Pharmaceutical industry Lab. Effervescent granules

Page 1

Lab 2

Dr.Hussein

Al Qadisyiah College of pharmacy

Granules

Granules are defined as a dosage form composed of dry aggregates of

powder particles that may contain one or more APIs, with or without

other ingredients. They may be swallowed as such, dispersed in food, or

dissolved in water. Granules are frequently compacted into tablets or

filled into capsules, with or without additional ingredients.

Reason For Granulation

1. To prevent segregation of the constituents of powder Mix

2. To improve the flow properties of the powder mix

3. To improve the compaction characteristics of powder mix

4. Granules have higher porosity than powders

5. To improve the compressibility of powders.

6. The granulation of toxic materials will reduce the hazard of

generation of toxic dust, which may arise during the handling of the

powders.

7. Materials, which are slightly hygroscope, may adhere & form a cake

if stored as a powder.

8. good tasting, sparkling drinks containing ingredients which do not

normally taste good in liquid form

9. high dose products where large conventional tablets would have to

be swallowed

10. quicker and more complete absorption of dosages

11. compounds normally not stable or soluble in liquid form

Effervescent Granulated

An effervescent dosage form, frequently tablets or granules, contains

ingredients that, when in contact with water, rapidly release carbon

dioxide. The dosage form is dissolved or dispersed in water to initiate the

effervescence prior to ingestion.

Effervescent salts are granules or coarse to very coarse powders

containing a medicinal agent in a dry mixture usually composed of

sodium bicarbonate, citric acid, and tartaric acid. When added to

water, the acids and the base react to liberate carbon dioxide, resulting

in effervescence. The resulting carbonated solution masks undesirable

taste of any medicinal agent.

Pharmaceutical industry Lab. Effervescent granules

Page 2

Lab 2

Dr.Hussein

Al Qadisyiah College of pharmacy

Using granules or coarse particles of the mixed powders rather than

small powder particles decreases the rate of solution and prevents

violent and uncontrollable effervescence. Sudden and rapid

effervescence could overflow the glass and leave little residual

carbonation in the solution.

Using a combination of citric and tartaric acids rather than either acid

alone avoids certain difficulties. When tartaric acid is used as the sole

acid, the resulting granules readily lose their firmness and crumble.

Citric acid alone results in a sticky mixture difficult to granulate.

Limitations of effervescent formulations

1. It cannot be given to the children because of possibility of gas (CO2)

toxicity.

2. If packaging is not done properly then there are chances of degradation

by environmental moisture.

