By

Dr. Ashraf MA. Hussain

Msc./PhD. Community Medicine

PDF created with pdfFactory Pro trial version

Occupational Health

: is a multidisciplinary

activity, defined by

I.L.O.

(

International Labor

Organization

), as

the promotion and maintenance of highest degree of

physical, mental and social wellbeing of workers in all

occupations.

PDF created with pdfFactory Pro trial version

Occupational health should aim at the

}

promotion and maintenance of the physical,

mental and social well-being of workers in all

occupations;

}

the prevention among workers of departures

from health caused by their working conditions;

}

The protection of workers in their employment

from risks resulting from factors adverse to

health;

}

The placing and maintenance of the worker in an

occupational environment adapted to his

physiological and psychological equipment, or,

the adaptation of work to man and of each man

to his job

PDF created with pdfFactory Pro trial version

}

Occupational health is a Preventive medicine

and have the

same aim - the prevention of disease and

maintenance of the of health. And the levels

of application of preventive measures are the

same –

health promotion, specific protection, early

diagnosis and treatment, disability limitation

and rehabilitation;

PDF created with pdfFactory Pro trial version

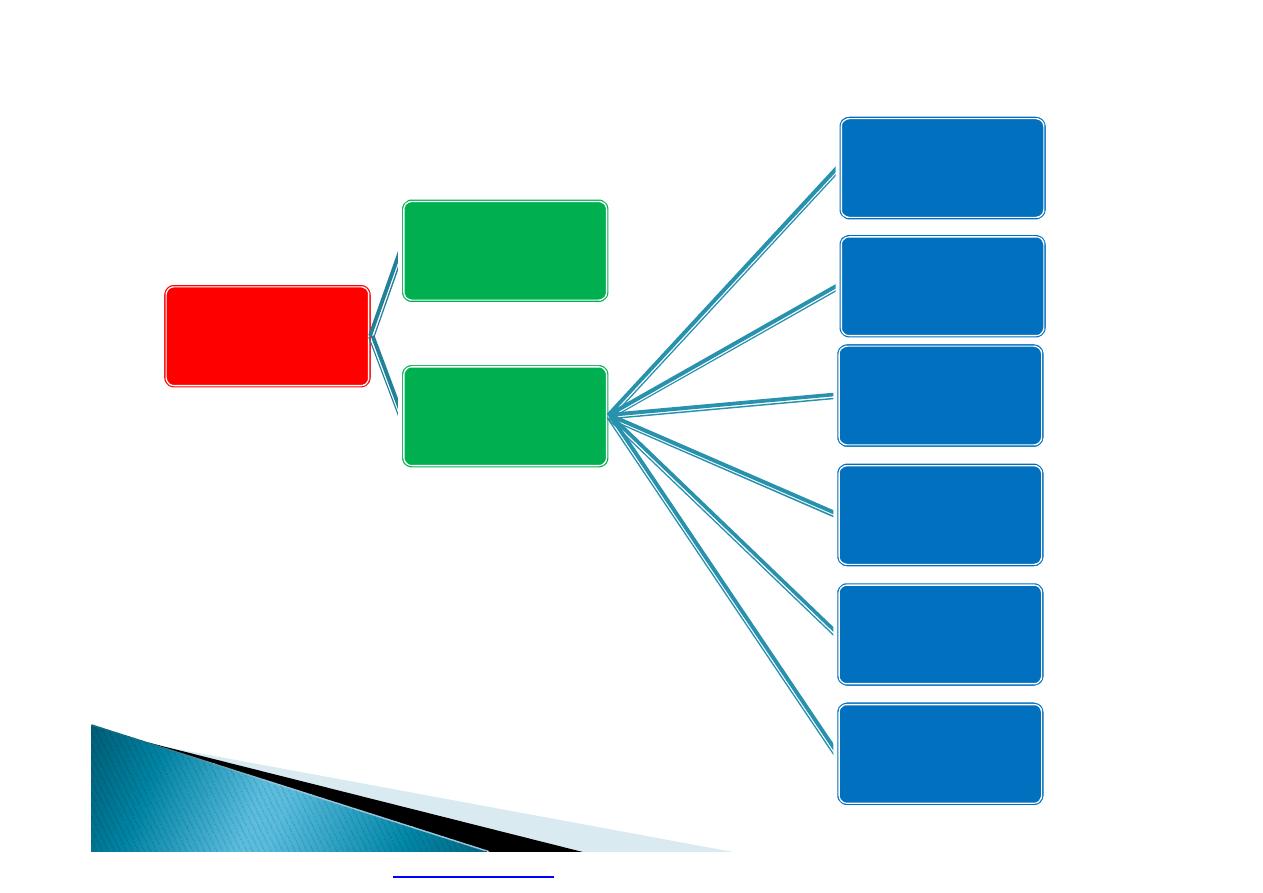

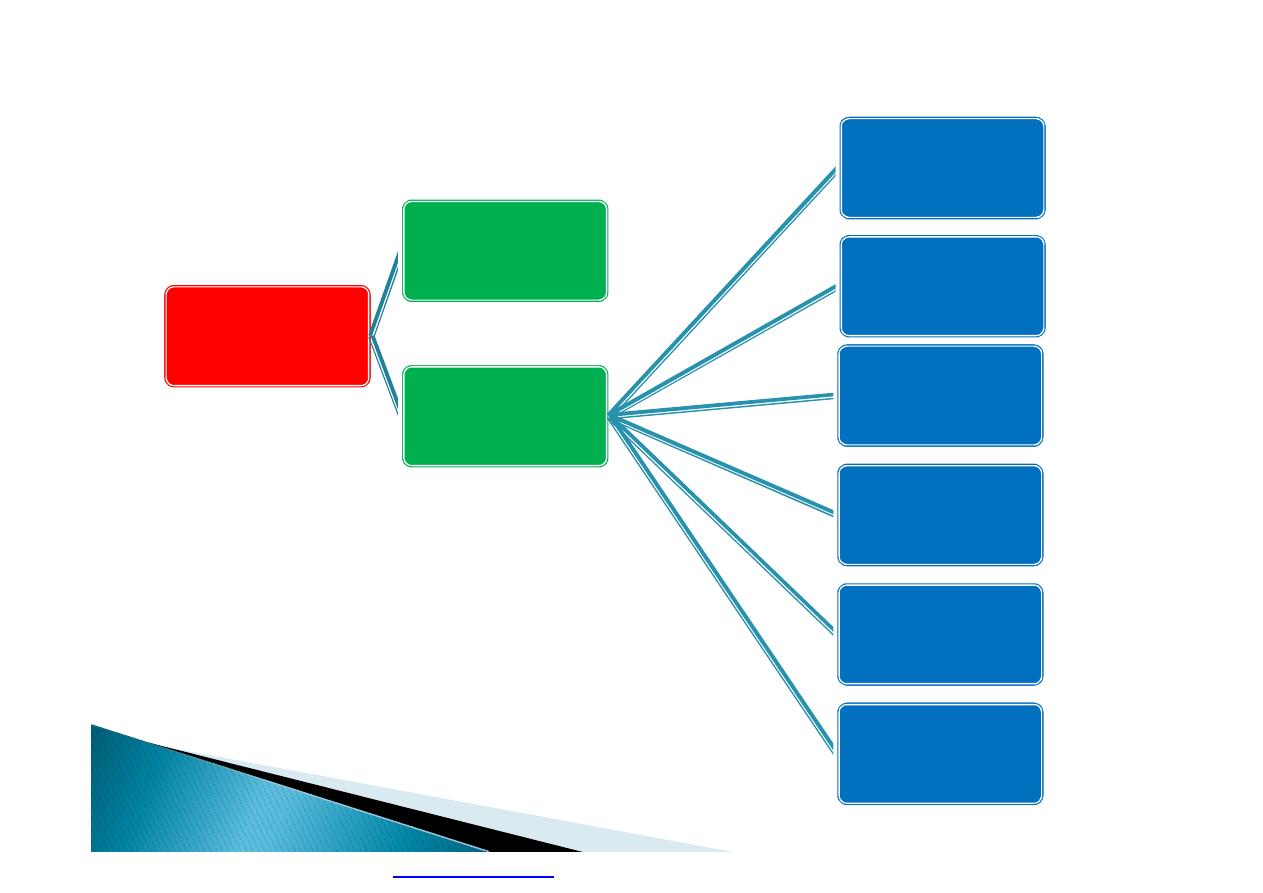

Occupational

Health

Occupational

Hygiene

Occupational

Medicine

Industrial

Medicine.

Agricultural

Medicine.

Navigation

Medicine.

Sport

Medicine.

Military

Medicine.

Aviation

Medicine.

PDF created with pdfFactory Pro trial version

}

The International Occupational Hygiene Association

(IOHA) refers to occupational hygiene

}

as the discipline of anticipating, recognizing,

evaluating and controlling health hazards in the

working environment with the objective of protecting

worker health and well-being and safeguarding the

community at large

PDF created with pdfFactory Pro trial version

The Practice of Occupational Hygiene

}

The recognition of the possible health

hazards in the work environment

}

The evaluation of hazards, which is the

process of assessing exposure and reaching

conclusions

}

Prevention and control of hazards, which is

the process of developing and implementing

strategies to eliminate, or reduce to

acceptable levels, the occurrence of harmful

agents and factors in the workplace, while

also accounting for environmental protection.

PDF created with pdfFactory Pro trial version

Activities of Occupational Medicine :

1. Medical exam. Of the workers;

a. pre employment exam.

b. periodic exam.

2. Health education.

3. First –aid facilities.

4. Rehabilitation.

5. Epidemiological studies and

medical records.

6. Environmental and biological

monitoring.

10 October 2019

٨

PDF created with pdfFactory Pro trial version

*

Types of occupational hazards :

1.

Physical hazards (noise, vibration,

temperature, electricity, radiation, light

and pressure ).

2.

Chemical hazards (dust, mists, fumes,

gases, fibers, vapors and liquids).

3.

Biological hazards (insects, mites, moulds,

yeasts, fungi, bacteria, viruses and

parasites) .

4.

Ergonomic : fitness of the work process

and work place to the workers (posture,

movement, repetitive motion and light) .

5.

Psychological hazards (tension, stress, and

phobia) .

6.

Accidents and mechanical hazards

.

10 October 2019

٩

PDF created with pdfFactory Pro trial version

1.

Occupational hazards can be controlled by a

variety of methods.

2.

The goal of controlling a hazard is to

prevent workers from being exposed to the

hazard.

3.

The most effective control measure is to

control hazards at the source by eliminating

the hazard or by substituting a hazardous

chemical, machine, work process, etc., with

a less dangerous one.

PDF created with pdfFactory Pro trial version

4.

It is important to recognize hazards and

health and safety problems in the

workplace.

5.

There are five general categories of control

measures: elimination, substitution,

engineering controls, administrative

controls and personal protective equipment.

6.

A combination of methods usually provides

a safer and healthier workplace than relying

on only one method.

7.

Personal protective equipment should be

the last choice in control measures.

PDF created with pdfFactory Pro trial version

}

Is the most effective method of control.

