Dental Chemistry

ProfDr. Amer A. Taqa

Cements

Classification of materials in dentistry

The materials may be classification as follows:

a-acid base reaction cement

b- polymerizing materials

1-acrylic polymer

2-cyanoacrylates

3-dimethacrylate polymers

4-polymer-ceramic composites

C-other materials

1-calicium hydroxide

2-Gutta percha

3-varnishes

Acid base reaction cements

Chief constituents

Dental cements are formulated as powders and liquid.

The powders are amphoteric or basic (proton acceptors) and the

liquid are acid or proton donors.

On mixing the two together a viscous paste is formed, which

subsequently hardens to a solid mass. The cements can be classified

by the nature of the cement powder.

a/ Zinc oxide: this can react with a range of liquids as detailed later.

b/ Ion –leachable glasses, particularly fluorine containing

aluminosilicate.

General reactions:

A cement reaction is the interaction between an acid and base in

general

MO+H

2

A→MA+H

2

O

MOXSiO

2

+H

2

A →MA+XSiO

2

+H

2

O

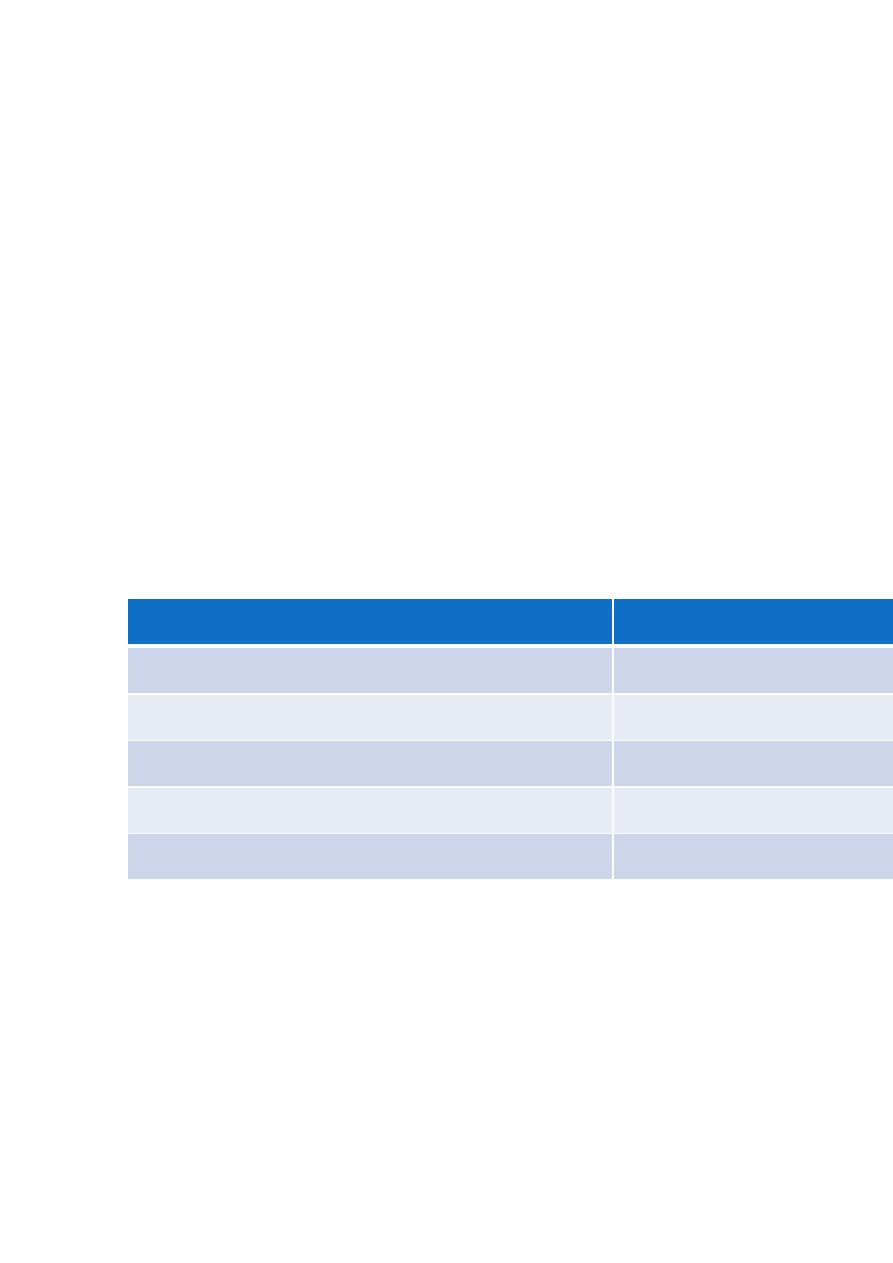

Table: chief constituents of acid –base reaction cements

Cement

powder

(proton

acceptor)

