Checking of Anaesthetic

Equipment

Description

Anaesthetic practice involves the extensive daily use of equipment. Routine

checking of this equipment is essential in the safe delivery of anaesthetic care.

This session provides an overview of the principles of checking the anaesthetic

equipment used in current common practice, in accordance with the

recommendations of the Association of Anaesthetists in Great Britain and

Ireland.

Session introduction

Learning objectives:

• Describe the tests performed in checking the

anaesthetic equipment.

• Identify potential equipment malfunctions in

anaesthetic practice.

• Recognize the design modifications of modern

anaesthetic equipment to prevent such

malfunction.

introduction

• Anaesthetic practice

involves the extensive,

daily use of equipment.

Routine checking of this

equipment is essential

for the safe delivery of

anaesthetic care.

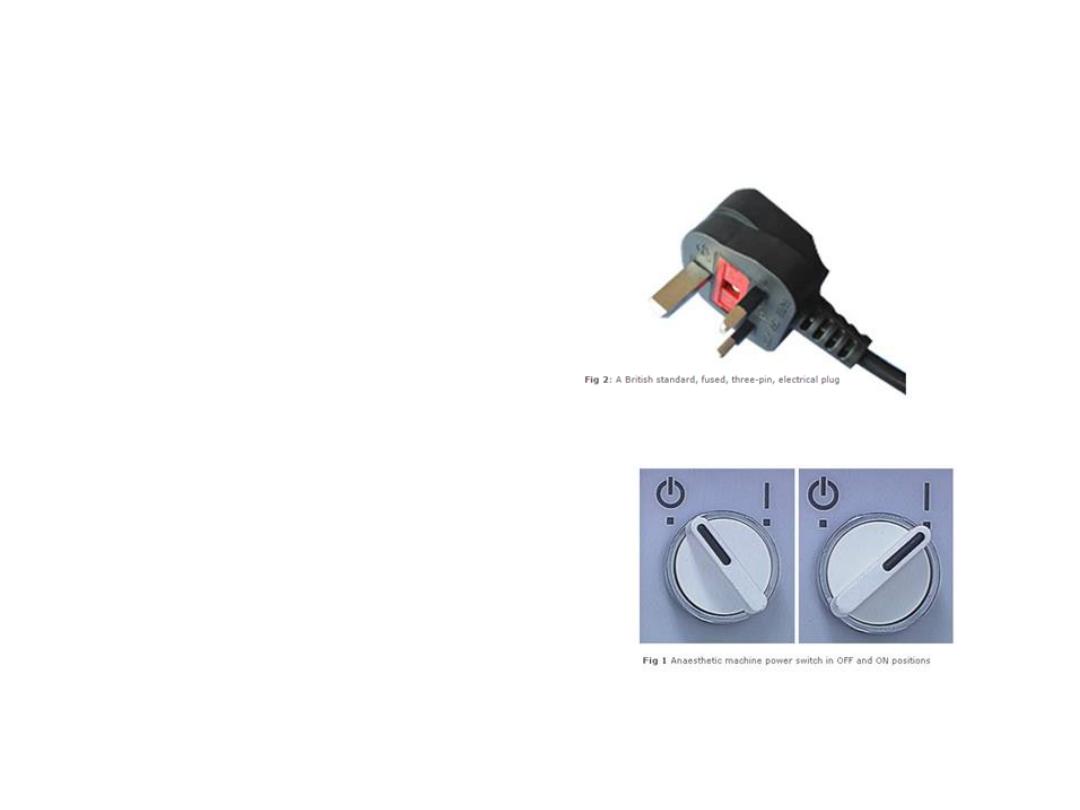

The anaesthetic machine

• The majority of modern

anaesthetic machines are

electrically powered. So the

first thing to do is to ensure

that your anaesthetic

machine is connected to the

mains and that the power is

switched on at the wall

socket.

• Some anaesthetic machine

designs have an on/off

switch. If your machine has

one, switched it on.

Monitoring equipment

• Monitoring equipment

should be functioning

within appropriate alarm

parameters.

• Standards monitors:

• Non – invasive blood

pressure

• Gas monitoring and

capnography

• Oxygen analyzer

• Pules oximeter

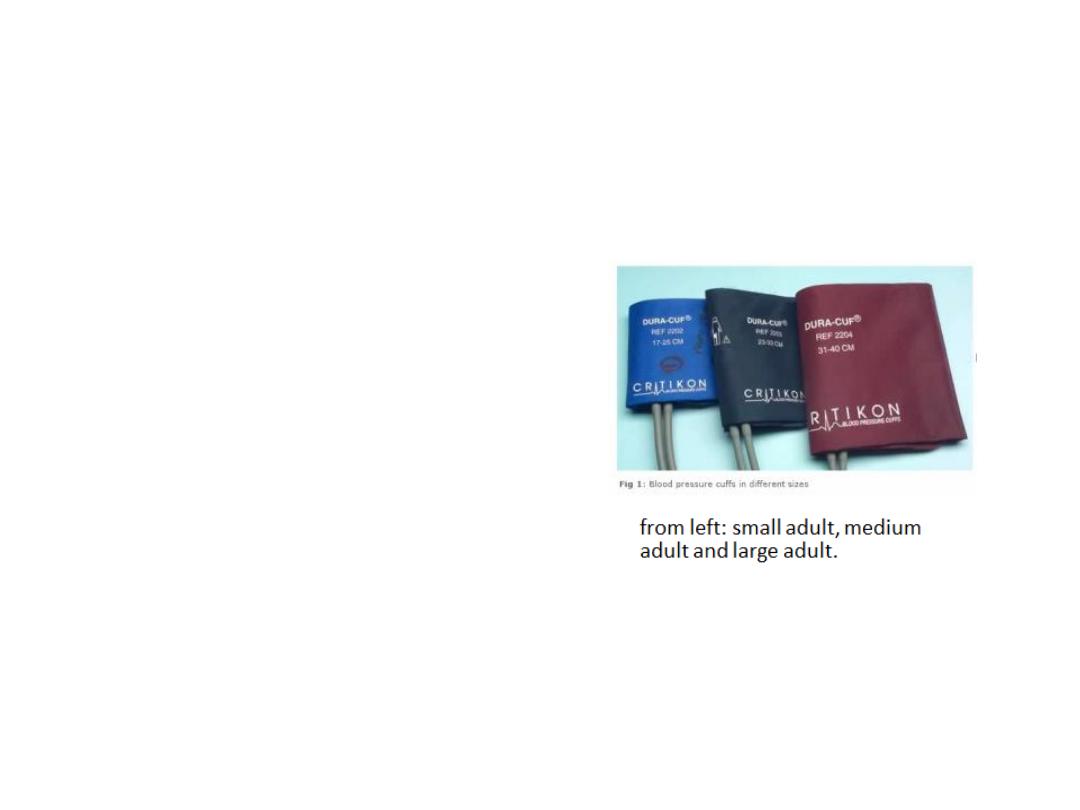

None – invasive blood pressure

In order to obtain an

accurate reading, an

appropriately sized blood

pressure cuff should be

used.

A guide to the correct

width of the cuff:

• 3cm: infant

• 6cm: child

• 9cm: small adult

• 12cm: standard adult cuff

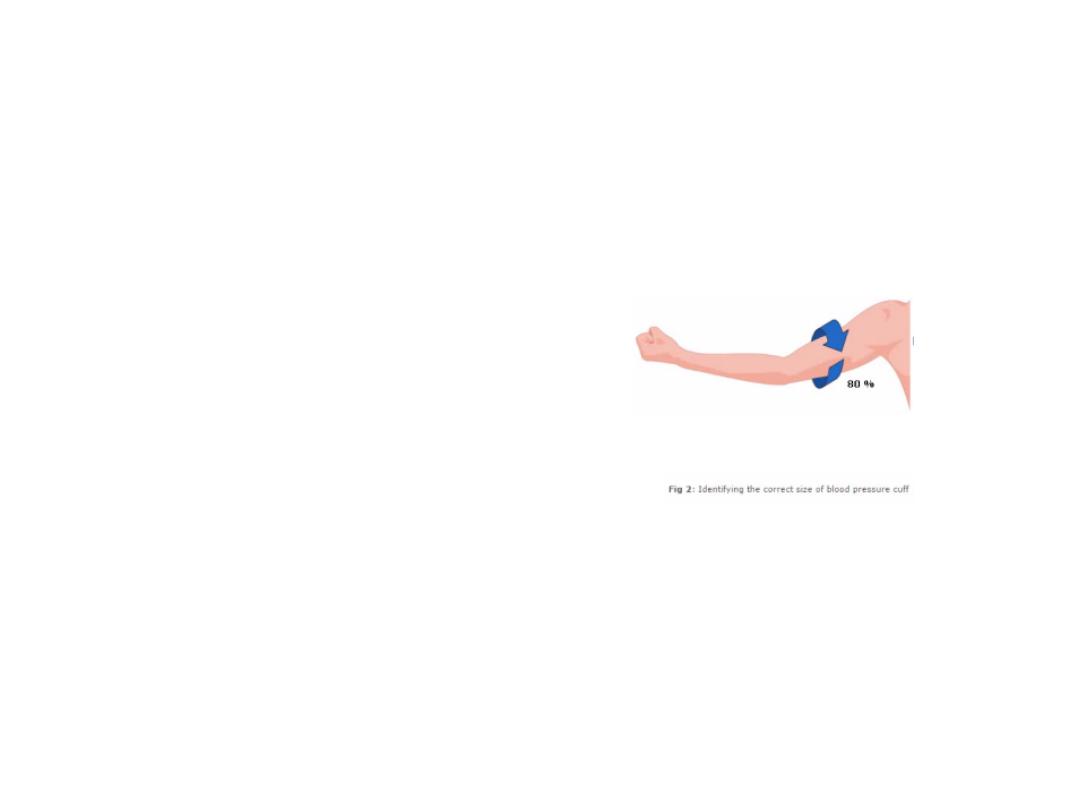

None – invasive blood pressure

• To identify the correct size of the

cuff, estimate the circumference

of the upper arm at mid point

between shoulder and elbow. The

bladder inside the cuff should

encircle at least 80% of the arm

circumference. The width of the

cuff should be 20% more than the

diameter of the arm. The cuff

should be placed so that the

midline of the bladder is over the

arterial pulsation. Also, adjust the

frequency of measurements

according to the clinical condition

of the patient and the type of

surgery. This is usually done every

3 or 5min.

Medical gas supply

pipeline supply

When checking medical gas supply,

you must identify and check the gas

pipeline. These are color coded:

•

White: oxygen

•

Blue: nitrous oxide

•

Black: medical air

•

Yellow: suction

•

Pink: scavenging

A tug test is done to confirm that

each pipeline is correctly inserted and

engaged into the appropriate gas supply

terminal. Inadequately inserted sockets

can appear to stay attached to the

terminal even when hanging vertically. In

this case, their would be no gas flow.

