1

Industrial Pharmacy

Lec. 2

Milling

It is the mechanical process of reducing particle size of solids. It depends on the

product, the equipment and the process involved. Milling, grinding, trituration,

comminution and micronization have the same meaning which is reduction of particle

size.

Size is conventionally expressed in terms of mesh (number of openings per linear

inch of a screen). Coarse milling produces particles larger than 20 mesh, intermediate

milling produces particles 200-20 mesh, and fine milling produces particles smaller

than 200 mesh. In addition, micrometer and nanometer units are used also to describe

the particle size in the micro or nano scale, respectively.

Pharmaceutical Application

The surface area per unit weight (which is known as Specific Surface) is

increased by size reduction, which will affect the therapeutic efficiency of medicinal

compounds. The particle size reduction of griseofulvin, as instance, led to an oral

dosage regimen half that of the original marketed product with the same effectiveness.

(Increase the contact surface with the dissolution fluid, see Noyes-Whitney equation).

Also penicillin G procaine is greatly affected by the particle size (its rheology,

bioavailability, syringe-ability and pain). The size of particles used in the inhalation

aerosols determines the position and retention of the particles in the broncho-

pulmonary system.

Also the drying of wet masses may be facilitated by milling which increases the

surface area and reduces the distance for the moisture which must travel within the

particle to reach the outer surface. Lubricant act by covering the outer surface of the

granules, therefore; fine particles of the lubricant should be used (usually 200 mesh or

finer) is essential for lubricants to function properly (lubricant added in the final step to

prevent adhesion of granules with the machine).

2

The milling of ointments and creams (homogenization) provides a smooth texture

and better appearance.

* ADVANTAGE OF MILLING

1- Increase in surface area by particle size reduction may enhance the dissolution

which consequently improves the bioavailability especially for materials which are

slightly soluble.

2- Improve the uniformity of tablet content by increasing the number of particles per

unit weight.

3- Improves flow properties of irregular and needle like materials.

4- Improves the color dispersion and color uniformity.

5- Mixing of solid ingredients is easier and more uniform if the ingredients are

approximately in the same size.

*DISADVANTAGE OF MILLING

1- A possible change in polymorphic state of the active ingredient (unstable to stable).

2- A possible degradation of drug (due to heat).

3- A decrease in bulk density of the ingredient, which might cause a flow problem and

segregation.

4- Decrease in particle size may sometimes create a static charge problem which

results in poor mixing. In addition, agglomeration of the fine particles may affect

negatively on mixing.

5- Increase in surface may promote the adsorption of air which may inhibit wettability

of the drug to the extent that it becomes a factor affecting dissolution rate.

As conclusion, particle size reduction, i.e., milling has advantages and disadvantages.

Therefore, one should balance the benefits against risks of particle size reduction. That

is to say, the particle size reduction should be continued as much as possible until the

disadvantages of milling begin to appear. Hence, the milling process should be stopped

at this point.

