!#

➣

➣

➣

➣

➣

General

➣

➣

➣

➣

➣

Circle Diagram for a Series

Circuit

➣

➣

➣

➣

➣

Circle Diagram of the

Approximate Equivalent

Circle

➣

➣

➣

➣

➣

Determination of G0 and B0

➣

➣

➣

➣

➣

No-load Test

➣

➣

➣

➣

➣

Blocked Rotor Test

➣

➣

➣

➣

➣

Construction of the Circle

Diagram

➣

➣

➣

➣

➣

Maximum Quantities

➣

➣

➣

➣

➣

Starting of Induction Motors

➣

➣

➣

➣

➣

Direct-Switching or Line

Starting of Induction Motors

➣

➣

➣

➣

➣

Squirrel-cage Motors

➣

➣

➣

➣

➣

Starting of Slip-ring Motors

➣

➣

➣

➣

➣

Starter Steps

➣

➣

➣

➣

➣

Crawling

➣

➣

➣

➣

➣

Cogging or Magnetic Locking

➣

➣

➣

➣

➣

Double Sqiurrel-cage Motor

➣

➣

➣

➣

➣

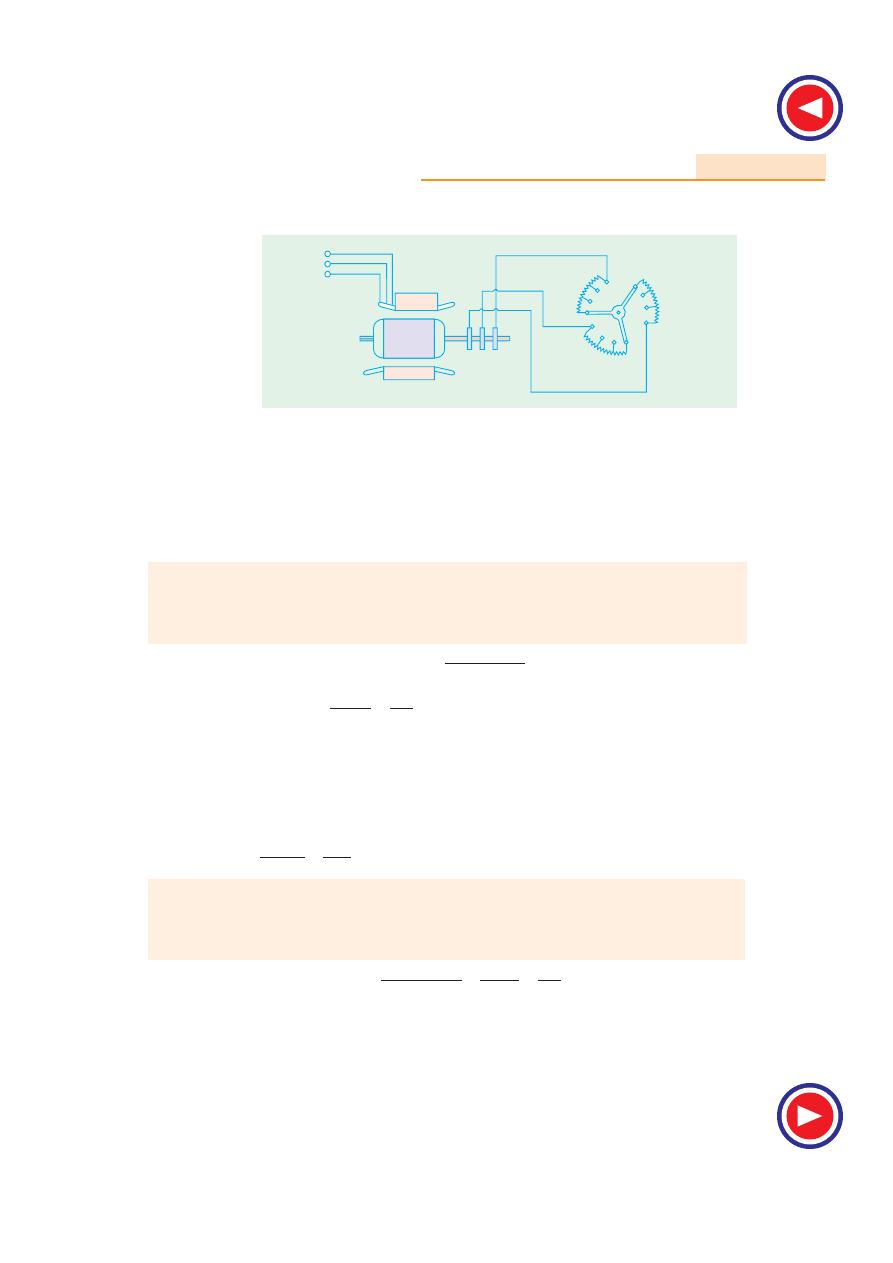

Equivalent circuit

➣

➣

➣

➣

➣

Speed Control of Induction

Motor

➣

➣

➣

➣

➣

Three-Phase A.C.

Commutator Motors

➣

➣

➣

➣

➣

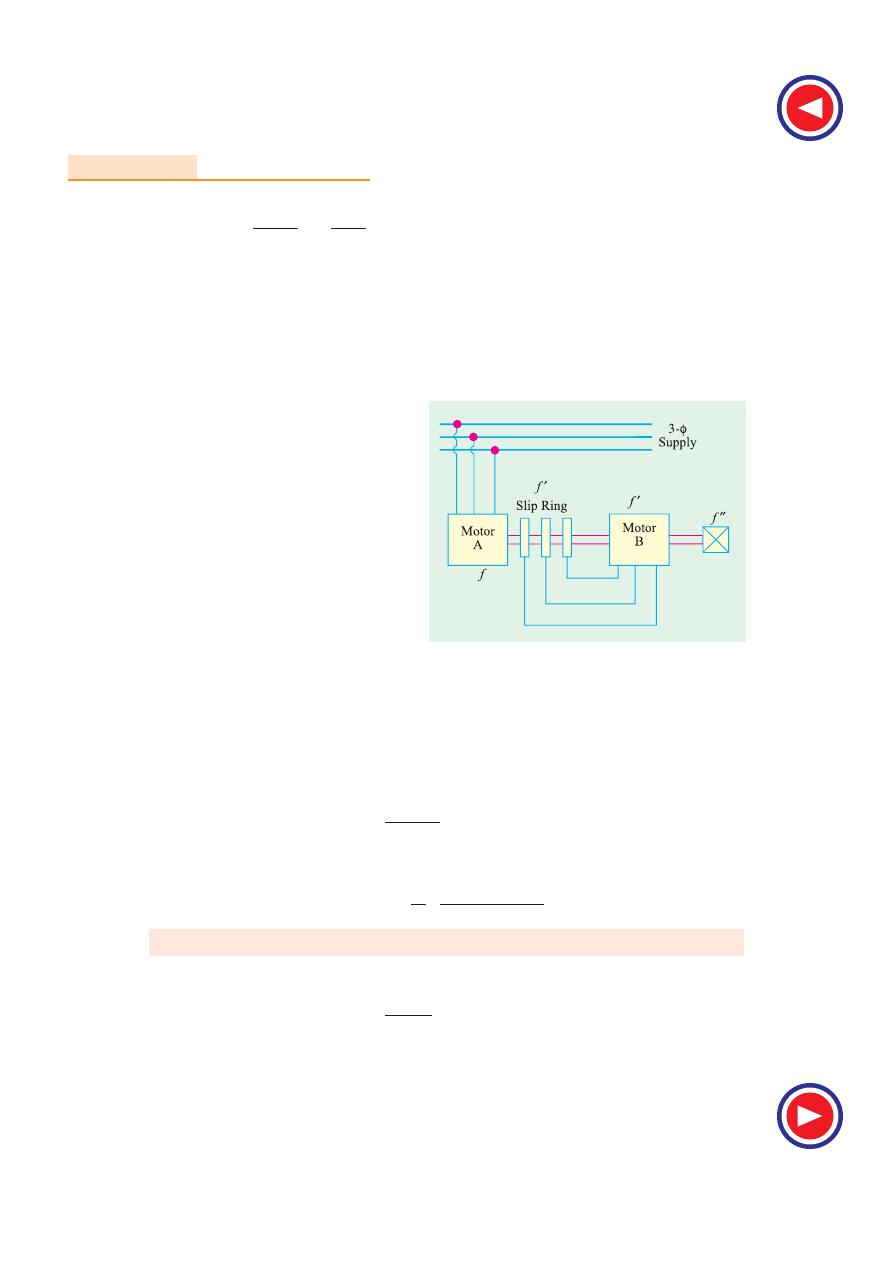

Schrage Motor

➣

➣

➣

➣

➣

Motor Enclosures

➣

➣

➣

➣

➣

Standard type of Squirrel-

cage Motors

➣

➣

➣

➣

➣

Class A Motors

➣

➣

➣

➣

➣

Class B Motors

➣

➣

➣

➣

➣

Class C Motors

➣

➣

➣

➣

➣

Class D Motors

➣

➣

➣

➣

➣

Class E Motors

➣

➣

➣

➣

➣

Class F Motors

➣

➣

➣

➣

➣

Questions and Answer on

Induction Motors

+ 0 ) 2 6 - 4

Learning Objectives

COMPUTATIONS

AND CIRCLE

DIAGRAMS

Ç

This chapter explains you how to derive

performance characteristics of induction

motors using circular diagrams

CONTENTS

CONTENTS

1314

Electrical Technology

35.1. General

In this chapter, it will be shown that the performance characteristics of an induction motor are

derivable from a circular locus. The data necessary to draw the circle diagram may be found from no-

load and blocked-rotor tests, corresponding to the open-circuit and short-circuit tests of a transformer.

The stator and rotor Cu losses can be separated by drawing a torque line. The parameters of the

motor, in the equivalent circuit, can be found from the above tests, as shown below.

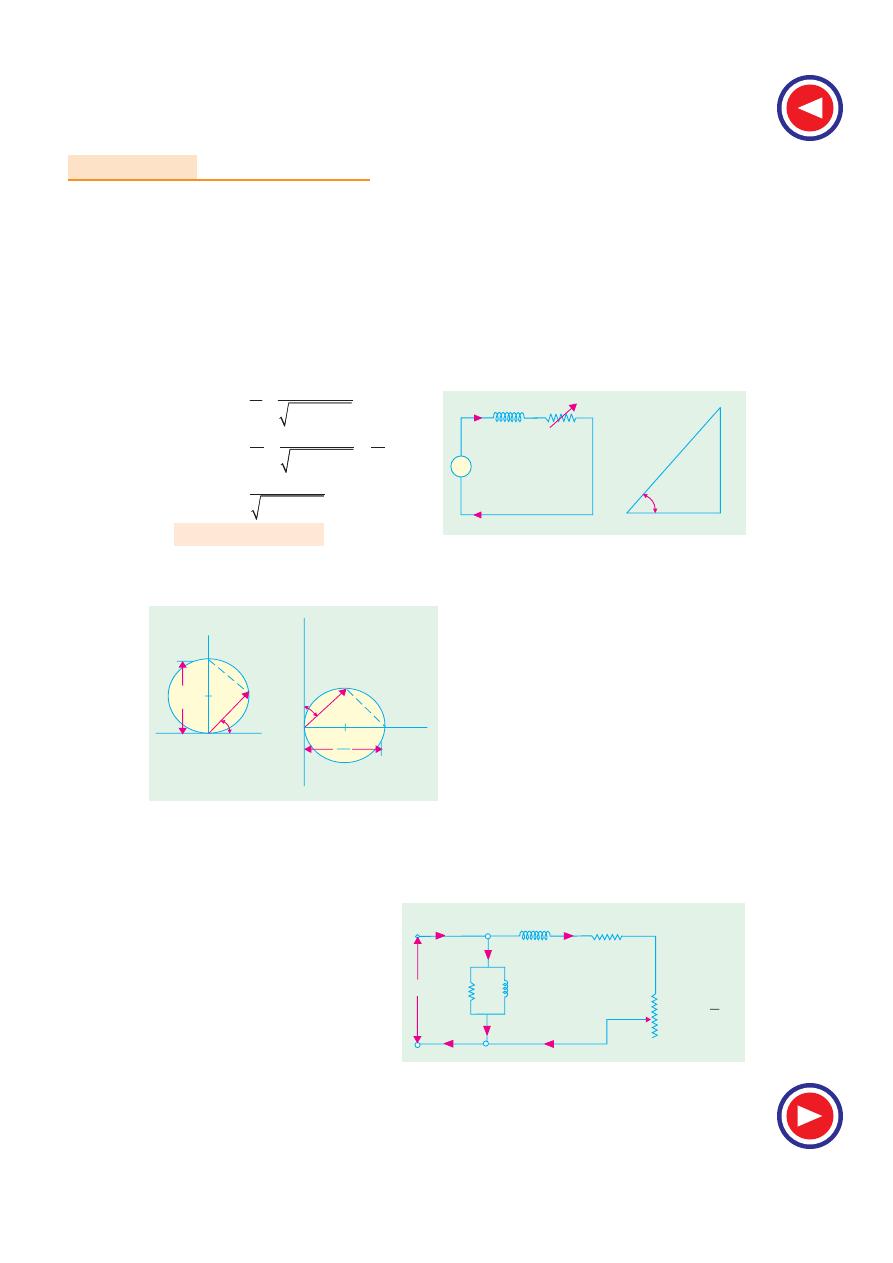

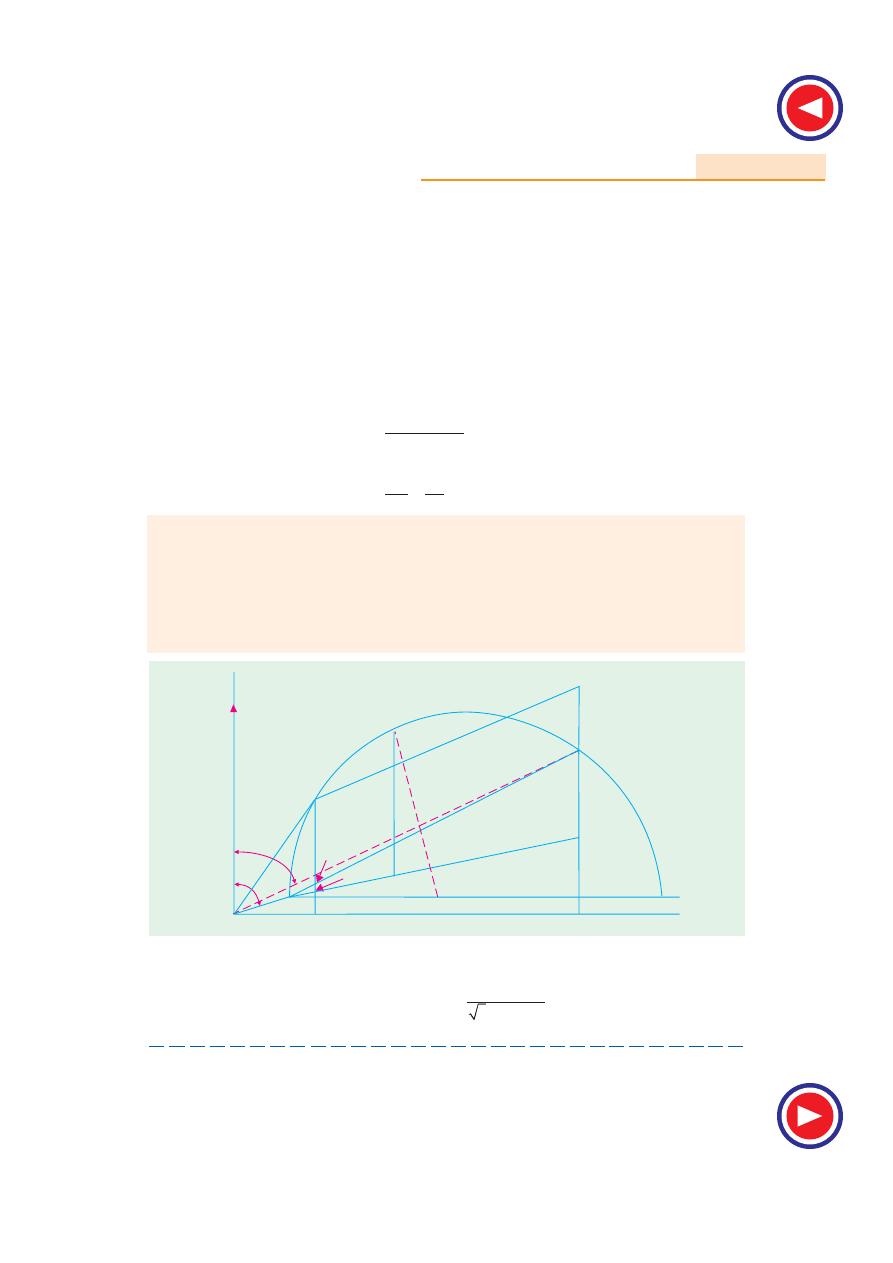

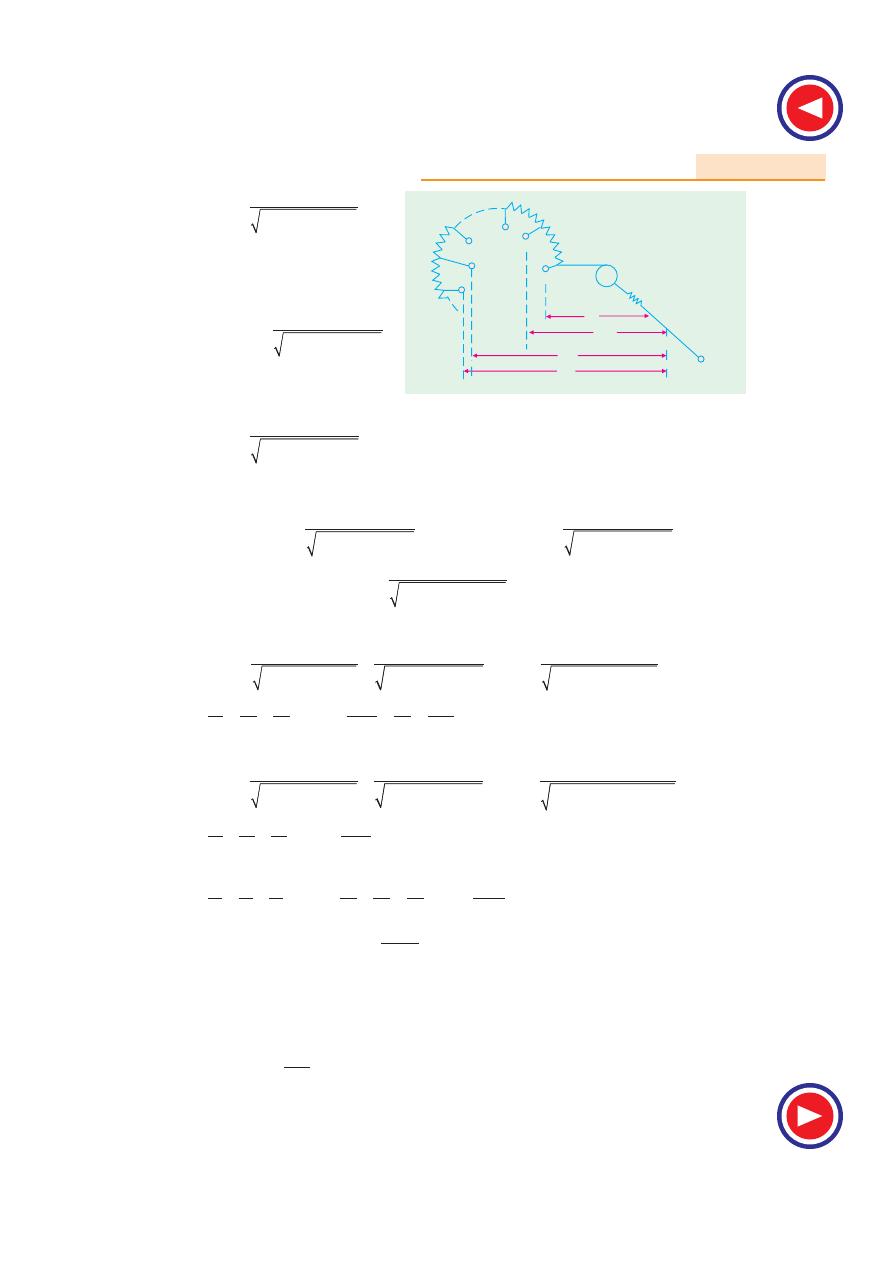

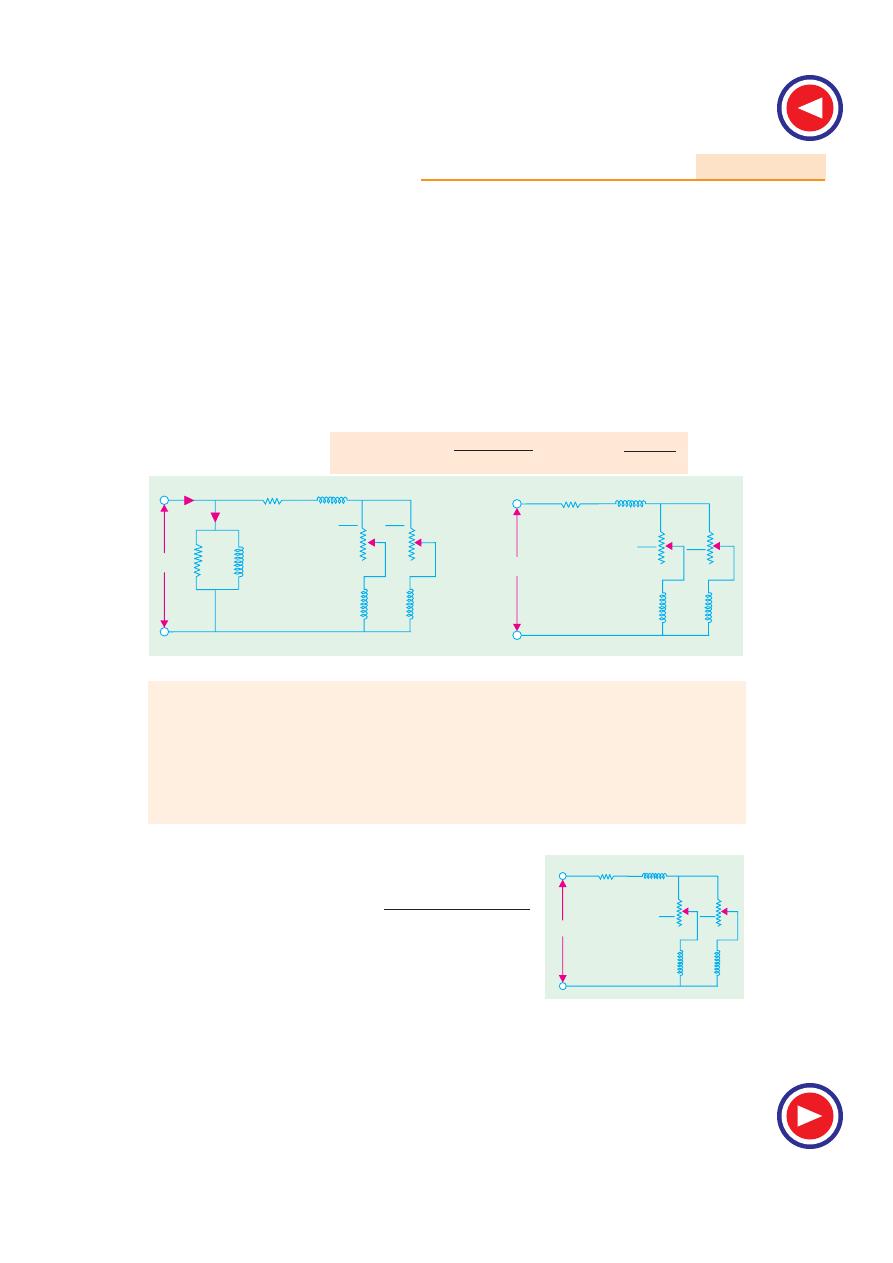

35.2. Circle Diagram for a Series Circuit

It will be shown that the end of the current vector for a series circuit with constant reactance and

voltage, but with a variable resistance is a circle. With reference to Fig. 35.1, it is clear that

I

=

2

2

(

)

=

+

V

V

Z

R

X

=

2

2

sin

(

)

×

=

φ

+

V

X

V

X

X

R

X

∵ sin φ =

2

2

(

)

+

X

R

X

– Fig. 35.2

∴

I

= (V /X) sin

φ

It is the equation of a circle in polar co-

ordinates, with diameter equal to V /X . Such a circle is drawn in Fig. 35.3, using the magnitude of the

current and power factor angle

φ as polar co-ordinates of the point A. In other words, as resistance R

is varied (which means, in fact,

φ is changed), the

end of the current vector lies on a circle with

diameter equal to V /X . For a lagging current, it is

usual to orientate the circle of Fig. 35.3 (a) such

that its diameter is horizontal and the voltage vector

takes a vertical position, as shown in Fig. 35.3 (b).