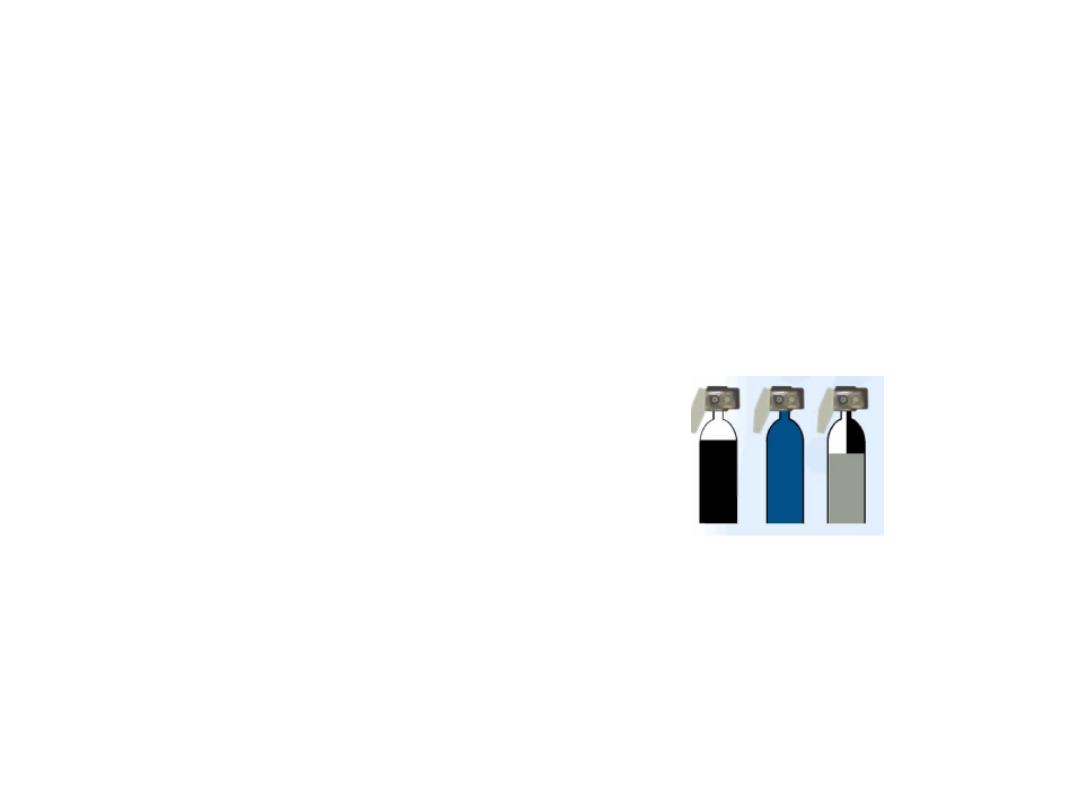

Medical gas supply

reserve gas cylinders

Reserve gas cylinders

should be available to ensure a

continuous supply of medical

gases, even in cases of central

gas supply failure.

Normally, oxygen, nitrous

oxide and air cylinders are

attached to the anaesthetic

machine as a reserve supply.

Carbone dioxide cylinders

should not normally present

on the anaesthetic machine

due to risk of administering

high concentration of CO2.

Seating, connecting and checking

reserve cylinders

The reserve oxygen,

nitrous oxide and medical

air cylinder will need to be

securely seated onto the

anaesthetic machine. They

should then be connected

and their contents checked.

After you have checked

the contents of these

cylinders, turn them off.

A blanking plug should be

fitted to any empty cylinder

yoke.

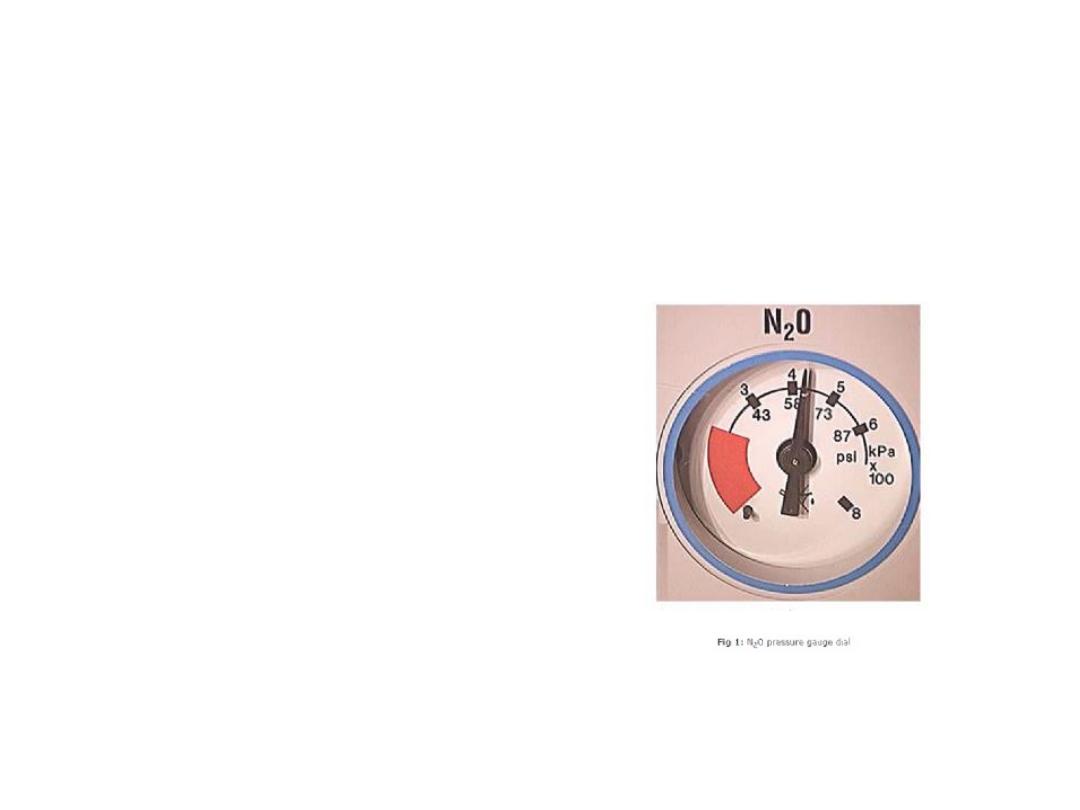

Checking pressure gauges

After you have ensured that each

pipeline is correctly inserted into the

appropriate gas supply terminal,

check the gauges pressure on the

anaesthetic machine.

The pressure gauges of pipelines

connected to the anaesthetic

machine should indicate 499 –

500KPa.