}

Elimination of a specific hazard or hazardous

work process, or preventing it from entering

the workplace (Eliminate hazards at the

“development stage”)

}

It is important to consider worker health and

safety when work processes are still in the

planning stages. For example, when

purchasing machines, safety should be the

first concern, not cost.

PDF created with pdfFactory Pro trial version

}

Machines that are not produced with the

proper guards on them may cost less to

purchase, but cost more in terms of

accidents, loss of production, compensation,

etc.

}

Unfortunately, many used machines that do

not meet safety standards are exported to

developing countries, causing workers to pay

the price with accidents, hearing loss from

noise, etc.

PDF created with pdfFactory Pro trial version

}

If a particularly dangerous chemical or work

process cannot be completely eliminated, then

try to replace it with a safer substitute

}

These materials can be more expensive to

purchase but they are safer for workers to

handle.

}

Ex:

}

less volatile (volatile liquids vaporize, or

evaporate easily) instead of a highly volatile one

}

many dry, dusty powders are also available in

brick, pellet, paste, flakes, oil damped powders,

and other forms that create less dust when

handled, and reduce the chance of inhaling the

dust.

PDF created with pdfFactory Pro trial version

}

detergent plus water-cleaning solutions

instead of organic solvents

}

leadless glazes in the ceramics industry

leadless pigments in paints

}

synthetic grinding wheels (such as aluminium

oxide, silicon carbide) instead of sandstone

wheels

}

vacuum cleaner when cleaning up toxic dust.

Never sweep toxic dust with brooms or

brushes

PDF created with pdfFactory Pro trial version

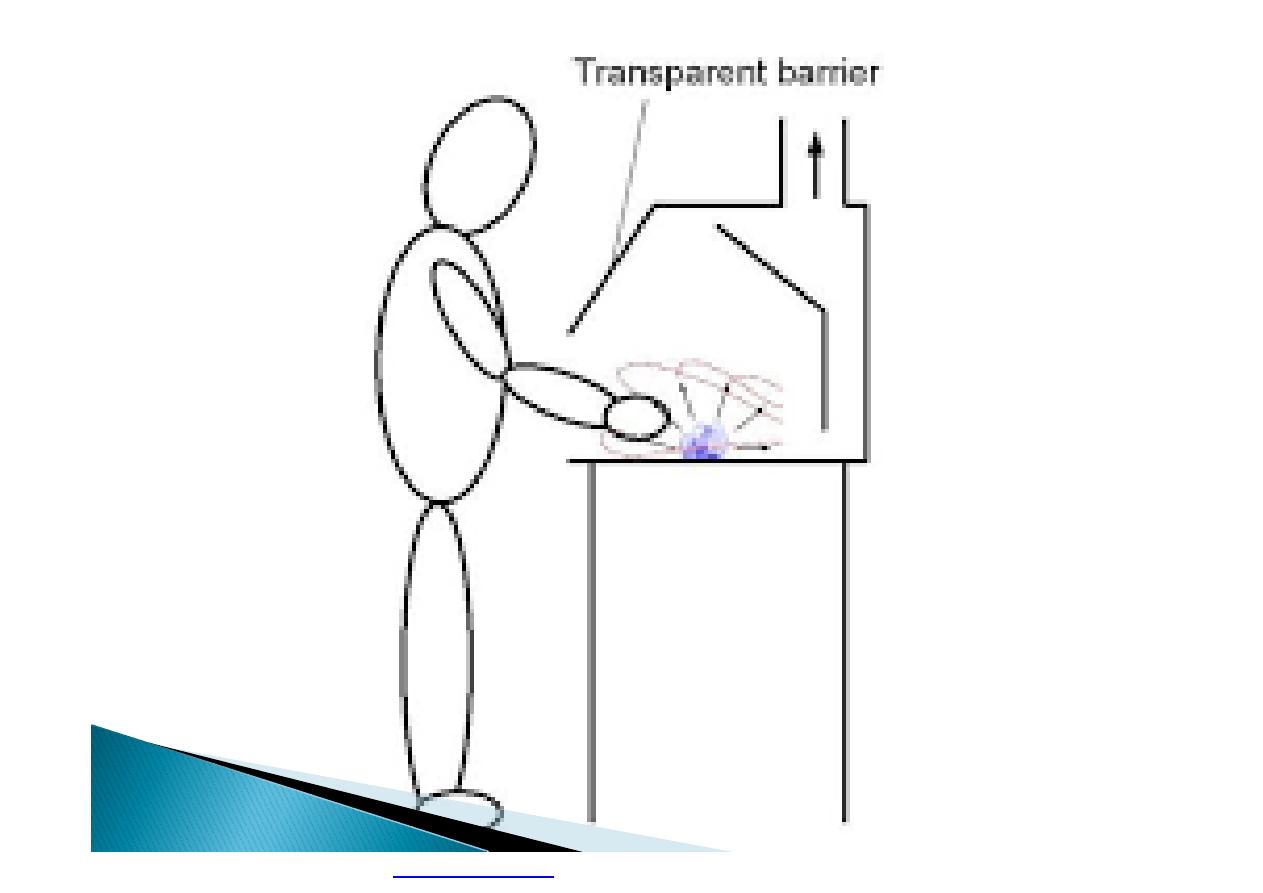

}

If a hazardous substance or work process

cannot be eliminated or substituted, then

enclosing it so workers are not exposed to

the hazard is the next best method of

control.

}

Many hazards can be controlled by partially

or totally enclosing the work process.

PDF created with pdfFactory Pro trial version

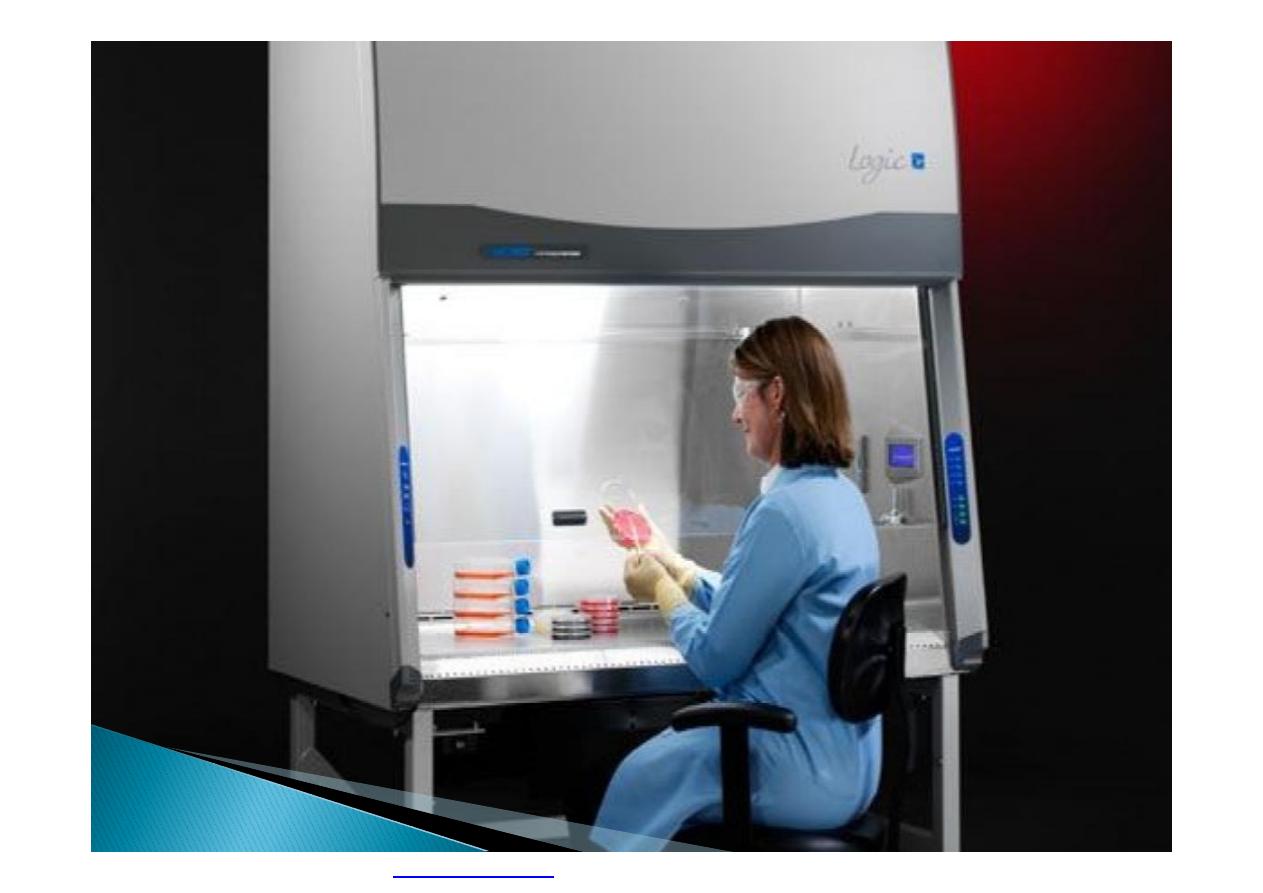

}

Highly toxic materials that can be released

into the air should be totally enclosed, usually

by using a mechanical handling device or a

closed glove system that can be operated

from the outside

}

Whole areas of a plant can be “enclosed” by

requiring workers to operate those areas

from a control room.

