Sources of central gas supply

Description:

Gases in piped medical gas and vacuum systems are

supplied from central supply sources in the hospital. This

session provides an overview of cylinder manifolds, liquid

oxygen stores and the oxygen concentrator.

Session introduction

learning objectives: By the end of this session

you will be able to

Define the key components, functionality and

safety features of cylinder manifolds.

Recognize the important aspects of liquid

oxygen stores (vacuum insulated evaporators)

and their associated safety features.

Recognize the key components, functionality

and safety features of oxygen concentrators.

Cylinder manifold

one source of central medical gas supply is

central manifolds. These are used to supply

nitrous oxide, entonox and oxygen at a constant

pressure. This is normally achieved via a control

panel from tow equal banks of large cylinders e.g.

large J known as:

Duty banks

Standby banks

The cylinders in each bank are connected through

non return valves to a common pipe. All cylinders

in each bank are turned on and interconnected.

The duty and the standby banks alternate in

supplying the pipe lines. The changeover from

one to the other is an automatic process.

Oxygen can also be supplied from vacuum

insulated evaporators were it is stored as liquid

oxygen or from large oxygen concentrators.

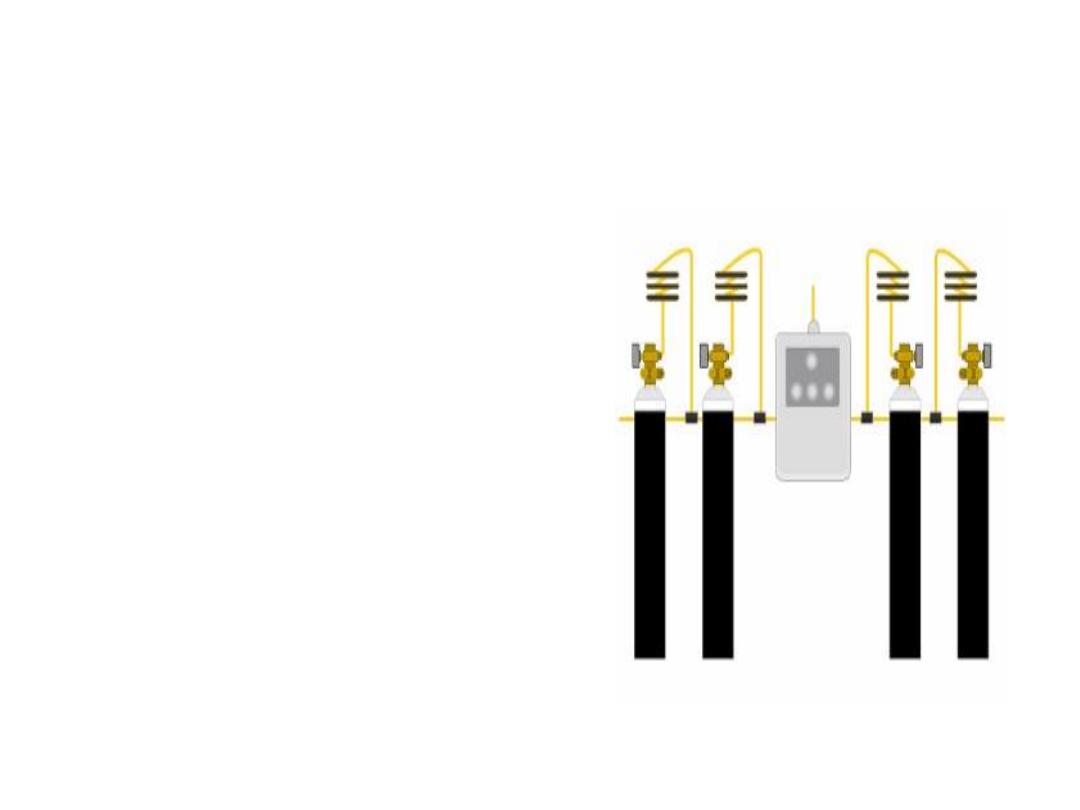

Automatic changeover

automatic changeover from the duty

to standby bank should occur at a

cylinder pressure that will ensure the

maximum usage of the contents of

the duty bank. Each bank of cylinders

has separate pressure regulator

valves.

Although the pipelines are fed from

pressure regulators and work at

about 400 KPa, changes in demand

can lead to small fluctuations in

pipeline pressure. Pressure gauges

are also use to indicate cylinder bank

pressures and distribution pressure.

The number of cylinders in each

bank is determined by expected

demand.

Automatic changeover

The total storage capacity:

It should be one week supply.

Each bank of cylinders should

contain not less than two days

supply, with a three days supply

of spare cylinders kept in the

manifold room.

The nitrous oxide manifold is

often larger than oxygen

manifold. This is because nitrous

oxide is present in cylinders only,

whereas liquid oxygen is normally

used to supply piped oxygen in

hospitals, so the oxygen manifold

is a back up.

The changeover units

In the normal operation of the changeover

control depends on an electrical supply, the

design ensures that in the event of an electrical

supply failure, there is no disruption to the flow

of gas into the piped medical gas and vacuum

system (PMGV).