The readings of pressure gauges of

full oxygen, nitrous oxide and air

medical gas cylinders should be:

• Oxygen: 13700KPa (137bar)

• Nitrous oxide: 4400KPa (44bar)

• Medical air: 13700KPa (137bar)

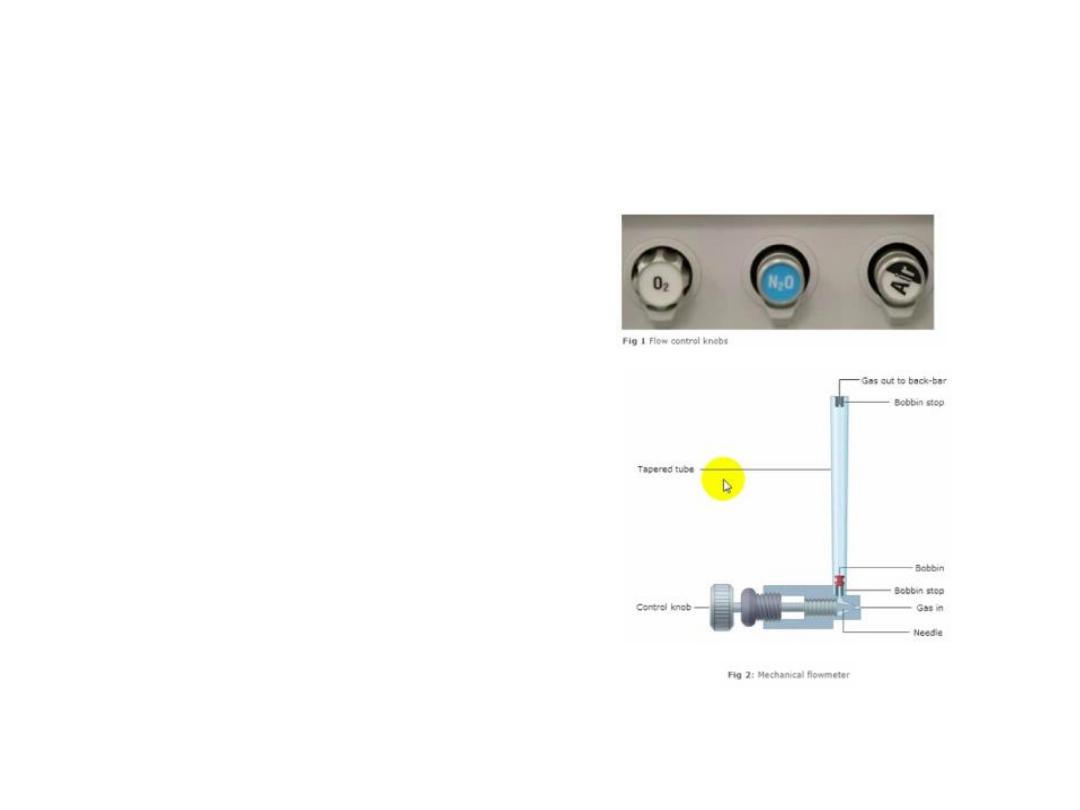

Medical gas supplies

mechanical flowmeters

• Although some

anaesthetic machine

have digital and

electronic flowmeters,

the majority have

mechanical ones.

• The bobbin should

move and rotate freely

at various flow rates.

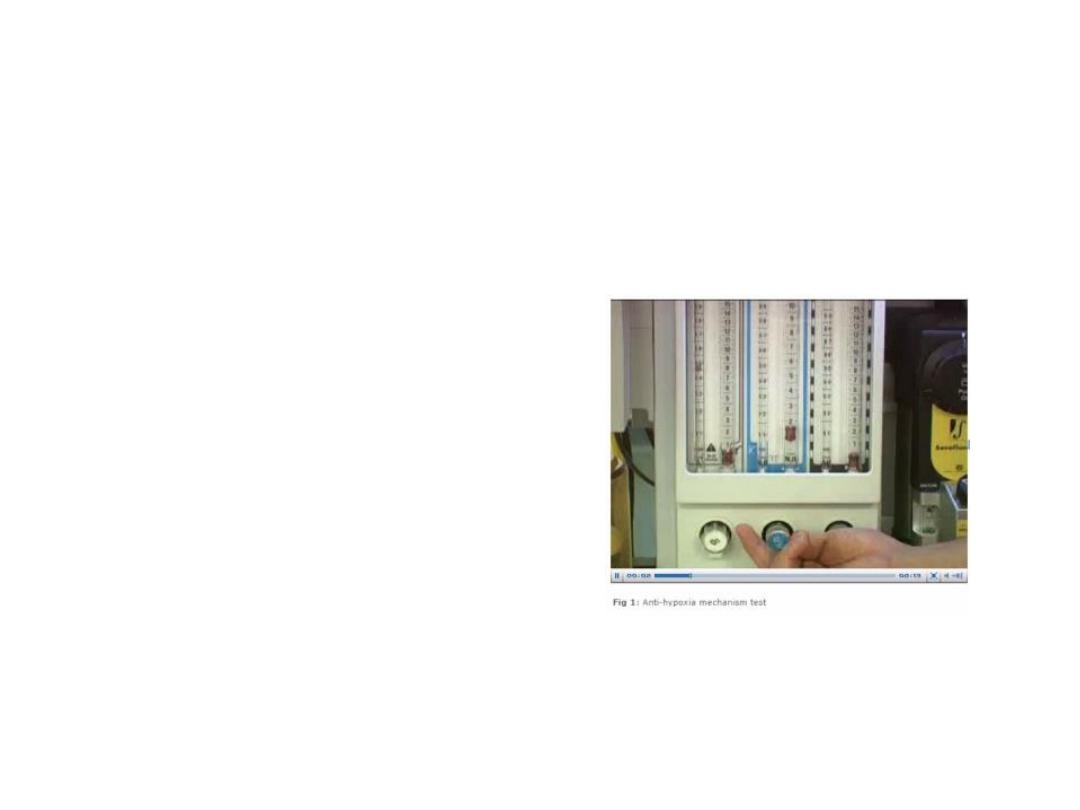

mechanical flowmeters

testing the anti - hypoxia device

• Anti – hypoxia device (the

means to prevent the delivery

of a gas mixture with an

oxygen concentration below

25%). This anti – hypoxia

device should be tested.

• Check the oxygen analyzer

function by turning on oxygen

flow. A reading approaching

100% should be displayed.

• Turn off all flow control valves.

