1-Generation stations

1-1 What is Power Plant?

A power plant or a power generating station, is basically an industrial

location that is utilized for the generation and distribution of electric power in mass

scale, usually in the order of several 1000 Watts. These are generally located at the

sub-urban regions or several kilometers away from the cities or the load centers,

because of its requisites like huge land and water demand, along with several

operating constraints like the waste disposal etc. For this reason, a power

generating station has to not only take care of efficient generation but also the fact

that the power is transmitted efficiently over the entire distance. And that’s why,

the transformer switch yard to regulate transmission voltage also becomes an

integral part of the power plant.

At the center of it, however, nearly all power generating stations has an A.C.

generator or an alternator, which is basically a rotating machine that is equipped to

convert energy from the mechanical domain (rotating turbine) into electrical

domain by creating relative motion between a magnetic field and the conductors.

The energy source harnessed to turn the generator shaft varies widely, and is

chiefly dependent on the type of fuel used.

1-2Types of Power Station:

A power plant can be of several types depending mainly on the type of fuel

used. Since for the purpose of bulk power generation, only thermal, nuclear and

hydro power comes handy, Let us have a look in these types of power stations in

details.

1-2-1 Steam Power Station:

A thermal power station or a coal fired thermal power plant is by far, the

most conventional method of generating electric power with reasonably high

efficiency. It uses coal as the primary fuel to boil the water available to

superheated steam for driving the steam turbine. The steam turbine is then

mechanically coupled to an alternator rotor, the rotation of which results in the

generation of electric power.