3

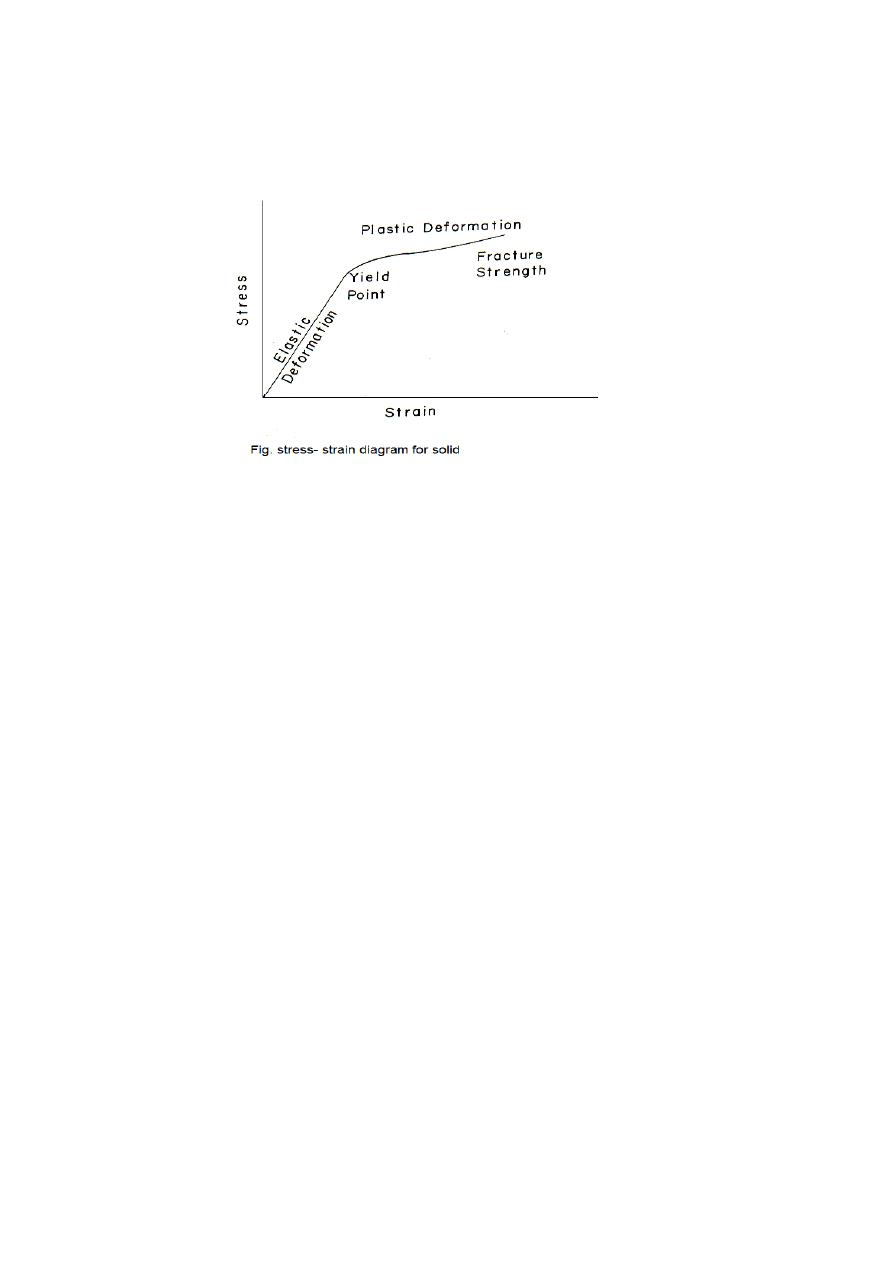

Theory of Milling

The mechanical behavior of solids under milling is shown in the following curve:

The initial linear portion of the curve expresses the softness of the particles. The

stress-strain curve becomes non linear at the yield point which is a measure of the

resistance to deformation (i.e. it is the point at which the particles start to break and

size reduction occur). With still greater stress, the region of irreversible plastic

deformation is reached.

Size reduction begins with the widening of any small cracks that were initially

present. Thus, larger particles with numerous cracks fracture more readily than smaller

particles with fewer cracks. In general, fine grinding requires more energy, not only

because of the increased new surface, but also because more energy is needed to

initiate cracks.

The most efficient mills utilize less than 1% of the energy input to fracture

particles. The rest of energy is dissipated in:

1- Elastic deformation of unfractured particles.

2- Transport of material within the milling chamber.

3- Friction between particles.

4- Friction between particles and mill.

5- Heat.

6- Vibration & noise.

4

* TYPE OF MILLS

In general a mill consist of 3 basic parts

1- Feeding chamber which delivers the material.

2- Grinding mechanism, usually consist of rotor & stator.

3- Discharge chamber to collect the milled material.

The force required for the milling process is supplied by either direct pressure,

impact, attrition or cutting. In most mills the grinding effect is a combination of two or

more of these actions.