There is no difference between the two so far as

the magnitude and phase relationships are

concerned.

35.3. Circle Diagram for the Approxi-

mate Equivalent Circuit

The approximate equivalent diagram is redrawn in Fig. 35.4. It is clear that the circuit to the right

of points ab is similar to a series circuit, having a constant voltage V

1

and reactance X

01

but variable

resistance (corresponding to different values of slip s).

Hence, the end of current vector for I

2

′ will lie on a circle with a diameter of V/X

01

. In Fig. 35.5,

I

2

′ is the rotor current referred to stator, I

0

is no-load current (or exciting current) and

I

1

is the total stator current and is the

vector sum of the first two. When I

2

′ is

lagging and

φ

2

= 90º, then the position of

vector for I

2

′ will be along OC i.e. at right

angles to the voltage vector OE. For any

other value of

φ

2

, point A will move along

the circle shown dotted. The exciting

current I

0

is drawn lagging V by an angle

φ

0

. If conductance G

0

and susceptance

Fig. 35.3

f

f

V

X

V

X

Y

Y

A

O

O

X

X

I

C

( )

a

( )

b

C

I

Fig. 35.1

Fig. 35.2

I

R

X

V

Z

X

R

f

Fig. 35.4

X

X X

01

1

2

=

+

R

R R

01

1

2

=

+

I

1

I

2

I

0

V

r

R

R

L

2

=

G

0

B

0

a

a

b

1

S

_1

( (

Computations and Circle Diagrams

1315

B

0

of the exciting circuit are assumed constant, then I

0

and

φ

0

are also constant. The end of current

vector for I

1

is also seen to lie on another circle which is displaced from the dotted circle by an

amount I

0

. Its diameter is still V /X

01

and is parallel to the horizontal axis OC. Hence, we find that if

an induction motor is tested at various loads, the locus of the end of the vector for the current (drawn

by it) is a circle.

35.4. Determination of G

0

and B

0

If the total leakage reactance X

01

of the

motor, exciting conductance G

0

and exciting

susceptance B

0

are found, then the position

of the circle O

′BC′ is determined uniquely.

One method of finding G

0

and B

0

consists in

running the motor synchronously so that slip

s

= 0. In practice, it is impossible for an

induction motor to run at synchronous speed,

due to the inevitable presence of friction and

windage losses. However, the induction

motor may be run at synchronous speed by

another machine which supplies the friction and windage

losses. In that case, the circuit to the right of points ab

behaves like an open circuit, because with s = 0, R

L

=

∞

(Fig. 35.6). Hence, the current drawn by the motor is I

0

only. Let

V

= applied voltage/phase; I

0

= motor current /

phase

W

= wattmeter reading i.e. input in watt ; Y

0

=

exciting admittance of the motor. Then, for a 3-phase

induction motor

W

= 3G

0

V

2

or

G

0

=

2

3

W

V

Also, I

0

= V Y

0

or

Y

0

= I

0

/V

B

0

=

2

2

2

2

0

0

0

0

(

)

[(

/ )

]

−

=

−

Y

G

I

V

G

Hence, G

0

and B

0

can be found.

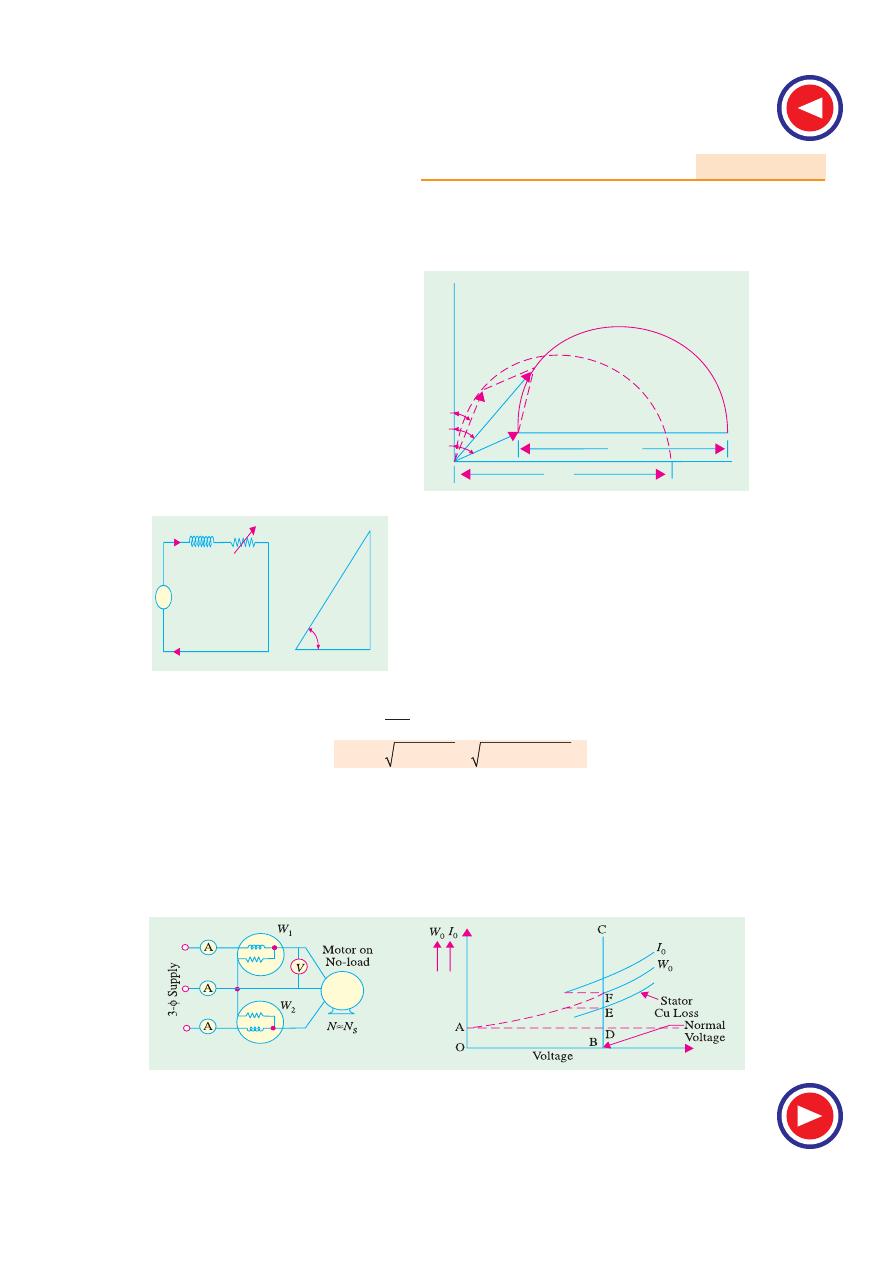

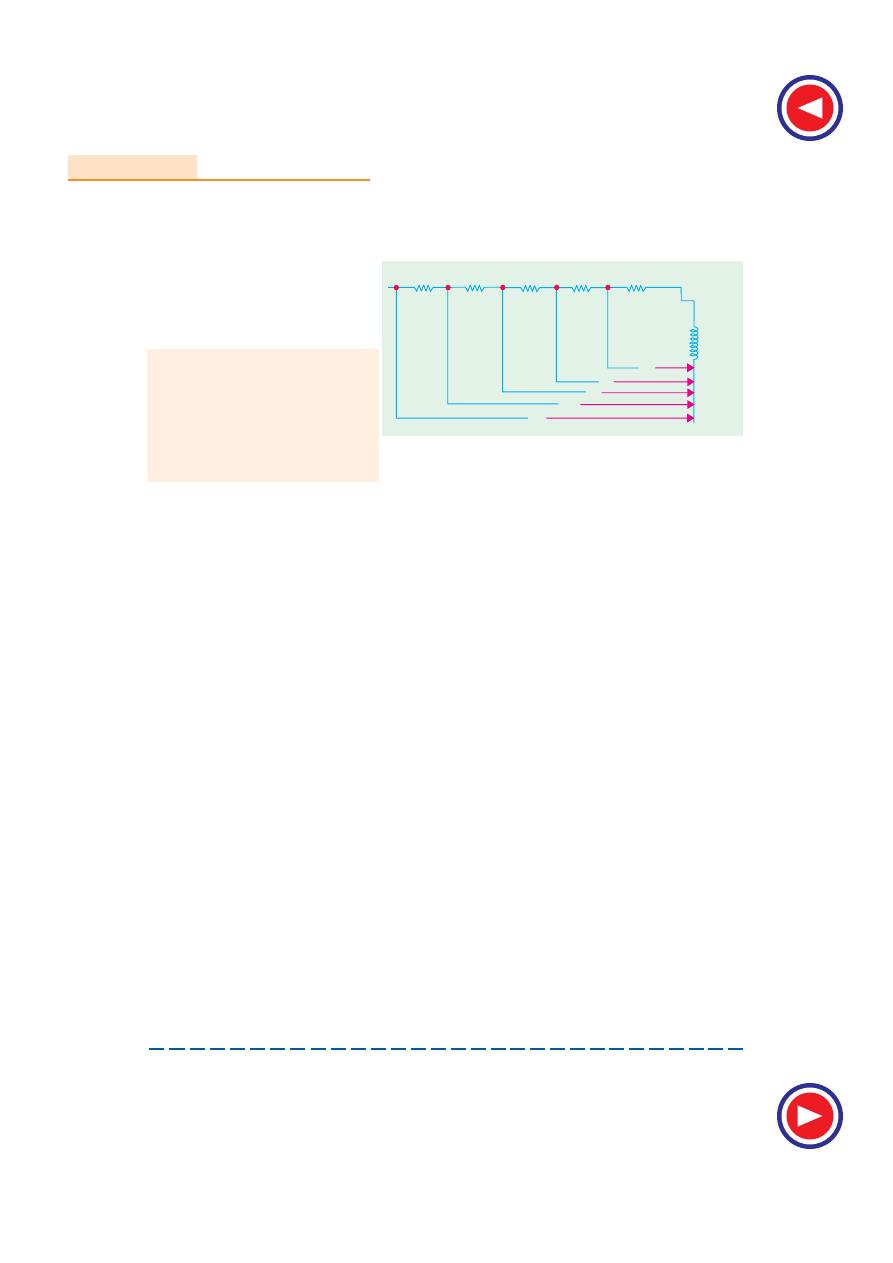

35.5. No-load Test

In practice, it is neither necessary nor feasible to run the induction motor synchronously for

getting G

0

and B

0

. Instead, the motor is run without any external mechanical load on it. The speed of

the rotor would not be synchronous, but very much near to it ; so that, for all practical purposes, the

speed may be assumed synchronous. The no load test is carried out with different values of applied

voltage, below and above the value of normal voltage. The power input is measured by two wattmeters,

Fig. 35.7

Fig. 35.8

Fig. 35.5

V/X

01

I

0

I

1

I

2

O

O

A

B

C

C

E

V/X

01

V

Fig. 35.6

I

R

X

V

Z

X

R

f

1316

Electrical Technology

I

0

by an ammeter and V by a voltmeter, which are included in the circuit of Fig. 35.7. As motor is

running on light load, the p.f. would be low i.e. less than 0.5, hence total power input will be the

difference of the two wattmeter readings W

1

and W

2

. The readings of the total power input W

0

, I

0

and

voltage V are plotted as in Fig. 35.8. If we extend the curve for W

0

, it cuts the vertical axis at point A .

OA

represents losses due to friction and windage. If we subtract loss corresponding to OA from W

0

,

then we get the no-load electrical and magnetic losses in the machine, because the no-load input W

0

to

the motor consists of

(

i)

small stator Cu loss 3 I

0

2

R

1

(

ii)

stator core loss W

CL

= 3G

0

V

2

(

iii)

loss due to friction and windage.

The losses (ii) and (iii) are collectively known as fixed losses, because they are independent of

load. OB represents normal voltage. Hence, losses at normal voltage can be found by drawing a

vertical line from B.

BD

= loss due to friction and windage DE = stator Cu loss EF = core loss

Hence, knowing the core loss W

CL

, G

0

and B

0

can be found, as discussed in Art. 35.4.

Additionally,

φ

0

can also be found from the relation W

0

= 3 V

L

I

0

cos

φ

0

∴

cos

φ

0

=

0

0

3

L

W

V I

where V

L

= line voltage and W

0

is no-load stator input.

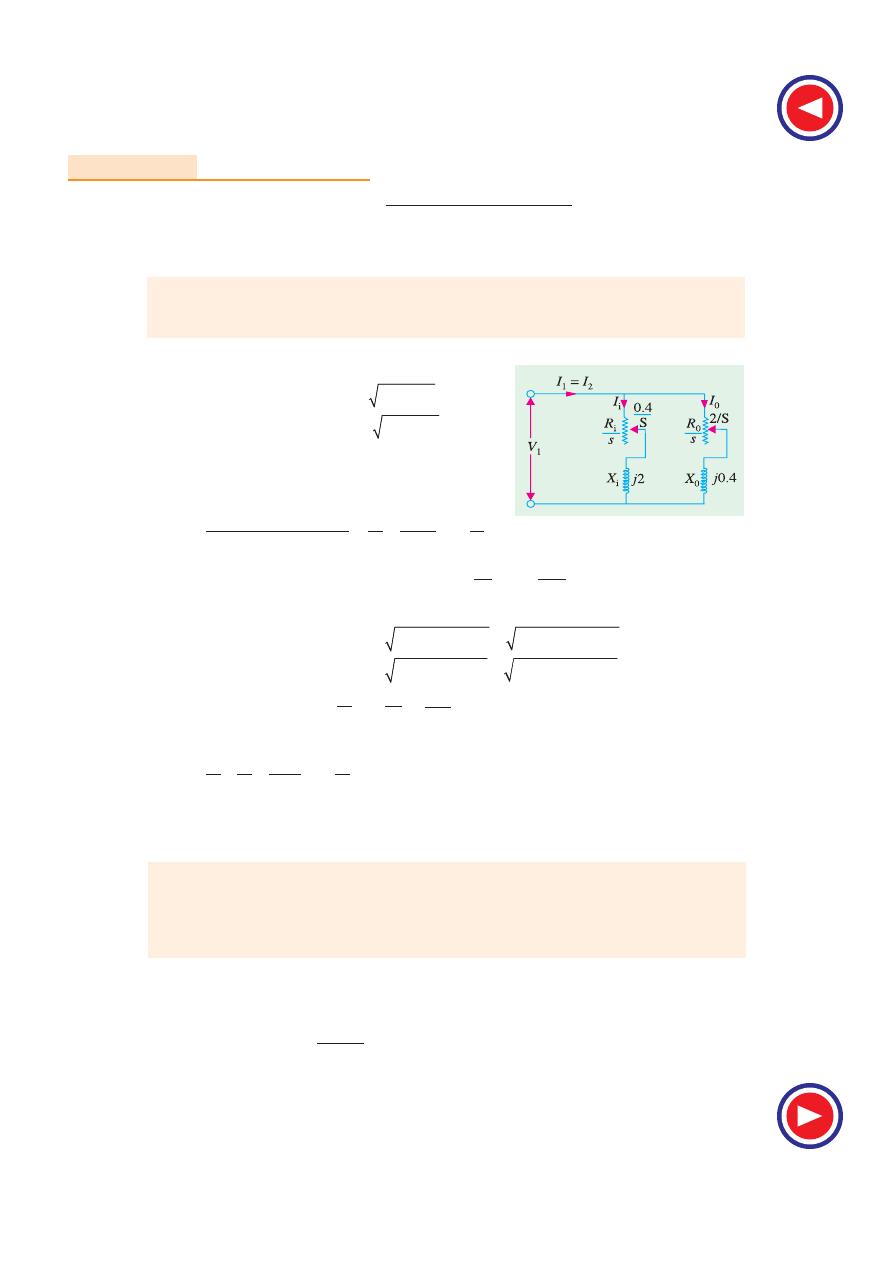

Example 35.1.

In a no-load test, an induction motor took 10 A and 450 watts with a line voltage

of 110 V. If stator resistance/phase is 0.05

Ω and friction and windage losses amount to 135 watts,

calculate the exciting conductance and susceptance/phase.

Solution.

stator Cu loss = 3 I

0

2

R

1

= 3

× 10

2

× 0.05 = 15 W

∴

stator core loss = 450

− 135 − 15 = 300 W

Voltage/phase V = 110/ 3 V ;

Core loss = 3 G

0

V

2

300 = 3 G

0

× (110/

3

)

2

; G

0

=

2

300

3 (110 / 3)

×

=

0.025 siemens/phase

Y

0

= I

0

/ V = (10

×

3

)/110 = 0.158 siemens/

phase

B

0

=

2

2

2

2

0

0

(

)

(0.158

0.025 )

−

=

−

Y

G

=

0.156 siemens/phase.

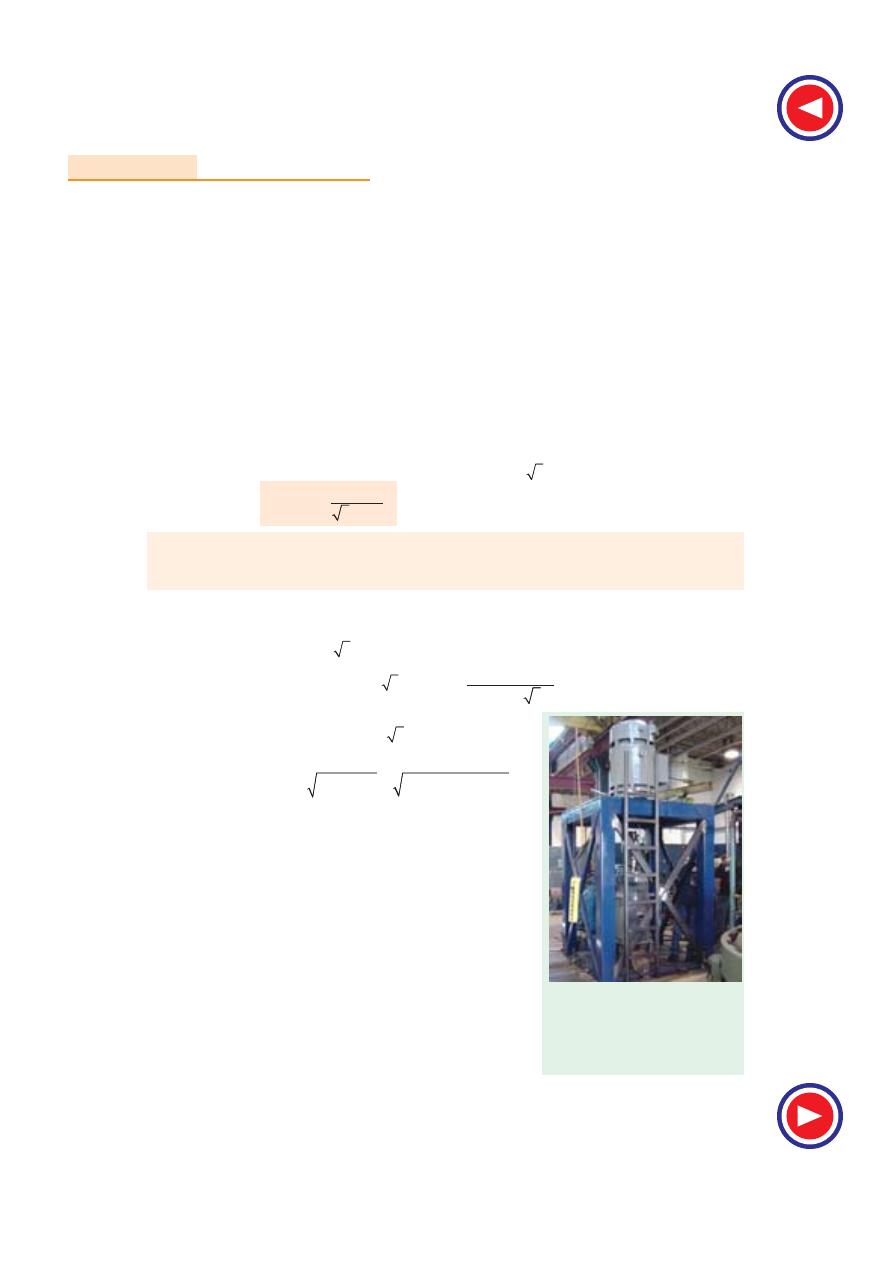

35.6. Blocked Rotor Test

It is also known as locked-rotor or short-circuit test. This test

is used to find–

1.

short-circuit current with

normal

voltage applied to sta-

tor

2.

power factor on short-circuit

Both the values are used in the construction of circle dia-

gram

3.

total leakage reactance X

01

of the motor as referred to pri-

mary (i.e. stator)

4.

total resistance of the motor R

01

as referred to primary.