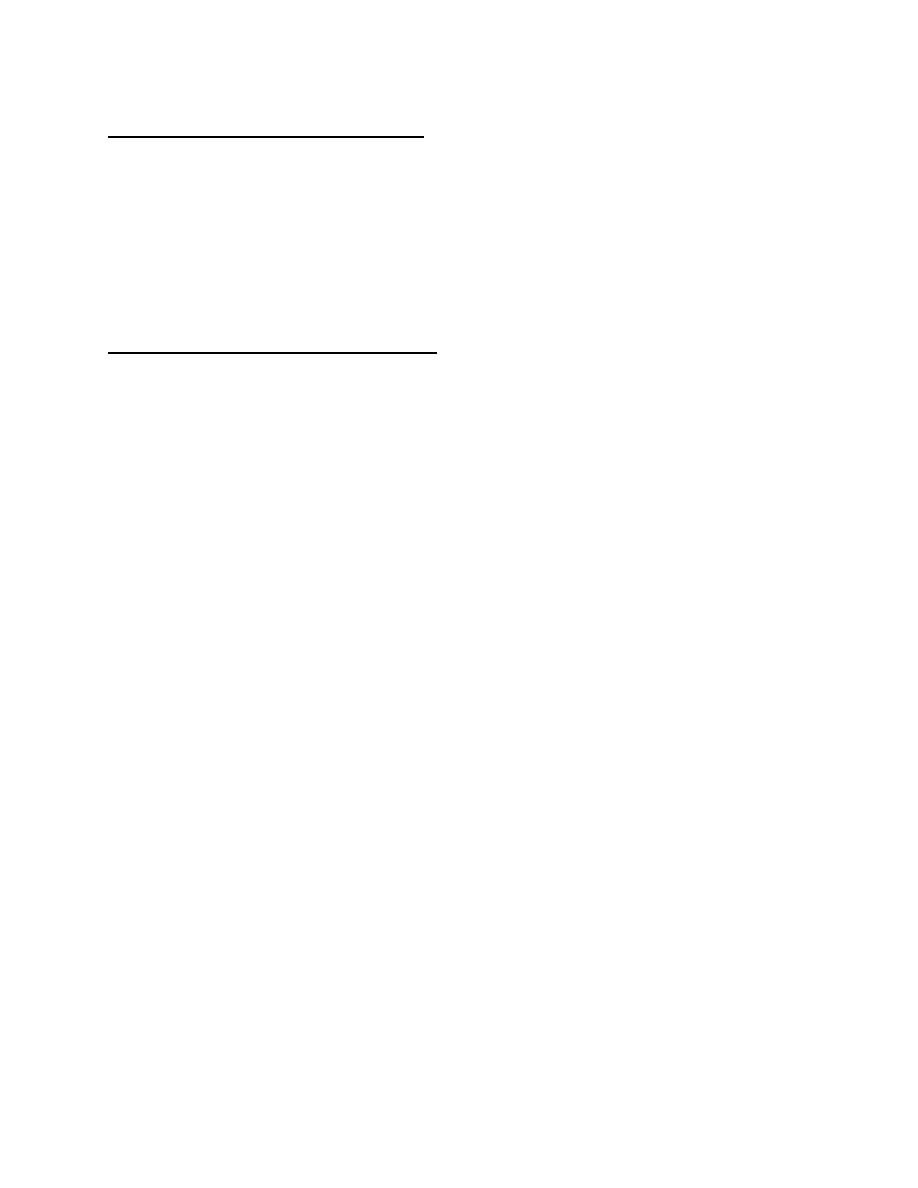

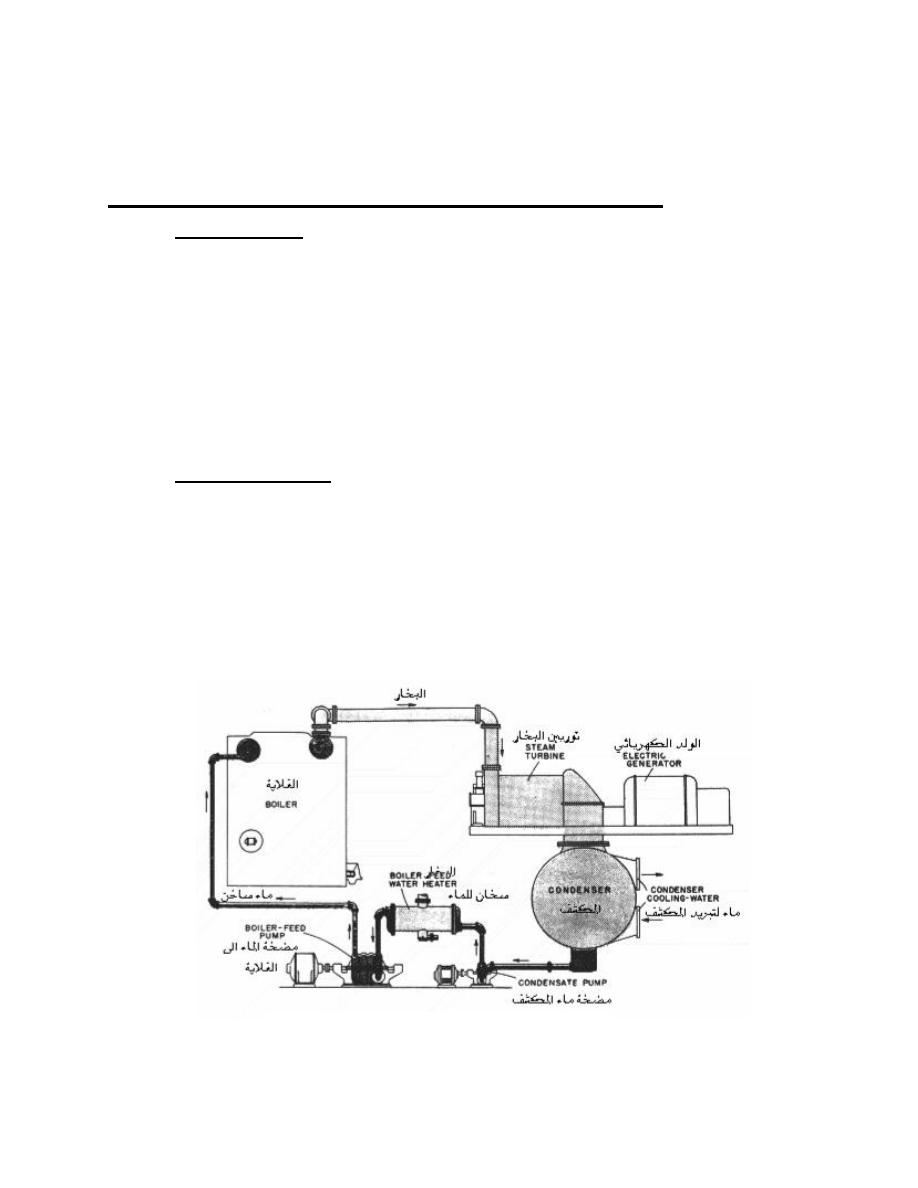

Theory of Steam Power Station:

The theory of thermal power station or working of thermal power station is

very simple. A power generation plant mainly consists of alternator runs with help

of steam turbine. The steam is obtained from high pressure boilers.

In coal thermal power plant, the steam is produced in high pressure in the

steam boiler due to burning of fuel (pulverized coal) in boiler furnaces. This steam

is further supper heated in a super heater. This supper heated steam then enters into

the turbine and rotates the turbine blades. The turbine is mechanically so coupled

with alternator that its rotor will rotate with the rotation of turbine blades. After

entering in turbine the steam pressure suddenly falls and corresponding volume of

the steam increases. After imparting energy to the turbine rotor the steam passes

out of the turbine blades into the condenser. In the condenser the cold water is

circulated with the help of pump which condenses the low pressure wet steam.

This condensed water is further supplied to low pressure water heater where the

low pressure steam increases the temperature of this feed water, it is again heated

in high pressure.

For better understanding we furnish every step of function of a thermal

power station as follows:-

1) First the pulverized coal is burnt into the furnace of steam boiler.

2) High pressure steam is produced in the boiler.

3) This steam is then passed through the super heater, where it further heated

up.

4) This supper heated steam is then entered into a turbine at high speed.

5) In turbine this steam force rotates the turbine blades that means here in

the turbine the stored potential energy of the high pressured steam is converted into

mechanical energy.

6) After rotating the turbine blades, the steam has lost its high pressure,

passes out of turbine blades and enters into a condenser.

7) In the condenser the cold water is circulated with help of pump which

condenses the low pressure wet steam.

8) This condensed water is then further supplied to low pressure water heater

where the low pressure steam increases the temperature of this feed water, it is then

again heated in a high pressure heater where the high pressure of steam is used for

heating.

9) The turbine in thermal power station acts as a prime mover of the

alternator.

Figure(1)

Line Diagram of Power Plant

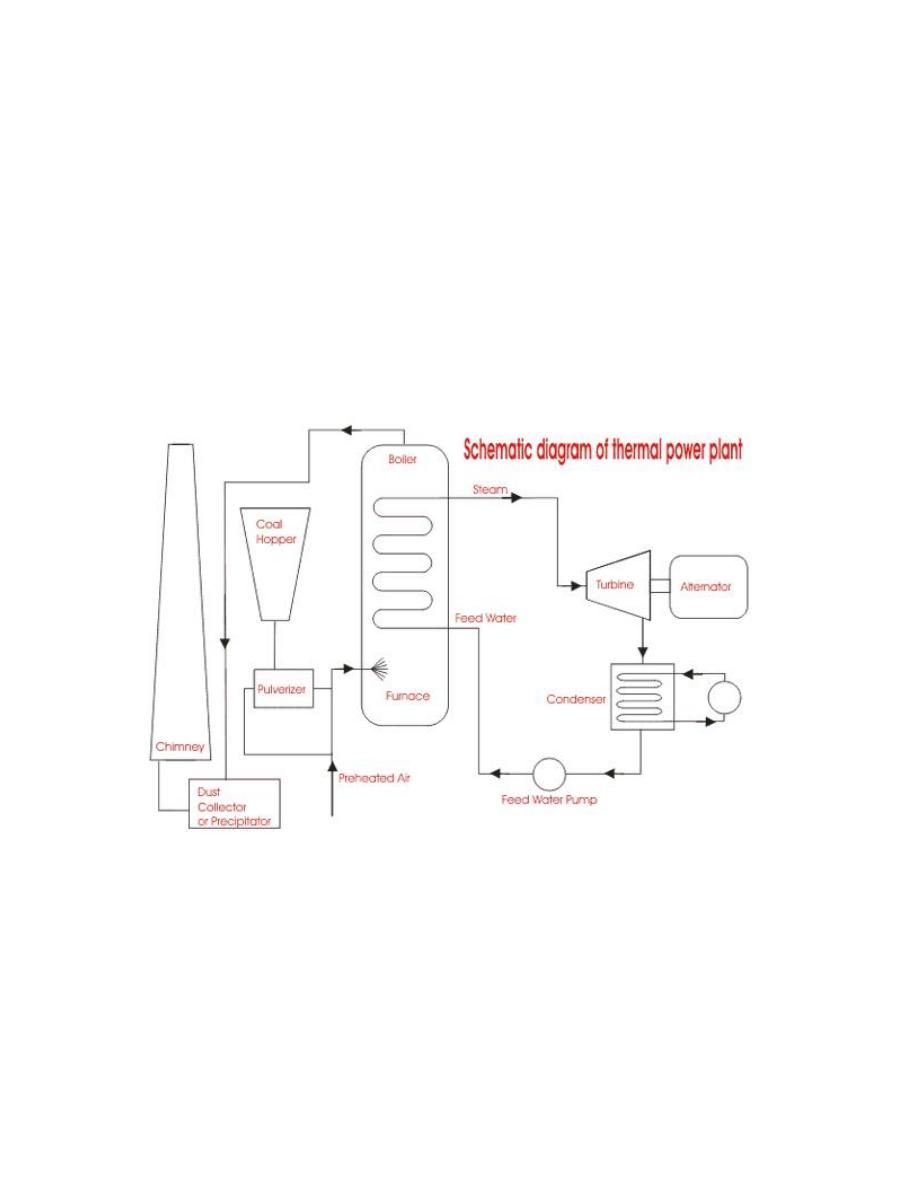

Efficiency of Steam Power Station or Plant:

The overall efficiency of a thermal power station or plant varies from 20% to

26% and it depends upon plant capacity.