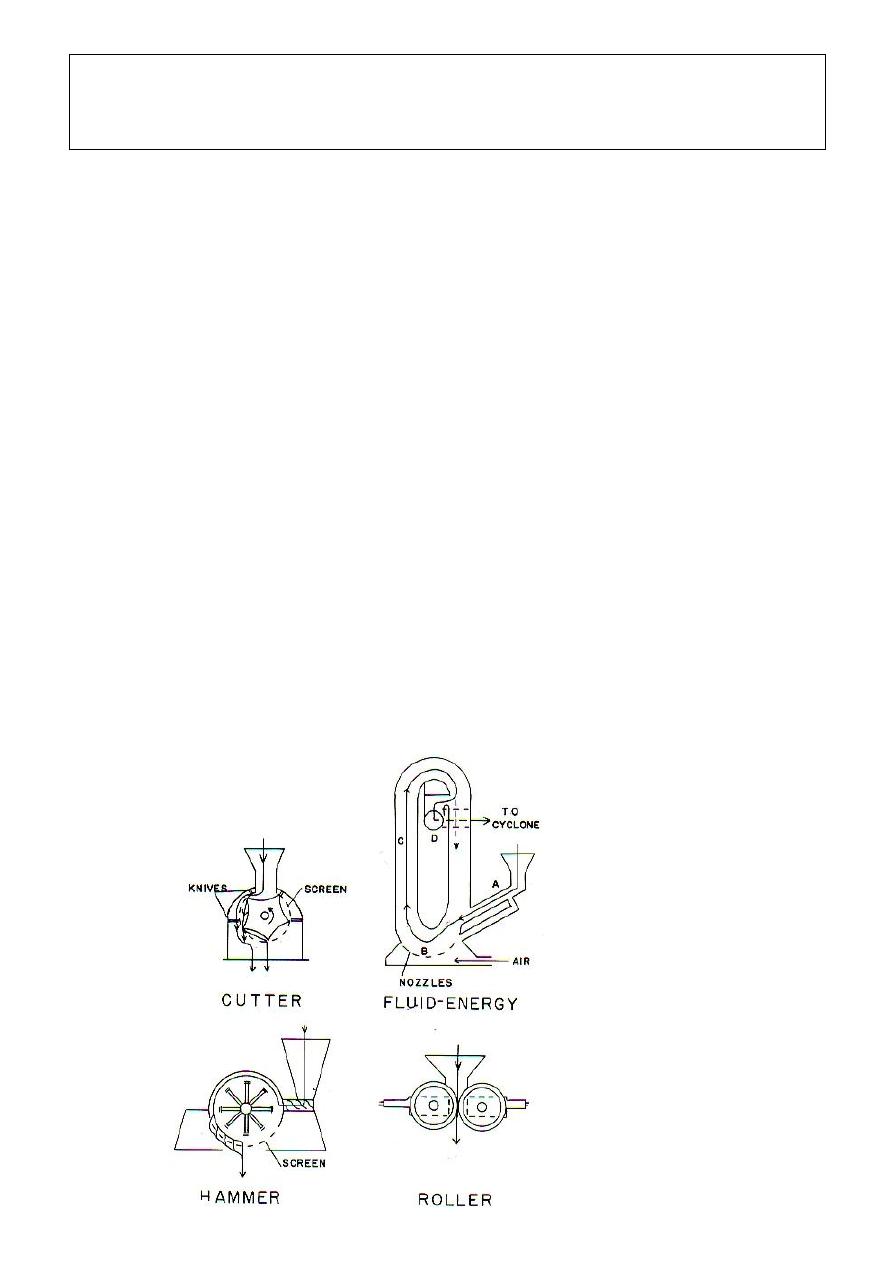

The most commonly used mills in pharmaceutical manufacturing are:

1- Cutter mill. 2- Hammer mill. 3- Roller mill. 4- Fluid-energy mill. 5. Ball mill

6. Colloidal mill

Note: Feeding speed is important because the rate of discharge should be equal

to the rate of feeding.

If the force of impact does not exceed the elastic limit, the material is

reversibly deformed. When the force is removed the particle returns to its original

condition and mechanical energy of stress in the deformed particles appear as heat.

5

If the milling operation is carried out so that the material is reduced to the desired

size by passing it once through the mill, the process is known as open-circuit milling.

A closed-circuit mill is one in which the discharge from the milling chamber is passed

through a size- separation device or classifier (sieve) and the oversize particles are

returned to the grinding chamber for further reduction of size.