In this test, the rotor is locked (or allowed very slow rotation)

This vertical test stand is capable of

absorbing up to 10,000 N-m of

torque at continuous load rating

(max 150.0 hp at 1800 rpm). It helps

to develop speed torque curves and

performs locked rotor testing

Computations and Circle Diagrams

1317

and the rotor windings are short-circuited at slip-rings, if the motor has a wound rotor. Just as in the

case of a short-circuit test on a transformer, a reduced voltage (up to 15 or 20 per cent of normal

value) is applied to the stator terminals and is so adjusted that full-load current flows in the stator. As

in this case s = 1, the equivalent circuit of the motor is exactly like a transformer, having a short-

circuited secondary. The values of current, voltage and power input on short-circuit are measured by

the ammeter, voltmeter and wattmeter connected in the circuits as before. Curves connecting the

above quantities may also be drawn by taking two or three additional sets of readings at progressively

reduced voltages of the stator.

(

a)

It is found that relation between the short-circuit current and voltage is approximately a

straight line. Hence, if V is normal stator voltage, V

s

the short-circuit voltage (a fraction of V ), then

short-circuit or standstill rotor current, if normal voltage were applied to stator, is found from the

relation

I

SN

= I

s

× V/V

s

where

I

SN

= short-circuit current obtainable with normal voltage

I

s

= short-circuit current with voltage V

S

(

b)

Power factor on short-circuit is found from

W

S

=

3 V

S L

I

SL

cos

φ

S

;

∴ cos φ

S

= W

S

/ ( 3 V

S L

I

S L

)

where

W

S

= total power input on short-circuit

V

SL

= line voltage on short-circuit

I

SL

= line current on short-circuit.

(

c)

Now, the motor input on short-circuit consists of

(

i)

mainly stator and rotor Cu losses

(

ii)

core-loss, which is small due to the fact that applied voltage is only a small percentage of the

normal voltage. This core-loss (if found appreciable) can be calculated from the curves of

Fig. 35.8.

∴

Total Cu loss = W

S

− W

CL

3 I

s

2

R

01

= W

s

− W

CL

:

R

01

= (W

s

− W

CL

) / 3 I

s

2

(

d)

With reference to the approximate equivalent circuit of an induction motor (Fig. 35.4), motor

leakage reactance per phase X

01

as referred to the stator may be calculated as follows :

Z

01

= V

S

/ I

S

X

01

=

2

2

01

01

(

)

−

Z

R

Usually, X

1

is assumed equal to X

2

′ where X

1

and X

2

are stator and rotor reactances per phase

respectively as referred to stator. X

1

= X

2

′ = X

01

/ 2

If the motor has a wound rotor, then stator and rotor resistances are separated by dividing R

01

in

the ratio of the d.c. resistances of stator and rotor windings.

In the case of squirrel-cage rotor, R

1

is determined as usual and after allowing for ‘skin effect’ is

subtracted from R

01

to give R

2

′ − the effective rotor resistance as referred to stator.

∴

R

2

′ = R

01

− R

1

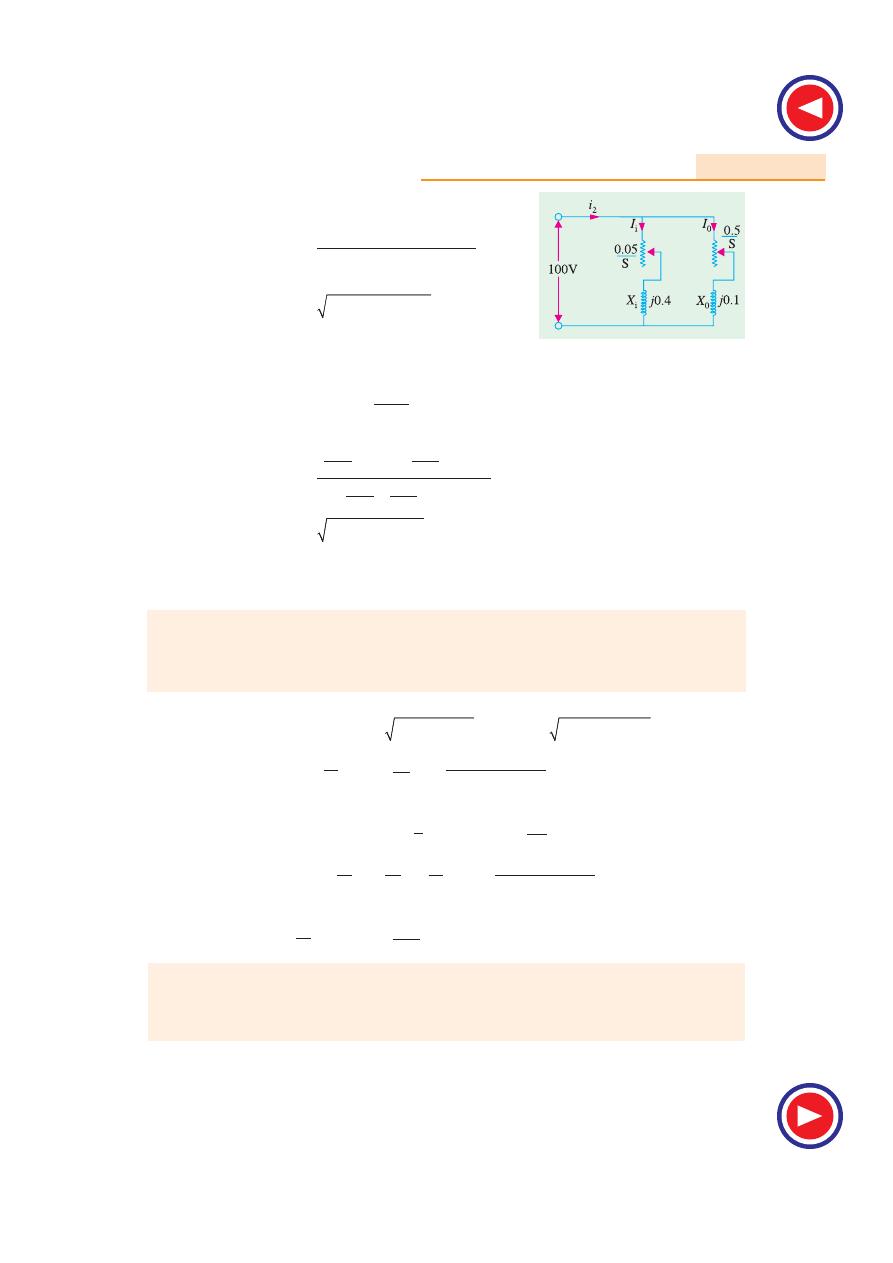

Example 35.2.

A 110-V, 3-

φ, star-connected induction motor takes 25 A at a line voltage of 30

V with rotor locked. With this line voltage, power input to motor is 440 W and core loss is 40 W. The

d.c. resistance between a pair of stator terminals is 0.1

Ω. If the ratio of a.c. to d.c. resistance is 1.6,

find the equivalent leakage reactance/phase of the motor and the stator and rotor resistance per

phase.

(Electrical Technology, Madras Univ. 1987)

Solution.

S.C. voltage/phase,

V

s

= 30 /

3

= 17.3 V : I

s

= 25 A per phase

Z

01

= 17.3/25 = 0.7

Ω (approx.) per phase

1318

Electrical Technology

Stator and rotor Cu losses = input

− core loss = 440 − 40 = 400 W

∴

3

× 25

2

× R

01

= 400

∴ R

01

= 400/3

× 625 =

0.21

Ω

Ω

Ω

Ω

Ω

where R

01

is equivalent resistance/phase of motor as referred to stator.

Leakage reactance/phase

X

01

=

2

2

(0.7

0.21 )

−

= 0.668

Ω

d.c. resistance/phase of stator = 0.1/2 = 0.05

Ω

a.c. resistance/phase

R

1

= 0.05

× 1.6 = 0.08 Ω

Hence, effective resistance/phase of rotor as referred to stator

R

2

′ = 0.21 − 0.08 =

0.13

Ω

Ω

Ω

Ω

Ω

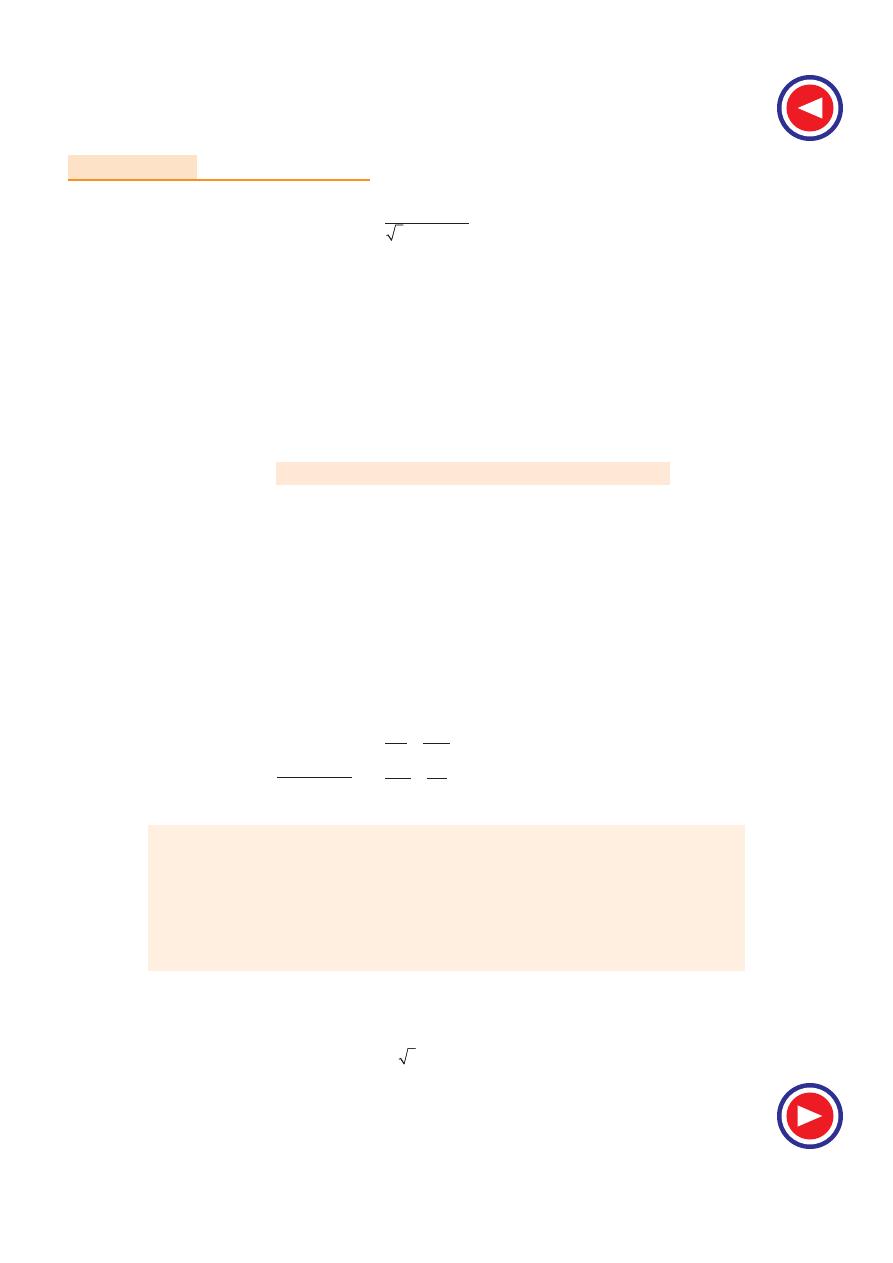

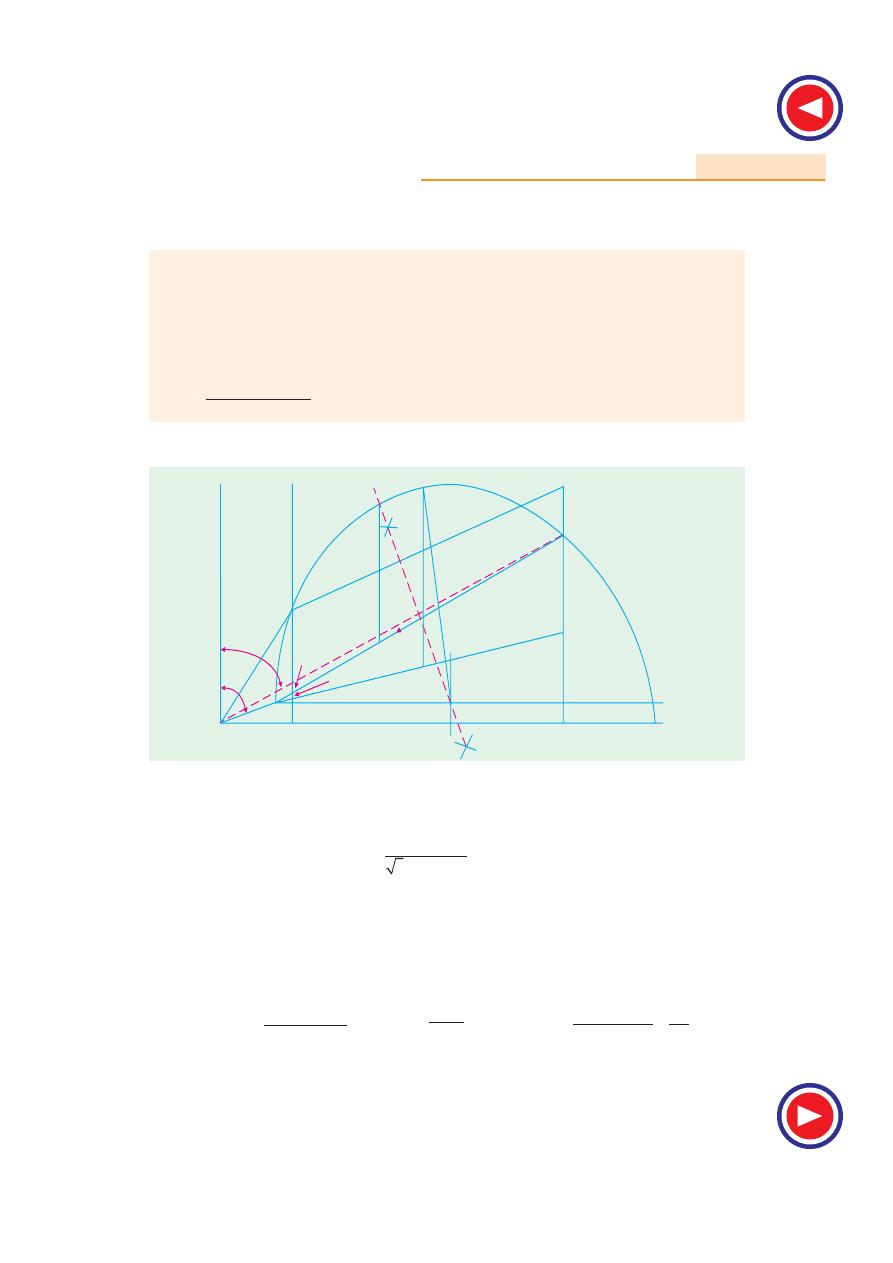

35.7. Construction of the Circle Diagram

Circle diagram of an induction motor can be drawn by

using the data obtained from

(1)

no-load

(2)

short-circuit

test

and

(3)

stator resistance test

, as shown below.

Step No. 1

From no-load test, I

0

and

φ

0

can be calculated. Hence,

as shown in Fig. 35.9, vector for I

0

can be laid off lagging

φ

0

behind the applied voltage V .

Step No. 2

Next, from blocked rotor test or short-circuit test, short-

circuit current I

S N

corresponding to normal voltage

and

φ

S

are found. The vector OA represents I

S N

= (I

S

V

/V

S

) in

magnitude and phase. Vector O

′A represents rotor current I

2

′ as referred to stator.

Clearly, the two points O

′ and A lie on the required circle. For finding the centre C of this circle,

chord O

′A is bisected at right angles–its bisector giving point C. The diameter O′D is drawn perpen-

dicular to the voltage vector.

As a matter of practical contingency,

it is recommended that the scale of

current vectors should be so chosen

that the diameter is more than 25 cm,

in order that the performance data of

the motor may be read with reason-

able accuracy from the circle diagram.

With centre C and radius = CO

′, the

circle can be drawn. The line O

′A is

known as

out-put line.

It should be noted that as the voltage

vector is drawn vertically, all vertical

distances represent the active or power

or energy components of the currents.

For example, the vertical component O

′P of no-load current OO′ represents the no-load input, which

supplies core loss, friction and windage loss and a negligibly small amount of stator I

2

R

loss. Similarly,

the vertical component AG of short-circuit current OA is proportional to the motor input on short-

circuit or if measured to a proper scale, may be said to equal power input.

Step No. 3

Torque line. This is the line which separates the stator and the rotor copper losses

. When the

Windings inside a motor

Fig. 35.9

F

1

F

s

F

0

I

0

I

1

I

¢

2

V

L

G

E

A

Ou

tpu

t

Li

ne

Torq

ue

Line

Stator

Cu Loss

C

P

K

O

D

J

O

¢

Fixed Loss

Rotor

Cu Loss

M

N

F

E

Computations and Circle Diagrams

1319

rotor is locked, then all the power supplied to the motor goes to meet core losses and Cu losses in the

stator and rotor windings. The power input is proportional to A G. Out of this, FG (= O

′P) represents

fixed losses i.e. stator core loss and friction and windage losses. AF is proportional to the sum of the

stator and rotor Cu losses. The point E is such that

AE

EF

=

rotor Cu loss

stator Cu loss

As said earlier, line O

′E is known as torque line.

How to locate point E ?

(

i) Squirrel-cage Rotor.

Stator resistance/phase i.e. R

1

is found from stator-resistance test.

Now, the short-circuit motor input W

s

is approximately equal to motor Cu losses (neglecting iron

losses).

Stator Cu loss = 3I

S

2

R

1

∴ rotor Cu loss = W

S

− 3 I

S

2

R

1

∴

AE

EF

=

2

1

2

1

3

3

−

S

S

S

W

I R

I R

(

ii) Wound Rotor.

In this case, rotor and stator resistances per phase r

2

and r

1

can be easily

computed. For any values of stator and rotor currents I

1

and I

2

respectively, we can write

AE

EF

=

2

2

2 2

2

2

2

1

1

1 1

=

I r

r

I

r

I

I r

;

Now,

1

2

I

I

= K = transformation ratio

AE

EF

=

2

2

2

2

2

1

1

1

/

equivalent rotor resistance per phase

1

stator resistance per phase

′

×

=

=

=

r

r

K

r

r

r

r

K

Value of K may be found from short-circuit test itself by using two ammeters, both in stator and

rotor circuits.

Let us assume that the motor is running and taking a current OL (Fig. 35.9). Then, the perpendicular

JK

represents fixed losses, JN is stator Cu loss, NL is the rotor input, NM is rotor Cu loss, ML is rotor

output and LK is the total motor input.

From our knowledge of the relations between the above-given various quantities, we can write :

3 . V

L

. L K = motor input

3 . V

L

. JK = fixed losses

3 . V

L

. JN = stator copper loss

3 . V

L

. MN = rotor copper loss

3 . V

L

. MK = total loss

3 . V

L

. M L = mechanical output

3 . V

L

. NL = rotor input

∝ torque

1.

ML

/ LK = output/input = efficiency

2.

MN

/ N L = (rotor Cu loss)/(rotor input) = slip, s.

3.

ML

NL

=

rotor output

rotor input

= 1

− s =

S

N

N

=

actual speed

synchronous speed

4.

LK

OL

= power factor

Hence, it is seen that, at least, theoretically, it is possible to obtain all the characteristics of an

induction motor from its circle diagram. As said earlier, for drawing the circle diagram, we need

(

a)

stator-resistance test for separating stator and rotor Cu losses and

(

b)

the data obtained from

(

i)

no-

load test and

(

ii)

short-circuit test.