Installed plant capacity

Average overall thermal efficiency

upto 1MW

4%

1MW to 10MW

12%

10MW to 50MW

16%

50MW to 100MW

24%

above 100MW

27%

Steam Power Plant Location:

Many points to be considered to decide the best optimized location of the

power plant .

1) The electric power generation plant must be constructed at such a place

where the cost of land is quite reasonable.

2) The land should be such that the acquisition of private property must be

minimum .

3) A large quantity of cooling water is required for the condensers etc of

thermal power generation plant, hence the plant should preferably situated beside

big source of natural water source such as big river.

4) Availability of huge amount of fuel at reasonable cost is one of the major

criterion for choosing plant location.

5) The plant should be established on plane land.

6) The soil should be such that it should provide good and firm foundation

of plant and buildings.

7) The thermal power plant location should not be very nearer to dense

locality as there are smoke, noise steam, water vapors etc.

8) There must be ample scope of development of future demand.

9) Place for ash handling plant for thermal power station should also be

available very nearby.

10) Very tall chimney of power station should not obstruct the traffics of air

ships.

Advantages & Disadvantages of Steam Power Station:

a)

Advantages:

1) Economical for low initial cost other than any generating plant.

2) Land required less than hydro power plant.

3) Since coal is main fuel & its cost is quite cheap than petrol/diesel so

generation cost is economical.

4) There are easier maintenance.

5) Thermal power plant can be installed in any location where transportation

& bulk of water are available.

b) Disadvantages:

1) The running cost for a thermal power station is comparatively high due

to fuel , maintenance etc.

2) Large amount of smoke causes air pollution .The thermal power station is

responsible for Global warming.

3) The heated water that comes from thermal power plant has an adverse

effect on the lives in the water and disturbs the ecology.

4) Overall efficiency of thermal power plant is low like less 30%.

Figure(2)

Steam Power Plant

1-2-2 Gas Power Station:

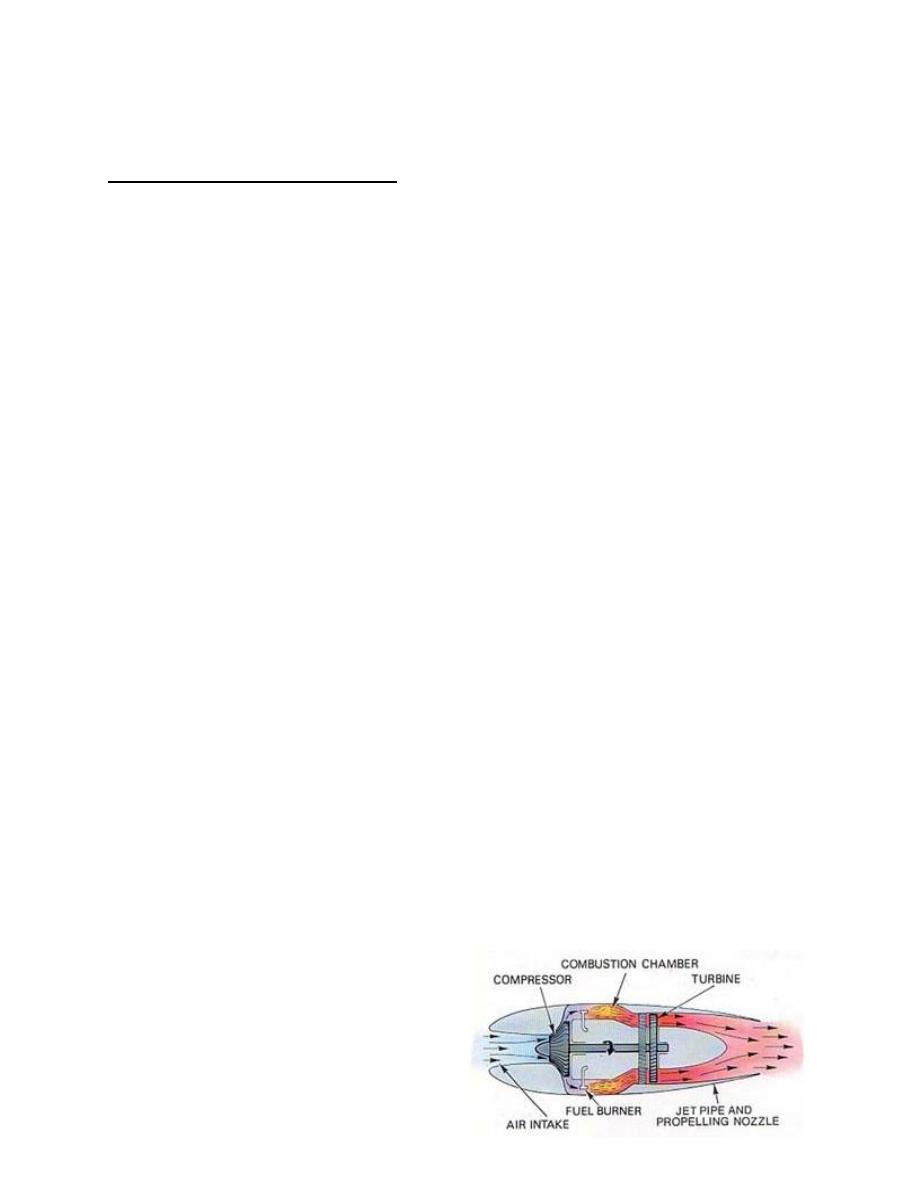

Gas turbine engines derive their power from burning fuel in a combustion

chamber and using the fast flowing combustion gases to drive a turbine in much

the same way as the high pressure steam drives a steam turbine.

One major difference however is that the gas turbine has a second turbine

acting as an air compressor mounted on the same shaft. The air turbine

(compressor) draws in air, compresses it and feeds it at high pressure into the

combustion chamber increasing the intensity of the burning flame.

It is a positive feedback mechanism. As the gas turbine speeds up, it also

causes the compressor to speed up forcing more air through the combustion

chamber which in turn increases the burn rate of the fuel sending more high

pressure hot gases into the gas turbine increasing its speed even more.

Uncontrolled runaway is prevented by controls on the fuel supply line which limit

the amount of fuel fed to the turbine thus limiting its speed.