PDF created with pdfFactory Pro trial version

}

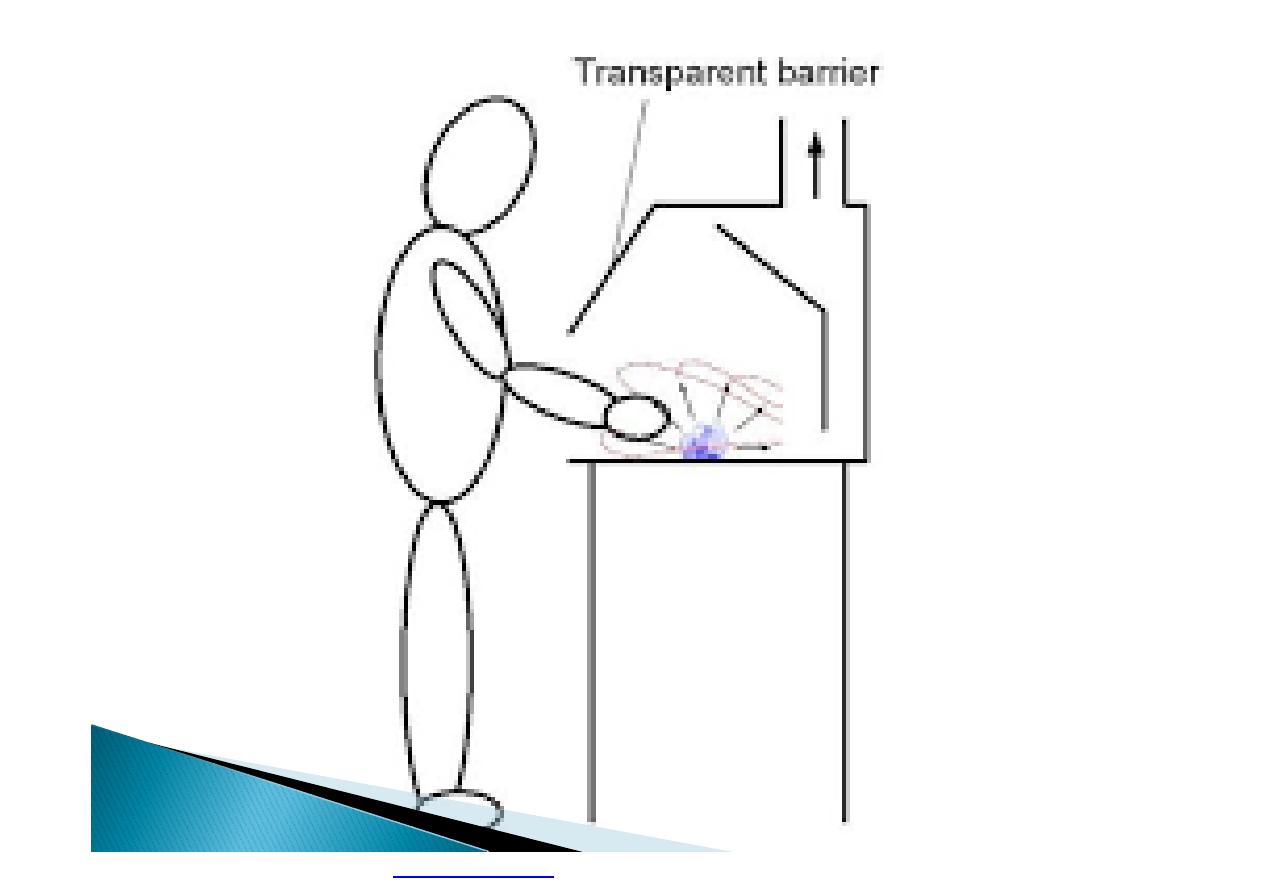

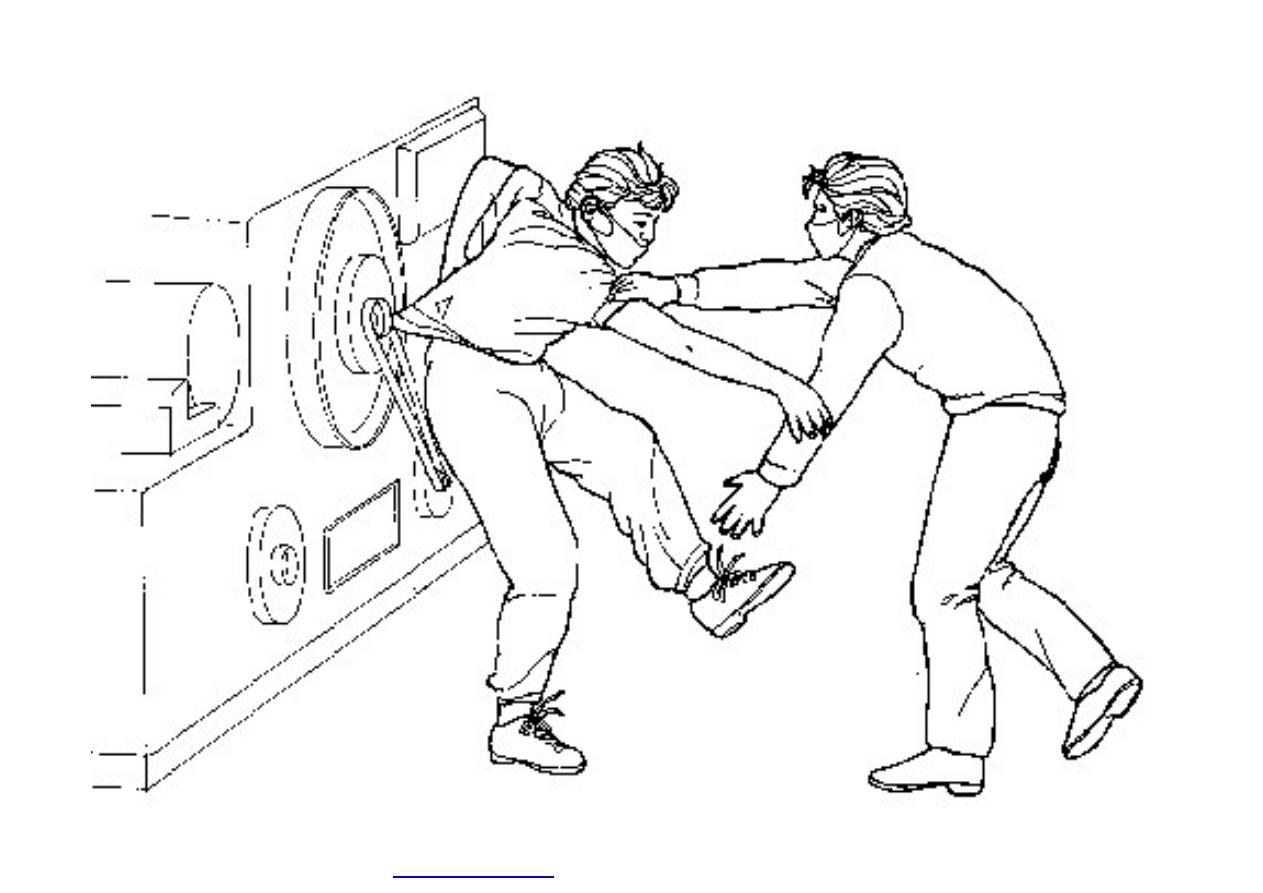

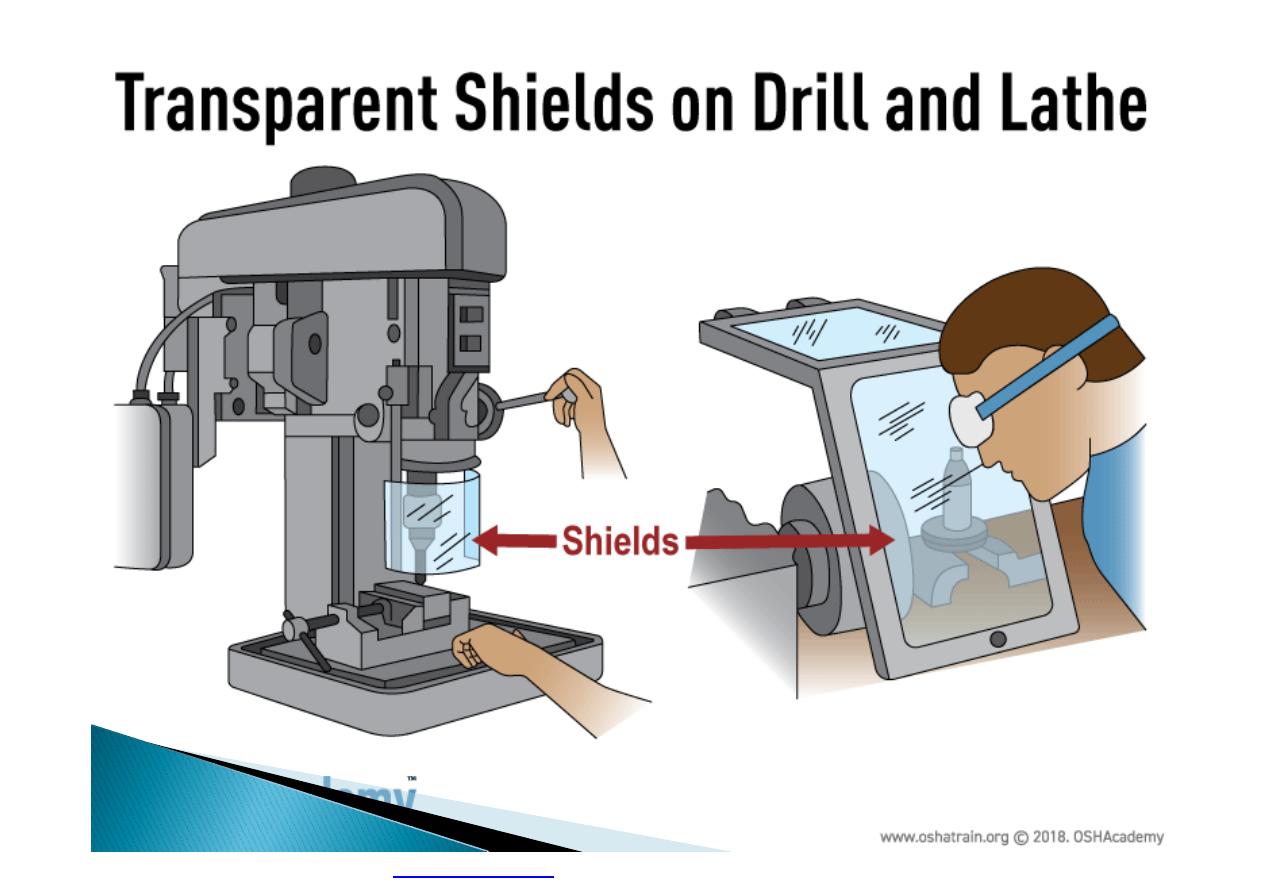

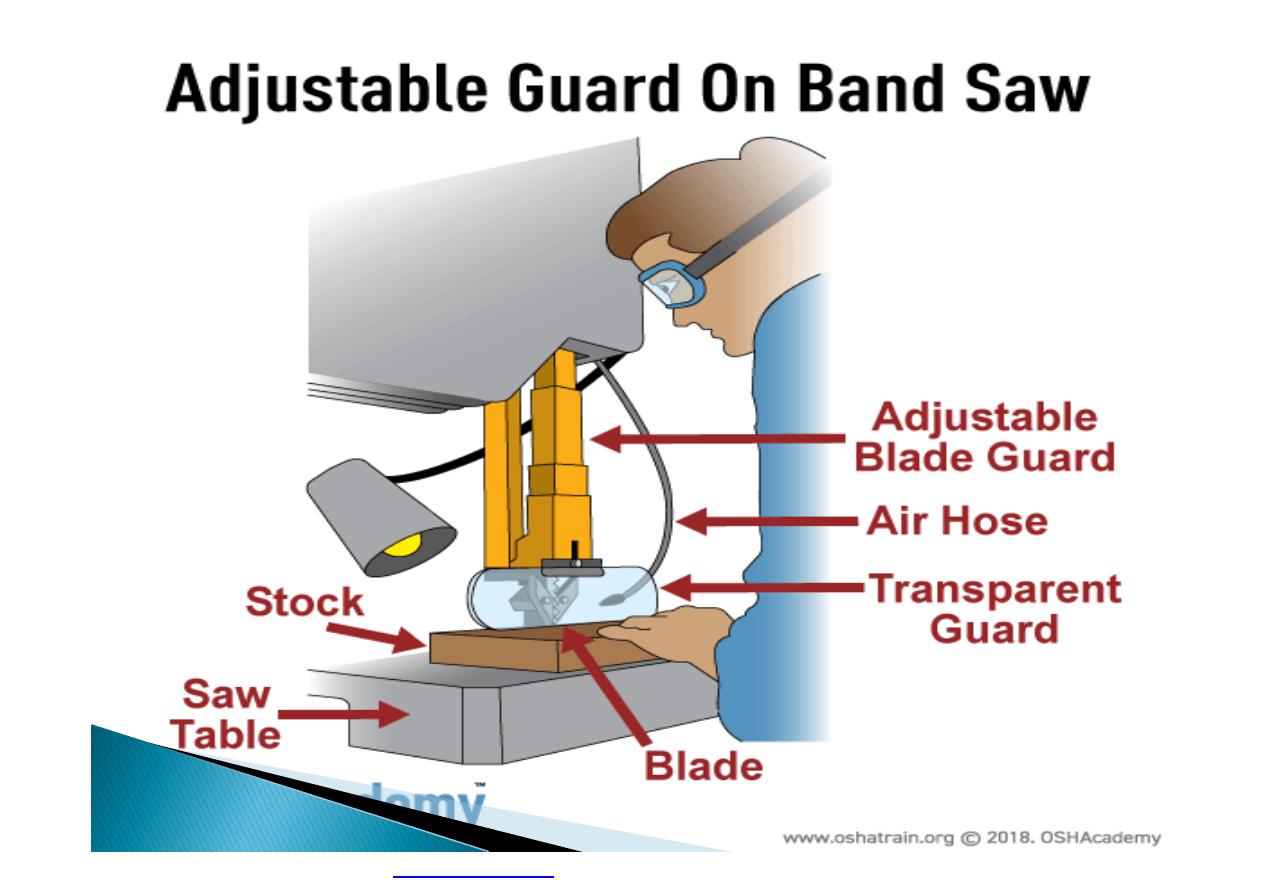

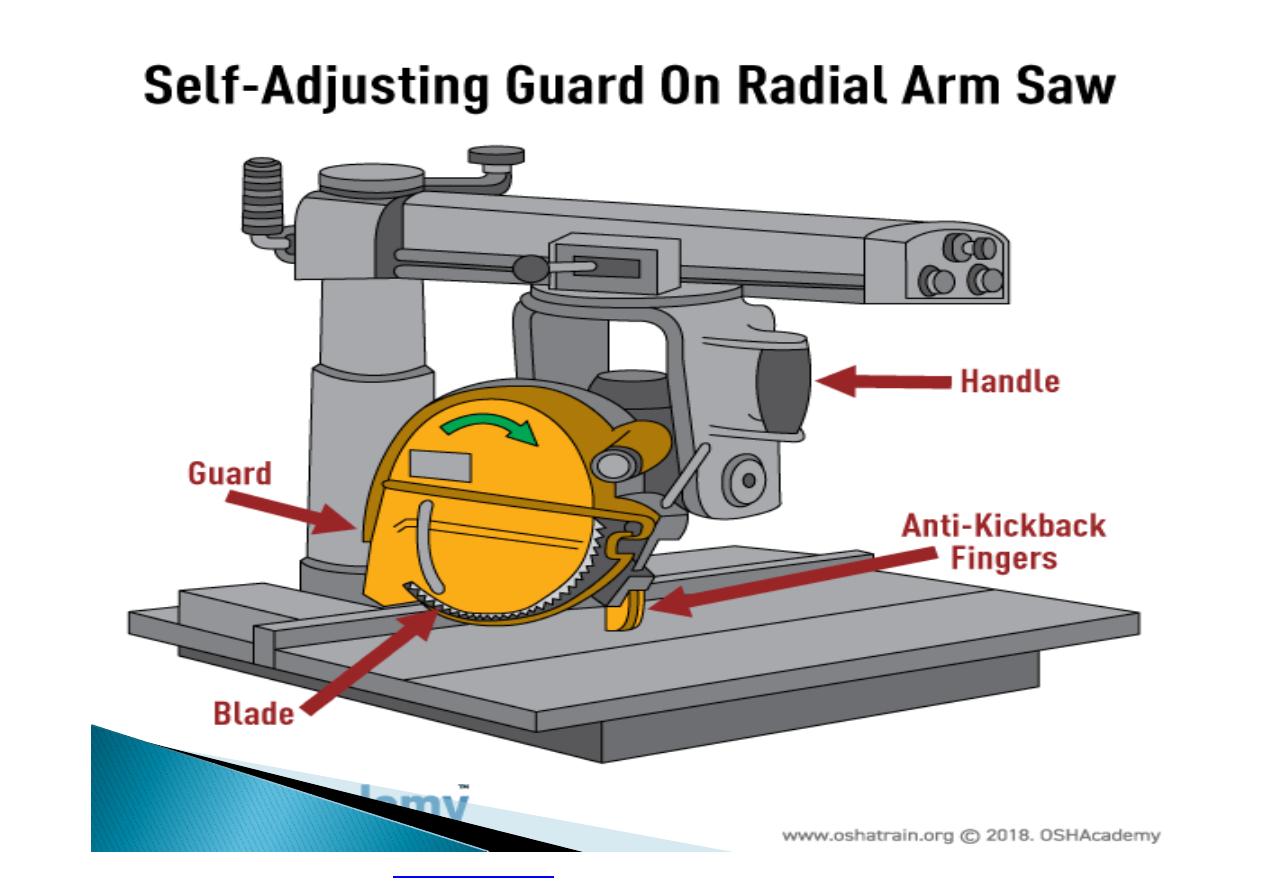

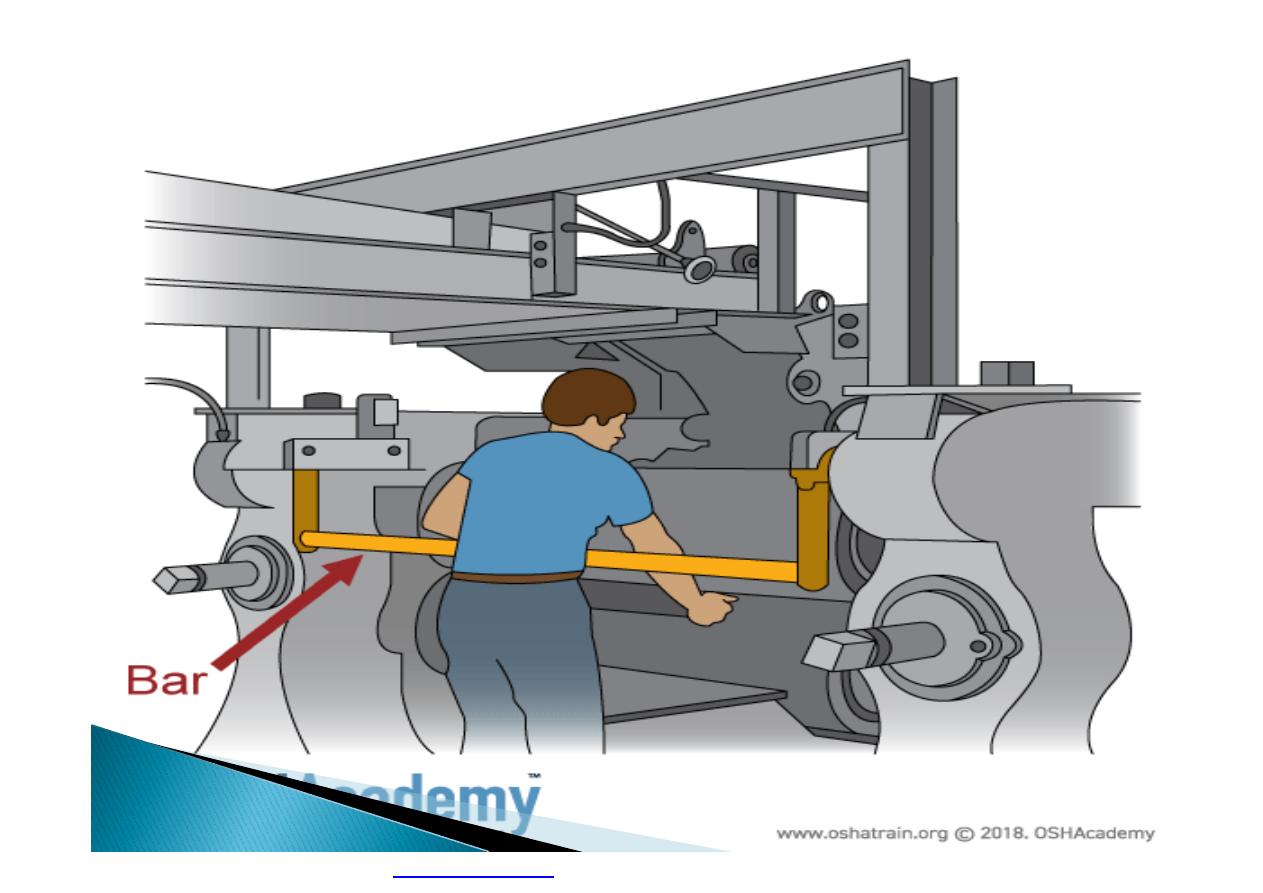

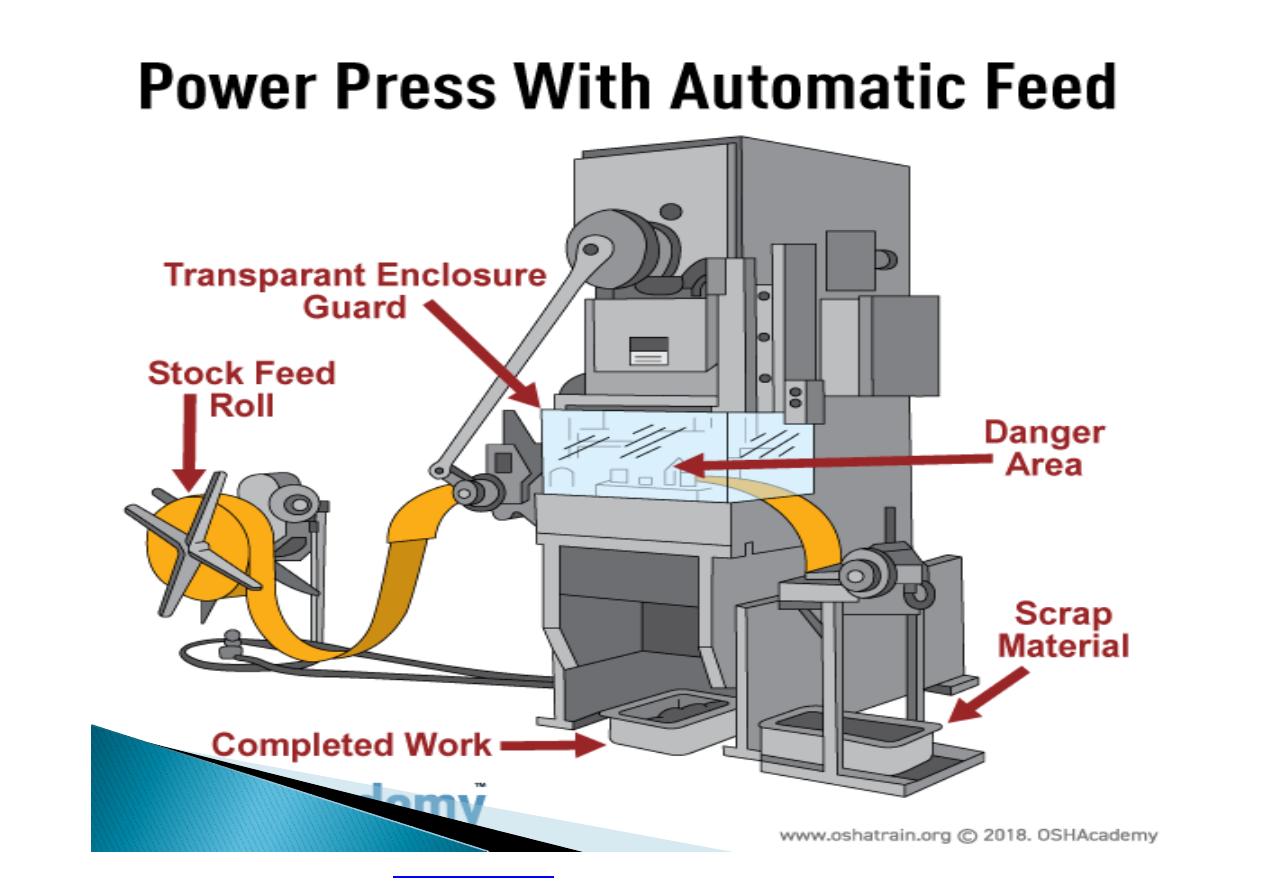

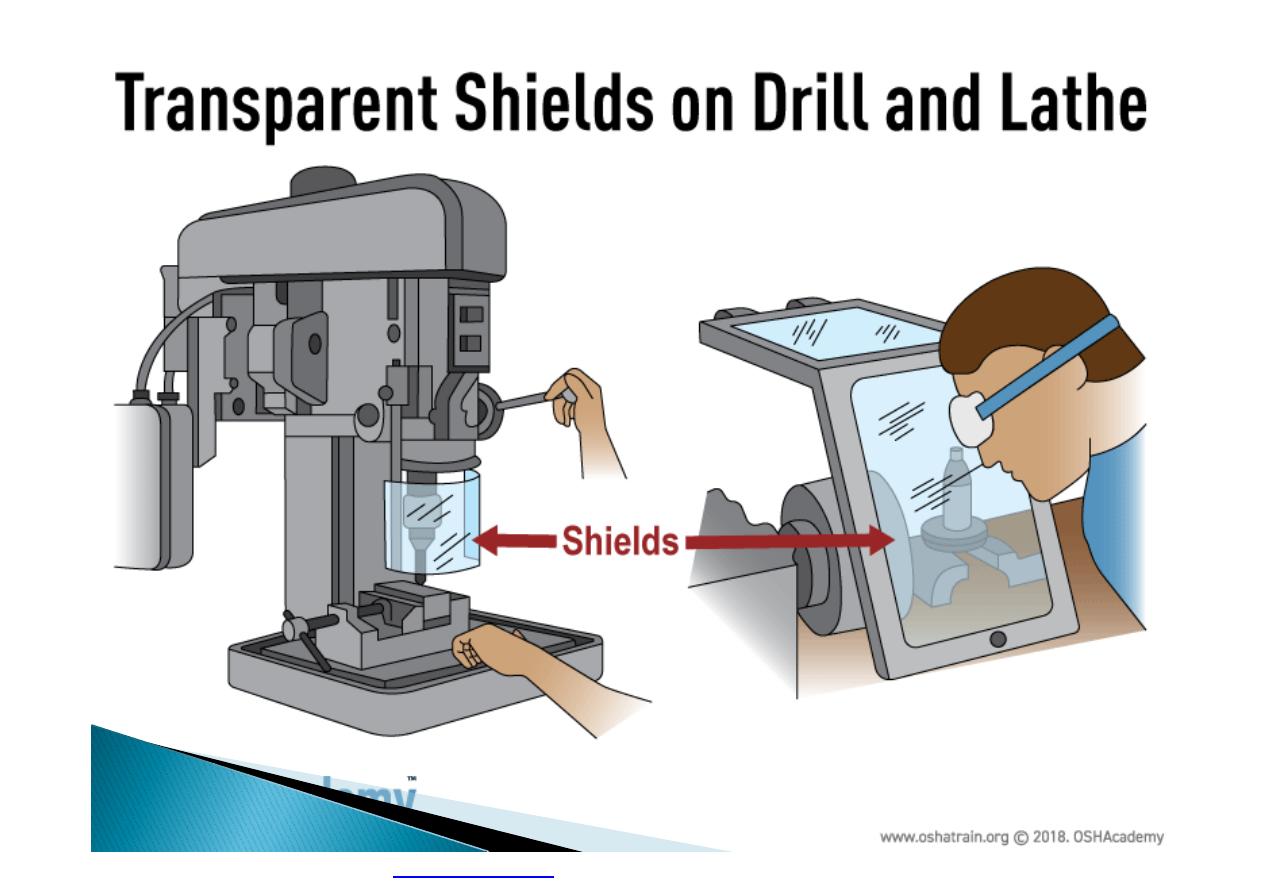

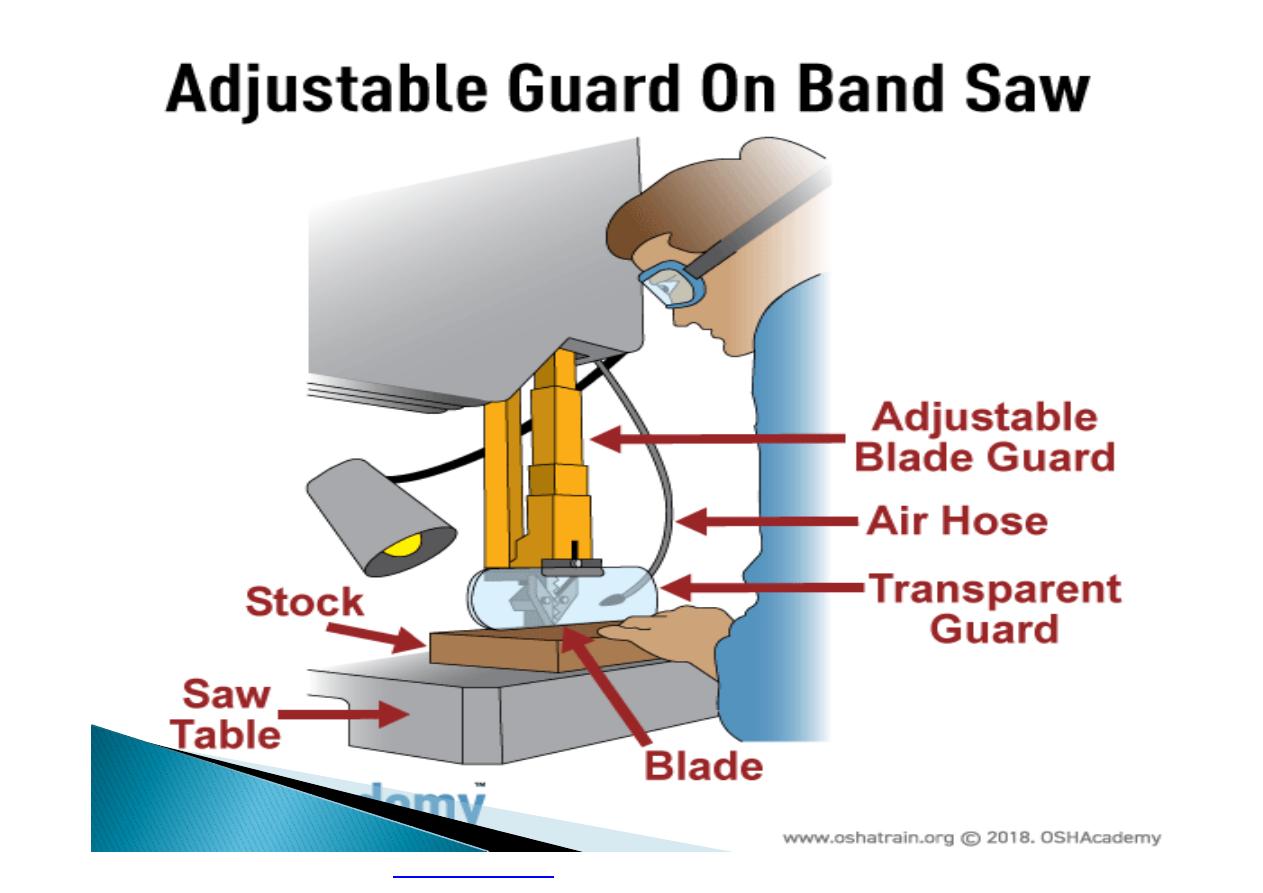

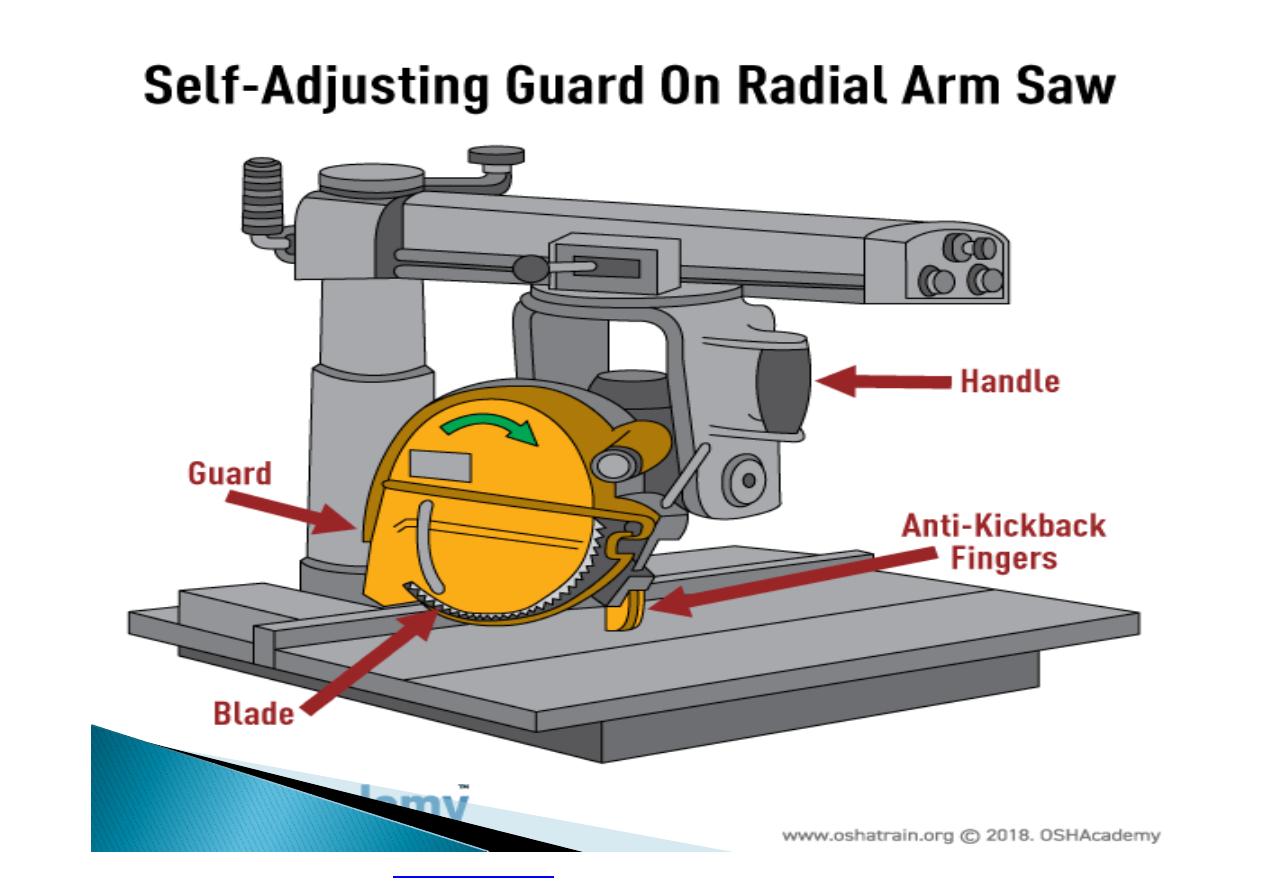

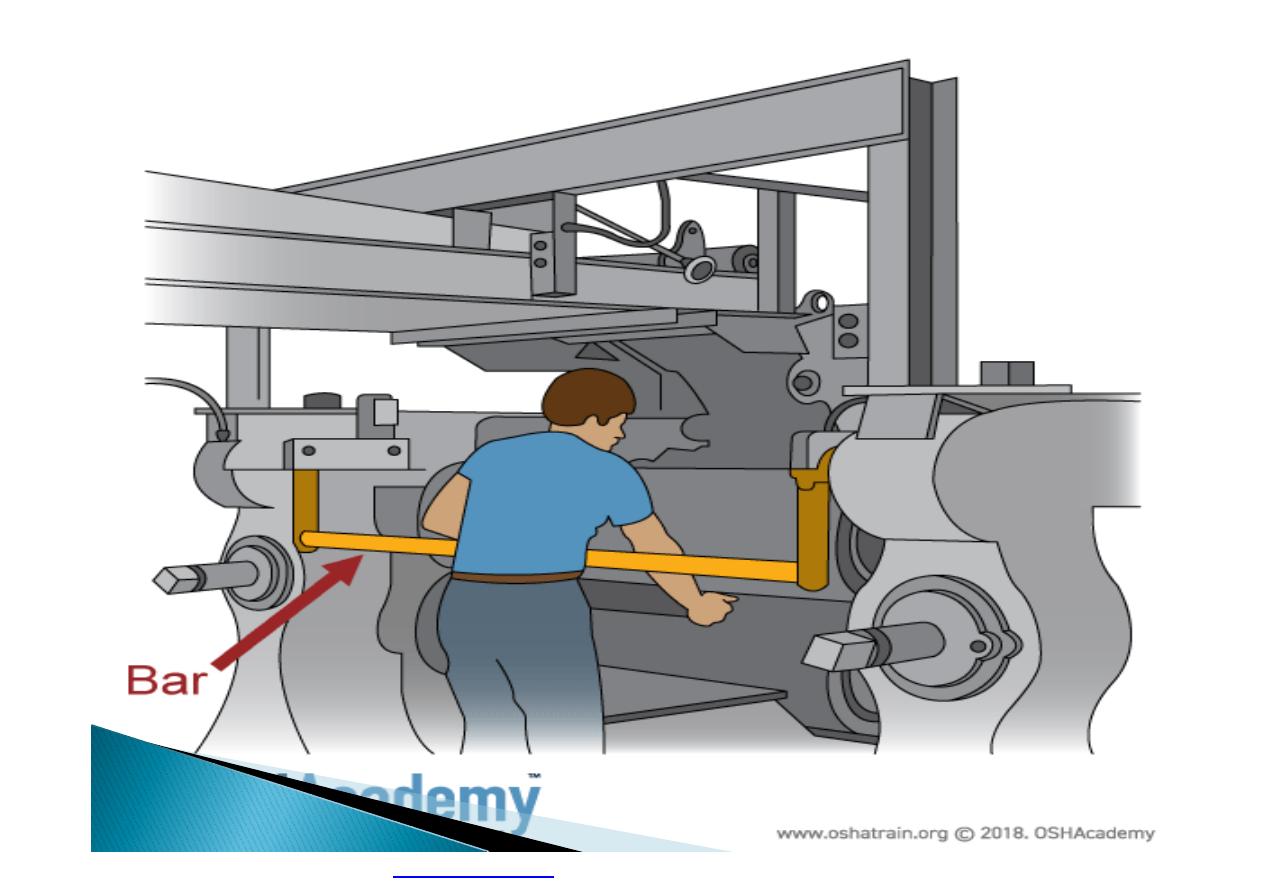