Cement

liquid

(proton

donor)

Type of cement Related materials

Zinc oxide

Eugenol

Zinc oxide-

eugenol(ZOE)

EBA cement

Zinc oxide

Aqueous

solution of

phosphoric

acid

Zinc phosphate Copper and silver

cement

Zinc oxide

Aqueous

solution of

poly

acrylic

acid

Zinc

polycarboxylate

or polyacrylate

Poly acrylic acid may

be in solid form as a

powder components

Fluorine

containing

aluminosilicate

glass

Aqueous

solution of

phosphoric

acid

Silicate cement Silicaphosphatcement

Fluorine

containing

aluminosilicate

Aqueous

solution of

poly

acrylic

acid or

polymer

Glass-ionomer

General structure

Set cements are heterogeneous, only part of the powder reacts with

the liquids and the final set material is composed of a core un

reacted powder surrounded by a matrix of reaction products, i.e. the

gel-salt.

Requirements of cements

1-They should be non-toxic, and non irritant to the pulp and other

tissues.

2-Insoluble in saliva and liquid taken into the mouth.

3-Mechanical properties: these must meet the requirements for their

particular applications, for example , for a cavity lining , a cement

should develop sufficient strength rapidly to enable a filling materials

to be packed on it.

4-Protection of the pulp from effect of other restoration materials

Zinc phosphate cement

The compositions of powder and liquid in a typical cement are given

in table:

Powder ZnO 90%

Other metallic oxide 10%

Liquid aqueous solution of phosphoric acid 50-60%

Al

3

(PO

4

)

2

up to 10% as

buffers

Zn

3

(PO

4

)

2

Setting reaction

On mixing the powder and liquid together a vigorous reaction

occurs, resulting in the formation of a relatively insoluble zinc

phosphate

3ZnO+2H

3

PO

4

+H

2

O →Zn

3

(PO

4

)

2

+4H

2

O

Only the surface layers of the zinc oxide particles react leaving

unconsumed cores bound together by the phosphate matrix (the

reaction is exothermic)

Copper cements

These are similar to phosphate cement except that the powder

contains a copper compound in addition to zinc oxide. If copper (I)

oxide (copprous oxide) is used, the cement is red, while

copper(II)oxide(cupric oxide) gives black materials.

The black copper cements have the following properties

1-Their effect on the pulp may be even greater than that of an

unmodified phosphate cement.

2-They are considered to be bactericidal, so have been used to

prolong the life of deciduous teeth. If all the carious tooth substance

cannot be removed.

They are sometimes used in the cementation of splints and fixed

orthodontic appliances.

Silver cements

Same phosphate type cements contain silver salt in an endeavor to

render there bactericidal.

— Cements based on zinc oxide

— Zinc oxide-eugenol and related materials

— Composition

— a-powder

— Zinc oxide

— Magnesium oxide may be present in small quantities, it react with

eugenol in a similar manner to zinc oxide.

— Zinc acetate( or other salts) in quantities up to about 1%, are used

accelerators for the setting reaction.

— b-liquid

— Eugenol, the major constituent of oil of cloves.

— Olive oil, up to 15%.

— Some times acetic acid , to act as an accelerator.

Setting reaction

One or both of two things may occur on mixing the powder and liquid:

— Chemical reaction, to form a compound called zinc eugenolate.

The reaction between zinc oxide and eugenol begins gives the structural

formula of eugenol. The basis of the reaction is that the phenolic –OH of

the eugenol act as a weak acid and undergoes an acid –base reaction with

zinc oxide to form a salt, zinc eugenolate, as follows:

— 2C

10

H

12

O

2

+ ZnO Zn(C

10

H

11

O

2

)

2

+H

2

O

— Two molecules of eugenol reacts with zinc oxide to form the salt.