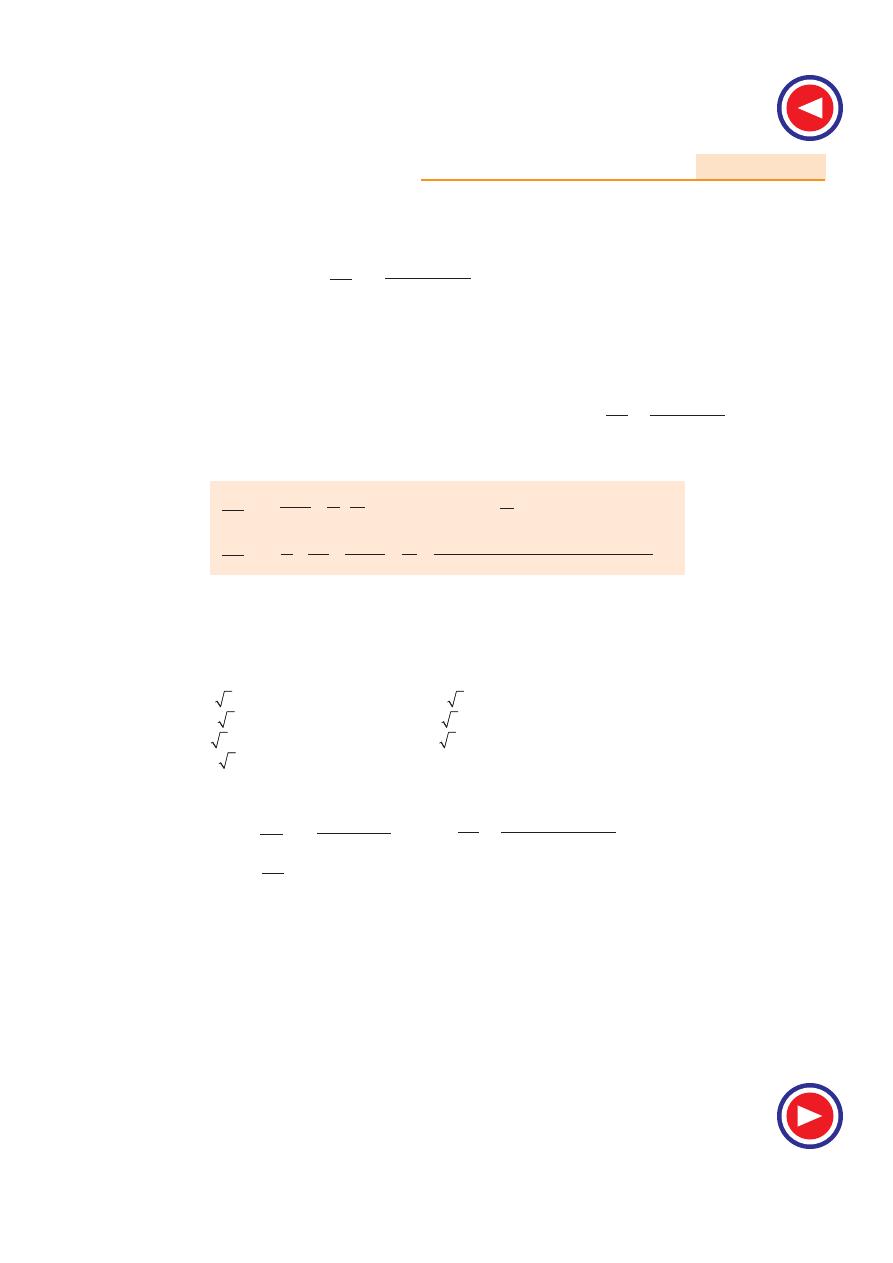

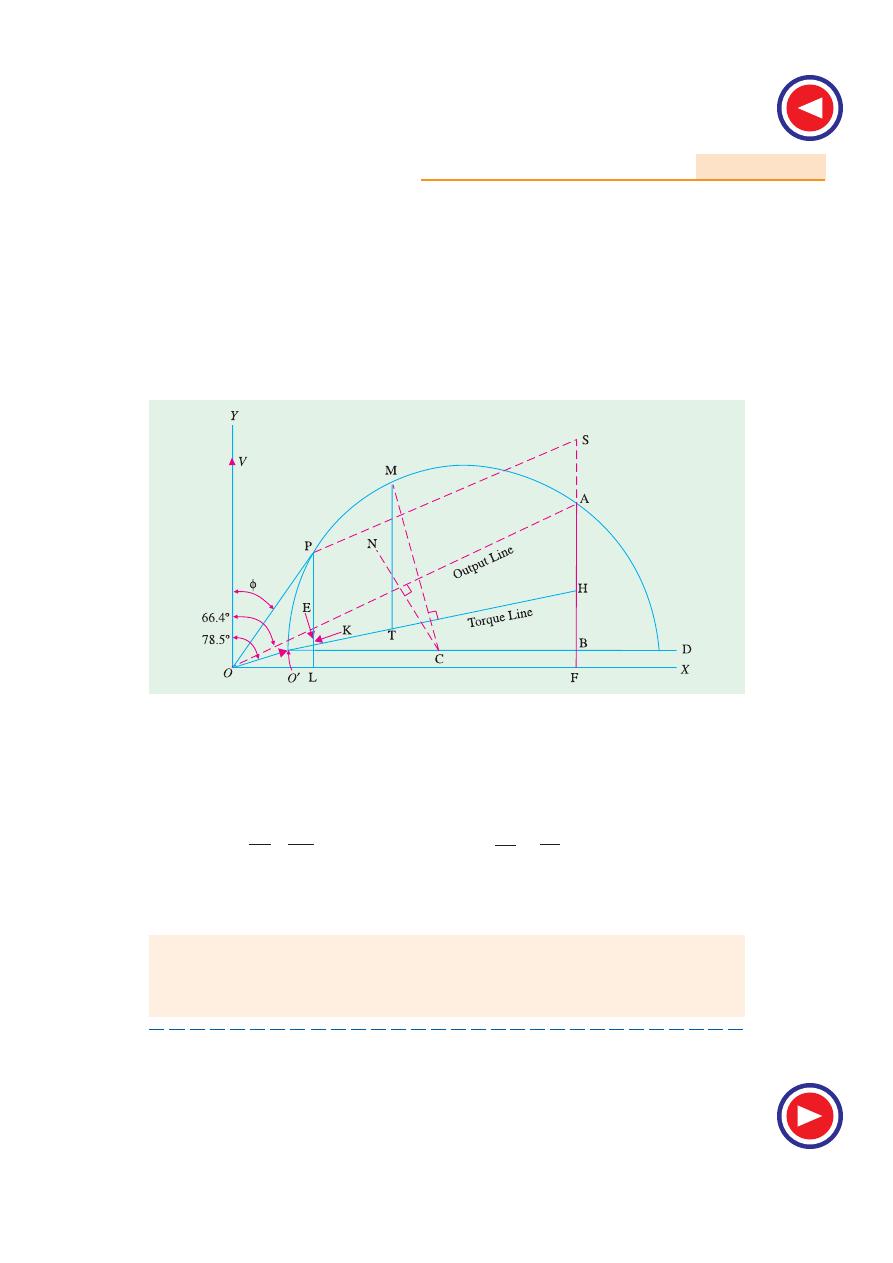

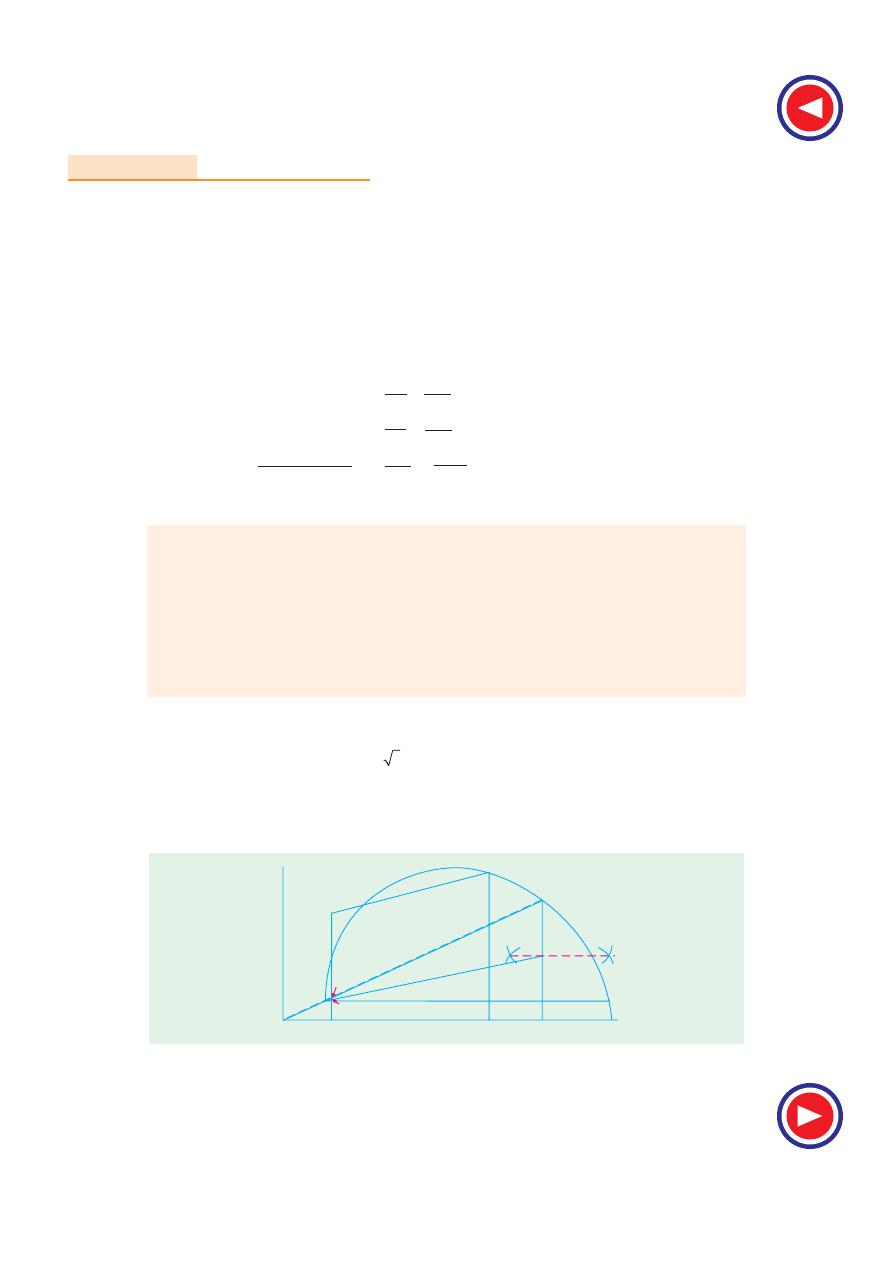

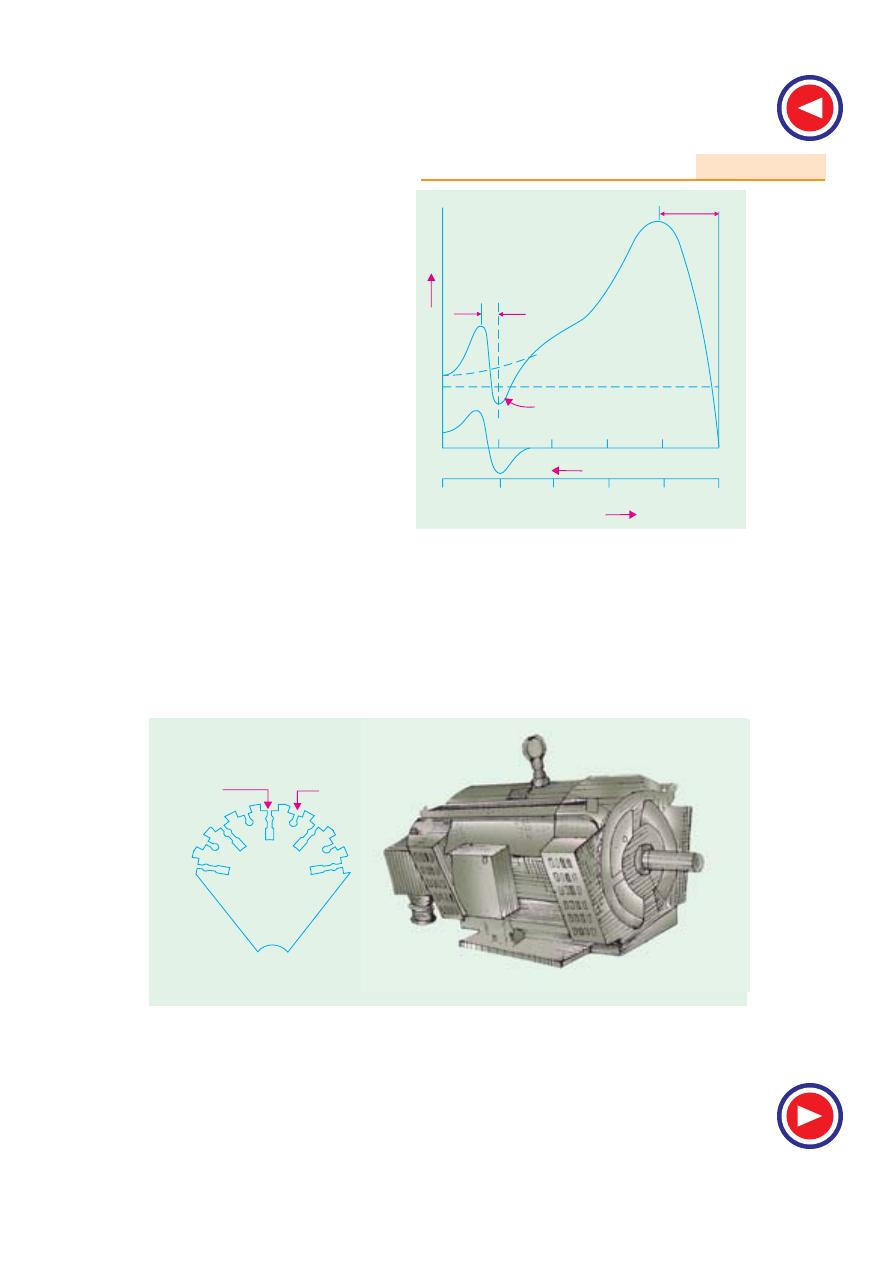

35.8. Maximum Quantities

It will now be shown from the circle diagram (Fig. 35.10) that the maximum values occur at the

positions stated below :

(

i) Maximum Output

It occurs at point M where the tangent is parallel to output line O

′A. Point M may be located by

1320

Electrical Technology

drawing a line CM from point C such that it

is perpendicular to the output line O

′A. Maxi-

mum output is represented by the vertical MP.

(

ii) Maximum Torque or

Rotor Input

It occurs at point N where the tangent is

parallel to torque line O

′E. Again, point N

may be found by drawing CN perpendicular

to the torque line. Its value is represented by

NQ

. Maximum torque is also known as

stalling or pull-out torque.

(

iii) Maximum Input Power

It occurs at the highest point of the circle

i

.e. at point R where the tangent to the circle is horizontal. It is proportional to RS. As the point R is

beyond the point of maximum torque, the induction motor will be unstable here. However, the maximum

input is a measure of the size of the circle and is an indication of the ability of the motor to carry short-

time over-loads. Generally, RS is twice or thrice the motor input at rated load.

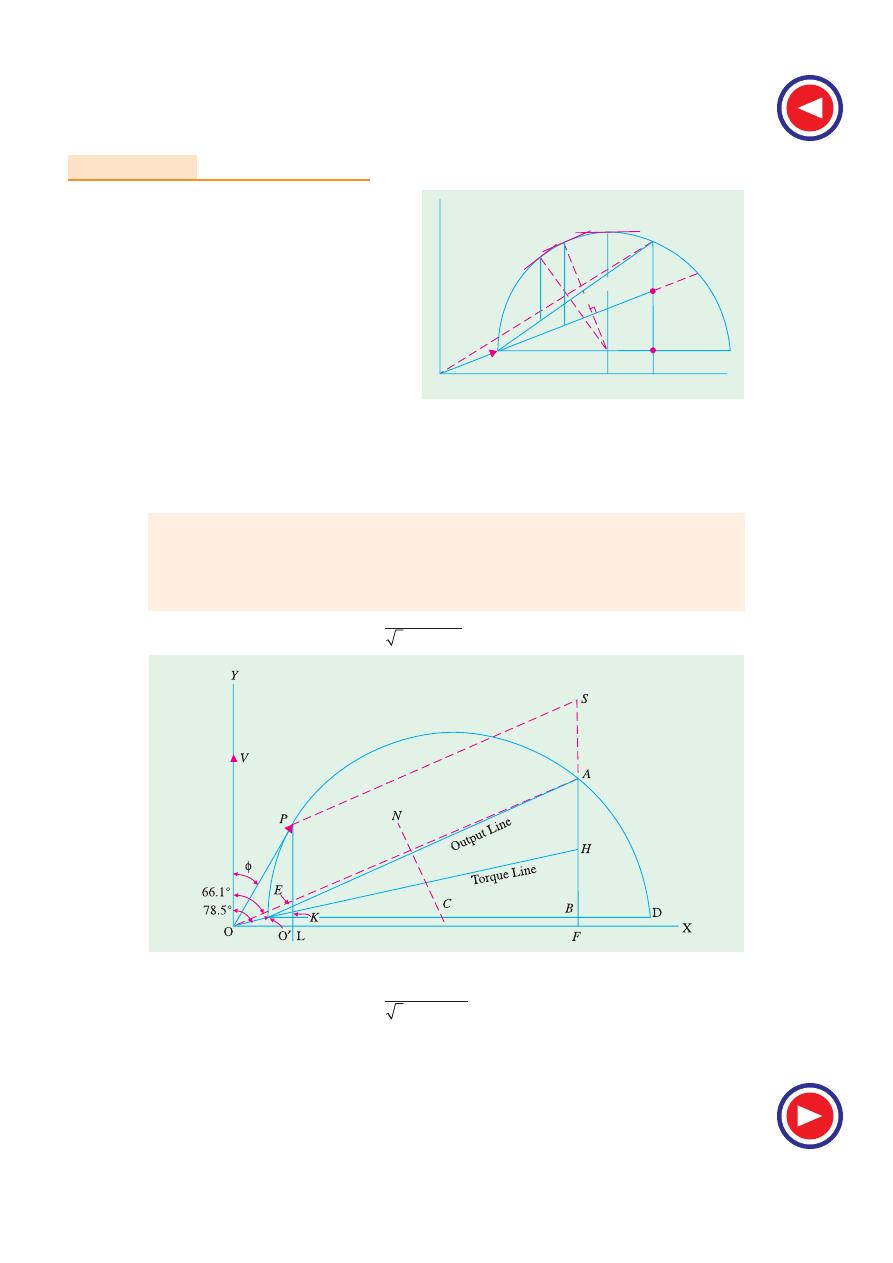

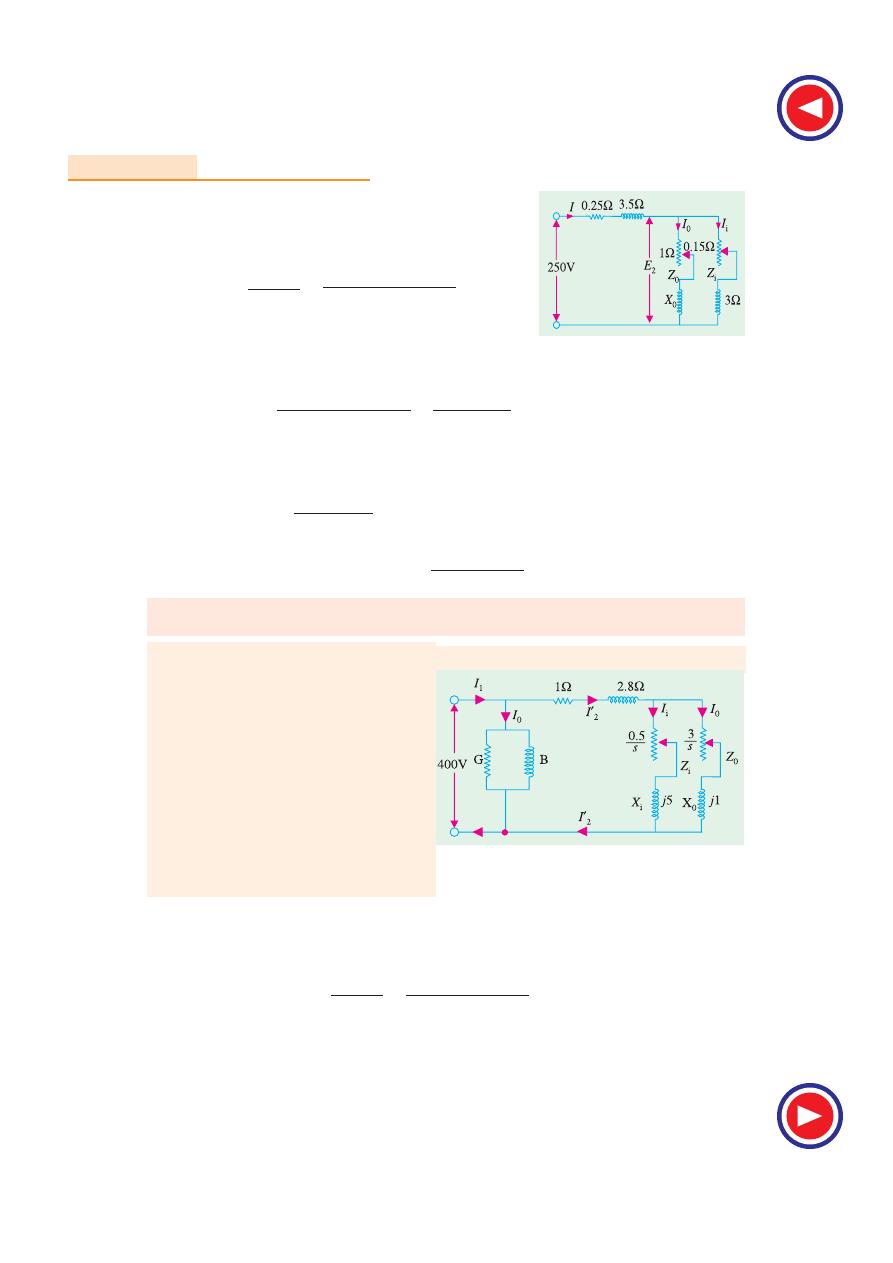

Example 35.3.

A 3-ph, 400-V induction motor gave the following test readings;

No-load : 400 V, 1250 W, 9 A, Short-circuit : 150 V, 4 kW, 38 A

Draw the circle diagram.

If the normal rating is 14.9 kW, find from the circle diagram, the full-load value of current, p.f.

and slip

.

(Electrical Machines-I, Gujarat Univ. 1985)

Solution.

cos

φ

0

=

1250

3

400

9

×

×

= 0.2004 ;

φ

0

= 78.5º

Fig. 35.11

cos

φ

S

=

4000

3

150

38

×

×

= 0.405 ;

φ

S

= 66.1º

Short-circuit current with normal voltage is I

S N

= 38 (400/150) = 101.3 A. Power taken would be

= 4000 (400/150)

2

= 28,440 W. In Fig. 33.11, OO

′ represents I

0

of 9 A. If current scale is 1 cm = 5 A,

Fig. 35.10

M

N

R

E

Max

Max

Max

T

o

rque

Output

Input

Ou

tp

ut

Lin

e

Tor

que

Lin

e

P

Q

Locked

Input

O

O

S

G

C

F

D

V

A

Computations and Circle Diagrams

1321

then vector OO

′ = 9/5 = 1.8 cm

*

and is drawn at an angle of

φ

0

= 78.5º with the vertical OV (which

represents voltage). Similarly, OA represents I

S N

(S.C. current with normal voltage applied) equal to

101.3 A. It measures 101.3/5 = 20.26

*

cm and is drawn at an angle of 66.1º, with the vertical O V.