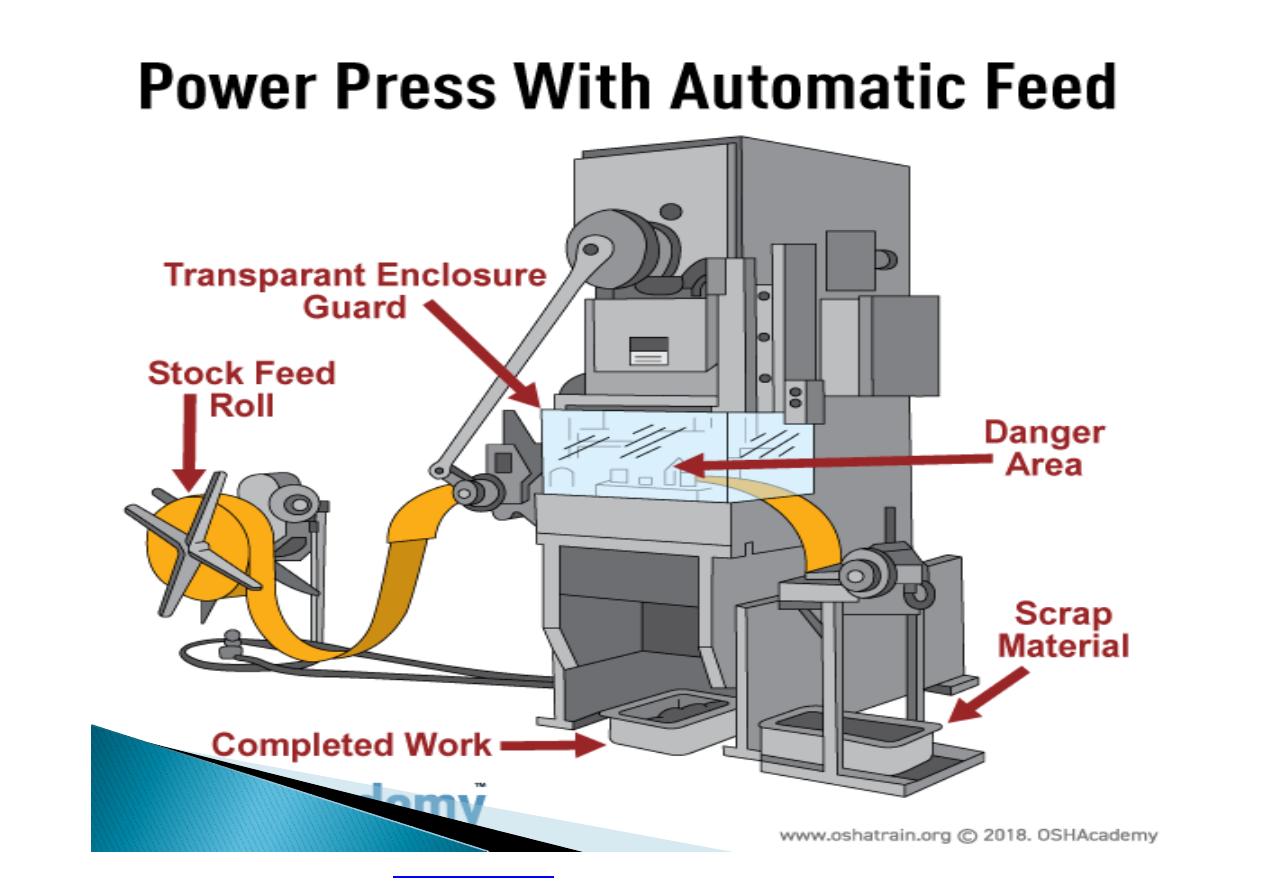

Machine guarding is another form of

enclosure that prevents workers from coming

into contact with dangerous parts of

machines.

}

Some of the areas of a machine that can

injure the worker are: the point of operation

pinch-points; sharp areas, such as blades;

exposed electrical components, which can

cause electrical shock or burns; presses,

which can crush; rotating parts; flying chips

and sparks.

PDF created with pdfFactory Pro trial version

}

Isolation can be an effective method of

control if a hazardous job can be moved to a

part of the workplace where fewer people will

be exposed,

}

or if a job can be changed to a shift when

fewer people are exposed (such as a weekend

or midnight shift).

}

The worker can also be isolated from a

hazardous job, for example by working in an

air-conditioned control booth.

}

isolating the work process or the worker does

not eliminate the hazard, which means

workers can still be exposed

PDF created with pdfFactory Pro trial version

}

Ventilation in the workplace can be used for

two reasons:

}

(1) to prevent the work environment from

being too hot, cold, dry or humid;

}

(2) to prevent contaminants in the air from

getting into the area where workers breathe.

PDF created with pdfFactory Pro trial version

}

Generally there are two categories of

ventilation:

1.

local exhaust ventilation

2.

general ventilation.

}

Ventilation should be used together with

other methods of control.