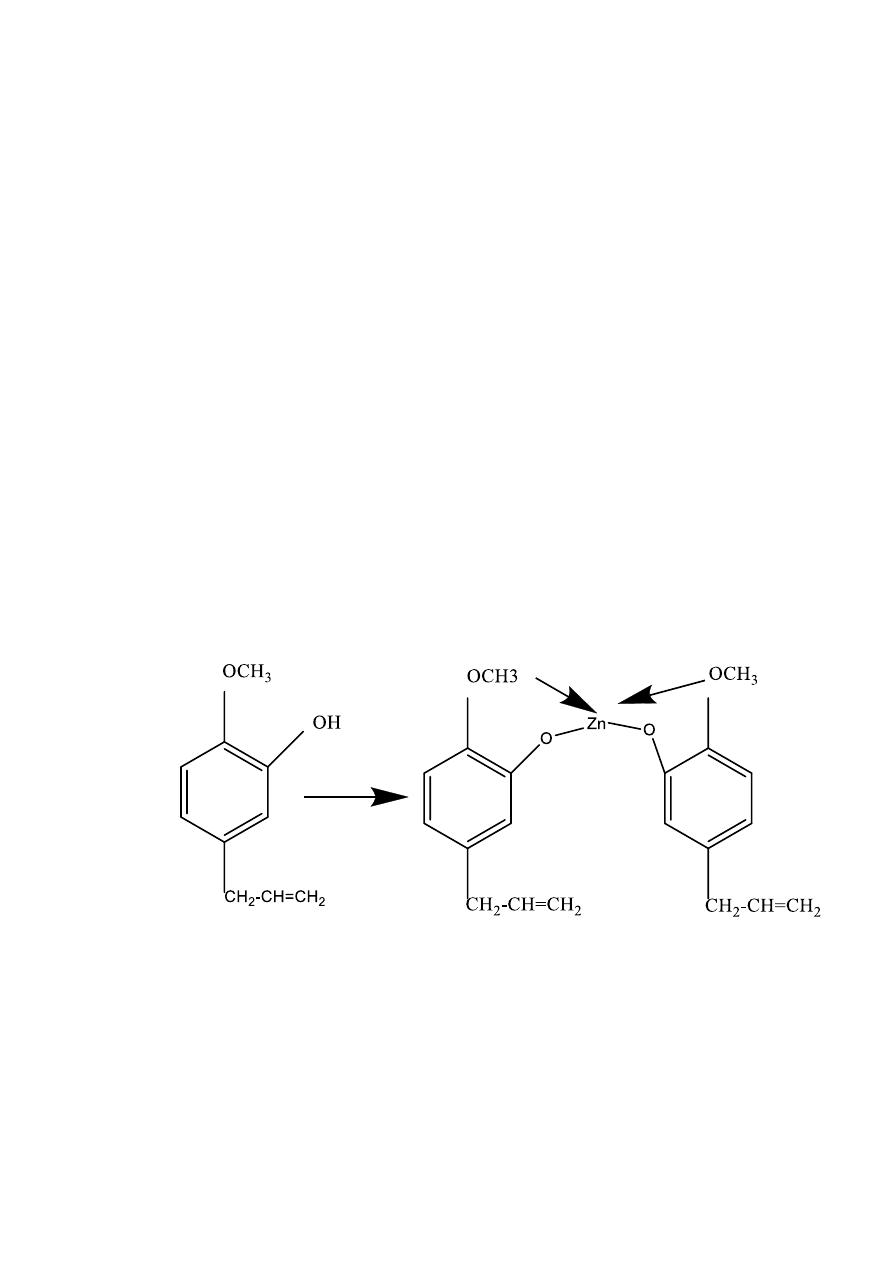

The structural formula of zinc eugenolate.

— The ionic salt bonds are formed between zinc and the phenolic

oxygen of each molecule of eugenol. Two further co-ordinate

bonds are formed by donation of pairs of electrons from the

methoxy oxygens to zinc. These bonds are indicated by the arrows

in figure

Complex of zinc eugenolate

— Absorption of the eugenol by the zinc oxide may also occur other

factors to be noted are:

—

— 1-the setting reaction between pure zinc oxide and pure eugenol,

will not occur in the absence of water. Thus , a mixture of zinc

oxide and eugenol, without add(accelerators), can be kept in a

desiccators for several days without undergoing much change.

— 2- the set materials contains both some unreacted oxide and

eugenol.

—

— Setting time

— This depends on

— The powder ( its method to preparation, the particles size of the

powder

— The accelerating additives

— The powder/liquid ratio a thicker mixing gives a faster setting

materials.

— Exposure to moister on mixing or the addition of water will

accelerator the reaction.

— An increase in temperature also causes faster setting.

— Properties of cement

— All the cement(include ZOE) must be have the following

requirements

— Effect on the pulp is small, thus the material has been

recommended for use in deep cavities near the pulp.

— Chemical properties: the solubility of the set cement in water is

high- by the far the highest off all dental cements-mainly due to the

elution of eugenol.

— Mechanical properties: (ZOE cement)these are the weakest of all

the cement(except calicium hydroxide).