Figure(3)

Gas Power Plant

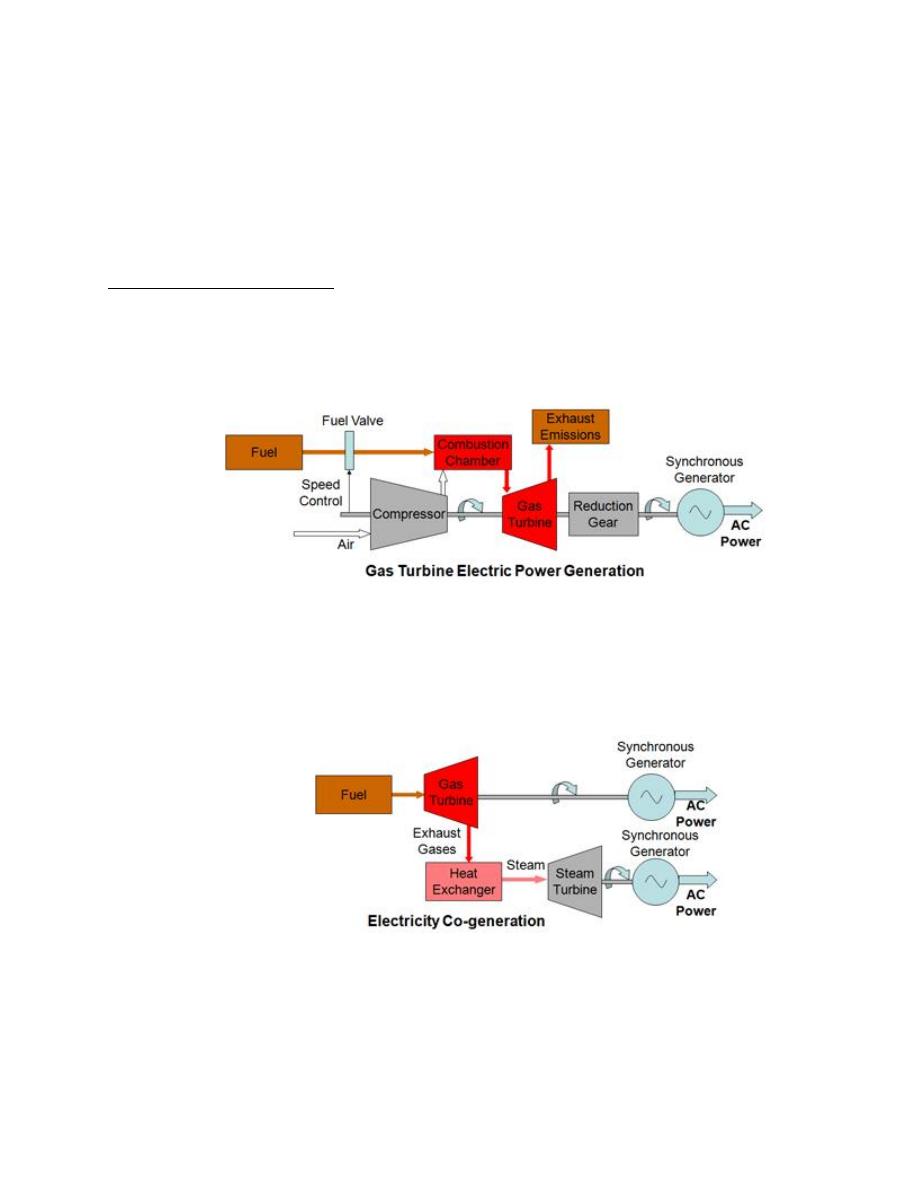

The thermodynamic process used by the gas turbine is known as the Brayton

cycle. Analogous to the Carnot cycle in which the efficiency is maximised by

increasing the temperature difference of the working fluid between the input and

output of the machine, the Brayton cycle efficiency is maximised by increasing the

pressure difference across the machine. The gas turbine is comprised of three main

components: a compressor, a combustor, and a turbine. The working fluid, air, is

compressed in the compressor (adiabatic compression - no heat gain or loss), then

mixed with fuel and burned by the combustor under constant pressure conditions in

the combustion chamber (constant pressure heat addition). The resulting hot gas

expands through the turbine to perform work (adiabatic expansion). Much of

the power produced in the turbine is used to run the compressor and the rest is

available to run auxiliary equipment and do useful work. The system is an open

system because the air is not reused so that the fourth step in the cycle, cooling the

working fluid, is omitted .

Gas turbines have a very high power to weight ratio and are lighter and

smaller than internal combustion engines of the same power. Though they are

mechanically simpler than reciprocating engines, their characteristics of high speed

and high temperature operation require high precision components and exotic

materials making them more expensive to manufacture

Turbine Configurations

Gas turbine power generators are used in two basic configurations

Simple Systems

consisting of the gas turbine driving an

electrical power generator.

Combined Cycle Systems

which are designed for maximum

efficiency in which the hot exhaust gases from the gas turbine are

used to raise steam to power a steam turbine with both turbines being

connected to electricity generators.

Advantages & Disadvantages Of Gas Turbine Plants:

a) Advantages

1. They are more compact, since fuel is burnt directly in the small

combustion Chamber in the gas turbine rather than in a bulky boiler.

2. Gas Turbine has no condenser.

3. They can be started and take more load quickly (i.e.15 - 30 min).

4. They are simpler in design and easy to maintain.

5. They consume less metal and other materials for the same capacity.

6. They cost less.

7.

Unlike steam turbines , they require very less water for cooling.

8. Gas Turbine is more suitable for power generation, where water

scarcity exists or the water is more precious.

b) Disadvantages:

1. They have a lower specific power .

2. They have lower efficiency at the modern state of progress.

3. They have a shorter service life .

4. They are more sensitive to fuel quality .

1-2-3 Hydro Power Plant :

Power system mainly contains three parts namely generation, transmission

and distribution. Generation means how to generate electricity from the available

source and there are various methods to generate electricity but in this article we

only focused on generation of electricity by the means of hydro or water (hydro

power plant). As we know that the power plant is defined as the place where power

is generated from a given source, so here the source is hydro that’s why we called

it hydro power plant.