(Some machines that are fitted

with a gas supply master

switch will continue to deliver

a basal flow of oxygen; about

250ml/min.

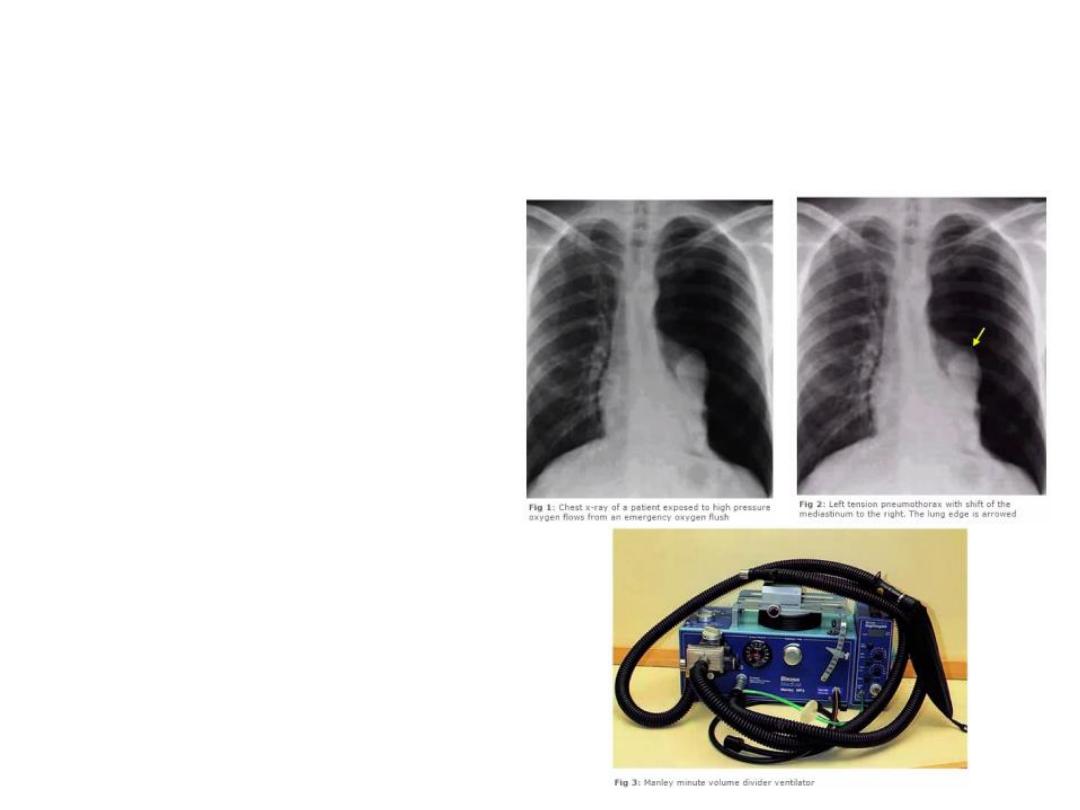

Oxygen flash

oxygen bypass

• The emergency oxygen bypass

control should be checked next.

When the bypass button is

pressed, the oxygen flow without

significant decrease in the

pipeline supply pressure. It is

important to check that the

control valve shuts off when the

button is released.

• The emergency oxygen flash,

when activated, supplies pure

oxygen with flow of about 35 –

75L/min at a pressure of about

400KPa.

• As a safety feature, the button is

recessed in a housing to prevent

accidental activation.

Oxygen flash

The risks to the patient of excessive

use of emergency oxygen flash:

• Put the patient at a higher risk of

barotrauma due to the high

operating pressure and flow of

the oxygen flash.

• Inappropriate use can lead to

dilution of anaesthetic gases and

possible awareness.

• Should not be activated while

using a minute volume divider

ventilator, a minute volume

divider ventilator delivers to the

patient the fresh gas flow from

the anaesthetic machine. It is

inappropriate to deliver flows in

excess of 35L/min.

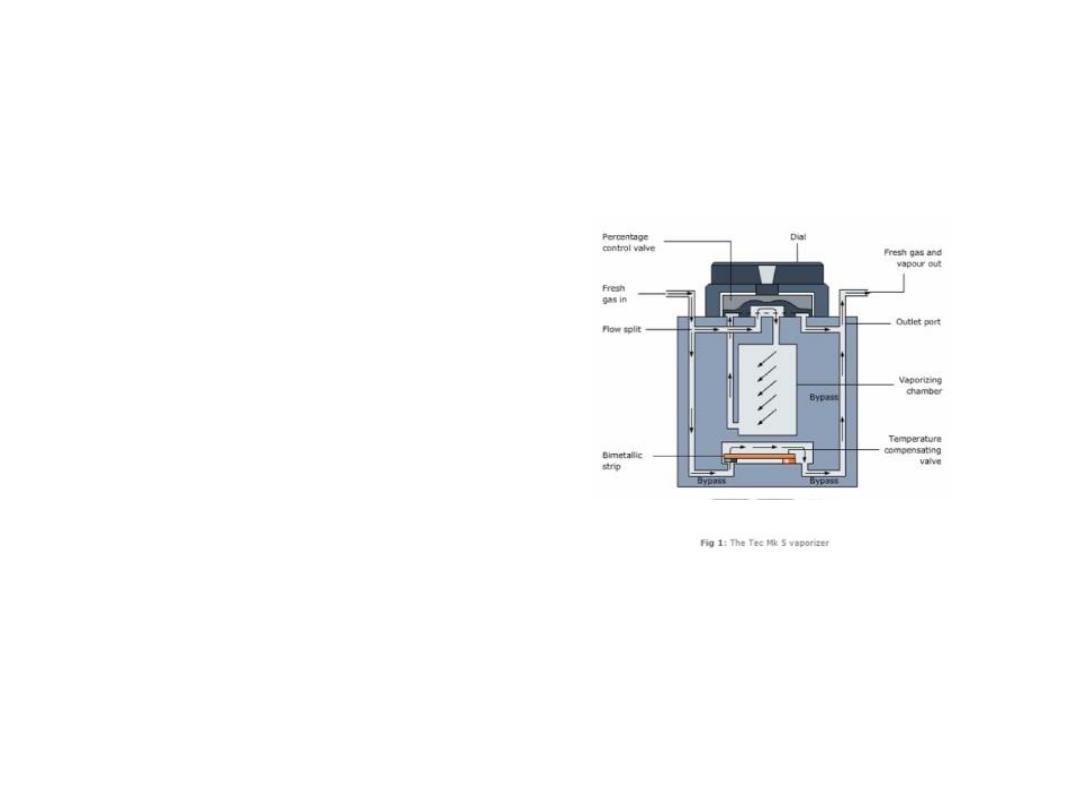

Vaporizers

anti – spill design

•

Vaporizers are filled with volatile agents.