— Protection of the pulp.

— Optical properties.

— Adhesion : ZOE cement do not adhere to enamel and dentine. This

is one reason why they are not frequently used for the final

cementation of dental restoration

— ZOE cement are bacteriostatic and abundant.

— Thermal insulation: a cement is used under a large metallic

restoration (e.g. amalgam) to protect the pulp from temperature

changes.

— Chemical protection : a cement should be able to prevent

penetration into the pulp of harmful chemicals from the restorative

material.

— Electrical insulation under a metallic restoration to minimize

galvanic effects.

— Optical properties: for cementation of translucent restoration (for

example, a porcelain crown) the optical properties of the cement

should parallel these of tooth substance.

— A cement should ideally be adhesion to enamel and dentine, and to

gold alloys, porcelain and acrylic, but not to dental instruments.

— A cement should be bacteriostatic if inserted in a cavity with

residual caries.

— Cement should be have an abundant effect on the pulp.

— Rheological properties are important, a luting cement should have

sufficiently low viscosity to give a low film thickness and should

have a adequate working time at mouth temperature to prevent

placement of the restoration

— Dental amalgam

An amalgam consist of a mixture of two or more metals, one of

which is mercury combined with a powdered silver-tin alloy.

Mercury is a liquid at R.T. and is able to form a workable mass

when mixed with the alloy. This behavior renders the material

suitable for use in dentistry.

The reaction between mercury and alloy which follows mixing is

termed an “amalgamation’ reaction . dental amalgam is the most

widely used of all the available filling materials.

Chemical composition

Mercury used in dental amalgam is purified by distillation, this ensure the

elimination of impurities which would adversely affect the setting

characterization and physical properties of the set amalgam.

The composition of the alloy powder particles varies from one product to

another. Many alloys conveniently described as “conventional alloys”

have a composition in which the concentration of the component metals

are given in table:

Composition of conventional amalgam alloy

Metals

Wt%

Silver

65

Tin

29

Zinc

6 max

copper

2max

Mercury

3 max

— The quantities of silver and tin specified ensure a preponderance of

the silver/tin inter metallic compound Ag

3

Sn, this compound

known as the δ (gamma) phase of the silver-tin system, is formed

over only a small composition range and is particularly

advantageous since it readily undergoes an amalgamation reaction

with mercury.

— The role of zinc is a “scavenger” during the production of the alloy.

The alloys is formed by melting all the constituents metals

together. At the elevated temperatures required for this purpose

there is a tendency for oxidation to occur.

— Oxidation of tin, copper or silver would seriously affect the

properties of the alloy and amalgam. Zinc reacts rapidly and

preferentially with the available oxygen, forming a slag of zinc

oxide which is easily removed. many alloys and oxidation during

melting is preventing by carrying out majority in an inert

atmosphere.

— The majority of alloys powders contain no mercury . those product

containing up to 3%. Mercury are called pre-amalgamated alloys.

They are said to react more rapidly when mixed with mercury.

— The reactions which take place when alloys powder and mercury

are mixed is complex. Mercury diffuses into the alloys particles,

very small particles may become totally dissolved in mercury. The

alloys structure of the surface layer is broken down and the

constituent metals undergo amalgamation with mercury. The

reaction products crystallize to give new phase in the set amalgam.

A large quantity of the initial alloys remains unreacted at the

completion of setting. The structure of the set materials is such

that the unreacted cores of alloy particles remain embedded in a

matrix of reaction products.

— In simplified terms, the reaction for conventional amalgam alloys

may be given by the following unbalanced equation

—

— Ag

3

Sn +Hg Ag

2

Hg

2

+Sn

x

Hg +Ag

3

Sn

— Or δ Hg δ

1

+ δ

2

+ δ

—

— The primary reaction products are a silver-mercury phase (the δ

1

phase) and a tin –mercury phase(the δ

2

phase) . the δ

2

phase has a

rather imprecise structure and the value of X in the formula Sn

x

Hg

may vary from 7 to 8. The equation emphasizes the fact that

considerable quantities of unreacted alloy (δ phase) remain

unconsumed.

— For copper –enriched alloys the reaction may be presented by

— Ag

3

Sn + Cu +Hg Ag

2

Hg

3

+ Cu

6

Sn

5

+Ag

3

Sn

Or

δ + Cu + Hg δ

1

+ Cu

6

Sn

5

+ δ

— the essential difference between this and the reaction for

conventional alloys is the replacement of the tin-mercury, δ

2

phase

in the reaction product with a copper-tin phase.