On restoration of the supply, the bank running

when it failed started up again.

Cylinders can be changed, or the pressure

regulating valves removed for overhaul without a

loss of continuity in the gas supply.

The changeover unit is provided with monitoring

to detect and display information regarding the

function of the two banks and the pipeline

pressure in cases of fault.

The unit is housed in a lockable, steel enclosure

with a glass fronted door to keep the control

cleans and free from contamination.

manifolds

For reasons of safety, the manifold is housed in a

well ventilated room, built of fireproof material,

away from the main buildings of the hospital. The

room should facilitate the easy and quick

changing of the cylinders.

The manifold room is not used as a general

cylinder store. All empty cylinders are removed

immediately and any separate emergency

cylinders are full and available for use. They are

checked and the stock is rotated on a regular

bases.

Audio and visual warning systems should be

constantly monitored, and if required, be placed

in multiple locations.

Responsibility for ensuring supplies to the

manifold should be clearly established, defined,

documented and implemented within the

hospital.

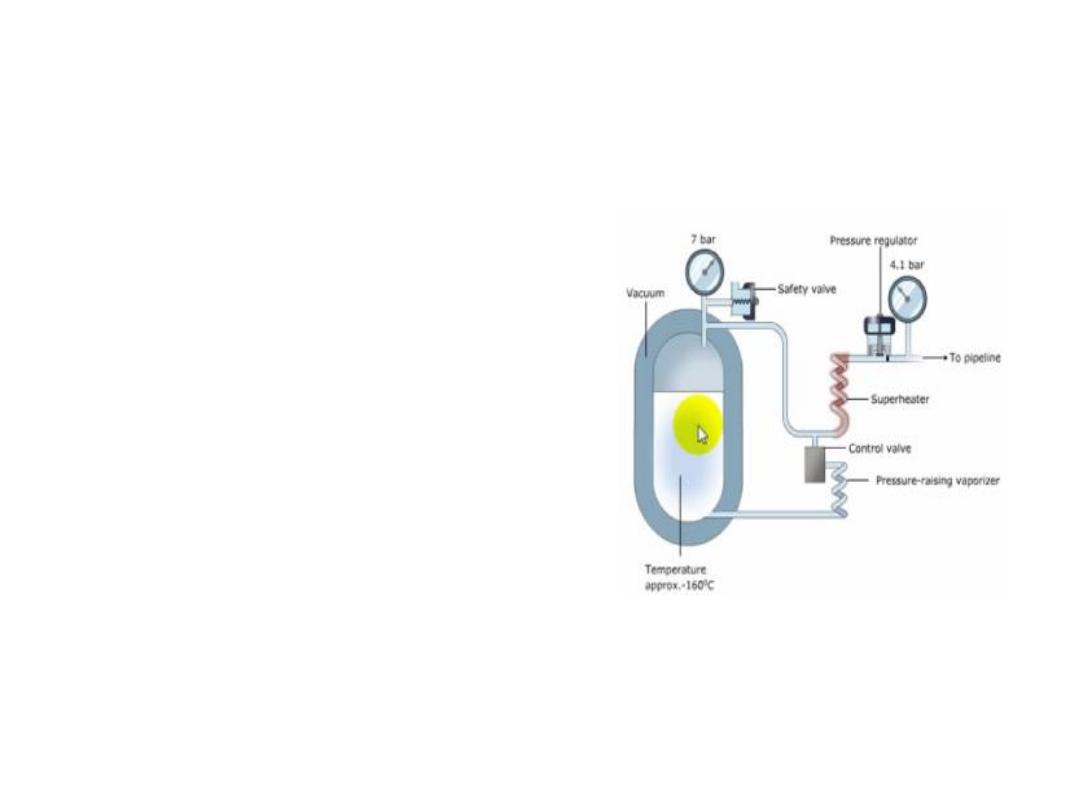

Liquid oxygen

Oxygen can also be stored as liquid, in a vacuum

insulated evaporator made of steel ( the inner wall of

stainless steel and the outer wall of carbon steel). This is

the most economical way to store and supply oxygen,

and allows for easy maintenance and access.

Liquid oxygen is stored at a temperature of – 150 to –

170 ˚C ( below its critical temperature of - 118˚C ) and at

a pressure of 5 – 10 atmospheres. The temperature of

the VIE is maintained by the high vacuum shell (

effectively a vacuum flask).

For a liquid oxygen to evaporate, it requires heat ( the

latent heat of vaporization). This heat is taken from the

liquid oxygen , helping to maintain its low temperature.

The out side surface of VIE is painted white to reduce

absorption of ambient heat.

The VIE should be capable of delivering up to a

maximum of 3000 L/min of oxygen. At a temperature of

15˚C and atmospheric pressure, liquid oxygen can give

842 times its volume as gas. VIEs can be supplied in up

to 50 different sizes depending on the oxygen use in the

hospital.

The liquid oxygen supply system

Oxygen pass through a

pressure regulator that

allows it to enter the

pipelines, and maintains the

pressure through the

pipelines at about 400 Kpa.