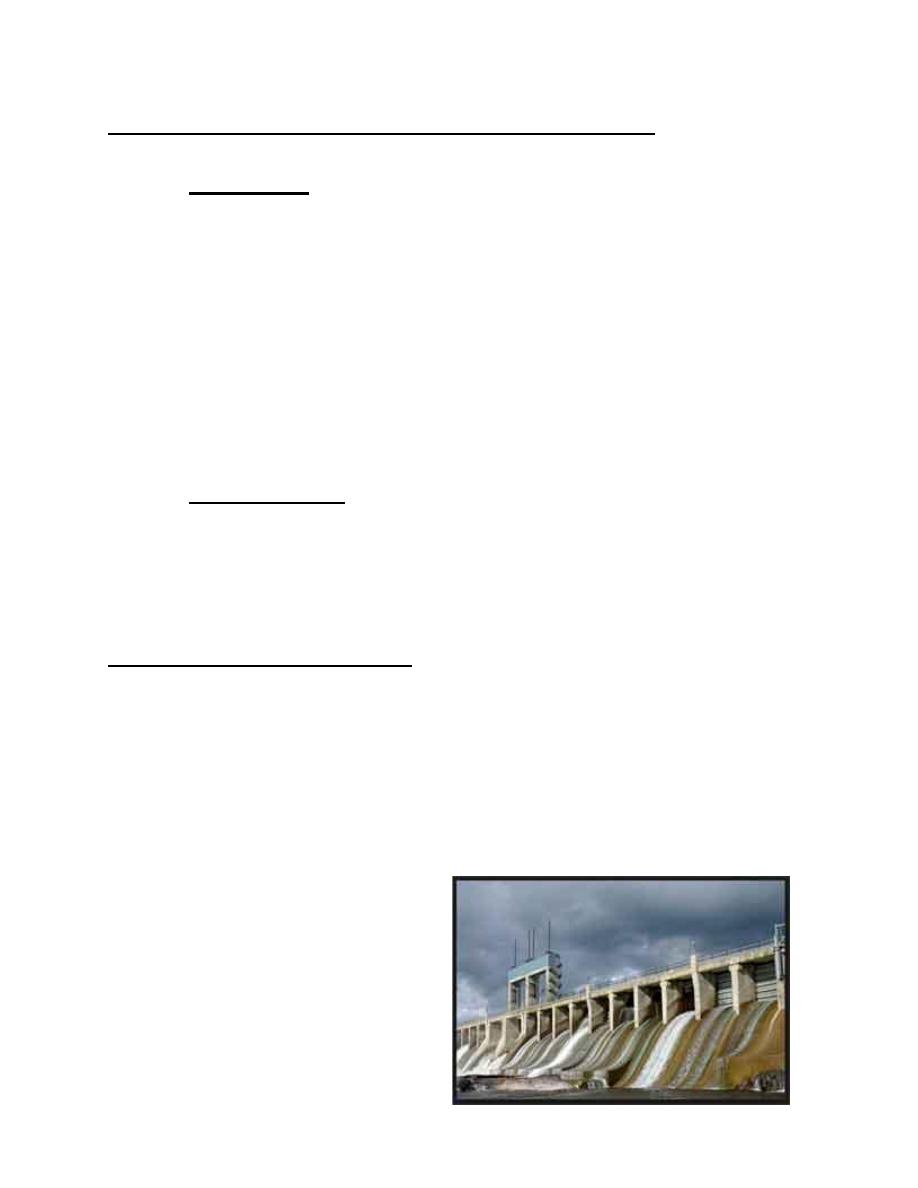

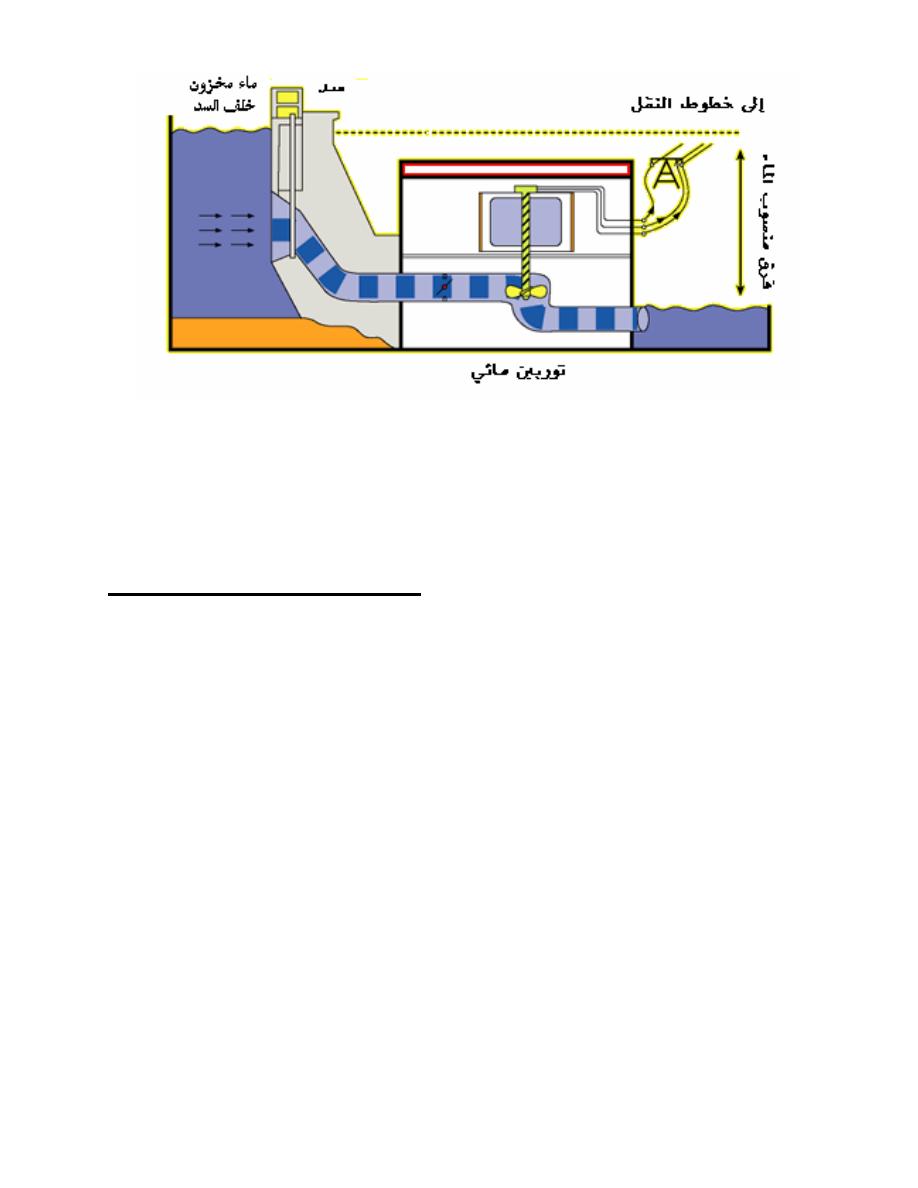

Figure(4)

Hydro Power Plant

In hydro power plant we use gravitational force of fluid water to run the

turbine which is coupled with electric generator to produce electricity. This power

plant plays an important role to protect our fossil fuel which is limited, because the

generated electricity in hydro power station is the use of water which is renewable

source of energy and available in lots of amount without any cost. The big

advantage of hydro power is the water which the main stuff to produce electricity

in hydro power plant is free, it not contain any type of pollution and after generated

electricity the price of electricity is average not too much high.