They must always be kept upright as a

precaution against spillage. Tilting can result

in accidental delivery of dangerously high

concentrations of anaesthetic vapor. With

early vaporizer designs, critical accident

would occur when the vaporizer was

inadvertently tipped upside down, causing

the liquid anaesthetic agent to enter the

bypass channel.

•

Modern vaporizers, such as Tec MK 5, are

designed to reduce the risk of the agent

spilling into the bypass channel.

•

IN spite of this, it is recommended that the

vaporizer is purged with a fresh gas flow of

5L/min for 30 min, with percentage dial set

at 5% in case of accidental tilting.

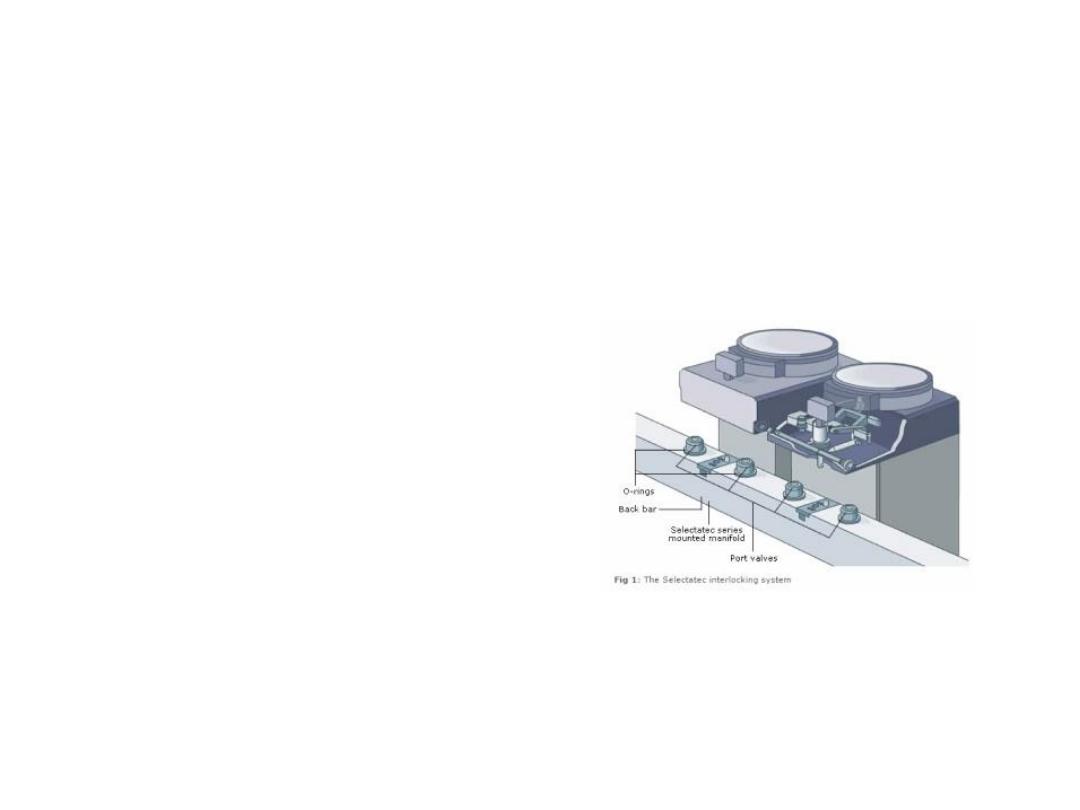

Vaporizers

the risk of leaks

The commonest causes of leaks

due to vaporizers are:

1. Incorrectly engaged

vaporizers on the back bar

2. Loss of one of the O – rings

on the mounts where the

vaporizer is positioned. As the

vaporizers are changed, the O –

rings can accidently adhere to the

vaporizer, so causing a leak when

another vaporizer is positioned.

a leak can lead to a delivery of

incorrect proportions of

anaesthetic gases.

Vaporizers maintenance

As vaporizers are used to deliver the

vapor of the volatile agents, it is

important to make sure that:

1. The vaporizing chambers are

adequately filled and that the filling

port(S) is/are tightly closed.

2. The vaporizers are correctly fitted

with a fully engaged back bar locking

mechanism.

3. The control knobs rotate fully

throughout their full range.

•

The consequences of any leakage of

volatile agents can be serious. It is

therefore essential that a leak test is

carried out whenever a vaporizer is

used or changed.