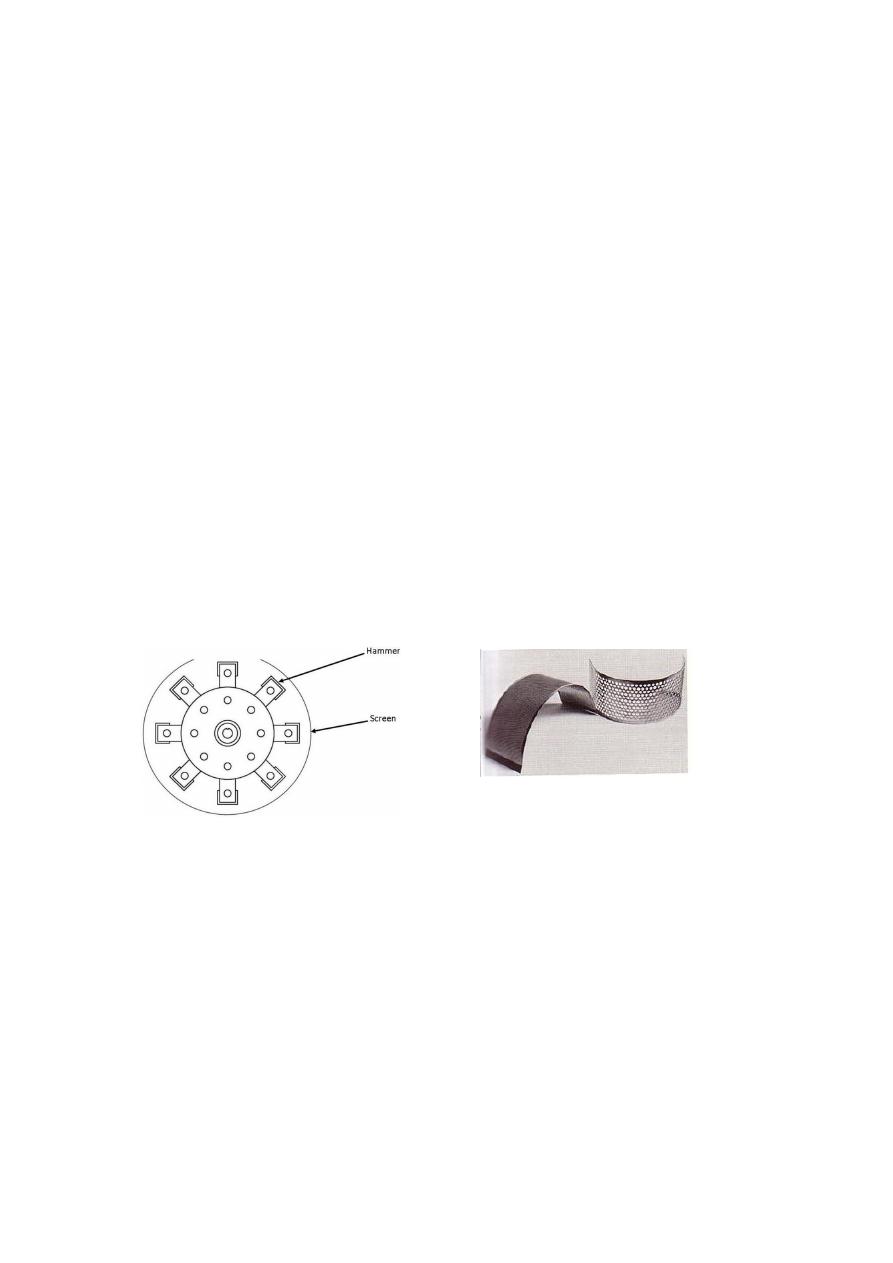

* Hammer mill

Hammer mill is an impact mill using a high speed rotor to which a number of

hammers are fixed. The material is retained until it is small enough to fall through the

screen that forms the lower portion of the milling chamber. Particles crushed are

discharged as fast as they are formed (i.e. particles fine enough to pass through the

screen are discharged almost as fast as they are formed).