Line O

′D is drawn parallel to OX. NC is the right-angle bisector of O′A. The semi-circle

Ο ′AD

is drawn with C as the centre. This semi-circle is the locus of the current vector for all load conditions

from no-load to short-circuit. Now, AF represents 28,440 W and measures 8.1 cm. Hence, power

scale becomes : 1 cm = 28,440/8.1 = 3,510 W. Now, full-load motor output = 14.9

× 10

3

= 14,900 W.

According to the above calculated power scale, the intercept between the semi-circle and output line

O

′A should measure = 14,900/3510 = 4.25 cm. For locating full-load point P, B A is extended. A S is

made equal to 4.25 cm and SP is drawn parallel to output line O

′A. PL is perpendicular to OX.

Line current = OP = 6 cm = 6

× 5 =

30 A

;

φ = 30º (by measurement)

p.f. = cos 30º =

0.886

(or cos

φ = PL/OP = 5.2/6 = 0.865)

Now,

slip =

rotor Cu loss

rotor input

In Fig. 35.11, EK represents rotor Cu loss and PK represents rotor input.

∴

slip =

0.3

4.5

=

EK

PK

= 0.067 or

6.7%

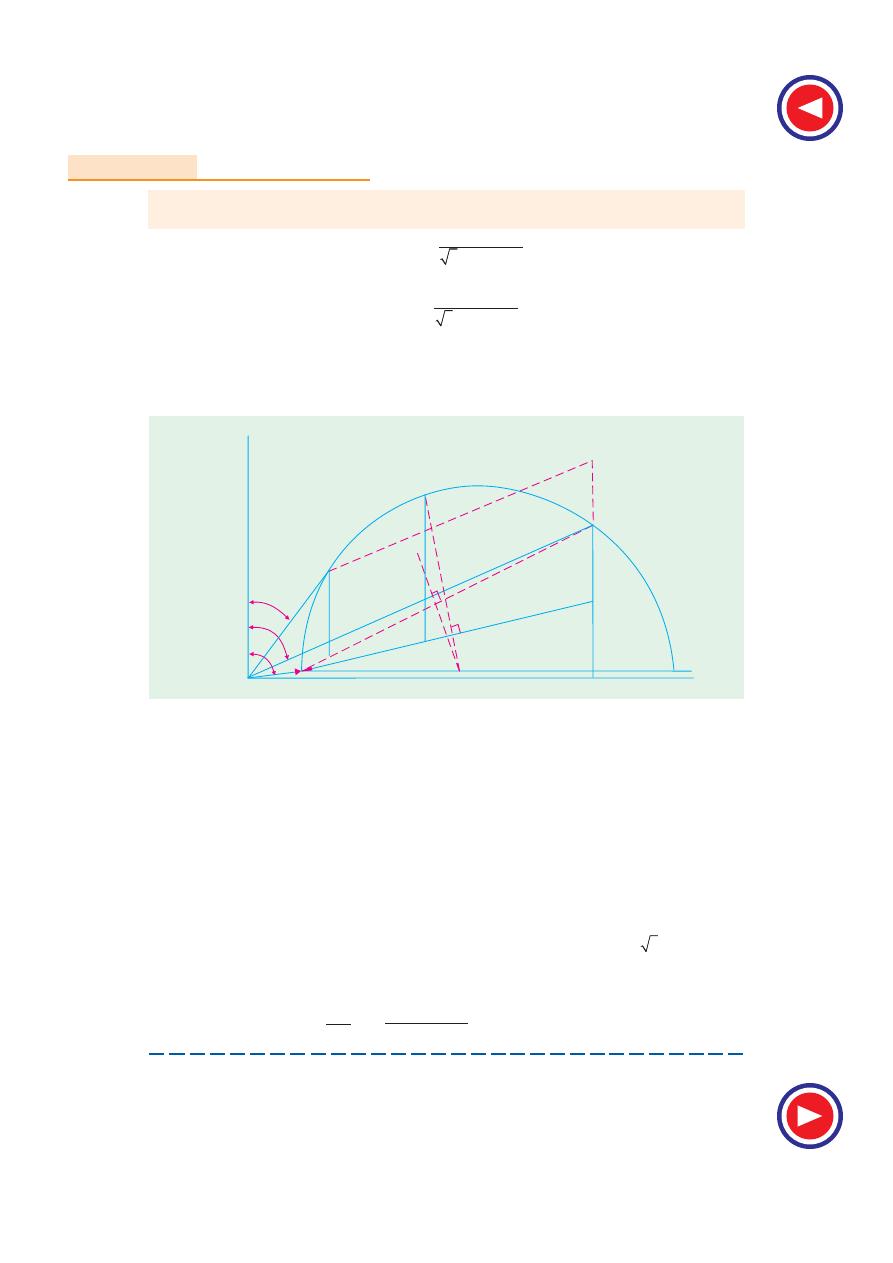

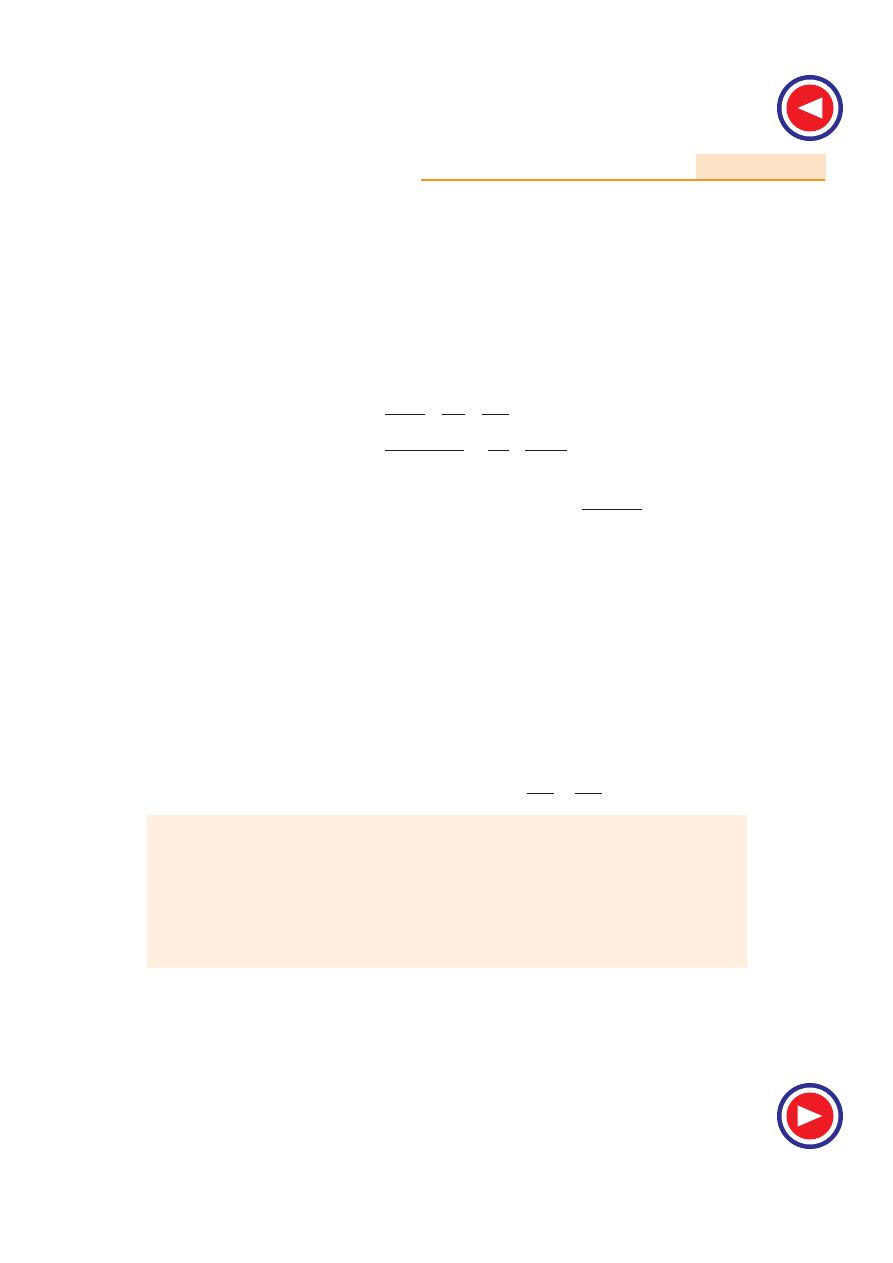

Example 35.4.

Draw the circle diagram for a 3.73 kW, 200-V, 50-Hz, 4-pole, 3-

φ star-connected

induction motor from the following test data :

No-load : Line voltage 200 V, line current 5 A; total input 350 W

Blocked rotor : Line voltage 100 V, line current 26 A; total input 1700 W

Estimate from the diagram for full-load condition, the line current, power factor and also the

maximum torque in terms of the full-load torque. The rotor Cu loss at standstill is half the total Cu

loss.

(Electrical Engineering, Bombay Univ. 1987)

78º15

¢

67º42

¢

Output

Line

Torque

Line

T

C

H

A

F

G

S

O

V

R

B

X

X

¢

D

M

E

Stator

Cu

Rotor

C

u

Max.

Torque

K

N

P

Loss

Loss

Fig. 35.12

Solution. No-load test

I

0

= 5 A, cos

φ

0

=

350

3

200

5

×

×

= 0.202 ;

φ

0

= 78º15

′

*

The actual lengths are different from these values, due to reduction in block making.

1322

Electrical Technology

Blocked-rotor test :

cos

φ

s

=

1700

3

100

26

×

×

= 0.378 ;

φ

s

= 67º42

′

Short-circuit current with normal voltage, I

S N

= 26

× 200/100 = 52 A

Short-circuit/blocked rotor input with normal voltage = 1700(52/26)

2

= 6,800 W

In the circle diagram of Fig. 35.12, voltage is represented along OV which is drawn perpendicular

to O X. Current scale is 1 cm = 2 A

Line OA is drawn at an angle of

φ

0

= 78º15

′ with OV and 2.5 cm in length. Line A X′ is drawn

parallel to O X. Line OB represents short-circuit current with normal voltage i.e. 52 A and measures

52/2 = 26 cm. A B represents output line. Perpendicular bisector of A B is drawn to locate the centre

C

of the circle. With C as centre and radius = CA, a circle is drawn which passes through points A and

B

. From point B, a perpendicular is drawn to the base. BD represents total input of 6,800 W for

blocked rotor test. Out of this, ED represents no-load loss of 350 W and BE represents 6,800

− 350 =

6,450 W. Now BD = 9.8 cm and represents 6,800 W

∴

power scale = 6,800/9.8 = 700 watt/cm

or

1 cm =

700 W

BE

which represents total copper loss in rotor and stator, is bisected at point T to separate the two

losses. AT represents torque line.

Now, motor output = 3,730 watt. It will be represented by a line = 3,730/700 = 5.33 cm

The output point P on the circle is located thus :

DB

is extended and BR is cut = 5.33 cm. Line RP is drawn parallel to output line AB and cuts the

circle at point P. Perpendicular PS is drawn and P is joined to origin O.

Point M corresponding to maximum torque is obtained thus :

From centre C, a line CM is drawn such that it is perpendicular to torque line AT. It cuts the circle

at M which is the required point. Point M could also have been located by drawing a line parallel to

the torque line. MK is drawn vertical and it represents maximum torque.

Now, in the circle diagram, OP = line current on full-load = 7.6 cm. Hence, OP represents 7.6

×

2 = 15.2 A

Power factor on full-load =

6.45

7.6

=

SP

OP

= 0.86

Max. torque

F.L. torque

=

10

5.6

=

MK

PG

= 1.8

∴

Max. torque = 180% of full-load torque.

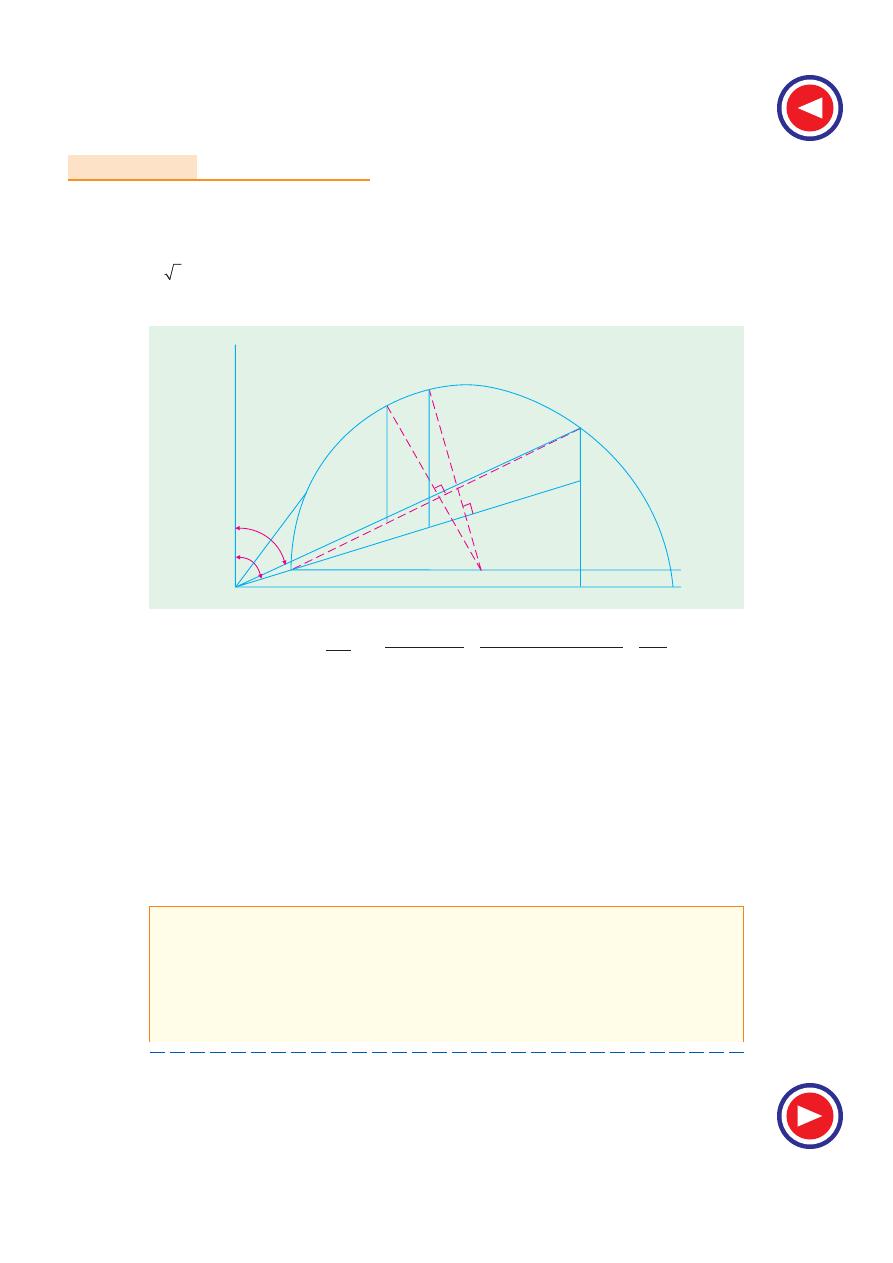

Example. 35.5.

Draw the circle diagram from no-load and short-circuit test of a 3-phase. 14.92

k W, 400-V, 6-pole induction motor from the following test results (line values).

No-load

: 400-V,

11 A,

p.f. = 0.2

Short-circuit

: 100-V,

25 A,

p.f. = 0.4

Rotor Cu loss at standstill is half the total Cu loss.

From the diagram, find

(a) line current, slip, efficiency and p.f. at full-load (b) the maximum

torque.

(Electrical Machines-I, Gujarat Univ. 1985)

Solution.

No-load p.f. = 0.2;

φ

0

= cos

− 1

(0.2) = 78.5º

Short-circuit p.f. = 0.4:

φ

s

= cos

− 1

(0.4) = 66.4º

S.C. current I

S N

if normal voltage were applied = 25 (400/100) = 100 A

S.C. power input with this current = 3

× 400 × 100 × 0.4 = 27,710 W

Computations and Circle Diagrams

1323

Assume a current scale of 1 cm = 5 A.

*

The circle diagram of Fig. 35.13 is constructed as

follows :

(

i)

No-load current vector OO

′ represents 11 A. Hence, it measures 11/5 = 2.2 cm and is drawn

at an angle of 78.5º with O Y.

(

ii)

Vector OA represents 100 A and measures 100/5 = 20 cm. It is drawn at an angle of 66.4º

with O Y.

(

iii)

O

′D is drawn parallel to OX. NC is the right angle bisector of O′A.

(

iv)

With C as the centre and CO

′ as radius, a semicircle is drawn as shown.

(

v)

AF

represents power input on short-circuit with normal voltage applied. It measures 8 cm

and (as calculated above) represents 27,710 W. Hence, power scale becomes

1 cm = 27,710/8 = 3,465 W

Fig. 35.13

(

a)

F.L motor output = 14,920 W. According to the above power scale, the intercept between the

semicircle and the output line O

′A should measure = 14,920/3,465 = 4.31 cm. Hence, vertical line PL

is found which measures 4.31 cm. Point P represents the full-load operating point.

**

(

a)

Line current = OP = 6.5 cm which means that full-load line current

= 6.5

× 5 =

32.5 A.

φ = 32.9º (by measurement)

∴

cos 32.9º =

0.84

(or cos

φ = PL/OP = 5.4/6.5 = 0.84)

slip =

0.3

5.35

=

EK

PK

= 0.056

or

5.6%

;

η = PE

PL

=

4.3

5.4

= 0.8

or

80%

(

b)

For finding maximum torque, line CM is drawn

⊥ to torque line O′H. MT is the vertical

intercept between the semicircle and the torque line and represents the maximum torque of the motor

in synchronous watts

Now, MT = 7.8 cm (by measurement)

∴ T

max

= 7.8

× 3465 =

27,030 synch. watt

Example 35.6.

A 415-V, 29.84 kW, 50-Hz, delta-connected motor gave the following test data :

No-load test

: 415 V,

21 A,

1,250 W

Locked rotor test : 100 V,

45 A,

2,730 W

Construct the circle diagram and determine

*

The actual scale of the book diagram is different because it has been reduced during block making.

**

The operating point may also be found by making AS = 4.31 cm and drawing SP parallel to O

′A.

1324

Electrical Technology

(

a)

the line current and power factor for rated output

(

b)

the maximum torque.

Assume stator and rotor Cu losses equal at standstill.

(A.C. Machines-I, Jadavpur Univ. 1990)

Solution.

Power factor on no-load is =

1250

3

415

21

×

×

= 0.0918

∴

φ

0

= cos

− 1

(0.0918) = 84º44

′

Power factor with locked rotor is =

2, 730

3

100

45

×

×

= 0.3503

∴

φ

S

= cos

− 1

(0.3503) = 69º30

′

The input current I

S N

on short-circuit if normal voltage were applied = 45 (415/100) = 186.75 A

and power taken would be = 2,730 (415/100)

2

= 47,000 W.

Let the current scale be 1 cm = 10 A. The circle diagram of Fig. 35.14 is constructed as follows :

f

¢

0

= 84º44

f

¢

s

= 69º30

O

¢

Ou

tpu

t L

ine

Torq

ue L

ine

H

C

P

L

O

S

A

X

D

F

M

B

K

N

f

E

Fig. 35.14

(

i)

Vector OO

′ represents 21 A so that it measures 2.1 cm and is laid at an angle of 84º44′ with

OE

(which is vertical i.e. along Y -axis).

(

ii)

Vector OA measures 186.75/10 = 18.675 cm and is drawn at an angle of 69º30

′ with OE.

(

iii)

O

′D is drawn parallel to OX. NC is the right-angle bisector of O′A

(

iv)

With C as the centre and CO

′ as radius, a semi-circle is drawn as shown. This semi-circle is

the locus of the current vector for all load conditions from no-load to short-circuit.

(

v)

The vertical AF represents power input on short-circuit with normal voltage applied. AF

measures 6.6 cm and (as calculated above) represents 47,000 W. Hence, power scale becomes,

1 cm = 47,000/6.6 = 7,120 W

(

a)

Full-load output = 29,840 W. According to the above power scale, the intercept between the

semicircle and output line O

′A should measure 29,840/7,120 = 4.19 cm. Hence, line PL is

found which measures 4.19 cm. Point P represents the full-load operating point.

*

Phase current = OP = 6 cm = 6

× 10 = 60 A; Line current = 3 60

×

=

104 A

Power factor = cos

∠ POE = cos 35º =

0.819

(

b)

For finding the maximum torque, line CM is drawn

⊥ to the torque line O′H. Point H is such

that

AH

BH

=

rotor Cu loss

stator Cu loss

*

The operating point may also by found be making AS = 4.19 cm and drawing SP parallel to O

′A.

Computations and Circle Diagrams

1325

Since the two Cu losses are equal, point H is the mid-point of A B.

Line MK represents the maximum torque of the motor in synchronous watts

MK

= 7.3 cm (by measurement) = 7.3

× 7,120 =

51,980 synch. watt.

Example 35.7.

Draw the circle diagram for a 5.6 kW, 400-V, 3-

φ, 4-pole, 50-Hz, slip-ring

induction motor from the following data :

No-load readings : 400 V, 6 A, cos

φ

0

= 0.087 : Short-circuit test : 100 V, 12 A, 720 W.

The ratio of primary to secondary turns = 2.62, stator resistance per phase is 0.67

Ω and of the

rotor is 0.185

Ω. Calculate

(

i)

full-load current

(

ii)

full-load slip

(

iii)

full-load power factor

(

iv)

maximum torque

full - load torque

(

v)

maximum power.

Solution. No-load condition

φ

0

= cos

−1

(0.087) = 85º

85º

69º40¢

Output

Line

Torque

Line

T

C

A

F

G

S

O

R

B

X

X¢

D

M

E

K

N

L

Y

P

Fig. 35.15

Short-circuit condition

Short-circuit current with normal voltage = 12

× 400/100 = 48 A

Total input = 720

× (48/12)

2

= 11.52 kW

cos

φ

s

=

720

3

100 12

×

×

= 0.347

or

φ

s

= 69º 40

′

Current scale is,

1 cm = 2 A

In the circle diagram of Fig. 35.15, OA = 3 cm and inclined at 85º with O V. Line OB represents

short-circuit current with normal voltage. It measures 48/2 = 24 cm and represent 48 A. BD is

perpendicular to O X.