PDF created with pdfFactory Pro trial version

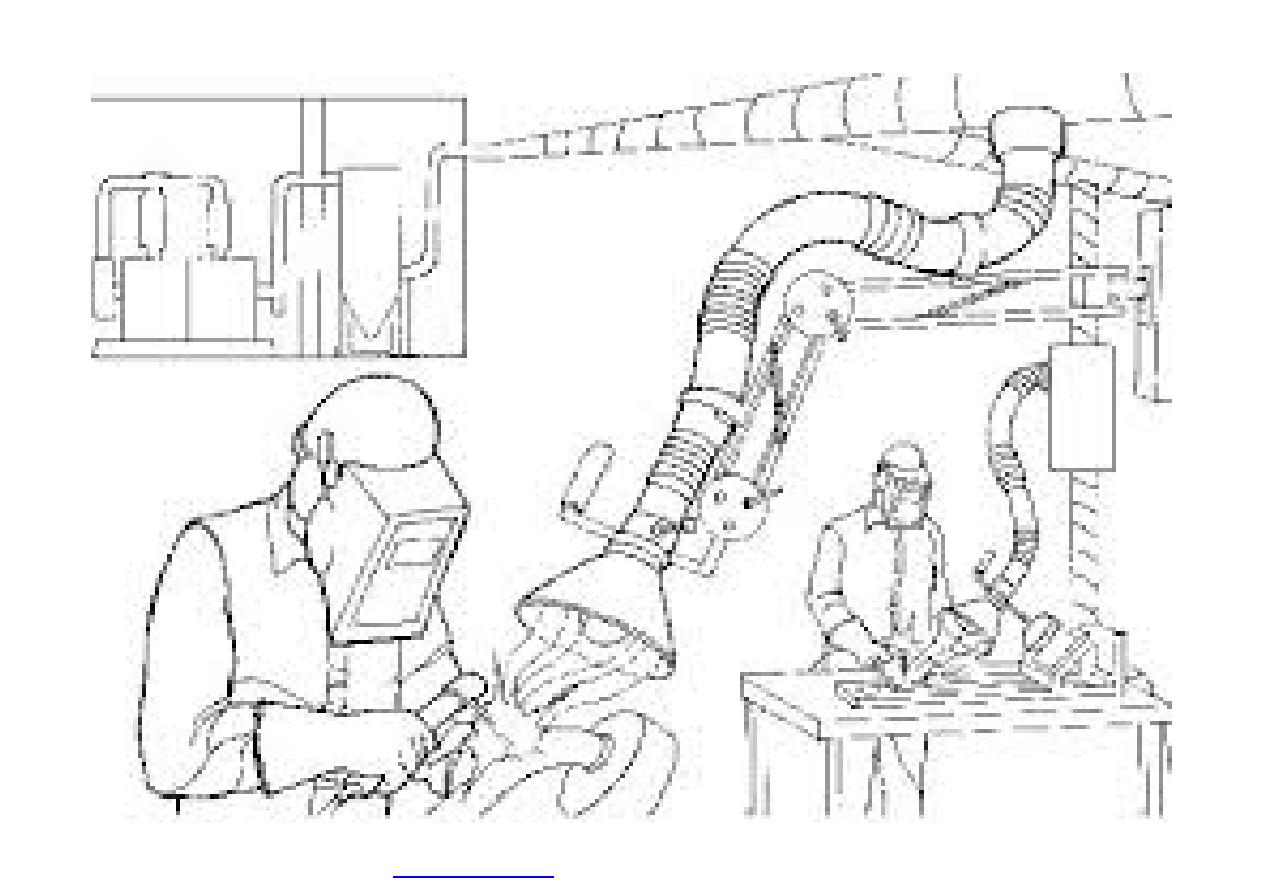

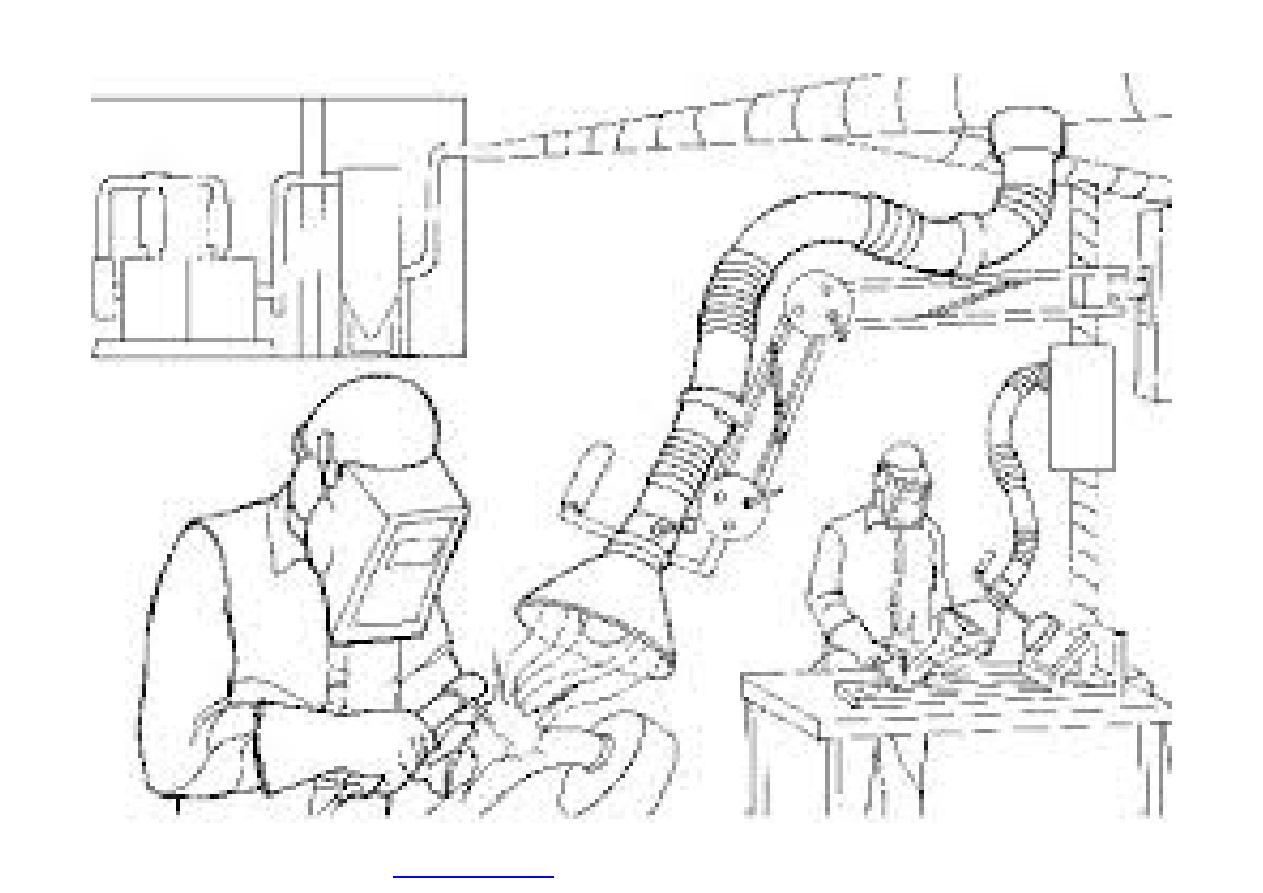

}

It usually uses suction, based on the principle of

a vacuum cleaner, to remove pollutants from the

air.

}

Exhaust ventilation can include the use of flexible

piping.

}

The end of the pipe that draws in the

contaminants (the inlet) must be placed as close

as possible to the source of the hazard in order

to be effective.

}

Flexible piping is often used to draw welding

fumes away from the worker and to draw away

contaminants in work areas that are hard to

reach.

PDF created with pdfFactory Pro trial version

}

Which is generally used for keeping the

workplace comfortable.

}

It is one of the least effective methods of

controlling hazards but one of the most

commonly used.

}

The purpose of any general ventilation

system is to remove contaminated air and

replace it with “fresh” air.

}

This system does not really remove

hazardous agents from the air; it simply

reduces the amounts in the air to levels that

are considered “safe” for breathing.

PDF created with pdfFactory Pro trial version

The effectiveness of a general ventilation

system depends on several things, including:

}

how quickly the hazardous agent is being

released into the air;

}

how much and how quickly fresh air is

coming in;

}

and how the contaminated air is being

removed.

PDF created with pdfFactory Pro trial version

By

Dr. Ashraf MA. Hussain

Msc./PhD. Community Medicine

PDF created with pdfFactory Pro trial version

Occupational Health

: is a multidisciplinary

activity, defined by

I.L.O.

(

International Labor

Organization

), as

the promotion and maintenance of highest degree of

physical, mental and social wellbeing of workers in all

occupations.

PDF created with pdfFactory Pro trial version

Occupational health should aim at the

}

promotion and maintenance of the physical,

mental and social well-being of workers in all

occupations;

}

the prevention among workers of departures

from health caused by their working conditions;

}

The protection of workers in their employment

from risks resulting from factors adverse to

health;

}

The placing and maintenance of the worker in an

occupational environment adapted to his

physiological and psychological equipment, or,

the adaptation of work to man and of each man

to his job

PDF created with pdfFactory Pro trial version

}

Occupational health is a Preventive medicine

and have the

same aim - the prevention of disease and

maintenance of the of health. And the levels

of application of preventive measures are the

same –

health promotion, specific protection, early

diagnosis and treatment, disability limitation

and rehabilitation;

PDF created with pdfFactory Pro trial version

Occupational

Health

Occupational

Hygiene

Occupational

Medicine

Industrial

Medicine.

Agricultural

Medicine.

Navigation

Medicine.

Sport

Medicine.

Military

Medicine.

Aviation

Medicine.

PDF created with pdfFactory Pro trial version

}

The International Occupational Hygiene Association

(IOHA) refers to occupational hygiene

}

as the discipline of anticipating, recognizing,

evaluating and controlling health hazards in the

working environment with the objective of protecting

worker health and well-being and safeguarding the

community at large

PDF created with pdfFactory Pro trial version

The Practice of Occupational Hygiene

}

The recognition of the possible health

hazards in the work environment

}

The evaluation of hazards, which is the

process of assessing exposure and reaching

conclusions

}

Prevention and control of hazards, which is

the process of developing and implementing

strategies to eliminate, or reduce to

acceptable levels, the occurrence of harmful

agents and factors in the workplace, while

also accounting for environmental protection.

PDF created with pdfFactory Pro trial version

Activities of Occupational Medicine :

1. Medical exam. Of the workers;

a. pre employment exam.

b. periodic exam.

2. Health education.

3. First –aid facilities.

4. Rehabilitation.

5. Epidemiological studies and

medical records.

6. Environmental and biological

monitoring.

10 October 2019

٨

PDF created with pdfFactory Pro trial version

*

Types of occupational hazards :

1.

Physical hazards (noise, vibration,

temperature, electricity, radiation, light

and pressure ).

2.

Chemical hazards (dust, mists, fumes,

gases, fibers, vapors and liquids).

3.

Biological hazards (insects, mites, moulds,

yeasts, fungi, bacteria, viruses and

parasites) .

4.

Ergonomic : fitness of the work process

and work place to the workers (posture,

movement, repetitive motion and light) .

5.

Psychological hazards (tension, stress, and

phobia) .

6.

Accidents and mechanical hazards

.

10 October 2019

٩

PDF created with pdfFactory Pro trial version

1.

Occupational hazards can be controlled by a

variety of methods.

2.

The goal of controlling a hazard is to

prevent workers from being exposed to the

hazard.

3.

The most effective control measure is to

control hazards at the source by eliminating

the hazard or by substituting a hazardous

chemical, machine, work process, etc., with

a less dangerous one.

PDF created with pdfFactory Pro trial version

4.

It is important to recognize hazards and

health and safety problems in the

workplace.

5.

There are five general categories of control

measures: elimination, substitution,

engineering controls, administrative

controls and personal protective equipment.

6.

A combination of methods usually provides

a safer and healthier workplace than relying

on only one method.

7.

Personal protective equipment should be

the last choice in control measures.

PDF created with pdfFactory Pro trial version

}

Is the most effective method of control.

}

Elimination of a specific hazard or hazardous

work process, or preventing it from entering

the workplace (Eliminate hazards at the

“development stage”)

}

It is important to consider worker health and

safety when work processes are still in the

planning stages. For example, when

purchasing machines, safety should be the

first concern, not cost.

PDF created with pdfFactory Pro trial version

}

Machines that are not produced with the

proper guards on them may cost less to

purchase, but cost more in terms of

accidents, loss of production, compensation,

etc.

}

Unfortunately, many used machines that do

not meet safety standards are exported to

developing countries, causing workers to pay

the price with accidents, hearing loss from

noise, etc.