The hammer mill can be used for almost all types of drugs. Its versatility makes it

popular in pharmaceutical industry where it used to mill dry materials, wet materials,

creams and ointments.

Advantages of hammer mill:

1- Easy to clean.

2- Minimal problem.

3- Easy to install.

4- Wide ranges in size are available.

5- Small space required.

6- May be operated as a closed system to reduce dust and explosion hazards.

6

Disadvantages:

1- Potential clogging of screen.

2- Heat buildup during milling might lead to the degradation of the material.

3- Mill and screen may wear with abrasive material.

* Ball Mill

It is used to obtain extremely small particles. The mill consists of rotating

cylinder which is partially filled with balls of steel that act as grinding medium. Ball

milling is a combination of impact and attrition.

Most ball mills are batch operated, however there are continuous ball millers

available nowadays with continuous milling action.

* Cutting Mill

Cutting mill is similar to hammer mill, they are used for fibrous materials and

provide a successive cutting action rather than attrition or compaction. The rotary knife

cutter has a rotor with 2-12 knives spaced uniformly on its periphery.

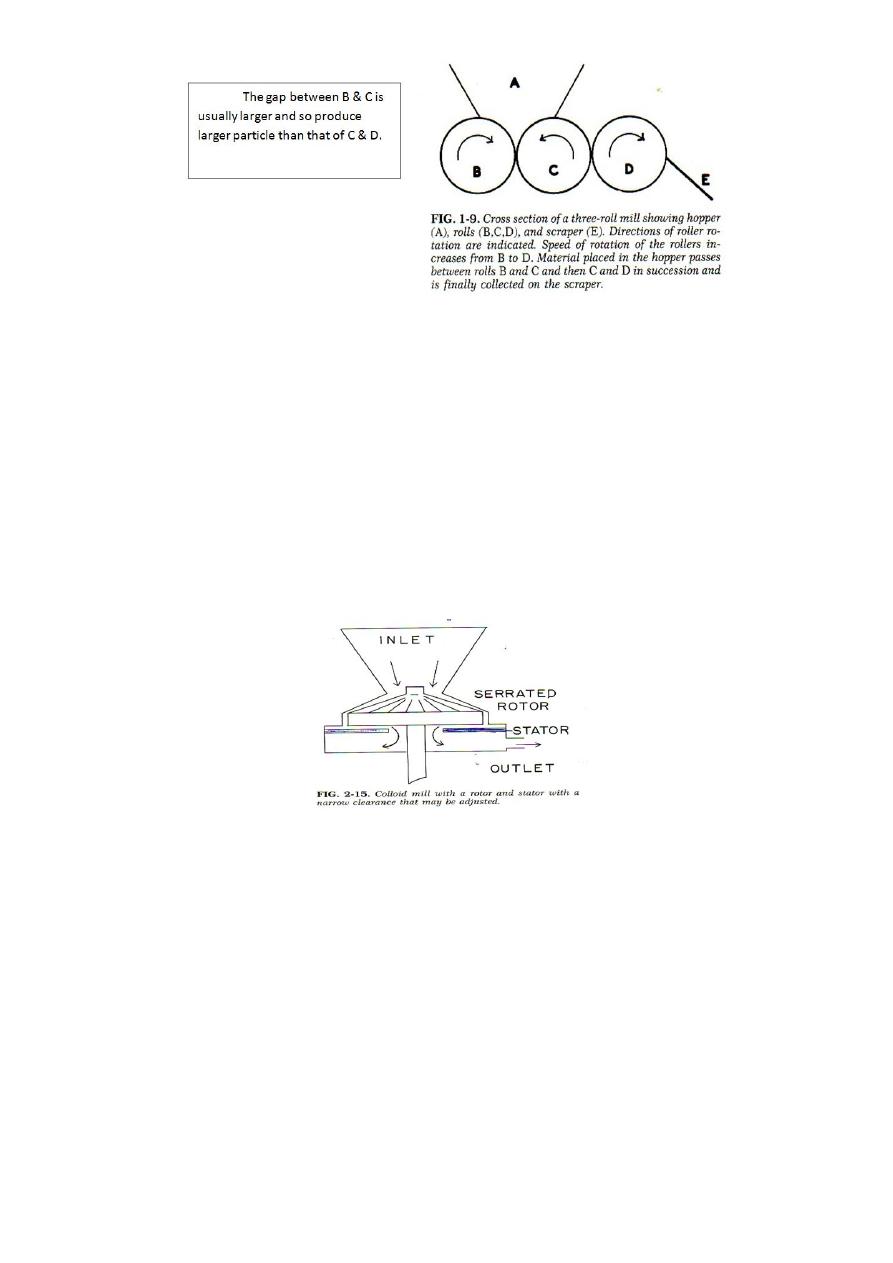

* Roller mill

It consists of 2-5 smooth rollers operating at different speeds. The size reduction

is achieved by a compression action.

7

* Colloidal Mill

It is consists of a high speed rotor and stator with conical milling surfaces.

Colloid mill is used pharmaceutically in the preparation of suspensions and emulsions;

it is not used for dry materials. The pre-milled solids are mixed with the liquid vehicle

before being introduced into colloid mill.

Sometimes during operation the temperature of the machine rises up to 40 C°, so

that a cold water jacket may reduce the temperature as much as 20 C°.