If there is an under demand

for oxygen, the pressure in

the VIE starts to builds up, a

safety valve opens at 1700

Kpa, allowing the gas to

escape and there by

reducing the pressure.

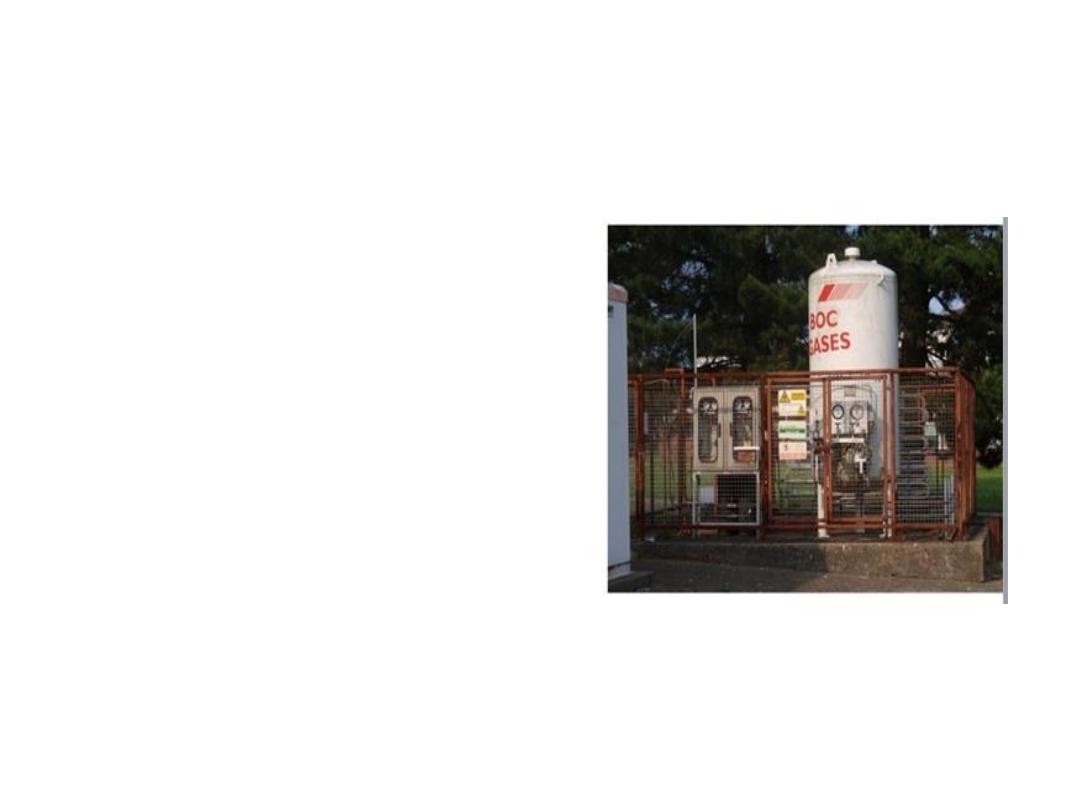

Hazards of central gas supply

Due to the potential fire hazard,

any liquid oxygen storage vessel

should be housed away from

main hospital buildings.

The storage vessel is protected by

a caged enclosure which also

houses two banks of reserve

cylinders.

These reserve banks take over

automatically as the hospital

supply if the VIE out put fails.

The risk of fire is increased in

cases of liquid spillage. Spillage of

cryogenic liquid can cause cold

burns, frostbite and hypothermia.

Oxygen concentrators

Oxygen concentrators can be used to

supply oxygen by extracting it from air by

differential adsorption.

Ambient compressed air is filtered and

pressurized to about 137kPa and enters

one of two parallel, alternating absorber

towers located on either side of the

central mix tank, strongly attract nitrogen

molecules, while allowing oxygen

molecules to pass through. By the time

all of the nitrogen and most other

impurities have been removed.

All that remains is the oxygen and trace

amounts of inert argon. This oxygen

passes into the mix tank, completing the

one cycle of the concentrator.

Portable oxygen concentrators

Also available portable

oxygen concentrators that

produce less than one liter

per minute of oxygen. They

use a demand valve to

deliver oxygen only when

the patient is inhaling.

These portable

concentrators plug into the

wall out let using either AC

or DC power.

Session key points

• Cylinder manifolds can be used to supply piped gases

at a constant pressure. Large size cylinders are used in

two banks, duty and standby. There is automatic

changeover between the two banks.

• Liquid oxygen is usually used to supply piped oxygen in

hospitals. It is stored in vacuum insulated evaporators

at a temperature of – 150 to – 170 ˚C ( below its critical

temperature of - 118˚C ) and at a pressure of 5 to 10

atmospheres.

• Oxygen concentrators are used to extract oxygen from

air using differential adsorption. Oxygen concentration

of 93 – 95 % can be achieved.

Session summary

• Learning objectives:

• Define the key components, functionality and

safety features of cylinder manifolds.

• Recognize the important aspects of liquid

oxygen stores ( vacuum insulated evaporators)

and their associated safety features.

• Recognize the key components, functionality

and safety features of oxygen concenterators.