp, uses the latest solid-state PWM technology to control a 3-phase squirrel

cage induction motor (IM). A keypad and an LCD screen allow modification

and visualization of many different parameters, such as min/max speed,

acceleration/deceleration time, torque, etc. The following Figure (1) has

shown the driver and Wiring Diagram.

Figure (1)

The V/Hz output characteristic is user-selectable for constant torque, pump,

or fan applications. The preset of speeds and rotate direction may be

Machines Simulation Lab/ AC Driver

Of 2

2

|

P a g e

programmed. Speed can be controlled using either the digital keypad or the

analog input on the front panel of the module.

Procedure:

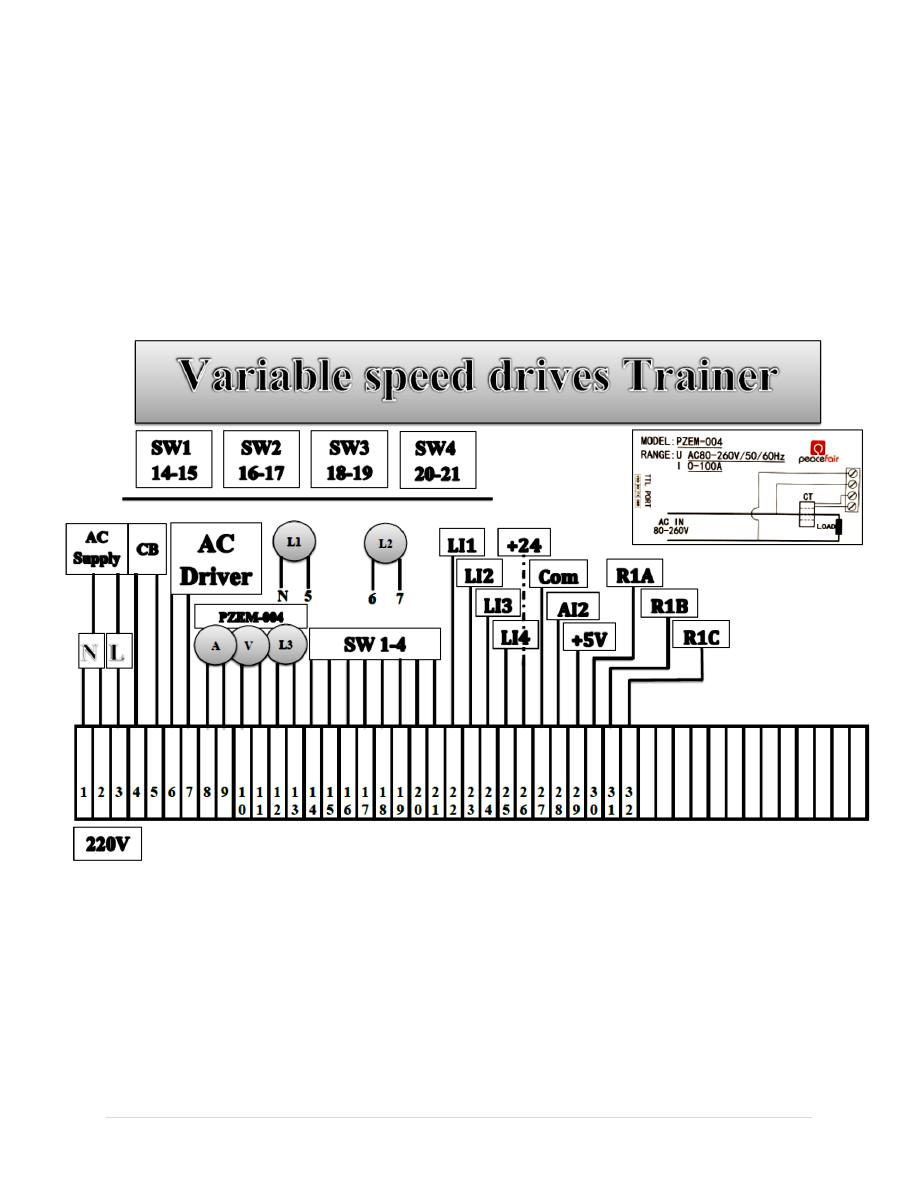

1- Connect the power, IM and control circuit as shown in Figure (2).

2- Run the motor form the pad and remote control with different directions.

3- Run the motor form Nr=0 rpm to Nr= 1500 rpm, in steps of 100 rpm.

Write all values of frequency, current and supply voltage.

Figure (2)

Report:

1- What are the benefits of the analog and digitals signals of AC Driver?

2- How can you use PLC to control AC driver?

3- Outlines (in clearly and briefly) all speed control methods for the three

phase induction motor with drawing the torque speed characteristic for

each one.