Construction and Working of Hydro Power Plant:

Fundamental parts of hydro power plant are

a) Area.

b) Dam.

c) Reservoir.

d) Penstock.

e) Storage tank.

f) Turbines and generators.

g) Switchgear and protection.

For construction of hydro power plant first we choose the area where the

water is sufficient to reserve and no any crisis of water and suitable to build a dam,

then we construct the dam. The main function of dam is to stop the flow of water

and reserve the water in reservoir. Mainly dam is situated at a good height to

increase the force of water. Reservoir stocks up lots of water which is employed to

generate power by means of turbines . After that Penstock, the pipe which is

connected between dam and turbine blades and most important purpose of the

penstock is to enlarge the kinetic energy of water that’s why this pipe is made up

of extremely well-built material which carry on the pressure of water. To control

the pressure of water means increase or decrease water pressure whenever

required, we use a valve. Storage tank comes in picture when the some reason the

pressure of water in reservoir is decreases then we use storage tank it is directly

connected to penstock and use only in emergency condition. After that we employ

turbine and generator. Turbine is the main stuff, when water comes through the

penstock with high kinetic energy and falls on turbine blades, turbine rotates at

high speed. As we know that the turbine is an engine that transfers energy of fluid

into mechanical energy which is coupled with generator and generator converts

mechanical energy into electrical energy which we utilize at the end. In hydro

power plant we also add switchgears and protections which control and protect the

whole process inside the plant. The control equipments consists control circuits,

control devices, warning, instrumentation etc and connect to main control board.

After generating electricity at low voltage, we use step up transformer to enlarge

the level of voltage (generally 132KV, 220KV, 400KV and above) as per our

requirement. After that we transmit the electric power to the load center, and then

we step down the voltage for industrial and large consumer and then again we step

down the voltage to distribute electricity at domestic level which we used at home.

This is the whole process of generating electricity by the means of hydro

(hydro power plant) and then transmitting and distributing electricity.

History of Hydro Power Plant

First hydro power is used by the Greekins to spin water wheels for crushing

wheat into flour before more than 2000 years ago. In the 1700's, hydropower was

generally used for pumping irrigation (non-natural use of water on the way to the

land) water. We start to generate electricity from hydro power in 1882 when

United States (U S) establishes a first hydro power station which generate 12.5

kilowatts (KW) of power. The rapid growth of hydro power comes in 1900’s when

hydraulic reaction turbine comes in picture as a result in 1900’s hydro power plants

fulfill the requirement of 40% of total United States' electricity. In between 1905-

1911 largest hydro power station (Roosevelt Dam) is built by the united state and

its generated capacity is increased from 4500kW to 36,000kW.In 1914 S.J. Zowski

developed the high specific speed reaction (Francis) turbine runner for low head

applications. 1922 the first time a hydroelectric plant was built specifically for

crest power. In 1933 Hoover Dam, Arizona generated electricity first time. In 1940

over 1500 hydro power plants generate about one third of the United States'

electrical energy.

If we compare the countries on the basis of generated electricity by the

means of hydro power, Canada on the top after that United State then Brazil then

Russia then China then Norway and at 7th number India is present. India fulfills

the 3.5% power to the total world power through hydro power plants.

In India scope of hydro power is very good, first hydro power station,

capacity of 130kW establishes in Asia at mounts of Darjeeling in 1898 and after

that in 1902 Shimsh (Shivanasamudra) is established and both located in India.

Now a day in India the leading hydro power plant is located of river Naptha Jhakri

hydro project of 1500MW in Himachal Pradesh. In India main boost come in the

field of hydro power in august 1998 when the Government of India publicized a

plan on ‘Hydro Power Development’ after that in November 2008 once again

Indian government announced this plan and as a result India become leading

country list to produce hydro power.

This a general idea about hydro power plant.

1-2-4 Diesel Power Station:

For generating electrical power, it is essential to rotate the rotor of an

alternator by means of a prime mover. The prime mover can be driven by different

methods. Using diesel engine as prime mover is one of the popular methods of

generating power. When prime mover of the alternators is diesel engine, the power

station is called diesel power station.

The mechanical power required for driving alternator comes from

combustion of diesel. As the diesel costs high, this type of power station is not

suitable for producing power in large scale in our country.

But for small scale production of electric power, and where, there is no other

easily available alternatives of producing electric power, diesel power station are

used.

Steam power stations and hydro power plants are mainly used to produce

maximum portion of the electrical load demands. But for steam power station,

sufficient supply of coal and water are required.

Figure(5)

Diagram of Hydro Power Plant

For hydro power station, plenty source of water and big dams are required.

But where all these facilities are not available, such as no easy way of coal

transportation and no scope of constructing dam, there it is established.

Diesel power plants are also popularly used as standby supply of different

industries, commercial complexes, hospitals, etc. During power cut, these diesel

power generators are run to fulfil required demand.

Advantages & Disadvantages of Diesel Power Station:

a. Advantages

1. This is simple in design point of view.

2. Required very small space.

3. It can also be designed for portable use.

4. It has quick starting facility, the small diesel generator set can be started

within few seconds.

5. It can also be stopped as when required stopping small size diesel power

station, even easier than it’s starting

6. As these machines can easily be started and stopped as when required,

there may not be any standby loss in the system.

7. Cooling is easy and required smaller quantity of water in this type power

station.

8. Initial cost is less than other types of power station.

9. Thermal efficiency of diesel is quite higher than of coal.

10.Small involvement is less than steam power station.

b. Disadvantages:

1. As we have already mentioned, the cost of diesel is very high compared

to coal. This is the main reason for which a diesel power plant is not

getting popularity over other means of generating power. In other words

the running cost of this plant is higher compared to steam and hydro

power plants.

2. The plant generally used to produce small power requirement.

3. Cost of lubricants is high.

4. Maintenance is quite complex and costs high.

Different Components of Diesel Power Station

In addition to diesel generator set or DG set there are many other auxiliaries

attached to at diesel power station. Let’s discuss one by one.

a) Fuel Supply System:

In fuel supply system there are one storage tank, where oil in stored.

Strainer : This oil then pump to dry tank, by means of transfer pump.

During transferring from main tank to smaller dry tank, the oil passes

through strainer to remove solid impurities. From dry tank to main tank, there is

another pipe connection. This is over flow pipe. This pipe connection is used to

return the oil from dry tank to main tank in the event of over flowing.

