Pharmaceutical industry lab Powder flow

Page 1

Lab 3

Powder flow

The largest use of powders pharmaceutically is to produce tablets and

capsules. Together with mixing and compression properties, the

flowability of a powder is of critical importance in the production of

pharmaceutical dosage forms. Some of the reasons for producing free-

flowing pharmaceutical powders include:

1. uniform feed from bulk storage containers or hoppers into the feed

mechanisms of tableting or capsule-filling equipment, allowing

uniform particle packing and a constant volume-to-mass ratio which

maintains tablet weight uniformity;

2. reproducible filling of tablet dies and capsule dosators, which

improves weight uniformity and allows tablets to be produced with

more consistent physicomechanical properties;

3. uneven powder flow can result in excess entrapped air within

powders, which in some high-speed tableting conditions may promote

capping or lamination;

4. uneven powder flow can result from excess fine particles in a powder,

which increase particle-die-wall friction, causing lubrication problems,

and increase dust contamination risks during powder transfer.

Adhesion and cohesion

The presence of molecular forces produces a tendency for solid

particles to stick to themselves and to other surfaces. Adhesion and

cohesion can be considered as two aspects of the same phenomenon.

Adhesive and cohesive forces acting between particles in a powder bed

are composed mainly from short-range non-specific van der Waals forces

which increase as particle size decreases and vary with changes in

relative humidity.

Densities of particles:

A- true density

Pharmaceutical industry lab Powder flow

Page 2

Lab 3

The true density, or absolute density, of a sample excludes the volume of

the pores and voids within the sample.

B- bulk density

The bulk density of a powder is the ratio of the mass of an untapped

powder sample and its volume including the contribution of the

interparticulate void volume. Hence, the bulk density depends on both the

density of powder particles and the spatial arrangement of particles in the

powder bed.

The bulking properties of a powder are dependent upon the preparation,

treatment and storage of the sample, i.e. how it was handled. The particles

can be packed to have a range of bulk densities and, moreover, the

slightest disturbance of the powder bed may result in a changed bulk

density.

Thus, the bulk density of a powder is often very difficult to measure

with good reproducibility and, in reporting the results, it is essential to

specify how the determination was made.