For Drawing Torque Line

K

= 2.62

R

1

= 0.67

Ω

R

2

= 0.185

Ω

(in practice, an allowance of 10% is made for skin effect)

∴

rotor Cu loss

stator Cu loss

= 2.62

2

×

0.185

0.67

= 1.9

∴

rotor Cu loss

1.9

total Cu loss

2.9

=

= 0.655

Now

BD

= 8.25 cm and represents 11.52 kW

power scale = 11.52/8.25 = 1.4 kW/cm

1326

Electrical Technology

∴

1 cm = 1.4 kW

BE

represents total Cu loss and is divided at point T in the ratio 1.9 : 1.

BT

= BE

× 1.9/2.9 = 0.655 × 8 = 5.24 cm

AT

is the torque line

Full-load output = 5.6 kW

It is represented by a line = 5.6/1.4 =4 cm

DB

is produced to R such that BR = 4 cm. Line RP is parallel to output line and cuts the circle at

P

. OP represents full-load current.

PS

is drawn vertically. Points M and Y represent points of maximum torque and maximum output

respectively.

(

i)

F.L. current = OP = 5.75 cm = 5.75

× 2 =

11.5 A

(

ii)

F.L. slip =

0.2

4.25

=

FG

PG

= 0.047

or

4.7%

(

iii)

p.f. =

SP

OP

=

4.6

5.75

=

0.8

(

iv)

max. torque

full-load torque

=

MK

PG

=

10.05

4.25

=

2.37

(

v)

Maximum output is represented by Y L = 7.75 cm.

∴

Max. output = 7.75

× 1.4 =

10.8 kW

Example 35.8.

A 440-V, 3-

φ, 4-pole, 50-Hz slip-ring motor gave the following test results :

No-load reading : 440 V, 9 A,

p.f. = 0.2

Blocked rotor test : 110 V, 22 A,

p.f. = 0.3

The ratio of stator to rotor turns per phase is 3.5/1. The stator and rotor Cu losses are divided

equally in the blocked rotor test. The full-load current is 20 A. Draw the circle diagram and obtain

the following :

(

a)

power factor, output power, efficiency and slip at full-load

(

b)

standstill torque or starting torque.

(

c)

resistance to be inserted in the rotor circuit for giving a starting torque 200 % of the

full-load torque. Also, find the current and power factor under these conditions.

Solution.

No-load

p.f. = 0.2

∴

φ

0

= cos

− 1

(0.2) = 78.5º

Short-circuit

p.f. = 0.3

∴

φ

S

= 72.5º

Short-circuit current at normal voltage = 22

× 440/110 = 88 A

S.C. input =

3

× 440 × 88 × 0.3 = 20,120 W = 20.12 kW

Take a current scale of 1 cm = 4 A

In the circle diagram of Fig. 35.16, OA = 2.25 cm drawn at an angle of 78.5º behind O V.

Similarly, OB = 88/4 = 22 cm and is drawn at an angle of 72.50 behind OV. The semi-circle is drawn

as usual. Point T is such that BT = TD. Hence, torque line AT can be drawn. BC represents 20.12 kW.

By measurement BC = 6.6 cm.

Ou

tpu

t

Line

Li

ne

Torque

T

A E

O

M

B

C

D

P

H

L

S

R

N

F

V

Fig. 35.16

Computations and Circle Diagrams

1327

∴

power scale = 20.12/6.6 = 3.05

∴

1 cm = 3.05 kW

Full-load current = 20 A. Hence, it is represented by a length of 20/4 = 5 cm. With O as centre

and 5 cm as radius, an arc is drawn which cuts the semi-circle at point P. This point represents full-

load condition. PH is drawn perpendicular to the base OC.

(

a) (i)

p.f. = cos

φ = PH/OP = 4.05/5 =

0.81

(

ii)

Torque can be found by measuring the input.

Rotor input = PE = 3.5 cm = 3.5

× 3.05 = 10.67 kW

Now

N

s

= 120

× 50/4 = 1500 r.p.m.

∴

T

g

= 9.55 P

2

/N

s

= 9.55

× 10,670/1500 =

61 N-m

(

iii)

output = PL = 3.35

× 3.05 =

10.21 kW

(

iv)

efficiency =

output

3.35

input

4.05

=

=

PL

PH

= 0.83

or

83%

(

v)

slip s =

rotor Cu loss

rotor input

=

0.1025

3.5

LE

PE

=

= 0.03

or

3%

(

b)

Standstill torque is represented by B T.

B T

= 3.1 cm = 3.1

× 3.05 = 9.45 kW

∴ T

st

=

3

9.45 10

9.55

1500

×

×

=

60.25 N-m

(

c)

We will now locate point M on the semi-circle which corresponds to a starting torque twice

the full-load torque i.e. 200% of F.L. torque.

Full-load torque = PE. Produce EP to point S such that PS = PE. From point S draw a line

parallel to torque line AT cutting the semi-circle at M. Draw MN perpendicular to the base.

At starting when rotor is stationary, MN represents total rotor copper losses.

NR

= Cu loss in rotor itself as before ; RM = Cu loss in external resistance

RM

= 4.5 cm = 4.5

× 3.05 = 13.716 kW = 13,716 watt.

Cu loss/phase = 13,716/3 =4,572 watt

Rotor current AM = 17.5 cm = 17.5

× 4 = 70 A

Let r

2

′ be the additional external resistance in the rotor circuit (as referred to stator) then

r

2

′ × 70

2

= 4,572

or r

2

′ = 4,572/4,900 = 0.93 Ω

Now

K

= 1/3.5

∴ rotor resistance/phase, r

2

= r

2

′ × K

2

= 0.93/3.5

2

=

0.076

Ω

Ω

Ω

Ω

Ω

Stator current = OM = 19.6

× 4 =

78.4 A

; power factor =

MF

OM

=

9.75

18.7

=

0.498

Example 35.9.

Draw the circle diagram of a 7.46 kW, 200-V, 50-Hz, 3-phase slip-ring induction

motor with a star-connected stator and rotor, a winding ratio of unity, a stator resistance of 0.38

ohm/phase and a rotor resistance of 0.24 ohm/phase. The following are the test readings ;

No-load

: 200 V, 7.7 A,

cos

φ

0

= 0.195

Short-circuit : 100 V, 47.6 A,

cos

φ

s

= 0.454

Find

(

a)

starting torque and

(

b)

maximum torque, both in synchronous watts

(

c)

the maximum power factor

(

d)

the slip for maximum torque

(

e)

the maximum output

(Elect. Tech.-II, Madras Univ. 1989)

Solution.

φ

0

= cos

−1

(0.195) = 78º45

′;

φ

S

= cos

−1

(0.454) = 63º

The short-circuit I

S N

with normal voltage applied is = 47.6

× (200/100) = 95.2 A

The circle diagram is drawn as usual and is shown in fig. 35.17.

With a current scale of 1 cm = 5 A, vector OO

′ measures 7.7/5 =1.54 cm and represents the no-

load current of 7.7 A.

1328

Electrical Technology

Similarly, vector OA represents I

S N

i.e. short-circuit current with normal voltage and measures

95.2/5 = 19.04 cm

Both vectors are drawn at their respective angles with OE.

The vertical line AF measures the power input on short-circuit with normal voltage and is

=

3

× 200 × 95.2 × 0.454 = 14,970 W.

Since AF measures 8.6 cm, the power scale is 1 cm = 14,970/8.6 = 1740 W

The point H is such that

63º

78º45

Ou

tpu

t L

ine

Torque

Line

C

O

0

A

X

G

F

M

B

N

K

D

L

P

H

E

Fig. 35.17

AH

AB

= rotor Cu loss

rotor resistance

0.24

total Cu loss

rotor + stator resistance

0.62

=

=

*

Now AB = 8.2 cm (by measurement)

∴ AH = 8.2 × 0.24/0.62 = 3.2 cm

(

a)

Starting torque = AH = 3.2 cm = 3.2

× 1740 =

5,570 synch. watt.

(

b)

Line CM is drawn perpendicular to the torque line O

′H. The intercept MN represents the

maximum torque in synchronous watts.

Maximum torque = MN = 7.15 cm = 7.15

× 1740 =

12,440 synch. watts.

(

c)

For finding the maximum power, line OP is drawn tangential to the semi-circle.

∠ POE = 28.5º

∴

maximum p.f. = cos 28.5º =

0.879

(

d)

The slip for maximum torque is = K N/M N= 1.4/7.15 =

0.195

(

e)

Line CL is drawn perpendicular to the output line O

′A. From L is drawn the vertical line LD.

It measures 5.9 cm and represents the maximum output.

∴

maximum output = 5.9

× 1740 =

10,270 W

Tutorial Problems 35.1

1.

A 300 h.p. (223.8 kW), 3000-V, 3-

φ, induction motor has a magnetising current of 20 A at 0.10 p.f.

and a short-circuit (or locked) current of 240 A at 0.25 p.f. Draw the circuit diagram, determine the

p.f. at full-load and the maximum horse-power.

[0.85 p.f. 621 h.p. (463.27 kW)] (

I.E.E. London)

2.

The following are test results for a 18.65 kW, 3-

φ, 440.V slip-ring induction motor :

Light load : 440-V, 7.5 A, 1350 W (including 650 W friction loss).

*

Because K = 1, otherwise it should be R

2

′ = R

2

/K

2

.

Computations and Circle Diagrams

1329

S.C. test : 100 V, 32 A, 1800 W

Draw the locus diagram of the stator current and hence obtain the current, p.f. and slip on full-load.

On short-circuit, the rotor and stator copper losses are equal.

[30 A, 0.915, 0.035] (

London Univ)

3.

Draw the circle diagram for 20 h.p. (14.92 kW), 440-V, 50-Hz, 3-

φ induction motor from the following

test figures (line values) :

No-load : 440 V, 10A, p.f. 0.2

Short-circuit : 200 V, 50 A, p.f. 0.4

From the diagram, estimate (a) the line current and p.f. at full-load (b) the maximum power developed

(c) the starting torque. Assume the rotor and stator I

2

R

losses on short-circuit to be equal.

[(

a) 28.1 A at 0.844 p.f. (b) 27.75 kW (c) 11.6 synchronous kW/phase] (London Univ.)

4.

A 40 h.p. (29.84.kW), 440-V, 50-Hz, 3-phase induction motor gave the following test results

No. load : 440 V, 16 A, p.f. = 0.15 S.C. test : 100 V, 55 A, p.f. = 0.225

Ratio of rotor to stator losses on short-circuit = 0.9. Find the full-load current and p.f., the pull-out

torque and the maximum output power developed.

[49 A at 0.88 p.f. ; 78.5 synch. kW or 2.575 times F.L. torque ; 701.2 kW] (

I.E.E. London)

5.

A 40 h.p. (29.84 kW), 50-Hz, 6-pole, 420-V, 3-

φ, slip-ring induction motor furnished the following

test figures :

No-load : 420 V, 18 A, p.f. = 0.15

S.C. test : 210 V, 140 A, p.f. = 0.25

The ratio of stator to rotor Cu losses on short-circuit was 7 : 6. Draw the circle diagram and find

from it (a) the full-load current and power factor (b) the maximum torque and power developed.

[(

a) 70 A at 0.885 p.f. (b) 89.7 kg.m ; 76.09 kW] (I.E.E. London)

6.

A 500 h.p. (373 kW), 8-pole, 3-

φ, 6,000-V, 50-Hz induction motor gives on test the following

figures :

Running light at 6000 V, 14 A/phase, 20,000 W ; Short-circuit at 2000 V, 70 A/phase, 30,500 W

The resistance/phase of the star-connected stator winding is 1.1

Ω, ratio of transformation is 4 :1.

Draw the circle diagram of this motor and calculate how much resistance must be connected in each

phase of the rotor to make it yield full-load torque at starting.

[0.138

Ω

Ω

Ω

Ω

Ω] (London Univ.)

7.

A 3-phase induction motor has full-load output of 18.65 kW at 220 V, 720 r.p.m. The full-load p.f.

is 0.83 and efficiency is 85%. When running light, the motor takes 5 A at 0.2 p.f. Draw the circle

diagram and use it to determine the maximum torque which the motor can exert (a) in N-m (b) in

terms of full-load torque and (c) in terms of the starting torque.

[(

a) 268.7 N-m (b) 1.08 (c) 7.2 approx.] (London Univ.)

8.

A 415-V, 40 h.p. (29.84 kW), 50.Hz,

∆-connected motor gave the following test data :

No-load test : 415 V, 21 A, 1250 W ; Locked rotor test : 100 V, 45 A, 2,730 W

Construct the circle diagram and determine

(a)the line current and power factor for rated output (b) the maximum torque. Assume stator and

rotor Cu losses equal at standstill.

[(

a) 104 A : 0.819 (b) 51,980 synch watt] (A.C. Machines-I, Jadavpur Univ. 1978)

9.

Draw the no-load and short circuit diagram for a 14.92 kW., 400-V, 50-Hz, 3-phase star-connected

induction motor from the following data (line values) :

No load test : 400 V, 9 A, cos

φ = 0.2

Short circuit test : 200 V, 50 A, cos

φ = 0.4

From the diagram find (a) the line current and power factor at full load, and (b) the maximum output

power.

[(

a) 32.0 A, 0.85 (b) 21.634 kW]

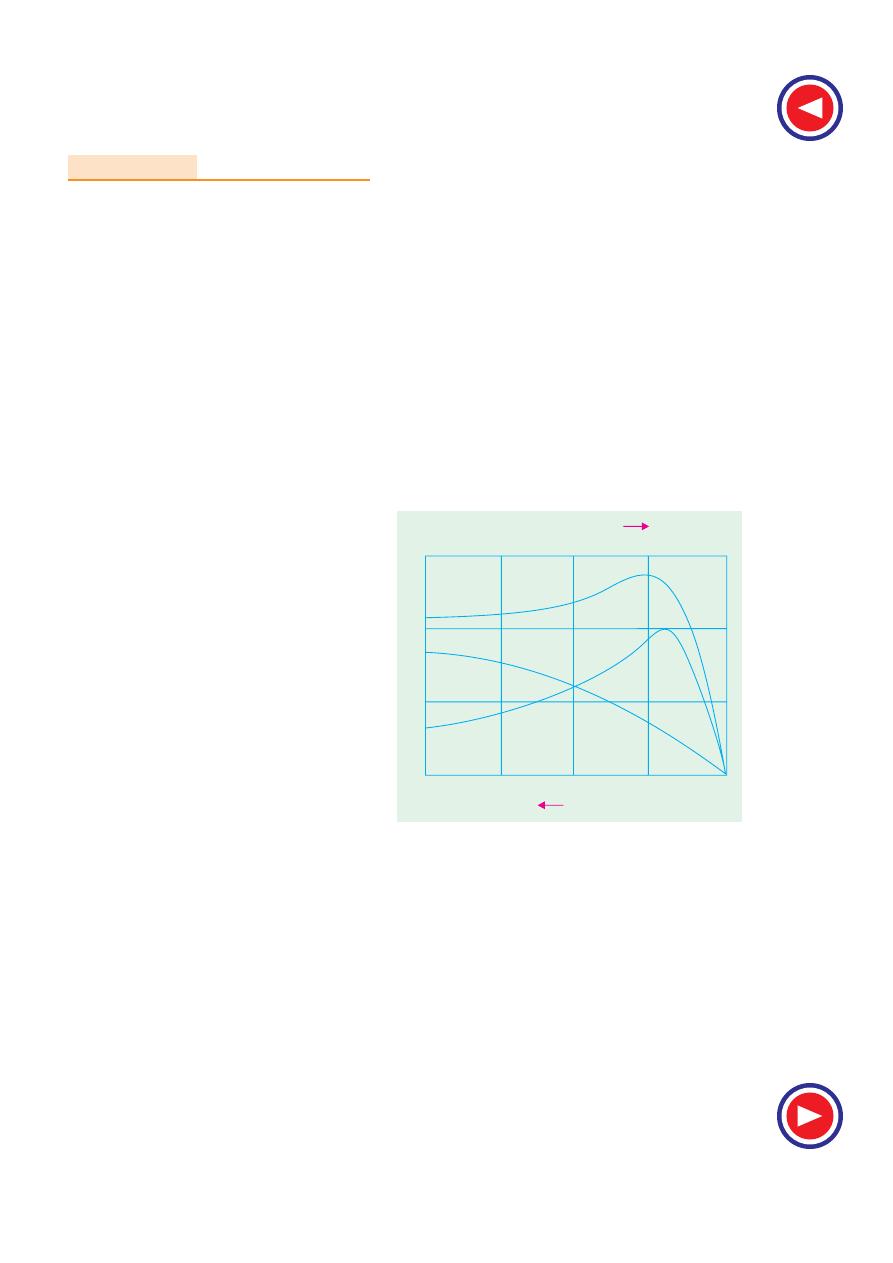

35.9. Starting of Induction Motors

It has been shown earlier that a plain induction motor is similar in action to a polyphase transformer

with a short-circuited rotating secondary. Therefore, if normal supply voltage is applied to the stationary

motor, then, as in the case of a transformer, a very large initial current is taken by the primary, at least,

for a short while. It would be remembered that exactly similar conditions exist in the case of a d.c.

motor, if it is thrown directly across the supply lines, because at the time of starting it, there is no back

e.m.f. to oppose the initial inrush of current.

1330

Electrical Technology

Induction motors, when direct-switched, take five to seven times their full-load current and develop

only 1.5 to 2.5 times their full-load torque. This initial excessive current is objectionable because it

will produce large line-voltage drop that, in turn, will affect the operation of other electrical equipment

connected to the same lines. Hence, it is not advisable to line-start motors of rating above 25 kW to

40 kW.

It was seen in Art. 34.15 that the starting torque of an induction motor can be improved by

increasing the resistance of the rotor circuit. This is easily feasible in the case of slip-ring motors but

not in the case of squirrel-cage motors. However, in their case, the initial in-rush of current is controlled

by applying a reduced voltage to the stator during the starting period, full normal voltage being

applied when the motor has run up to speed.

35.10. Direct-switching or Line starting of Induction Motors

It has been shown earlier that

Rotor input = 2

π N

s

T = k T

–Art. 34.36

Also,

rotor Cu loss = s

× rotor input

∴

3

Ι

2

2

R

2

= s

× kT

∴

T

∝ I

2

2

/s

(if R

2

is the same)

Now

I

2

∝ I

1

∴

T

∝ I

1

2

/s

or

T

= K I

1

2

/s

At starting moment

s

= 1

∴ T

st

= K I

st

2

where I

st

= starting current

If

I

f

= normal full-load current and

s

f

= full-load slip

then T

f

= K I

f

2

/ s

f

∴

st

f

T

T

=

2

.

st

f

f

I

s

I

When motor is direct-switched onto normal voltage, then starting current is the short-circuit

current I

sc

.

∴

st

f

T

T

=

2

.

sc

f

f

I

s

I

= a

2

. s

f

where a = I

sc

/ I

f

Suppose in a case,

I

sc

= 7 I

f

, s

f

= 4% = 0.04, the T

st

/ T

f

= 7

2

× 0.04 = 1.96

∴

starting torque = 1.96

× full-load torque

Hence, we find that with a current as great as seven times the full-load current, the motor develops

a starting torque which is only 1.96 times the full-load value.

Some of the methods for starting induction motors are discussed below :

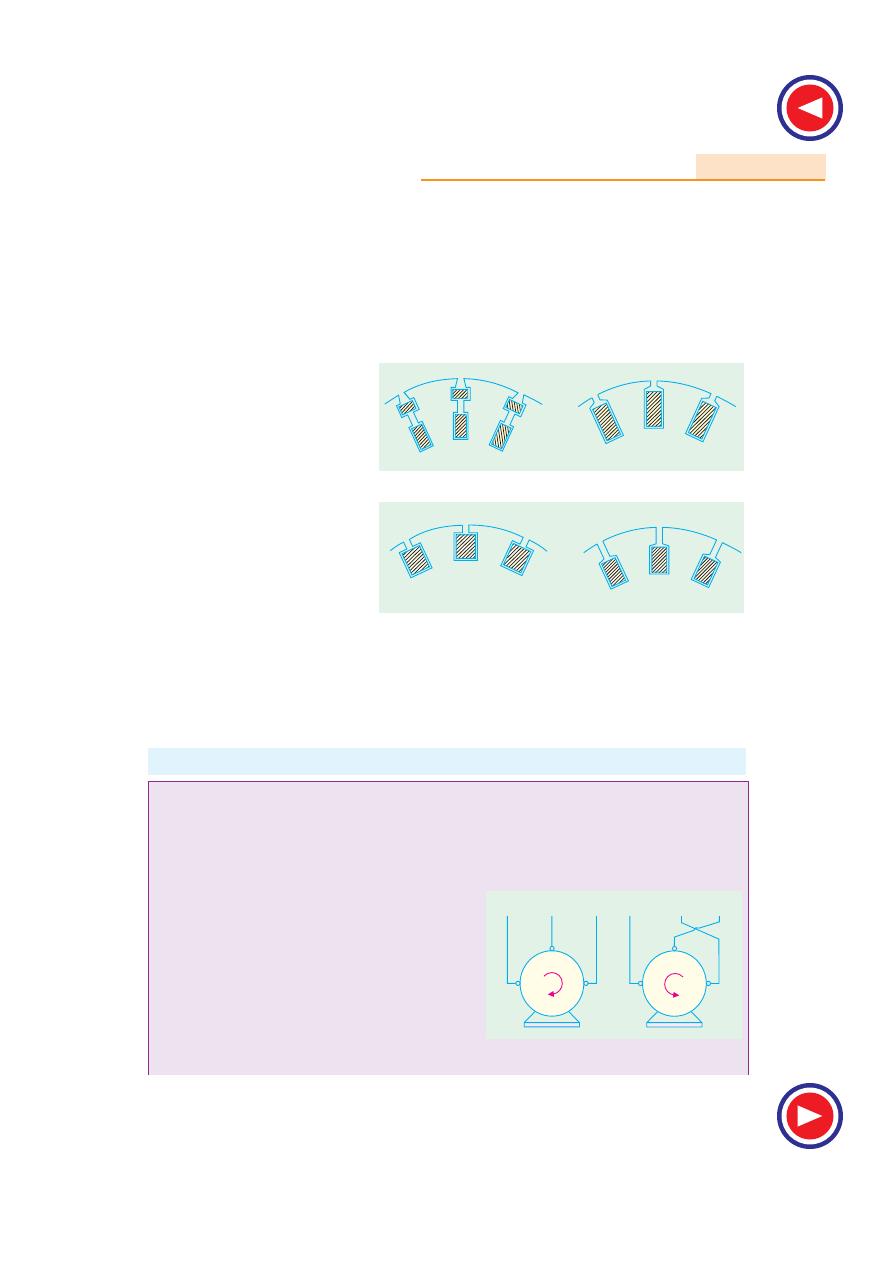

Squirrel-cage Motors

(

a)

Primary resistors (or rheostat) or reactors

(

b)

Auto-transformer (or autostarter)

(

c)

Star-delta switches

In all these methods, terminal voltage of the squirrel-cage motor is reduced during starting.