PDF created with pdfFactory Pro trial version

}

If a particularly dangerous chemical or work

process cannot be completely eliminated, then

try to replace it with a safer substitute

}

These materials can be more expensive to

purchase but they are safer for workers to

handle.

}

Ex:

}

less volatile (volatile liquids vaporize, or

evaporate easily) instead of a highly volatile one

}

many dry, dusty powders are also available in

brick, pellet, paste, flakes, oil damped powders,

and other forms that create less dust when

handled, and reduce the chance of inhaling the

dust.

PDF created with pdfFactory Pro trial version

}

detergent plus water-cleaning solutions

instead of organic solvents

}

leadless glazes in the ceramics industry

leadless pigments in paints

}

synthetic grinding wheels (such as aluminium

oxide, silicon carbide) instead of sandstone

wheels

}

vacuum cleaner when cleaning up toxic dust.

Never sweep toxic dust with brooms or

brushes

PDF created with pdfFactory Pro trial version

}

If a hazardous substance or work process

cannot be eliminated or substituted, then

enclosing it so workers are not exposed to

the hazard is the next best method of

control.

}

Many hazards can be controlled by partially

or totally enclosing the work process.

PDF created with pdfFactory Pro trial version

}

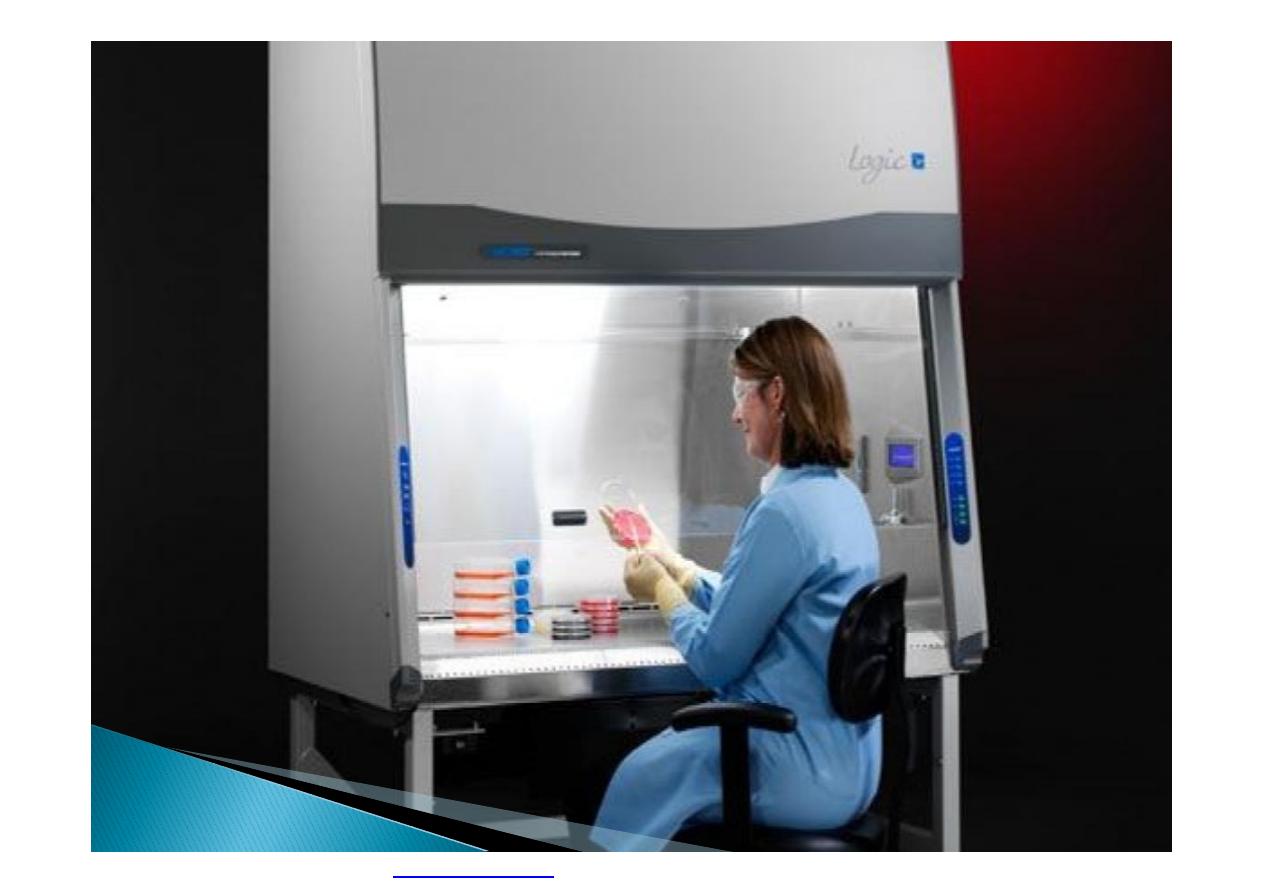

Highly toxic materials that can be released

into the air should be totally enclosed, usually

by using a mechanical handling device or a

closed glove system that can be operated

from the outside

}

Whole areas of a plant can be “enclosed” by

requiring workers to operate those areas

from a control room.

PDF created with pdfFactory Pro trial version

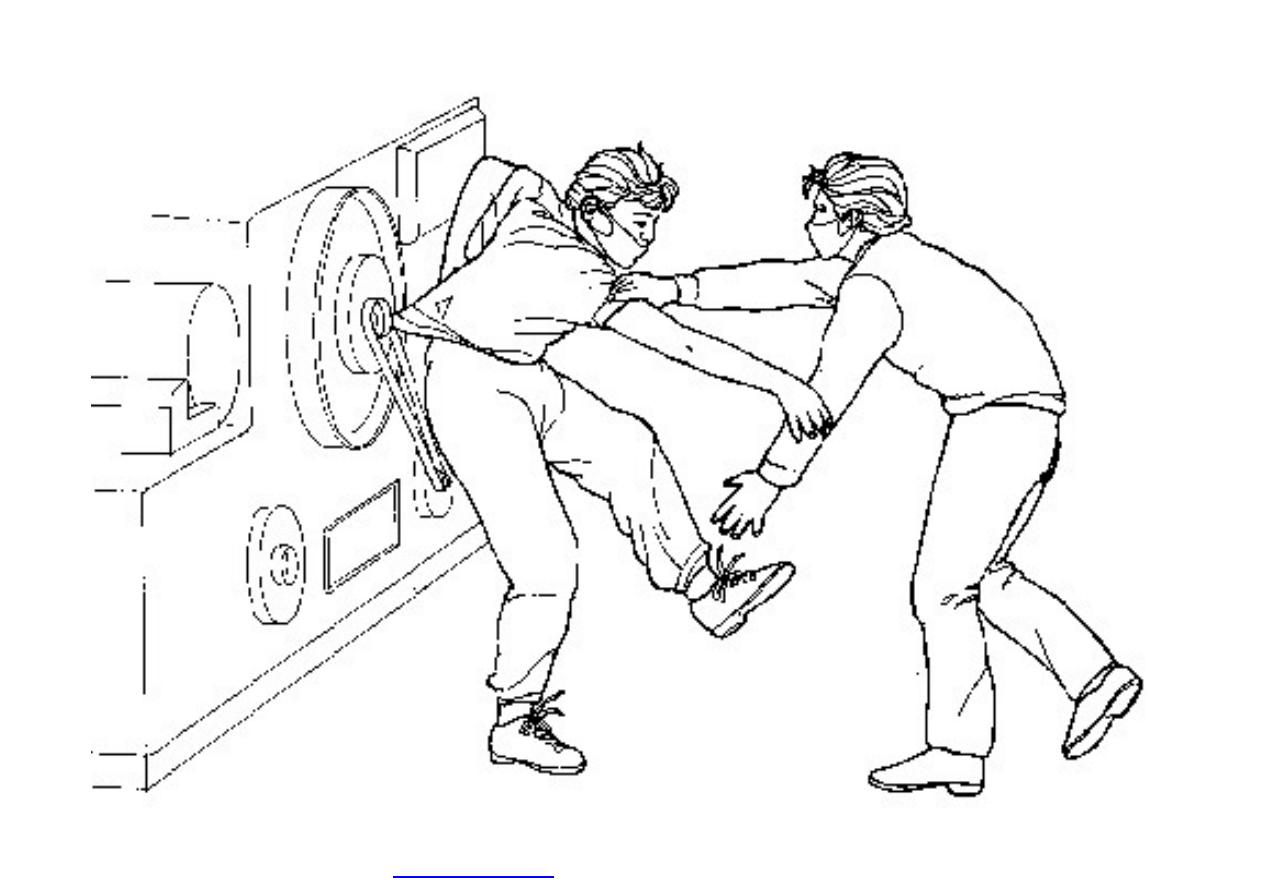

}

Machine guarding is another form of

enclosure that prevents workers from coming

into contact with dangerous parts of

machines.

}

Some of the areas of a machine that can

injure the worker are: the point of operation

pinch-points; sharp areas, such as blades;

exposed electrical components, which can

cause electrical shock or burns; presses,

which can crush; rotating parts; flying chips

and sparks.

PDF created with pdfFactory Pro trial version

}

Isolation can be an effective method of

control if a hazardous job can be moved to a

part of the workplace where fewer people will

be exposed,

}

or if a job can be changed to a shift when

fewer people are exposed (such as a weekend

or midnight shift).

}

The worker can also be isolated from a

hazardous job, for example by working in an

air-conditioned control booth.

}

isolating the work process or the worker does

not eliminate the hazard, which means

workers can still be exposed

PDF created with pdfFactory Pro trial version

}

Ventilation in the workplace can be used for

two reasons:

}

(1) to prevent the work environment from

being too hot, cold, dry or humid;

}

(2) to prevent contaminants in the air from

getting into the area where workers breathe.

PDF created with pdfFactory Pro trial version

}

Generally there are two categories of

ventilation:

1.

local exhaust ventilation

2.

general ventilation.

}

Ventilation should be used together with

other methods of control.

PDF created with pdfFactory Pro trial version

}

It usually uses suction, based on the principle of

a vacuum cleaner, to remove pollutants from the

air.

}

Exhaust ventilation can include the use of flexible

piping.

}

The end of the pipe that draws in the

contaminants (the inlet) must be placed as close

as possible to the source of the hazard in order

to be effective.

}

Flexible piping is often used to draw welding

fumes away from the worker and to draw away

contaminants in work areas that are hard to

reach.

PDF created with pdfFactory Pro trial version

}

Which is generally used for keeping the

workplace comfortable.

}

It is one of the least effective methods of

controlling hazards but one of the most

commonly used.

}

The purpose of any general ventilation

system is to remove contaminated air and

replace it with “fresh” air.

}

This system does not really remove

hazardous agents from the air; it simply

reduces the amounts in the air to levels that

are considered “safe” for breathing.

PDF created with pdfFactory Pro trial version

The effectiveness of a general ventilation

system depends on several things, including:

}

how quickly the hazardous agent is being

released into the air;

}

how much and how quickly fresh air is

coming in;

}

and how the contaminated air is being

removed.

PDF created with pdfFactory Pro trial version