The bulk density of a powder is determined by measuring the volume

of a known mass of powder sample, that may have been passed through a

screen, into a graduated cylinder

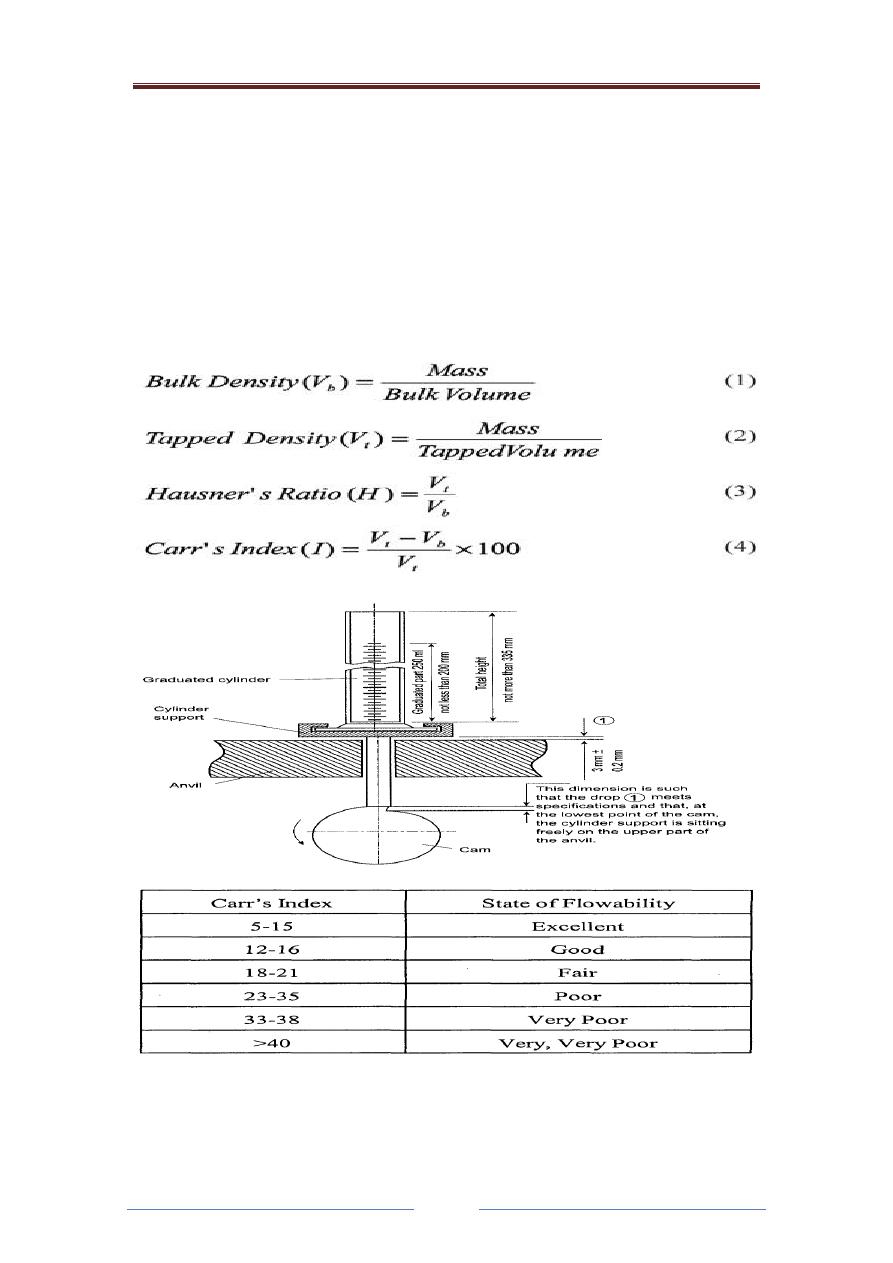

C-Tapped density

The tapped density is an increased bulk density attained after

mechanically tapping a container containing the powder sample. The

tapped density is obtained by mechanically tapping a graduated

measuring cylinder or vessel containing the powder sample. After

observing the initial powder volume or mass, the measuring cylinder or

vessel is mechanically tapped, and volume or mass readings are taken

until little further volume or mass change is observed. The mechanical

tapping is achieved by raising the cylinder or vessel and allowing it to

drop, under its own mass. Devices that rotate the cylinder or vessel during

Pharmaceutical industry lab Powder flow

Page 3

Lab 3

tapping may be preferred to minimize any possible separation of the mass

during tapping down.

Flowability can be estimated from the bulk density of the powder as

well. a typical tapped density measuring device. After the powder

sample is tapped by the rotating cam, the bulk density of the powder

increases from ρmin ( bulk density) to ρmax (tapped bulk density). The

percentage compressibility (Carr’s Index) can be calculated by the

following equation:

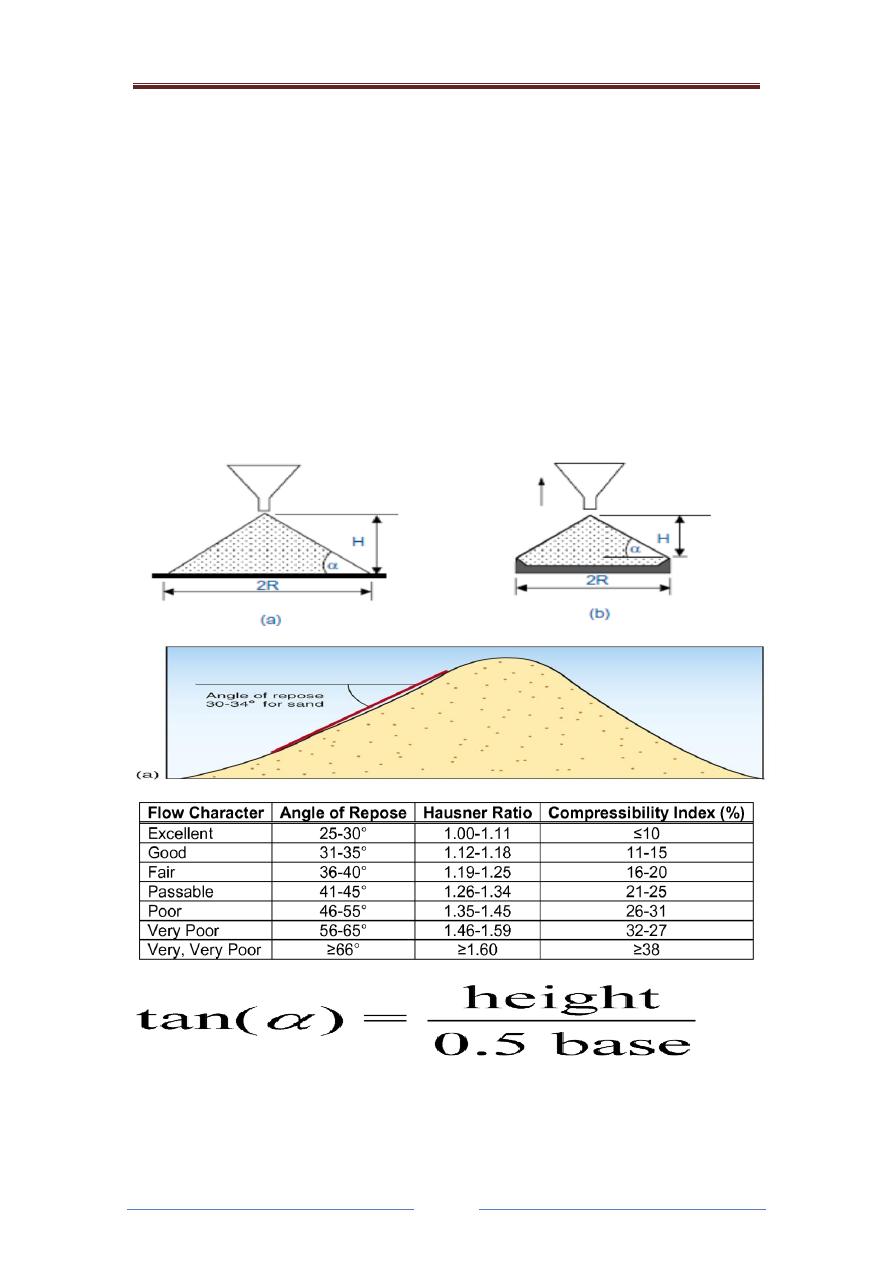

The angle of repose (α)

has been widely used to describe powder flowability. For an

accumulation of static powders, the angle between the free surface of the

Pharmaceutical industry lab Powder flow

Page 4

Lab 3

powder body and the horizontal plane is called the angle of repose. For

instance, when adding additional powder to a powder mound, the angle

between the side and the bottom surface reach a constant value, due to a

balance between gravity and powder friction . A smaller angle of repose

indicates smaller frictional forces and greater flowability. For a free-

flowing powder, the angle of repose is equal to or less than 30°; powders

with an angle of repose equal to or less than 40° have satisfactory

flowability; and, when the angle of repose is greater than 40°, the powder

does not flow freely. Different magnitudes for flowability data may be

obtained, depending on which method is chosen. In addition, the

reproducibility is typically poor for this method, so angle of repose is not

always considered a perfect representation for powder flowability.

Pharmaceutical industry lab Powder flow

Page 5

Lab 3

Procedure

1. Weight 100 gm of sugar and 100 gm of glucose powder

2. Use cylinder and measure the

Bulk density

Tap density

3. Calculate carr's index and hausner ratio

4. Measure the angle of repose using fennel