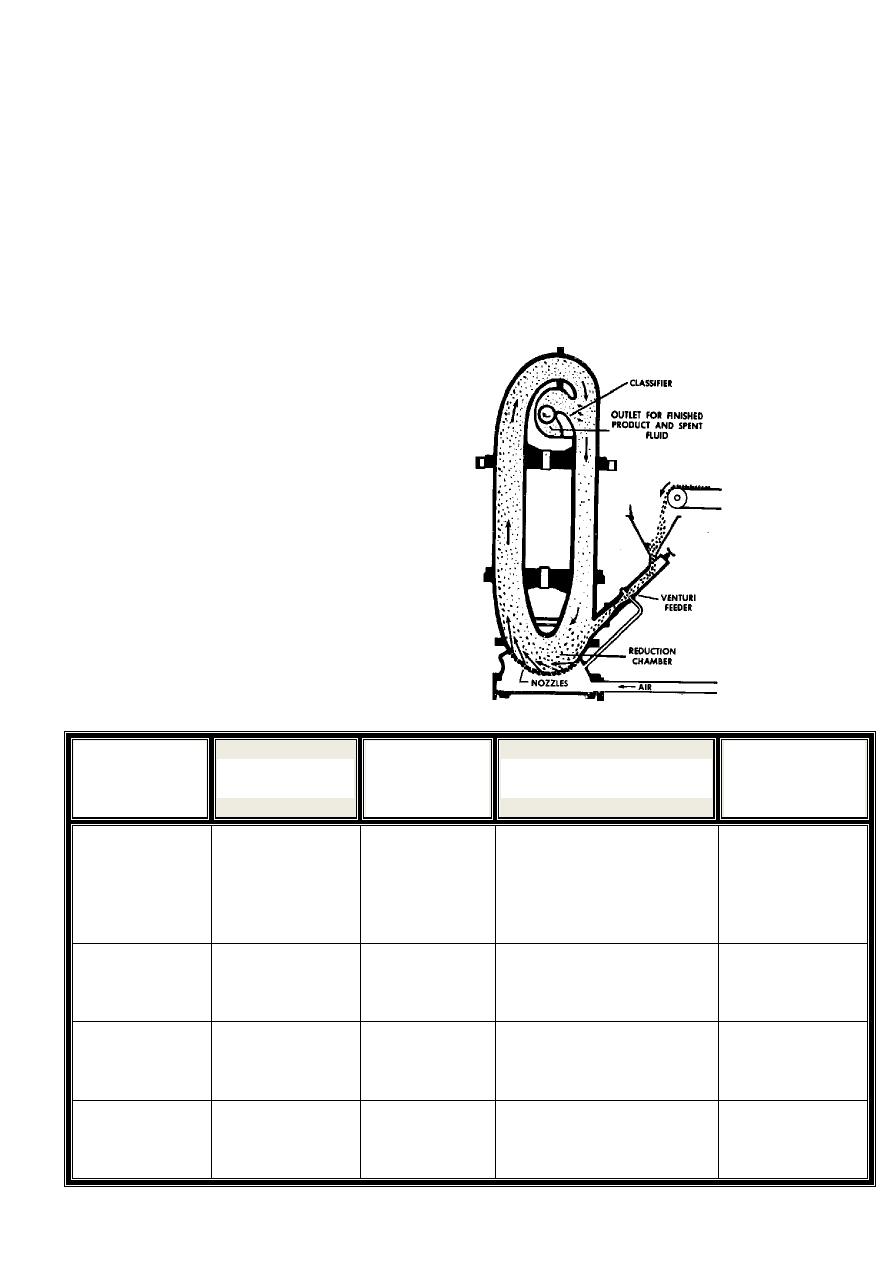

* Fluid-Energy Mill (Micronizer)

It has no moving par. It is rapid and relatively efficient method of reducing

particle with relatively narrow particle size distribution. The mill operates on the bases

of impact and attrition.

Materials is suspended and conveyed by a high velocity air stream introduces the

powder to the milling chamber, but if the materials are large in size (coarse) we prefer

to grind the materials by using hammer mill and then we use micronizer to make very

fine particles (i.e. the feed should be pre milled to facilitate milling).

8

The material is passed through nozzles at very high air speed (100-150 pound

per square inches (psi). The violent turbulence of the air reduces the particle size by

impact and attrition.

Air is usually used because most pharmaceutical substances are heat sensitive.

As the compressed air expands at the orifice, the cooling effect counteracts the heat

generated by milling.

The design of the fluid energy mill provides classification of particles, which

permits the fine particles to be discharged and the heavier oversized particles to be

retained until reduced to a smaller size.

Type of

Mill

Action

Product

Size

Used For

Not Used

For

Cutter

cutting

20- to 80-

mesh

fibrous, crude

animal and vegetable

drugs

friable

material

Hammer

impact

4- to 325-

mesh

almost all drugs

abrasive

material

Roller

pressure

20- to

200-mesh

soft material

abrasive

material

Fluid-

energy

attrition

and impact

1 to 30

µm

moderately hard and

friable material

soft and

sticky material

9

* FACTORS INFLUENCING MILLING

1- The properties of a solid determine its ability to resist milling and influence

the choice of equipment used for milling. Example, if we have fibrous materials (e.g.,

glycyrrhiza) which cannot be crushed by pressure or impact; they must be cut. Friable