— In the case of the dispersion-modified, copper-enriched material. It

is believed that the particles of conventional lathe-cut alloy

initially reacts to form δ

1

and δ

2

phases. The δ

2

phase than reacts

with copper from the silver-copper eutectic spheres to form the

copper- tin phase. Thus in these materials, the δ

2

phase exists as an

intermediate reaction product for a short time during setting.

— The reaction rate is quite slow and some times takes several days

or even weeks to reach completion. This is reflected in the rate of

development of mechanical properties.

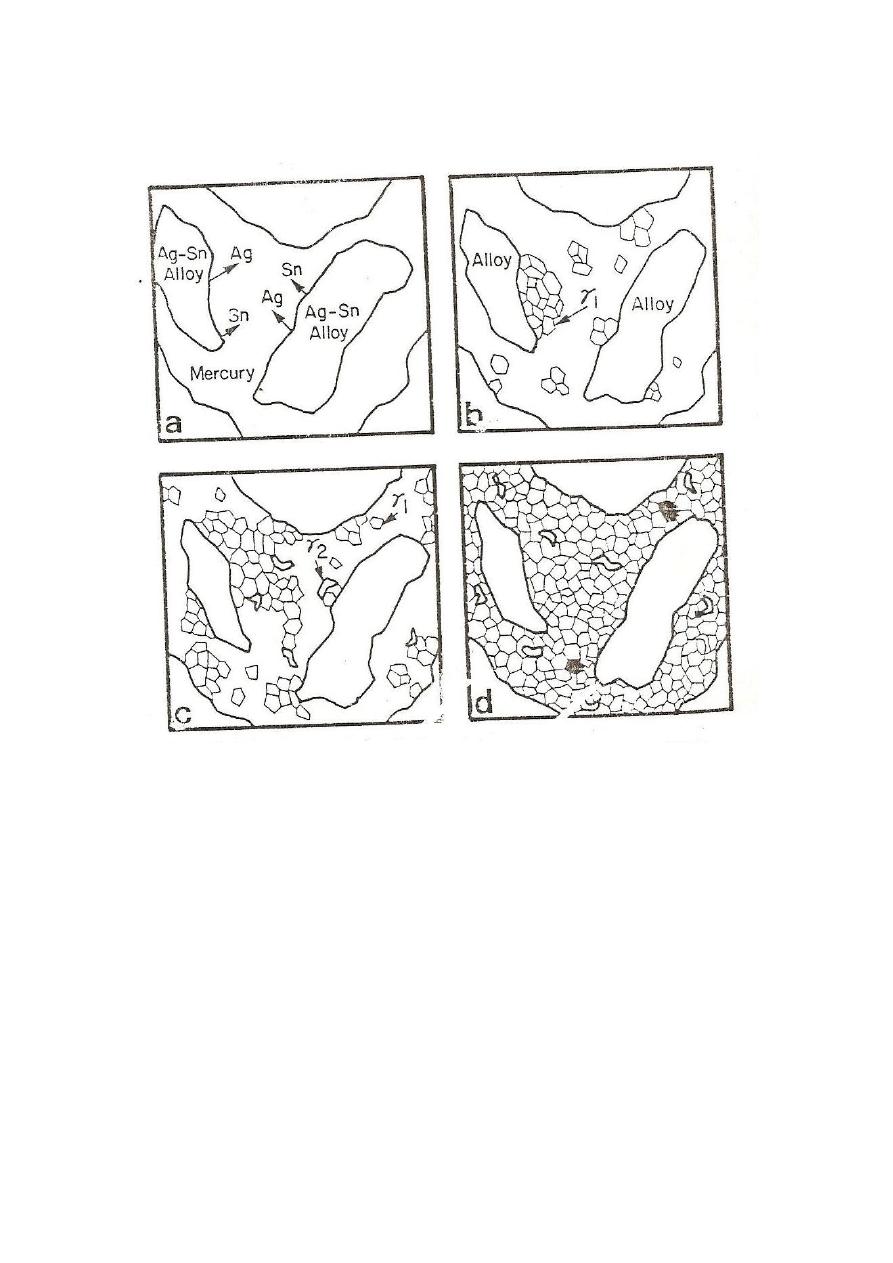

— Amalgamation and resulting structure(Low copper)

—

— Amalgamation occurs when mercury comes into contact with the

surface of Ag-Sn alloy particles. When a powder is triturated, the

silver and tin in the outer proton of the particles dissolve into

mercury. At the same time mercury diffuse into the alloy particles.

The mercury has a limited solubility for silver (0.035wt%) and tin

(0.6wt%).