Slip-ring Motors

(

a)

Rotor rheostat

35.11. Squirrel-cage Motors

(

a) Primary resistors

Their purpose is to drop some voltage and hence reduce the voltage applied across the motor

terminals. In this way, the initial current drawn by the motor is reduced. However, it should be noted

that whereas current varies directly as the voltage, the torque varies as square of applied voltage

*

*

When applied voltage is reduced, the rotating flux

Φ is reduced which, in turn, decreases rotor e.m.f. and

hence rotor current I

2

. Starting torque, which depends both on

Φ and I

2

suffers on two counts when

impressed voltage is reduced.

Computations and Circle Diagrams

1331

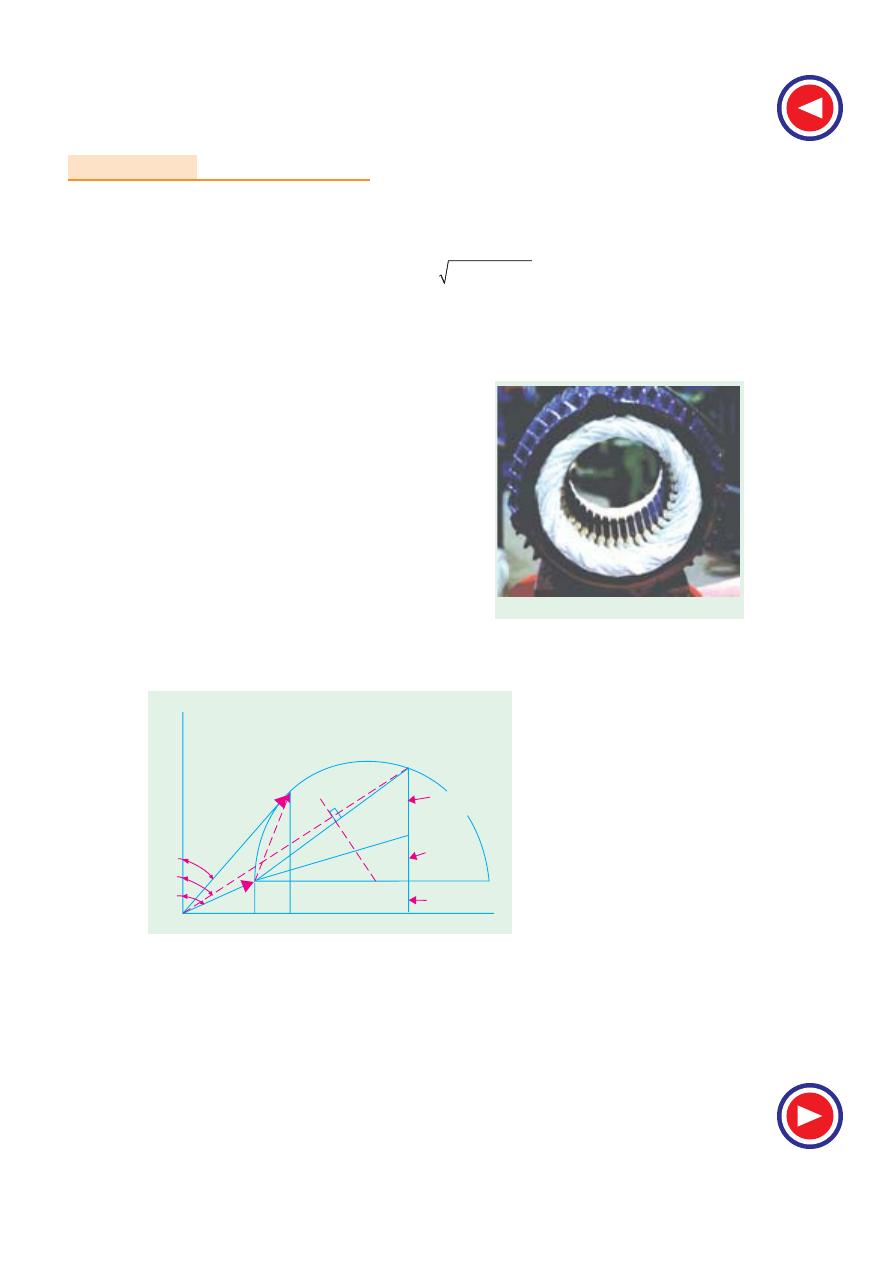

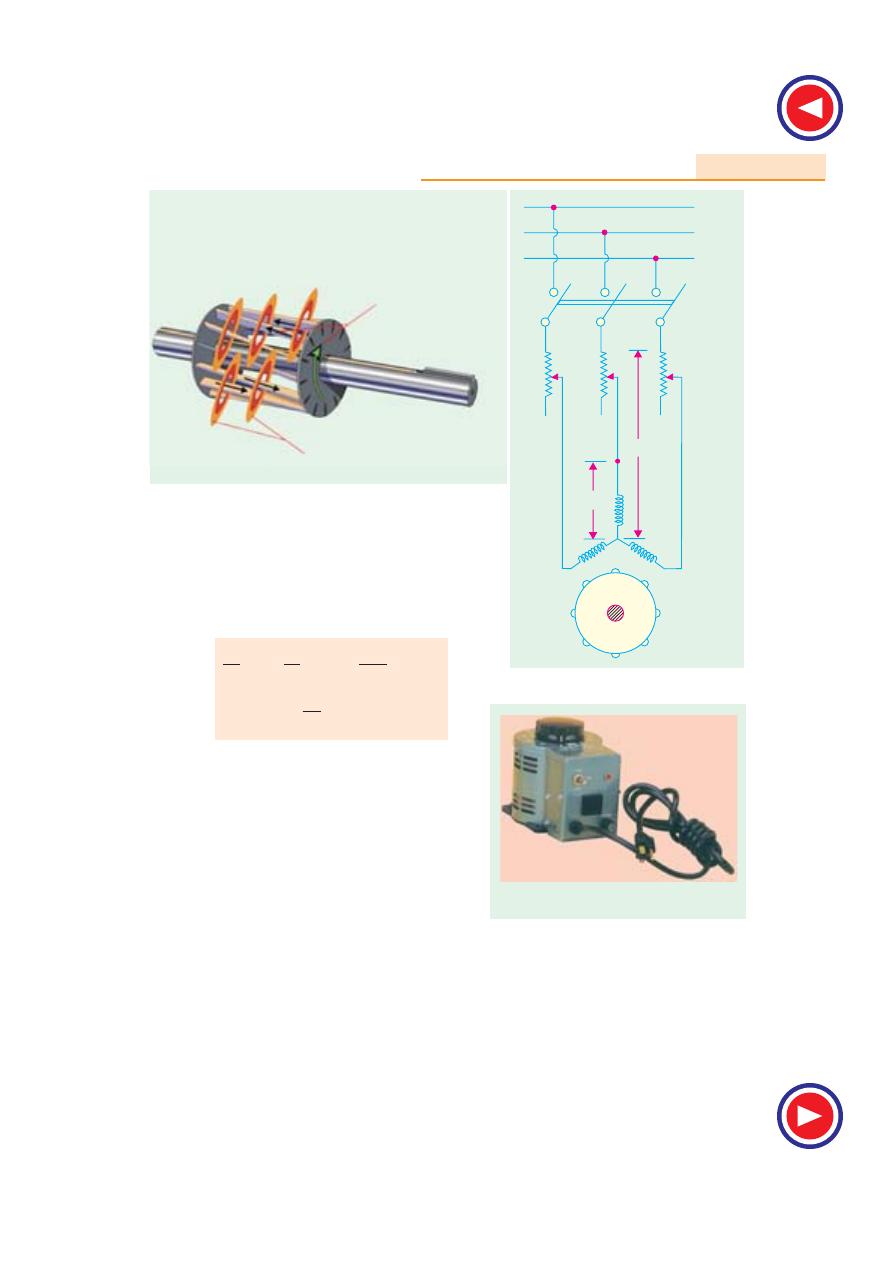

Squirrel Cage Rotor

When the stator’s moving magnetic field cuts across the rotor’s conductor bars, it induces

voltage in them.

This voltage produces current, which circulates through the bars and around the rotor

end ring. This current in turn produces magnetic fields around each rotor bar. The

continuously changing stator magnetic field results in a continuously changing rotor

field. The rotor becomes an electromagnet with continuously alternating poles, which

interact with the stator’s poles.

Magnetic Fields

Current

Squirrel cage rotor

(Art 34.17). If the voltage applied across the motor terminals

is reduced by 50%, starting current is reduced by 50%, but

torque is reduced to 25% of the full-voltage value.

By using primary resistors (Fig. 35.18), the applied

voltage/phase can be reduced by a fraction ‘x’ (and it

additionally improves the power factor of the line slightly).

I

st

= x I

sc

and

T

st

= x

2

T

sc

As seen from Art 35.10, above,

st

f

T

T

=

2

2

.

=

st

sc

f

f

f

f

I

x I

s

s

I

I

=

2

2

sc

f

f

I

x

s

I

= x

2

. a

2

. s

f

It is obvious that the ratio of the starting torque to

full-load torque is x

2

of that obtained with direct switch-

ing or across-the-line starting. This method is useful

for the smooth starting of small machines only.

(

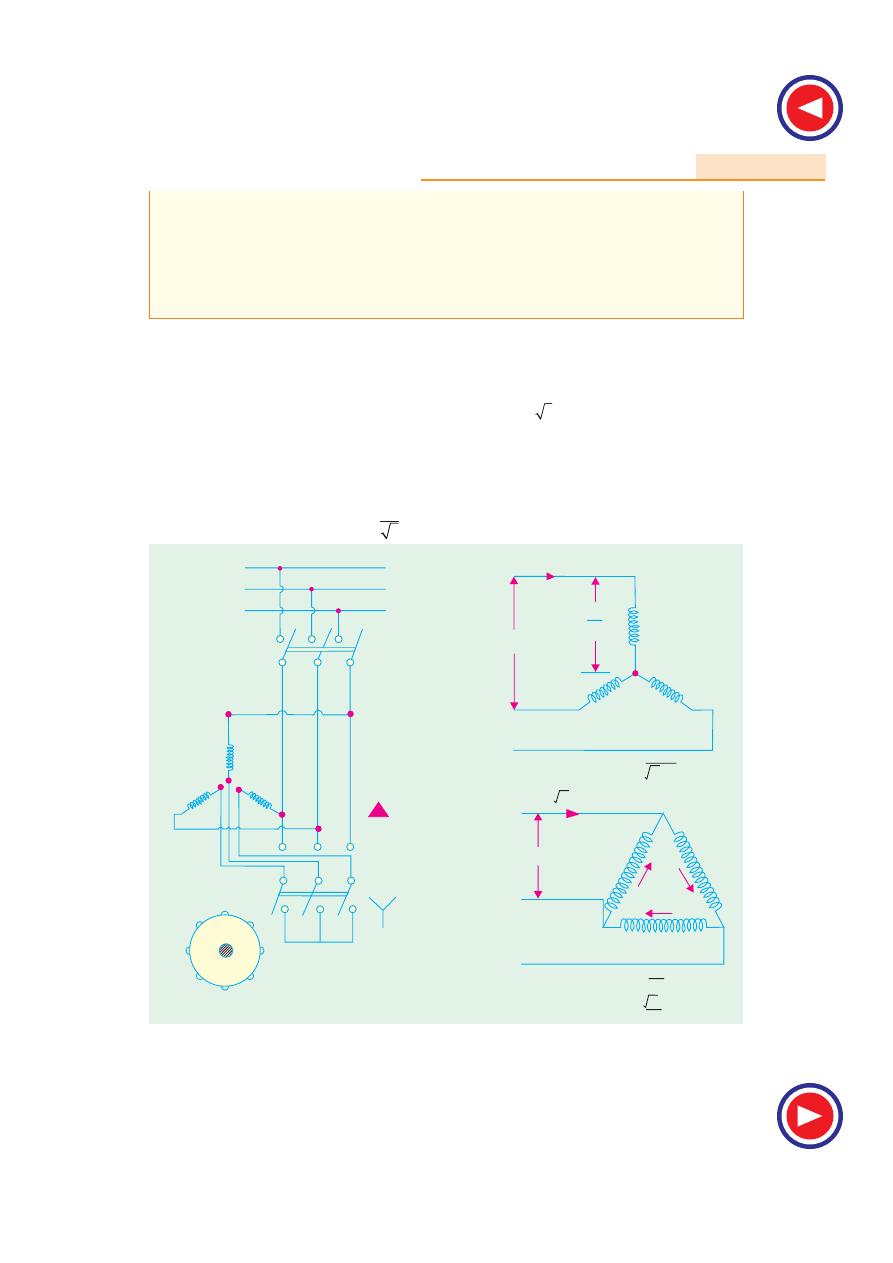

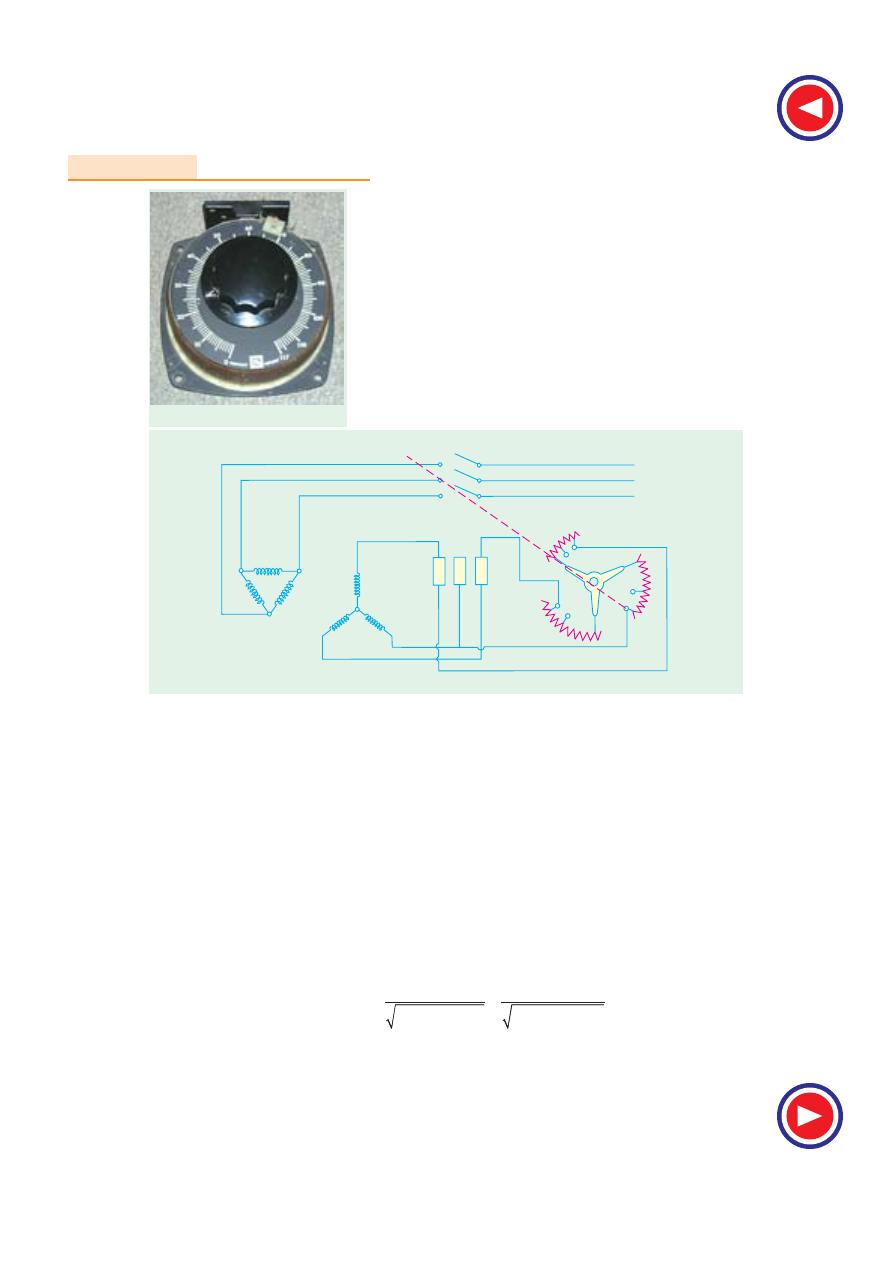

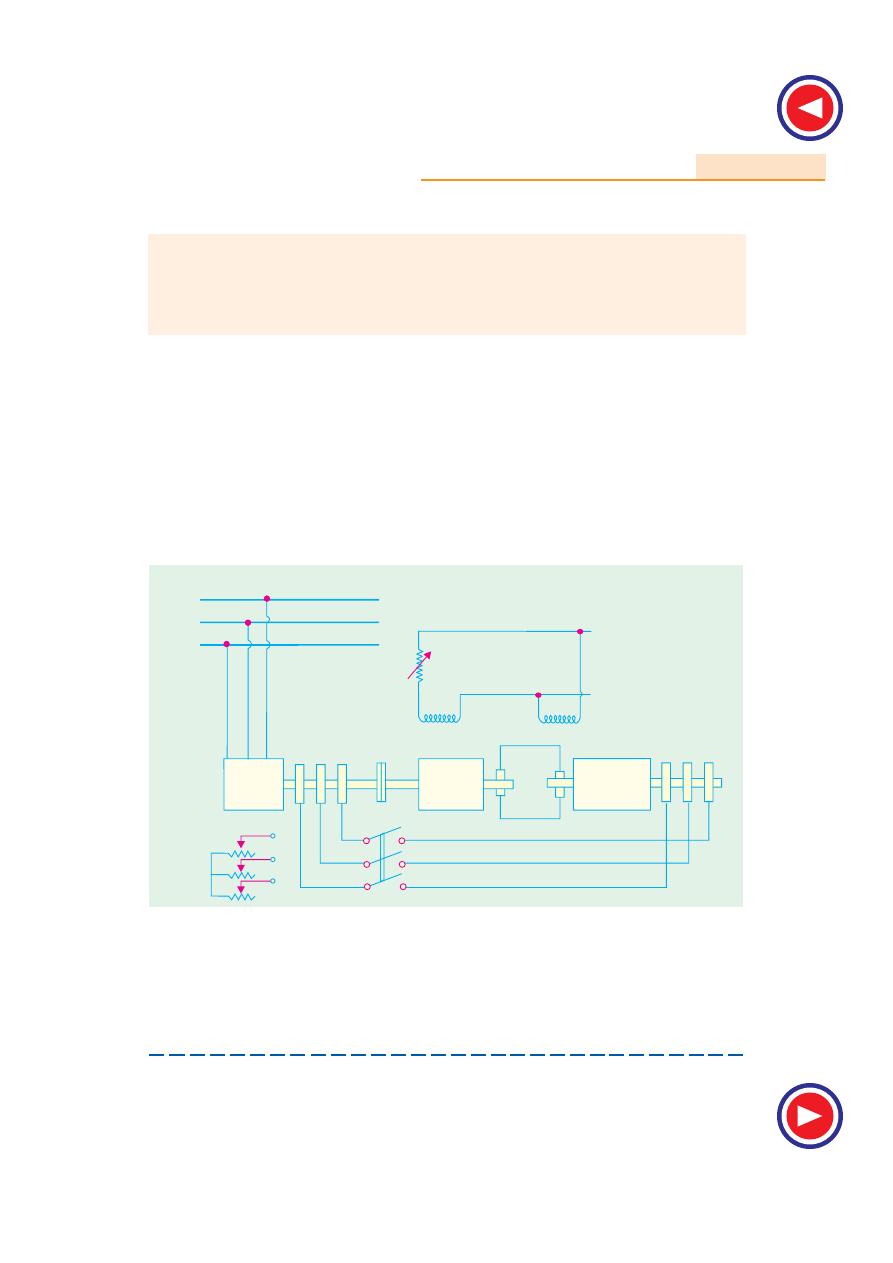

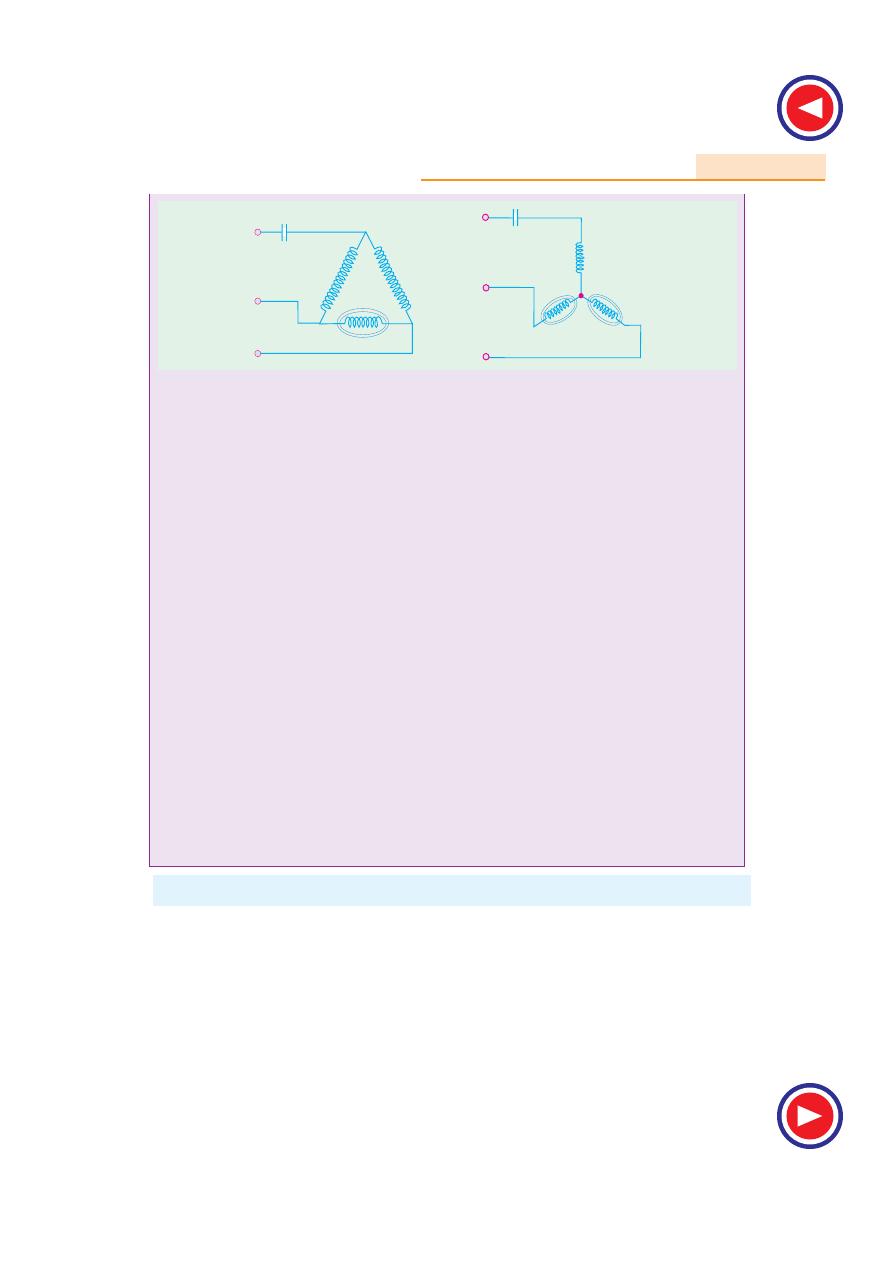

b) Auto-transformers

Such starters, known variously as

auto-starters or

compensators

, consist of an auto-transformer, with

necessary switches. We may use either two auto-

transformers connected as usual [Fig. 35.19 (b)] or 3

auto-transformers connected in open delta [Fig. 35.19

(a)].