materials (e.g., sucrose) may be milled by attrition or impact (e.g., hammer mill).

2- The presence of more than 5% water hinders comminution and often produces

a sticky mass upon milling, especially when the materials are fine. At concentration of

water greater than 50%, the mass become slurry or suspension, the process then is a

wet milling process (colloidal milling) which often aid in size reduction.

3- An increase in moisture can decrease the rate of milling. The water of

crystallization of certain material (e.g., citric acid) liberated during milling and causing

clogging of the mill. Hygroscopic materials (e.g., CaCl

2

) rapidly sorb moisture to the

extent that the wet mass sticks and clogs the mill.

4- The heat during milling softens and melts materials with low melting point.

Synthetic gums, waxes and resins become soft and plastic. Heat sensitive drugs may be

degraded. Pigments may change their shade of color if the milling temperature is

excessive.

5- The shape of the milled particles may be important; an impact mill produces

sharp, irregular particles, which may not flow readily. If the free flow materials are

desired, it would be better to use an attrition mill, which produces free flowing

spherical particles.

* SELECTION OF MILL

The choice of mill is based on:

1- Product specification (size range, particle size distribution, shape, moisture

content, physical and chemical properties of the materials).

2- Capacity of the mill and production rate requirements.

3- Versatility of operation (wet and dry milling, rapid change of speed and screen,

and safety features).

10

4- Dust control (especially when we are using expensive or toxic materials, so we

used closed system which is less hazardous).

5- Sanitation (ease of cleaning and sterilization).

6- Auxiliary equipments (cooling system, dust collectors).

7- Batch or continuous operation.

8- Economical factors (cost, power consumption, spaced occupied and labor cost).