3. It has shorter shelf life as compared to other solid dosage forms.

4. It requires special machinery requirements for manufacturing.

5. This dosage form is costly then tablets.

Preparation of Effervescent Granulation

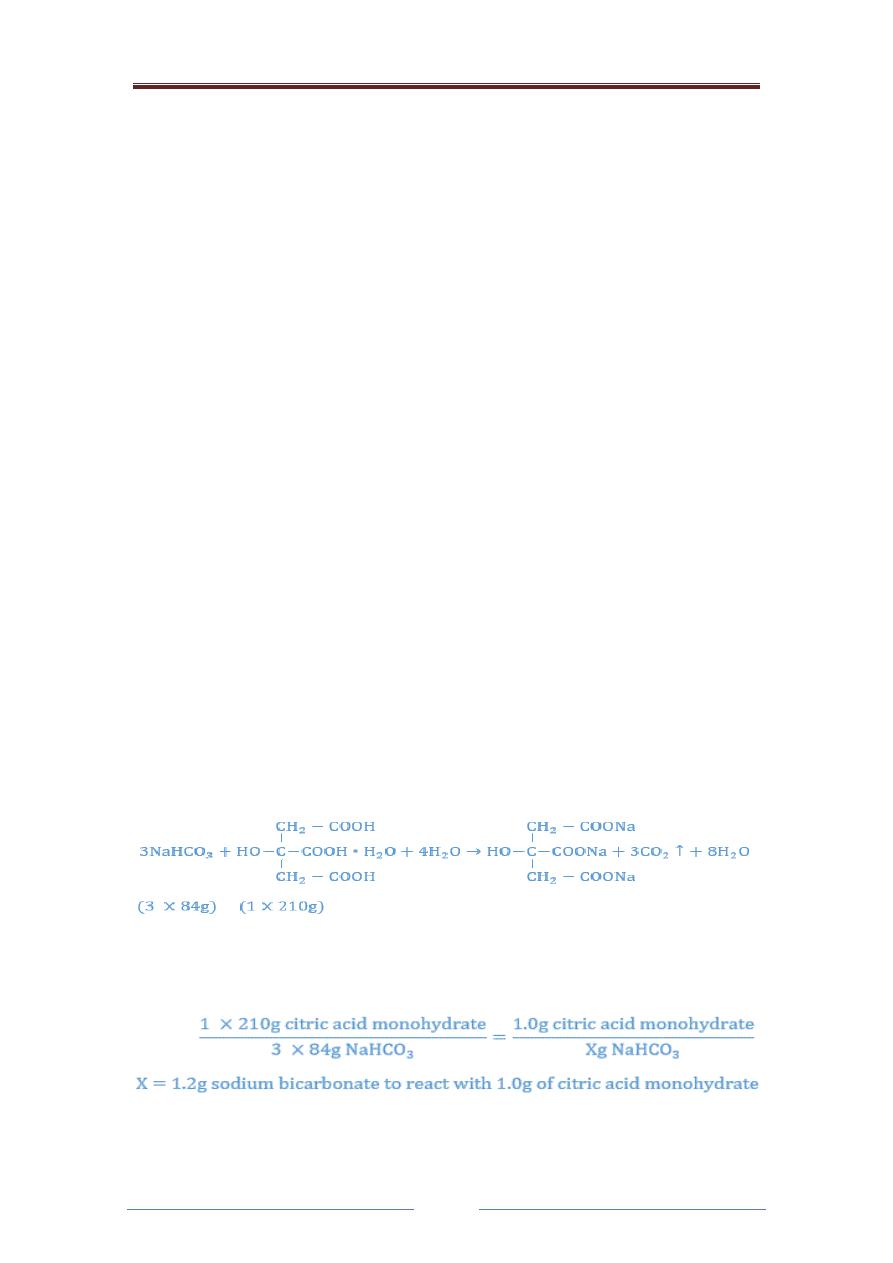

It has been found that citric acid monohydrate and tartaric acid used in

the ratio of 1:2, respectively, produces a powder with good effervescent

properties. The amount of sodium bicarbonate to be used may be

calculated from the reaction which occur when the granules come in

contact with water. The reaction equation between citric monohydrate

and sodium bicarbonate is given below:

Setting up a proportion to determine the amount of sodium bicarbonate

that will react with 1 gm of citric acid, one has:

Pharmaceutical industry Lab. Effervescent granules

Page 3

Lab 2

Dr.Hussein

Al Qadisyiah College of pharmacy

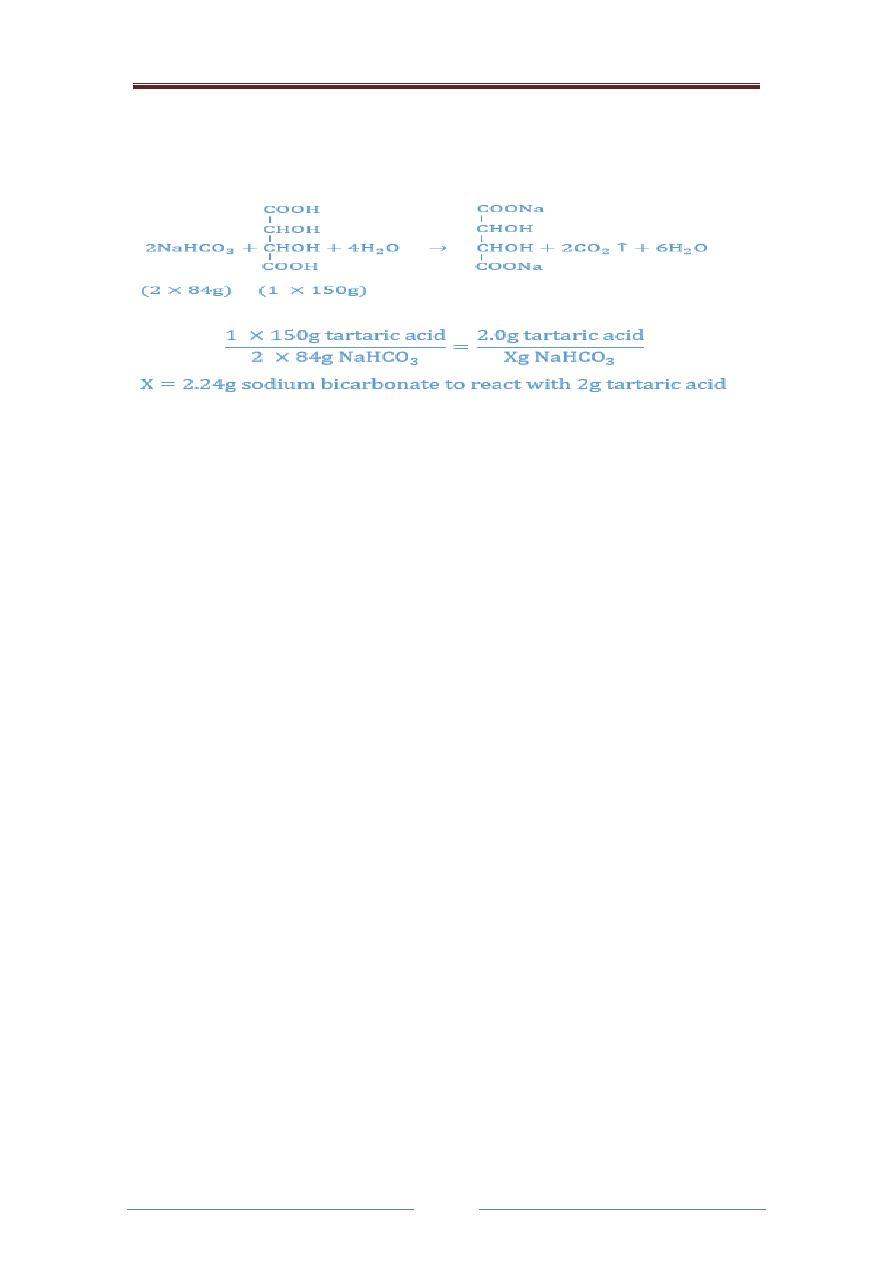

Similar calculations show that 2.24 gm of sodium bicarbonate react with

2

gm

of

tartaric

acid.

Thus, with the acids in a ratio of 1:2, it has been calculated that 3.44 g

(1.2 g + 2.24 g) of sodium bicarbonate is necessary to react

stoichiometrically with the 3 g of combined acids. To enhance the flavor,

the amount of sodium bicarbonate may be reduced to 3.4 gm to allow for

a small amount of unreacted acid to provide a tart taste.

Method of preparation

Dry or Fusion Method

In the fusion method, the one molecule of water present in each molecule

of citric acid acts as the binding agent for the powder mixture. Before

mixing the powders, the citric acid crystals are powdered and then mixed

with the other powders of the same sieve size to ensure uniformity of the

mixture.

The sieves and the mixing equipment should be made of stainless steel

or other material resistant to the effect of the acids.

The mixing of the powders is performed as rapidly as is practical,

preferably in an environment of low humidity to avoid absorption of

moisture and a premature chemical reaction.

After mixing, the powder is placed on a suitable dish in an oven at 34

C to 40 C. During the heating process, an acid resistant spatula is used

to turn the powder. The heat releases the water of crystallization from

the citric acid, which, in turn, dissolves

a portion of the powder

mixture, setting the chemical reaction and consequently releasing

some carbon dioxide.

Pharmaceutical industry Lab. Effervescent granules

Page 4

Lab 2

Dr.Hussein

Al Qadisyiah College of pharmacy

This causes the softened mass of powder to become somewhat

spongy, and when it has reached the proper consistency (as bread

dough), it is removed from the oven and rubbed through a sieve to

produce granules of the desired size. A No. 4 sieve produces large

granules, a No. 8 sieve prepares medium size granules, and a No. 10

sieve prepares small granules.

The granules are dried at a temperature not exceeding 54 C and are

immediately placed in containers and tightly sealed.

Wet Method

The wet method differs from the fusion method in that the source of

binding agent is not the water of crystallization from the citric acid but

the water added to alcohol as

the moistening agent, forming the pliable

mass for granulation. In this method, all of the powders may be

anhydrous as long as water is added to the moistening liquid. Just enough

liquid is added (in portions) to prepare a mass of proper consistency; then

the granules are prepared and dried in the same manner as previously

described.

H.W. Calculate the amount required from CaCO3 and KaHCO3

with citric acid and tartaric acid instead of NaHCO3?

Procedure

1. Weight 2.5 gm of citric acid and 4 gm of tartaric acid and 7 gm of

NaHCO3.

2. Triturate the mixture using pestle and mortar

3. Transfer the content into beaker and heat it on the heater

4. Mix the contents properly

5. Sieve the mixture using NO. 8 sieve

6. Store it in sealed package to prevent premature effervescent