From dry tank the oil is injected in the diesel engine by means of fuel

injection pump.

b) Air Intake System:

This system supplies necessary air to the engine for fuel combustion. It

consists of a pipe for supplying of fresh air to the engine. Filters are provided to

remove dust particles from air.

c) Exhaust System:

The exhaust gas is removed from engine, to the atmosphere by means of an

exhaust system. A silencer is normally used in this system to reduce noise level of

the engine.

d) Cooling System:

The heat produced due to internal combustion, drives the engine. But some

parts of this heat raise the temperature of different parts of the engine. High

temperature may cause permanent damage to the machine. Hence, it is essential to

maintain the overall temperature of the engine to a tolerable level. Cooling system

of diesel power station does exactly so. The cooling system requires a water

source, water source, water pump and cooling towers. The pump circulates water

through cylinder and head jacket. The water takes away heat from the engine and it

becomes hot. The hot water is cooled by cooling towers and is re-circulated for

cooling.

e) Lubricating System:

This system minimises the water of rubbing surface of the engine. Here

lubricating oil is stored in main lubricating oil tank. This lubricating oil is drawn

from the tank by means of oil pump. Then the oil is passed through the oil filter for

removing impurities. From the filtering point, this clean lubricating oil is delivered

to the different points of the machine where lubrication is required the oil cooler is

provided in the system to keep the temperature of the lubricating oil as low as

possible.

f) Starting System:

For starting a diesel engine, initial rotation of the engine shaft is required.

Until the firing start and the unit runs with its own power. For small DG set, the

initial rotation of the shaft is provided by handles but for large diesel power station.

Compressed air is made for starting.

Figure(6)

Diesel Power Plant

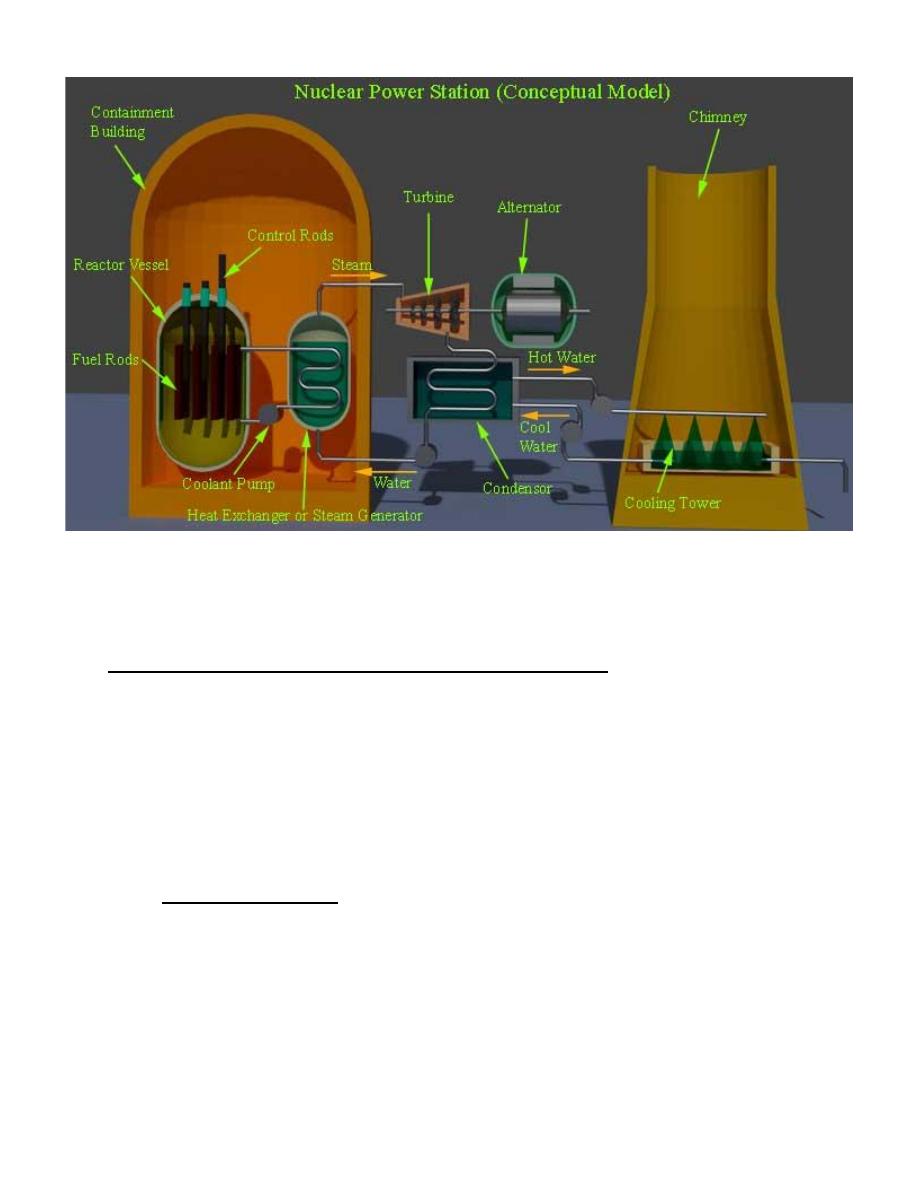

1-2-5 Nuclear Power Station or Nuclear Power Plant

Electrical power can be generated by means of nuclear power. In nuclear

power station, electrical power is generated by nuclear reaction.

Here, heavy radioactive elements such as Uranium (U235) or Thorium

(Th232) are subjected to nuclear fission. This fission is done in a special apparatus

called as reactor. Before going to details of nuclear power station, let’s try to

understand what is fission? In fission process, the nuclei of heavy radioactive

atoms are broken into two nearly equal parts. During this breaking of nuclei, huge

quantity of energy is released. This release of energy is due to mass defect. That

mean, the total mass of initial product would be reduced during fission. This loss

of mass during fission is converted into heat energy as per famous equation E =

mc2, established by Albert Einstein.

The basic principle of nuclear power station is same as steam power station.

Only difference is that, instead of using heat generated due to coal combustion,

here in nuclear power plant, heat generated due to nuclear fission is used to

produce steam from water in the boiler. This steam is used to drive a steam turbine.

This turbine is the prime mover of the alternator. This alternator generates

electrical energy. Although, the availability of nuclear fuel is not plenty but very

less amount of nuclear fuel can generate huge amount of electrical energy. This is

the unique feature of a nuclear power plant. One kg of uranium is equivalent to

4500 metric tons of high grade coal. That means complete fission of 1 kg uranium

can produce as much heat as can be produced by complete combustion of 4500

metric tons high grade coal. This is why, although nuclear fuel is much costlier, but

nuclear fuel cost per unit electrical energy is still lower than that cost of energy

generated by means of other fuel like coal and diesel. To meet up conventional fuel

crisis in present era, nuclear power station can be the most suitable alternatives.

Advantages & Disadvantages of Nuclear Power Station:

a) Advantages

1) As we said, the fuel consumption in this power station is quite low and

hence, cost for generating single unit is quite less than other conventional

power generation method.

2) A nuclear power station occupies much smaller space compared to other

conventional power station of same capacity.

3) This station does not require plenty of water, hence it is not essential to

construct plant near natural source of water. This also does not required

huge quantity of fuel; hence it is also not essential to construct the plant

near coal mine, or the place where good transport facilities are available.