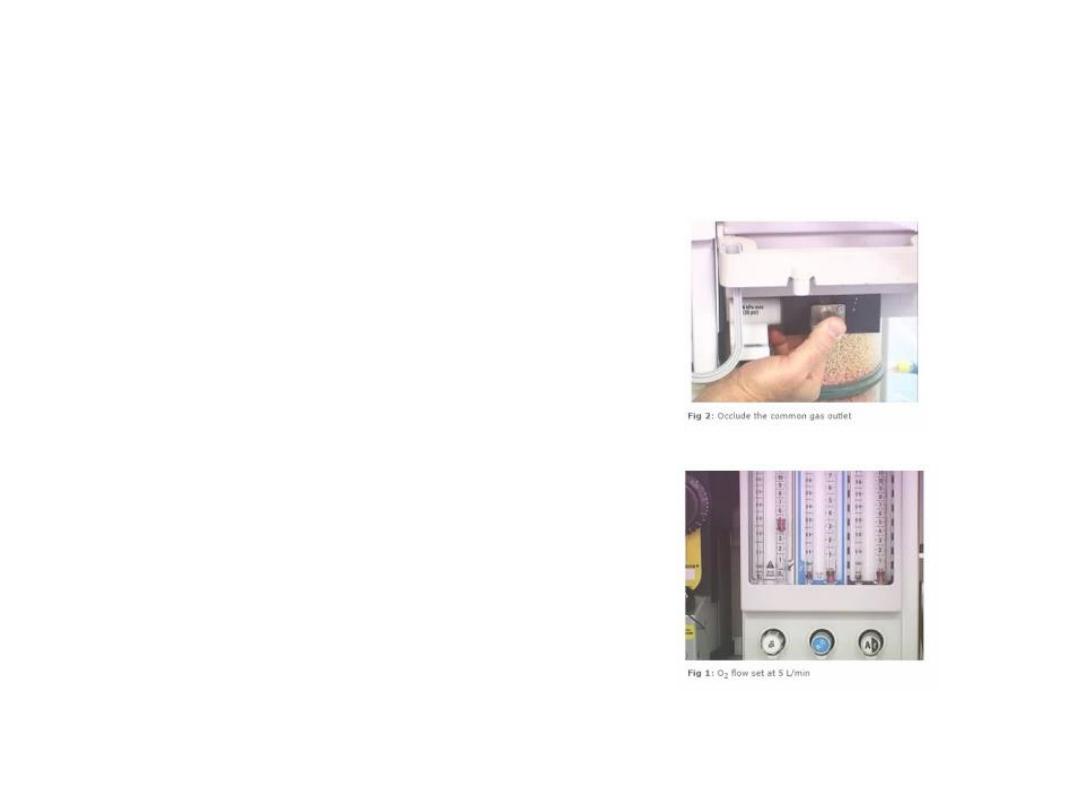

Leak testing

To test for leak:

1. Turn off the vaporizers

2. Set a flow of oxygen of 5L/min

3. Temporarily occlude the

common gas outlet of the

anaesthetic machine

4. Check for leak

5. There is no leak if the flow

meter bobbin (if present) dips

6. turn on the vaporizer and repeat

this test

7. There should be no leak of liquid

from the filling port

8. After testing, ensure that the

vaporizers and flowmeters are

turned off.

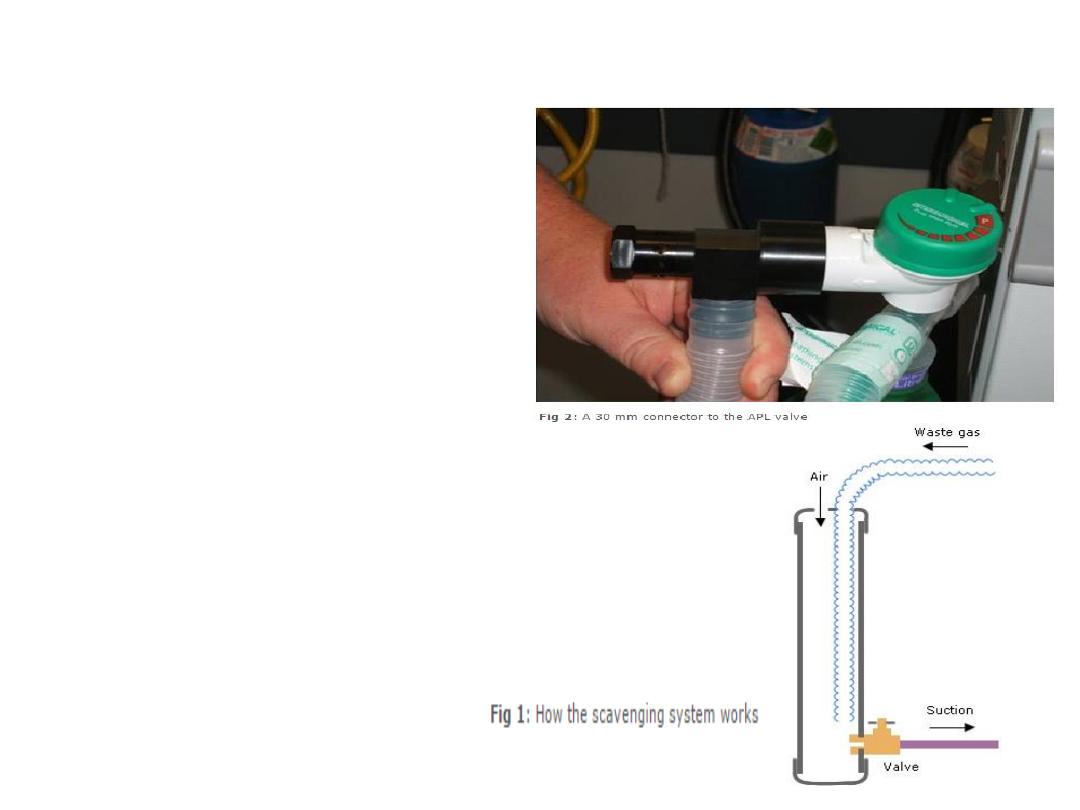

Scavenging

•

In order to reduce the risk of

pollution in the operating theatre,

the scavenging system, should be

used to ensure safe disposal of

anaesthetic waste gases.

•

So, ensure that it is switched on and

functioning. You should be able to

hear and feel the suction of the

disposal system.

•

The collecting and transfer

component of the scavenging system

should be attached to the

appropriate exhaust port of the

breathing system, ventilator or

anaesthetic workstation. A 30 mm

connector is used as a safety measure

in order to prevent accidental

misconnection to other ports of the

breathing system.

Suction equipment

Functioning suction equipment is essential for

safe conduct of anaesthesia. This allows

secretions or vomitus to be suctioned away from

the upper airway.

To test the suction system:

1.

Ensure that the vacuum probe is firmly

engaged with its outlet and that all

connection are secure

2.