This method can be used both for star-and delta-connected motors

. As shown in Fig. 35.20

with starting connections, a reduced voltage is applied across the motor terminals. When the motor

has ran up to say, 80% of its normal speed, connections are so changed that auto-transformers are cut

out and full supply voltage is applied across the motor. The switch making these changes from ‘start’

to ‘run’ may be airbreak (for small motors) or may be oil-immersed (for large motors) to reduce

sparking. There is also provision for no-voltage and over-load protection, along with a time-delay

device, so that momentary interruption of voltage or momentary over-load do not disconnect the

motor from supply line. Most of the auto-starters are provided with 3 sets of taps, so as to reduce

voltage to 80, 65 or 50 per cent of the line voltage, to suit the local conditions of supply. The

Fig. 35.18

3-f

Supply

Switch

Primary

resistors

Stator

Rotor

xV

V

Variable auto-transformer

1332

Electrical Technology

V

-connected auto-transformer is commonly used, because it is cheaper, although the currents are

unbalanced during starting period. This is, however, not much objectionable firstly, because the

current imbalance is about 15 per cent and secondly, because balance is restored as soon as running

conditions are attained.

The quantitative relationships between the motor current, line current, and torque developed can

be understood from Fig.35.20.

In Fig 35.20 (a) is shown the case when the motor is direct-switched to lines. The motor current

is, say, 5 times the full-load current. If V is the line voltage, then voltage/phase across motor is

/ 3

V

.

∴

I

sc

= 5 I

f

=

3

V

Z

where Z is stator impedance/phase.

In the case of auto-transformer, if a tapping of transformation ratio K is used, then phase voltage

across motor is KV /

3

, as marked in Fig. 35.20 (b).

∴ motor current at starting I

2

=

3

KV

Z

= K .

3

V

Z

= K . I

sc

= K . 5 I

f

3-

Supply

3-

Supply

Rotor

Rotor

xV

xV

Start

Start

Run

Run

Stator

Stator

( )

a

( )

b

v

V

3

V

3

KV

3

V

V

Stator

Auto-transformer

Stator

Z

Z

I

sc

f

= 5I

I

1

I

2

(a)

(b)

Fig. 35.20

Fig. 35.19

Computations and Circle Diagrams

1333

The current taken from supply or by auto-transformer is I

1

= K I

2

= K

2

× 5 I

f

= K

2

I

sc

if magnetising

current of the transformer is ignored. Hence, we find that although motor current per phase is re-

duced only K times the direct-switching current (∵ K < 1), the current taken by the line is reduced K

2

times.

Now, remembering that torque is proportional to the square of the voltage, we get

With direct-switching,

T

1

∝ (V /

3

)

2

;

With auto-transformer, T

2

∝ (KV /

3

)

2

∴

T

2

/T

1

= (KV /

3

)

2

/(V /

3

)

2

or

T

2

= K

2

T

1

or

T

st

= K

2

. T

sc

∴ torque with auto-starter

= K

2

× torque with direct-switching.

Relation Between Starting and F.L. Torque

It is seen that voltage across motor phase on direct-switching is V / 3 and starting current is I

st

=

I

sc

. With auto-starter, voltage across motor phase is K V/

3

and I

st

= K I

sc

Now,

T

st

∝ I

st

2

(s = 1)

and

T

f

∝

2

2

f

f

I

s

∴

st

f

T

T

=

2

st

f

f

I

s

I

or

st

f

T

T

= K

2

2

sc

f

I

I

s

f

= K

2

. a

2

. s

f

(∵ I

st

= K I

sc

)

Note that this expression is similar to the one derived in Art. 34.11. (a) except that x has been

replaced by transformation ratio K.

Example 35.10.

Find the percentage tapping required on an auto-transformer required for a

squirrel-cage motor to start the motor against 1/4 of full-load torque. The short-circuit current on

normal voltage is 4 times the full-load current and the full-load slip is 3%.

Solution.

st

f

T

T

= 1

4

,

sc

f

I

I

= 4,

s

f

= 0.03

∴ Using

st

f

T

T

= K

2

2

sc

f

f

I

s

I

, we get 1

4

= K

2

× 4

2

× 0.03

∴

K

2

=

1

64

0.03

×

∴ K = 0.722 or K =

72.2%

Example 35.11.

A 20 h.p. (14.92 kW), 400-V, 950 r.p.m., 3-

φ, 50-Hz, 6-pole cage motor with

400 V applied takes 6 times full-load current at standstill and develops 1.8 times full-load running

torque. The full-load current is 30 A.

(

a)

what voltage must be applied to produce full-load torque at starting ?

(

b)

what current will this voltage produce ?

(

c)

if the voltage is obtained by an auto-transformer, what will be the line current ?

(

d)

if starting current is limited to full-load current by an auto-transformer, what will be the

starting torque as a percentage of full-load torque ?

Ignore the magnetising current and stator impedance drops.

Solution.

(

a)

Remembering that T

∝ V

2

, we have

In the first case, 1.8 T

f

∝ 400

2

, ; In the second case, T

f

∝ V

2

∴

( )

2

400

V

=

1

1.8

or

V

=

400

1.8

=

298.1 V

(

b)

Currents are proportional to the applied voltage.

∴ 6 I

f

∝ 400 ; I ∝ 298.1 ∴ I = 6 ×

298.1

400

, I

f

=

6

298.1 30

400

×

×

=

134.2 A

1334

Electrical Technology

(

c)

Here

K

= 298.1/400

Line current = K

2

I

sc

= (298.1/400)

2

× 6 × 30 =

100 A

(

d)

We have seen in Art. 33.11 (b) that line current = K

2

I

sc

Now,

line current = full-load current I

f

(given)

∴

30 = K

2

× 6 × 30

∴

K

2

= 1/6

Now, using

st

f

T

T

=

2

2

×

sc

f

f

I

K

s

I

we get

st

f

T

T

=

2

6

1

0.05

6

×

×

f

f

I

I

= 0.3

Here

N

s

= 120

× 50/6 = 1000 r.p.m. N = 950 r.p.m.; s

f

= 50/1000 = 0.05

∴

T

st

= 0.3 T

f

or

30%

F.L. torque

Example 35.12.

Determine the suitable auto-transformation ratio for starting a 3-phase induction

motor with line current not exceeding three times the full-load current. The short-circuit current is 5

times the full-load current and full-load slip is 5%.

Estimate also the starting torque in terms of the full-load torque.

(Elect. Engg.II, Bombay Univ. 1987)

Solution.

Supply line current = K

2

I

sc

It is given that supply line current at start equals 3 I

f

and short-circuit current I

sc

= 5 I

f

where I

f

is the full-load current

∴

3 I

f

= K

2

× 5 I

f

or

K

2

= 0.6

∴ K = 0.775 or

77.5%

In the case of an auto starter,

st

f

T

T

=

2

2

×

sc

f

f

I

K

s

I

∴

st

f

T

T

= 0.6

×

2

5

f

f

I

I

× 0.05 = 0.75

∴

T

st

= 0.75 T

f

=

75%

of full-load torque.

Example 35.13.

The full-load slip of a 400-V, 3-phase cage induction motor is 3.5% and with

locked rotor, full-load current is circulated when 92 volt is applied between lines. Find necessary

tapping on an auto-transformer to limit the starting current to twice the full-load current of the

motor. Determine also the starting torque in terms of the full-load torque.

(Elect. Machines, Banglore Univ. 1991)

Solution.

Short-circuit current with full normal voltage applied is

I

sc

= (400/92) I

f

= (100/23) I

f

Supply line current = I

st

= 2 I

f

Now, line current

I

st

= K

2

I

sc

∴

2 I

f

= K

2

× (100/23) I

f

∴ K

2

= 0.46 ; K = 0.678 or

67.8%

Also,

st

f

T

T

=

2

2

×

sc

f

f

I

K

s

I

= 0.46

× (100/23)

2

× 0.035 = 0.304

∴

T

st

=

30.4%

of full-load torque

Tutorial Problems 35.2

1.

A 3-

φ motor is designed to run at 5% slip on full-load. If motor draws 6 times the full-load current

at starting at the rated voltage, estimate the ratio of starting torque to the full-load torque.

[1.8] (

Electrical Engineering Grad, I.E.T.E. Dec. 1986)

2.

A squirrel-cage induction motor has a short-circuit current of 4 times the full-load value and has a

full-load slip of 5%. Determine a suitable auto-transformer ratio if the supply line current is not to

Computations and Circle Diagrams

1335

exceed twice the full-load current. Also, express the starting torque in terms of the full-load torque.

Neglect magnetising current.

[70.7%, 0.4]

3.

A 3-

φ, 400-V, 50-Hz induction motor takes 4 times the full-load current and develops twice the full-

load torque when direct-switched to 400-V supply. Calculate in terms of full-load values (a) the line

current, the motor current and starting torque when started by an auto-starter with 50% tap and (b)

the voltage that has to be applied and the motor current, if it is desired to obtain full-load torque on

starting.

[(a) 100%, 200%, 50% (b) 228 V, 282%]

(

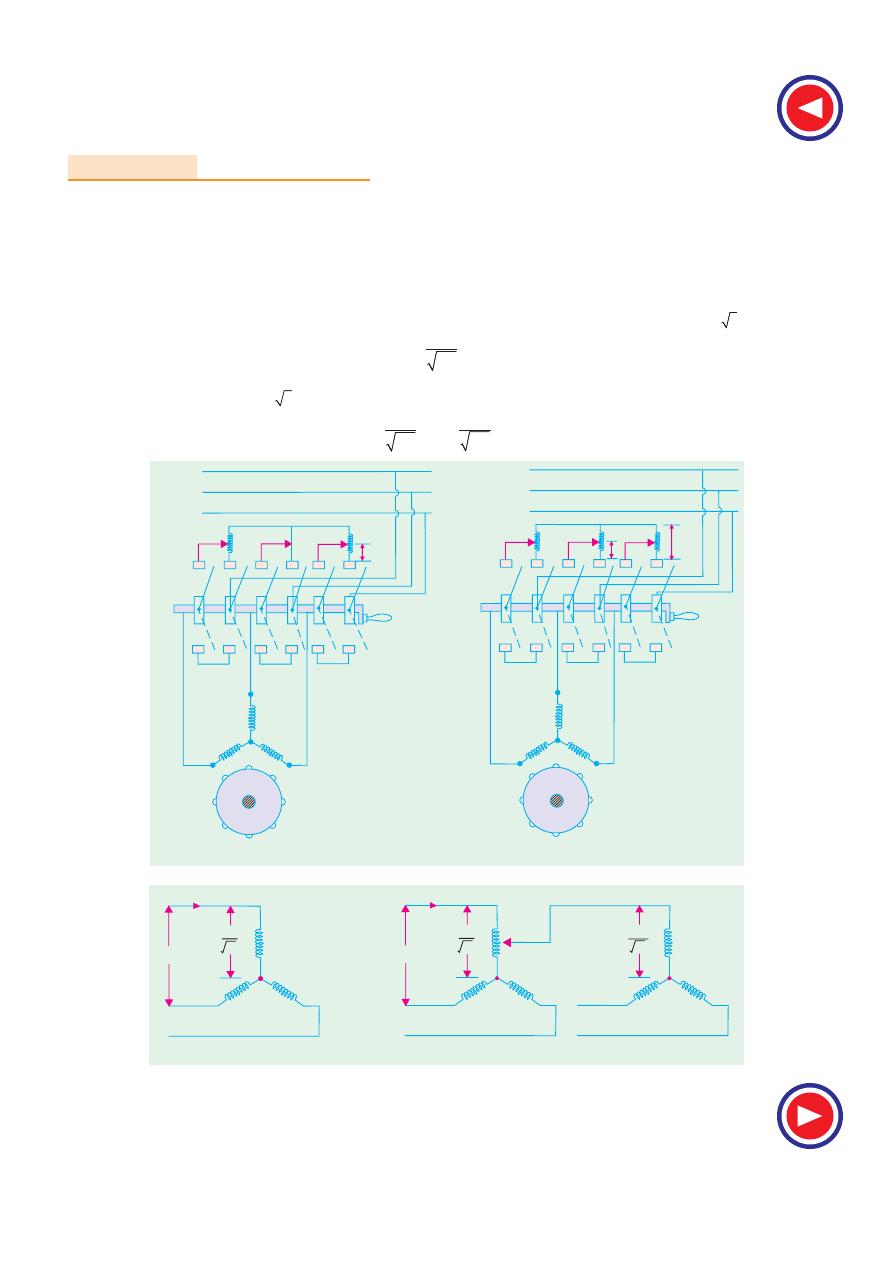

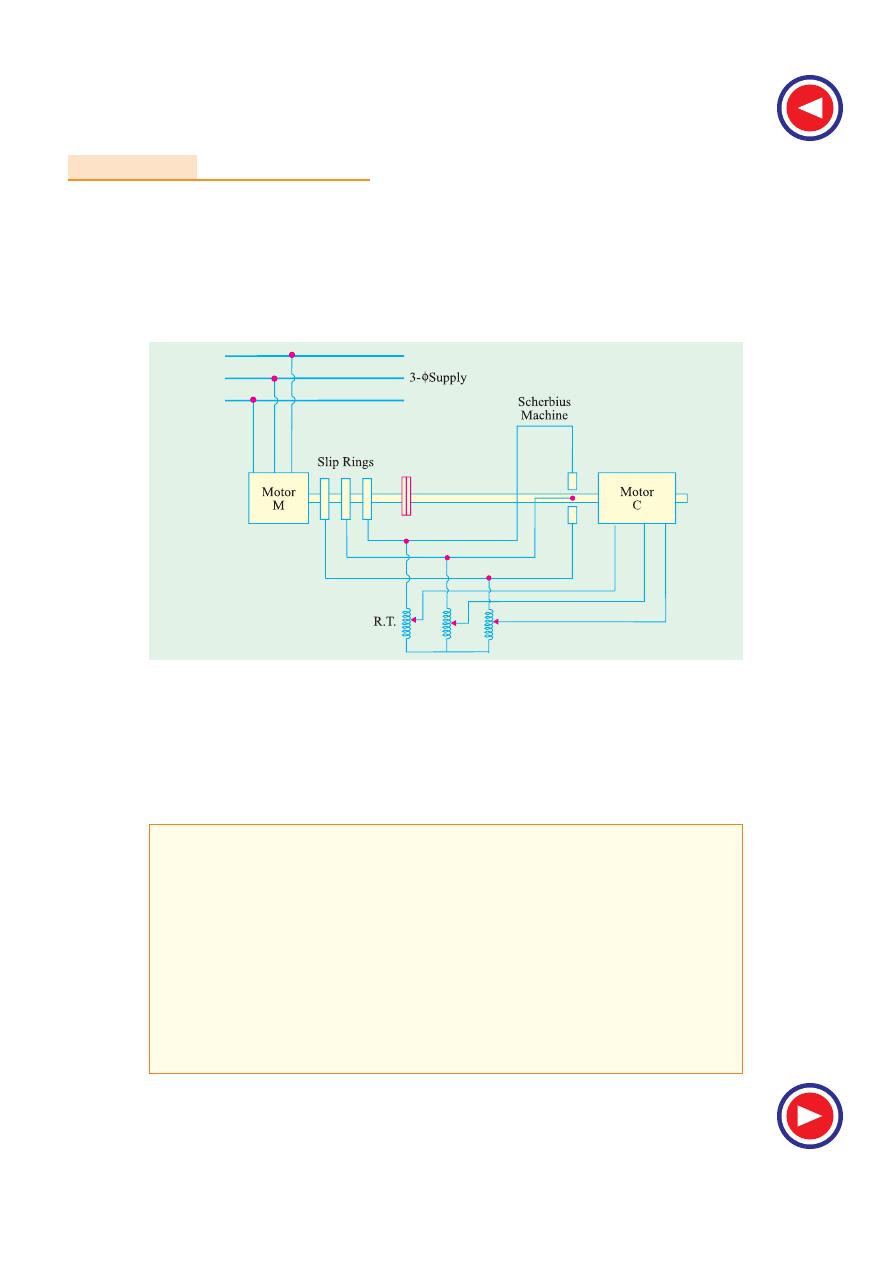

c) Star-delta Starter

This method is used in the case of motors which are built to run normally with a delta-connected

stator winding. It consists of a two-way switch which connects the motor in star for starting and then

in delta for normal running. The usual connections are shown in Fig. 35.21. When star-connected, the

applied voltage over each motor phase is reduced by a factor of 1/ 3 and hence the torque developed

becomes 1/3 of that which would have been developed if motor were directly connected in delta. The

line current is reduced to 1/3. Hence, during starting period when motor is Y -connected, it takes 1/3rd

as much starting current and develops 1/3rd as much torque as would have been developed were it

directly connected in delta.

Relation Between Starting and F.L. Torque

I

st

per phase =

1

3

I

sc

per phase

Fig. 35.21

where I

sc

is the current/phase which

∆-connected motor would have taken if switched on to the supply

directly (however, line current at start = 1/3 of line I

sc

)

3-f Supply

Rotor

V

3

V

3

V

Z

3 V

Z

V

Stator

I

st

3 I

sc

Start

Run

Stator

I / Phase = I / Line =

st

st

I / Phase =

sc

I / Line =

sc

Z

V

Z

Z

Z

I

sc

1336

Electrical Technology

Now

T

st

∝ I

st

2

(s = 1 )

– Art. 35.10

T

f

∝ I

f

2

/s

f

∴

st

f

T

T

=

2

2

2

2

1

1

3

3

3

=

=

=

st

sc

sc

f

f

f

f

f

f

f

I

I

I

s

s

s

a s

I

I

I

Here, I

st

and I

sc

represent phase values.

It is clear that the star-delta swith is equivalent

*

to an auto-transformer of ratio 1/

3

or 58%

approximately.

This method is cheap and effective provided the starting torque is required not to be more than

1.5 times the full-load torque. Hence, it is used for machine tools, pumps and motor-generators etc.

Example 35.14.

The full-load efficiency and power factor of a 12-kW, 440-V, 3-phase induction

motor are 85% and 0.8 lag respectively. The blocked rotor line current is 45 A at 220 V. Calculate

the ratio of starting to full-load current, if the motor is provided with a star-delta starter. Neglect

magnetising current.

(Elect. Machines, A.M.I.E. Sec. B, 1991)

Solution.

Blocked rotor current with full voltage applied

I

sc

= 45

× 440/220 = 90 A

Now,

3

× 440 × I

f

× 0.8 = 12,000/0.85,

∴ I

f

= 23.1 A

In star-delta starter,

I

st

= I

sc

/

3

= 90 /

3

= 52 A

∴

I

st

/ I

f

= 52 / 23.1 =

2.256

Example 35.15.

A 3-phase, 6-pole, 50-Hz induction motor takes 60 A at full-load speed of 940

r.p.m. and develops a torque of 150 N-m. The starting current at rated voltage is 300 A. What is the

starting torque? If a star/delta starter is used, determine the starting torque and starting current.

(Electrical Machinery-II, Mysore Univ. 1988)

Solution.

As seen from Art. 33.10, for direct-switching of induction motors

st

f

T

T

=

2

sc

f

I

I

s

f

. Here,

I

st

= I

sc

= 300 A (line value) ; I

f

= 60 A (line value),

s

f

= (1000

− 940)/1000 = 0.06 ; T

f

= 150 N-m

∴

T

st

= 150(300/60)

2

× 0.06 =

225 N-m

When star/delta starter is used

Starting current = 1/3

× starting current with direct starting = 300/3 =

100 A

Starting torque = 225/3 =

75 N-m

– Art 35-11 (c)

Example 35.16.

Determine approximately the starting torque of an induction motor in terms of

full-load torque when started by means of

(

a)

a star-delta switch

(

b)

an auto-transformer with 70.7

% tapping. The short-circuit current of the motor at normal voltage is 6 times the full-load current

and the full-load slip is 4%. Neglect the magnetising current.

(Electrotechnics, M.S. Univ. Baroda 1986)

Solution.

(

a)

st

f

T

T

=

2

2

1

1

6

0.04

0.48

3

3

= ×

×

=

sc

f

f

I

s

I

∴

T

st

= 0.48 T

f

or

48% of F.L. value

(

b)

Here

K

= 0.707 = 1/

2

; K

2

= 1/2

*

By comparing it with the expression given in Art. 35.11 (b)

Computations and Circle Diagrams

1337

Now,

st