Because of this, the nuclear power station can be established very near to

the load centre.

b) Disadvantages :

1) The fuel is not easily available and it is very costly.

2) Initial cost for constructing nuclear power station is quite high.

3) Erection and commissioning of this plant is much complicated and

sophisticated than other conventional power station.

4) The fission by products are radioactive in nature, and it may cause high

radioactive pollution.

5) The maintenance cost is higher and the man power required to run a

nuclear power plant is quite higher since speciality trained people are

required.

6) Sudden fluctuation of load cannot be met up efficiently by nuclear

plant.

7) As the by products of nuclear reaction is high radioactive, it is very big

problem for disposal of this by products. It can only be disposed deep

inside ground or in a sea away from sea share.

Different Components of Nuclear Power Station:

A nuclear power station has mainly four components.

1) Nuclear reactor.

2) Heat exchanger.

3) Steam turbine.

4) Alternator.

Let’s discuss these components one by one:

1) Nuclear Reactor:

In nuclear reactor, Uranium 235 is subjected to nuclear fission. It controls the chain

reaction that starts when the fission is done. The chain reaction must be controlled

otherwise rate of energy release will be fast, there may be a high chance of

explosion. In nuclear fission, the nuclei of nuclear fuel, such as U235 are

bombarded by slow flow of neutrons. Due to this bombarding, the nuclei of

Figure(7)

Nuclear Power Plant

Uranium is broken, which causes release of huge heat energy and during breaking

of nuclei, number of neutrons are also emitted.

These emitted neutrons are called fission neutrons. These fission neutrons cause

further fission. Further fission creates more fission neutrons which again accelerate

the speed of fission. This is cumulative process. If the process is not controlled, in

very short time the rate of fission becomes so high, it will release so huge amount

of energy, there may be dangerous explosion. This cumulative reaction is called

chain reaction. This chain reaction can only be controlled by removing fission

neutrons from nuclear reactor. The speed of the fission can be controlled by

changing the rate of removing fission neutrons from reactors.

A nuclear reactor is a cylindrical shaped stunt pressure vessel. The fuel rods are

made of nuclear fuel i.e. Uranium moderates, which is generally made of graphite

cover the fuel rods. The moderates slow down the neutrons before collision with

uranium nuclei. The controls rods are made of cadmium because cadmium is a

strong absorber of neutrons.

The control rods are inserted in the fission chamber. These cadmium controls rods

can be pushed down and pull up as per requirement. When these rods are pushed

down enough, most of the fission neutrons are absorbed by these rods, hence the

chain reaction stops. Again, while the controls rods are pulled up, the availability

of fission neutrons becomes more which increases the rates of chain reaction.

Hence, it is clear that by adjusting the position of the control rods, the rate of

nuclear reaction can be controlled and consequently the generation of electrical

power can be controlled as per load demand. In actual practice, the pushing and

pulling of control rods are controlled by automatic feedback system as per

requirement of the load. It is not controlled manually. The heat released during

nuclear reaction, are carried to the heat exchanger by means of coolant consist of

sodium metal.

2) Heat Exchanger:

In heat exchanger, the heat carried by sodium metal, is dissipated in water and

water is converted to high pressure steam here. After releasing heat in water the

sodium metal coolant comes back to the reactor by means of coolant circulating

pump.

3) Steam Turbine:

In nuclear power plant, the steam turbine plays the same role as coal power plant.

The steam drives the turbine in same way. After doing its job, the exhaust steam

comes into steam condenser where it is condensed to provide space to the steam

behind it.

4) Alternator:

An alternator, coupled with turbine, rotates and generates electrical power, for

utilization.

Site Selection of Nuclear Power Station

1)

Availability of water :

Although very large quantity of water is not

regulated as hydro-electric power plant, but still sufficient supply of neutral

water is obvious for cooling purposes in nuclear power station. That is why

it is always preferable to locate this plant near a river or sea side.

2)

Disposal of Water :

The by products or wastes of nuclear power station

are radioactive and may cause severe health hazards. Because of this, special

care to be taken during disposal of wastes of nuclear power plant. The

wastes must be buried in sufficient deep from earth level or these must be

disposed off in sea quite away from the sea share. Hence, during selecting

the location of nuclear plant, these factor must be taken into consideration.

3)

Distance from Populated Area :

As there is always a probability of

radioactivity, it is always preferable to locate a nuclear station sufficiently

away from populated area.

4)

Transportation Facilities :

During commissioning period, heavy

equipments to be erected, which to be transported from manufacturer site. So

good railways and road ways availabilities are required. For availability of

skilled manpower good public transport should also be present at the site.

Renewable energy sources

1) Solar Energy:

Now a day’s solar energy system play an important role in the field of

producing electricity or other domestic uses like water heating, cooking etc. As we

know that major part of generated electricity or electricity depends upon coal

which is used in thermal power plant (in In India 65% of total power is generated

by the thermal power plant). But the main problem is here that the fuel used in

thermal power plant is coal which is in limited amount and may be not available in

future to produce or generate electricity. That is the main reason to solar energy

system comes to the picture.

2)

Wind energy:

Or wind power is extracted from air flow using wind turbines or sails to

produce mechanical or electrical energy. Windmills are used for their mechanical

power, wind pumps for water pumping, and sails to propel ships. Wind power as

an alternative to fossil fuels, is plentiful, renewable, widely distributed, clean,

produces no greenhouse gas emissions during operation, and uses little land.

3) Geothermal Earth Energy:

Geothermal energy is thermal energy generated and stored in the Earth.

Thermal energy is the energy that determines the temperature of matter. The

geothermal energy of the Earth's crust originates from the original formation of

the planet and from radioactive decay of materials.

Geothermal power is cost effective, reliable, sustainable, and environmentally

friendly,[8] but has historically been limited to areas near tectonic plate

boundaries. Recent technological advances have dramatically expanded the range

and size of viable resources, especially for applications such as home heating,

opening a potential for widespread exploitation. Geothermal wells release

greenhouse gases trapped deep within the earth, but these emissions are much

lower per energy unit than those of fossil fuels. As a result, geothermal power has

the potential to help mitigate global warming if widely deployed in place of fossil

fuels.

4) Tidal Energy:

Tidal energy is produced by the surge of ocean waters during the rise and fall

of tides.

Tidal energy production is still in its infancy. The amount of power produced

so far has been small. There are very few commercial-sized tidal power plants

operating in the world.

Placing turbines in tidal streams is complex, because the machines are large

and disrupt the tide they are trying toharness. The environmental impact could be

severe, depending on the size of the turbine and the site of the tidal stream.

Turbines are most effective in shallow water. This produces more energy and

allows ships to navigatearound the turbines. A tidal generator's turbine blades also

turn slowly, which helps marine life avoid getting caught in the system.