Switch on the suction and occlude the

suction tubing. This is to test for the rapid

development of an adequate negative

pressure

3.

A suction unit should take no longer than

10S to generate a vacuum of 500mmHg

with a displacement of air of 25L/min

Ensure that the patient trolley, bed or operating

table can be tilted head – down rapidly.

Ancillary equipment

Airway management

equipment should be checked

next to ensure that each item

of ancillary equipment

required is available and

functioning correctly.

Ancillary equipment include:

1. Laryngoscopes

2. Intubation aids

3. Face masks, laryngeal

masks, airways, tracheal

tubes and connectors

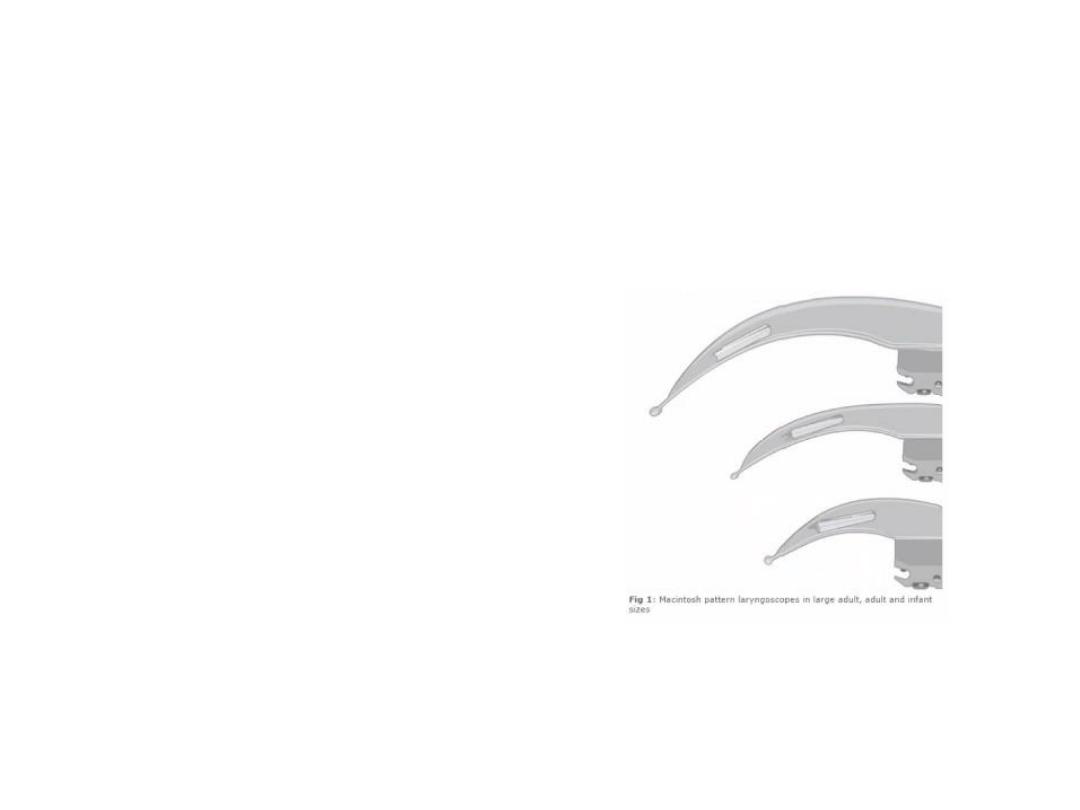

laryngoscopes

• Laryngoscopes should

be available in different

sizes. The bulbs must be

checked to ensure their

function.

Intubation aids

Several types of intubation aids may be

required: intubation forceps, bougies, stylets,

Magill forceps, etc.

Airways equipment

Make sure that all face masks, laryngeal masks,

airways, tracheal tubes and connectors are

patent.

Single use device

In order to reduce the risk of cross - infection between patients, it is recommended that single

– use equipment is used when possible.

Single – use equipment will be marked with the symbol:

It is recommended that when single – use equipment is used, the packing should not be removed

until the point of use. This helps in infection control, identification and safety.

It must be emphasized that any equipment any equipment that is designated single - use must

be used for one patient only, and not re – used.

Back-Up Systems

Some modern anaesthetic machines may default to little or no flow in the event of failure.

In such situations, it is essential that an alternative oxygen supply and means of ventilation,

such as a self-inflating bag, circuit and oxygen cylinder, must be available, and checked as

functioning correctly with an adequate supply of oxygen.

Alternative methods of maintaining anaesthesia in this situation should be available such as

syringe pumps to administer total intravenous anaesthesia.

Record Keeping

Each anaesthetic machine should have a log

book in which check records are documented.

The following checks should be accurately and

systematically recorded:

1.

Regular servicing of anaesthetic machine

2.

Weekly oxygen failure alarm checks

3.

Daily pre – session checks

The anaesthetist should clearly document in the

patients anaesthetic record that:

1.

The anaesthetic machine check has been

performed

2.

Appropriate monitoring is in place and

functional

3.

The integrity, patency and safety of the

whole breathing system has been assured

Such documentation of the routine checking and

regular servicing of anaesthetic machines, and

patient breathing systems should be sufficient to

permit routine auditing to be carried out a future

time.

Session key points

•

Routine checking of equipment is essential in the safe delivery of anaesthetic care

•

Ensure that you have turned on anaesthetic machine after connecting it to the

mains supply

•

Check the gas supply; both piped gases and cylinders

•

Make sure that the monitoring equipment is working adequately

•

Ensure that various components of the anaesthetic machine are functioning

correctly – flowmeters, vaporizers, oxygen emergency flash, scavenging system

and suction system. Also check for leaks

•

Check the breathing system and its components

•

Ensure the availability of different airway management devices

•

When possible, use single – use devices

•

In cases of anaesthetic machine failure, have available means of ventilation and

administration of oxygen

•

Session summary

Learning objectives:

. Describe the tests performed in checking the

anaesthetic equipment

. Identify potential equipment malfunctions in

anaesthetic practice

. Recognize the design modifications of modern

anaesthetic equipment to prevent such

malfunction